Method for purifying polyether ketone/polyether sulfone polymers

A purification method and polymer technology, applied in the field of polymers, can solve problems such as difficult to achieve purification effect, easy migration of impurities, small binding force, etc., and achieve the effect of good electrical insulation, excellent quality, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

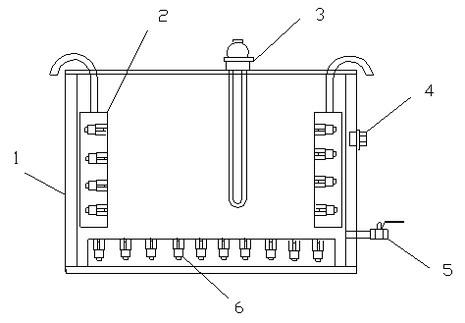

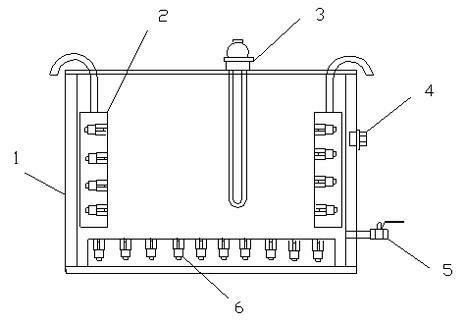

Image

Examples

Embodiment 1

[0039] Example 1: Purification of polyether ether ketone (PEEK) resin prepared with sulfolane as solvent

[0040] Take 700g of the above-mentioned polyether ether ketone and grind it, put it together with 7kg of deionized water into a 10L ultrasonic cleaning machine with heating function, and the power density of the ultrasonic wave is 0.3W / cm 2 , the frequency is 50KHz, after ultrasonication for 40 minutes at 30°C, the material mixture is filtered by a centrifuge to remove most of the water, a cleaning process is completed, and the treatment is repeated 5 times, in which 0.5% by mass is added in the third time Phosphoric acid (relative to the water quality of this time), the pH value of the material mixed liquid system is 1.71, dried to constant weight under vacuum at 130°C, and the content of solvent and impurity ions in polyether ether ketone is determined, and the solvent content is determined by gas chromatography analyzer Determination, the polymer was processed accord...

Embodiment 2

[0046] Example 2: Purification of polyether ether ketone (PEEK) resin prepared with diphenyl sulfone as solvent

[0047] Take 20kg of the above-mentioned polyether ether ketone and grind it, then boil and wash it with 300L acetone for 8 times to remove the diphenyl sulfone in the material, then put the material squeezed out of acetone and 200kg deionized water into a 300L heating mantle and In a stainless steel container with several ultrasonic generators installed on the outer wall, the ultrasonic power density is 10W / cm 2 , frequency 300KHz; ultrasonic for 40 minutes at 70°C, filter the material mixture with a centrifuge to remove most of the water, complete a cleaning process, repeat the treatment 4 times, and add 0.3% mass parts (relatively This water quality) hydrochloric acid, the PH value of the mixed liquid system of the material is 1.08, dry it under vacuum at 130°C to constant weight, measure the content of impurity ions in polyetheretherketone, and treat the polym...

Embodiment 3

[0053] Example 3: Purification of polyethersulfone (PES) resin prepared with sulfolane as solvent

[0054] Take 20kg of the above-mentioned polyethersulfone and pulverize it, put it into a 300L stirring kettle together with 200kg of deionized water, and use an ultrasonic generator to make the power density of the ultrasonic waves generated in the kettle to be 20W / cm at a temperature of 50°C 2 , frequency 800KHz; after 60 minutes of treatment, filter the material mixture with a centrifuge to remove most of the water, complete a cleaning process, repeat the treatment 5 times, and add 1% by mass in the second time (relative to the water quality of this time) Phosphoric acid, the pH value of the mixed liquid system of the material is 1.56, and it is dried to constant weight under vacuum at 130°C to measure the content of solvent and impurity ions in polyethersulfone. The content of solvent and impurity ions was measured after treatment as shown in Table 5. Comparing Examples 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com