Medicine type cover electroforming manufacturing process and equipment

The invention relates to a manufacturing process and a technology for a medicine type cover, which is applied in the field of electroforming manufacturing process and device of the medicine type cover, and can solve the problems of low deposition rate, easy adsorption of bubbles, coarse grains of the medicine type cover, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

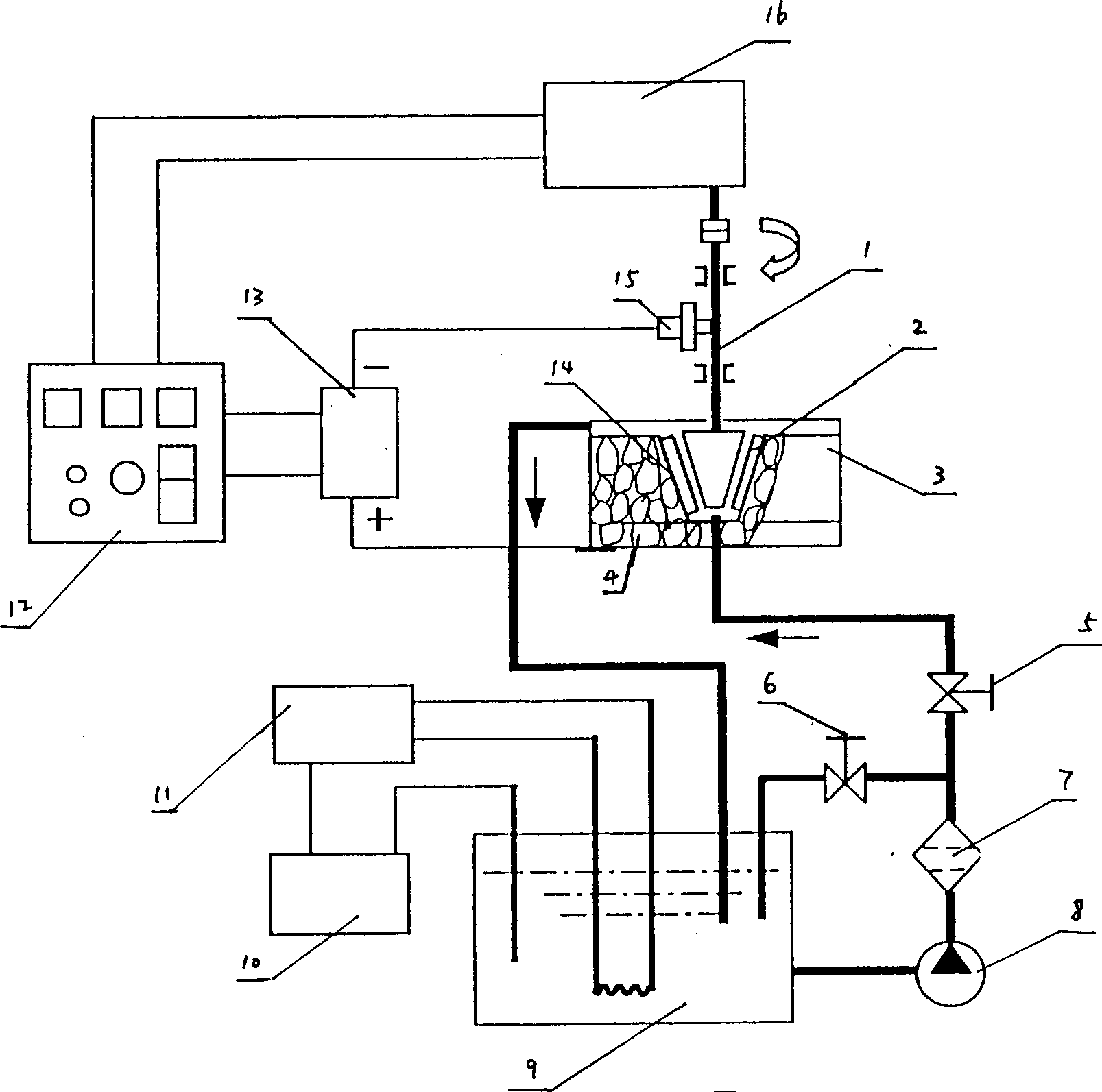

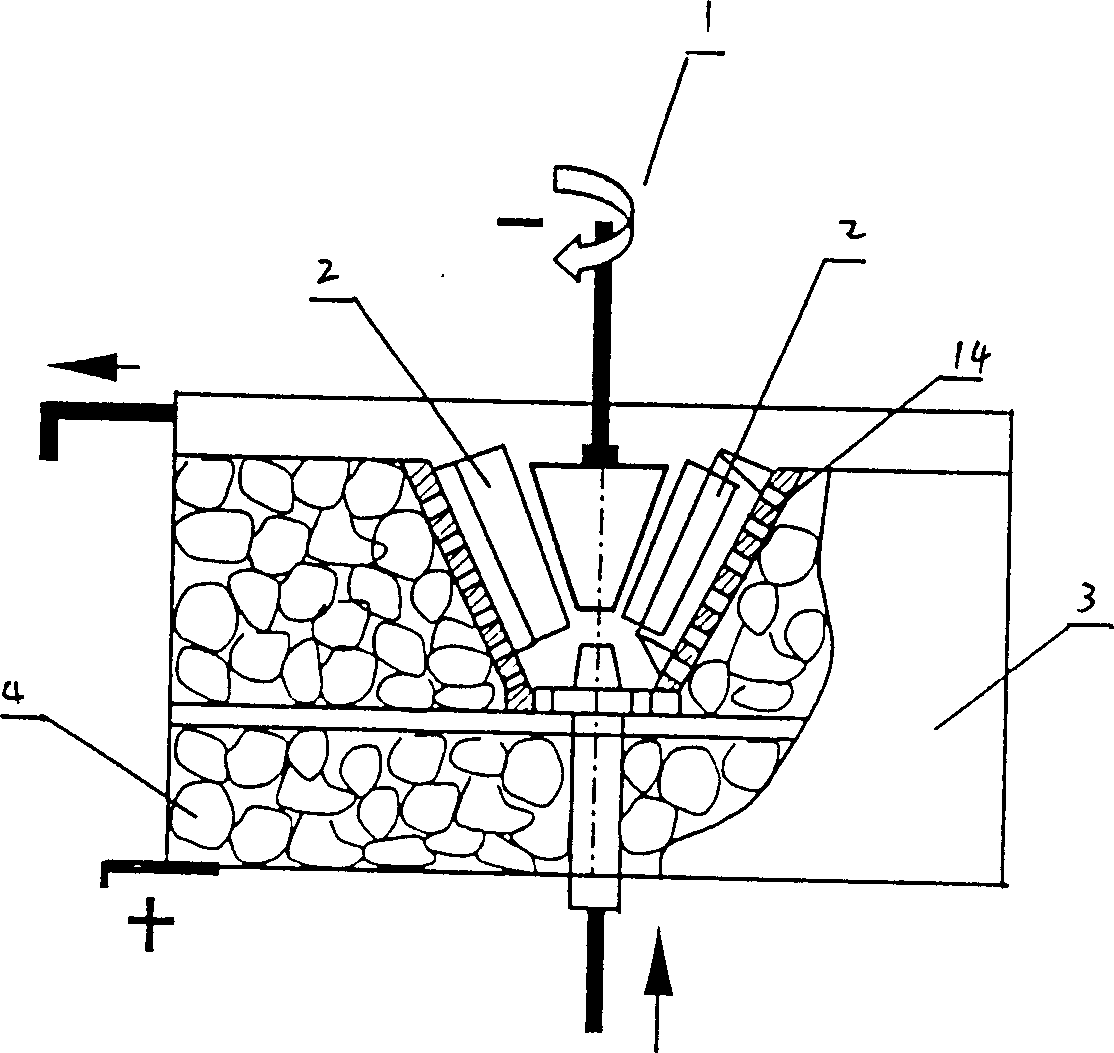

[0017] Implement the device of the present invention---"drug type cover electroforming manufacturing process", such as figure 1 and figure 2 As shown, the device includes a liquid storage tank 9, a magnetic pump 8, a filter 7, a ball valve 5, an overflow valve 6, a temperature controller 10, a heater 11, a control device 12, a pulse power supply 13, a conductive device 15, and a transmission device 16 and an electroforming process device. It is characterized in that the electroforming process device includes an inverted cone-shaped rotating cathode (mandrel) 1 placed between rolling (or friction) devices 2, and the rolling device or friction device 2 is placed in line with the shape of the drug-type cover mandrel. On the corresponding image-shaped anode 14, the anode chamber 3 formed by the image-shaped anode 14 and the bulk electroforming material 4 serves as its anode unit.

