Washing barrel for double-mode washing machine

A washing machine, dual-mode technology, applied in the field of washing tub, can solve the problems of complex balance mechanism, etc., and achieve the effect of uniform washing, low noise and vibration, and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to overcome the shortcomings of the existing drum washing machine and wave-wheel washing machine, the invention provides a washing tub for a dual-mode washing machine which has the advantages of both. The dual-mode washing machine has the advantages of saving water of the drum washing machine, the transmission mechanism is simple, and the drying process of the pulsator washing machine is easy to balance, that is, the method of the drum washing machine is used for washing, and the method of the pulsator washing machine is used for drying.

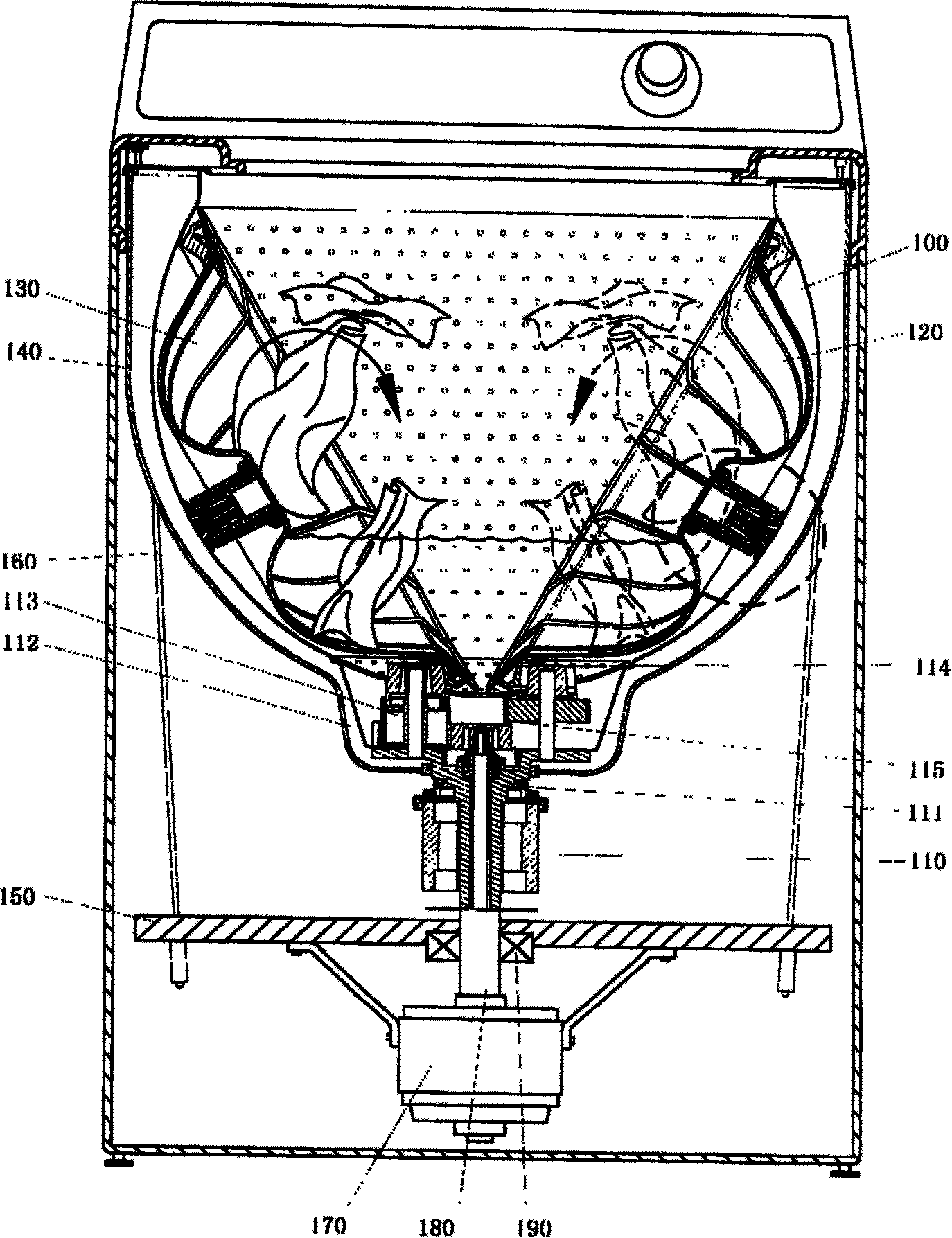

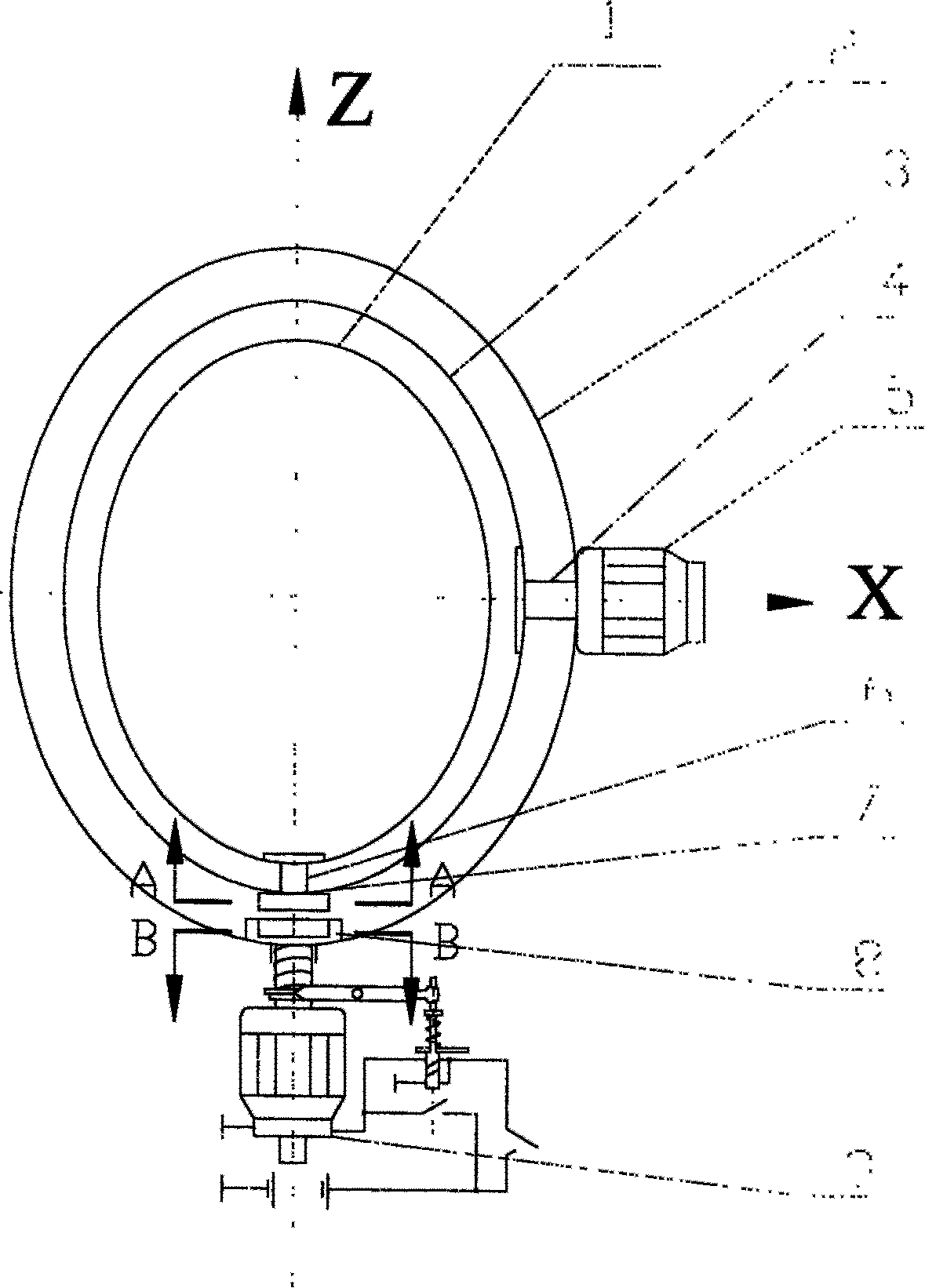

[0040] image 3 Shown is a schematic structural view of the dual-mode washing machine of the present invention, including: a housing 10, a water tub 3, a drum disposed in the water tub 3, a drive motor, and a clutch 8, and the water tub 3 is suspended from the In the housing, an upper cover is provided on the upper panel of the housing 10 for feeding clothes into the water tub 3 and the drum.

[0041] Depend on image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com