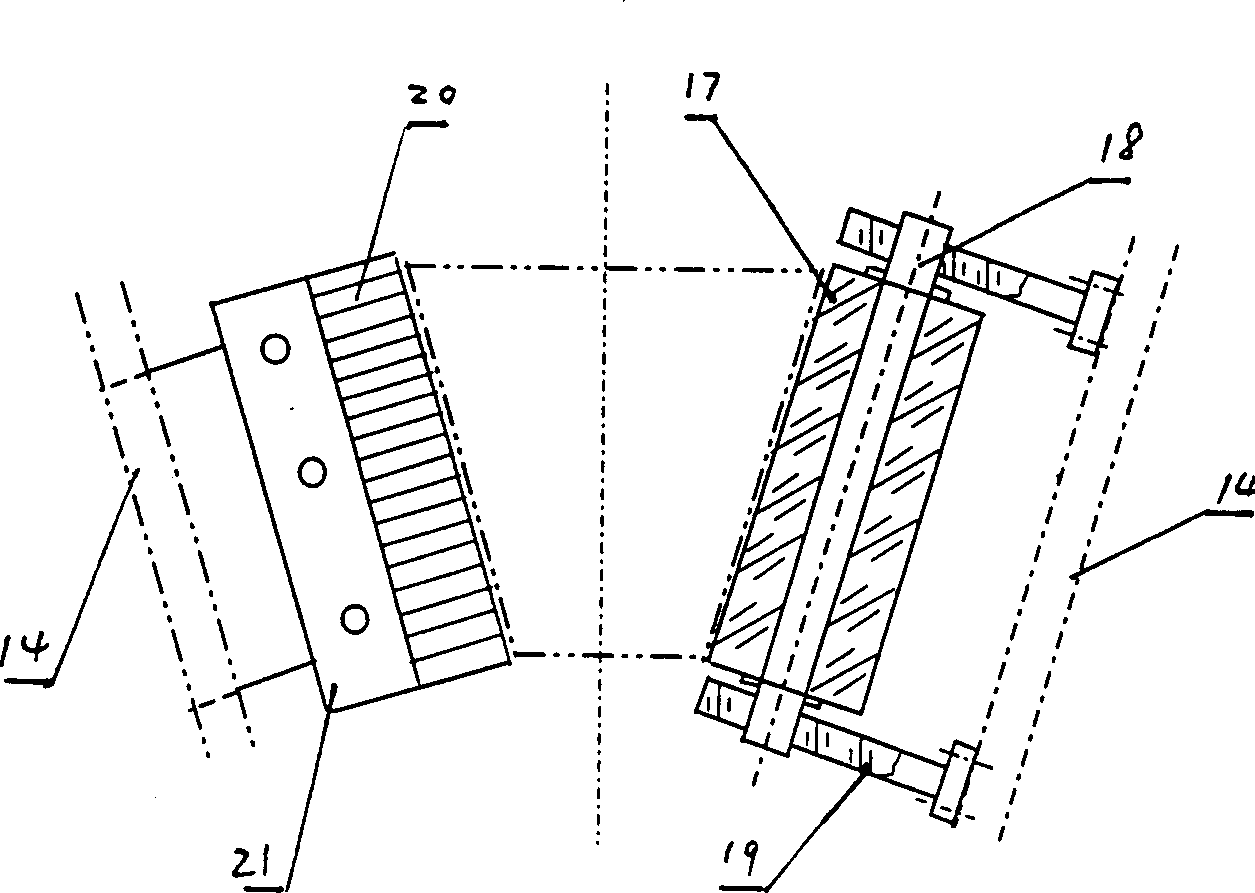

[0018] image 3 Shown is a schematic diagram of the composition of the rolling device and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com