Track-free intelligent moving device of goods shelf warehouse

A handling device and warehouse technology, applied in the field of logistics, can solve the problems of direct transformation of ordinary shelf warehouses, which consumes a lot of manpower, material resources, financial resources and time, etc., and achieves the effect of continuous operation, reduced work burden and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

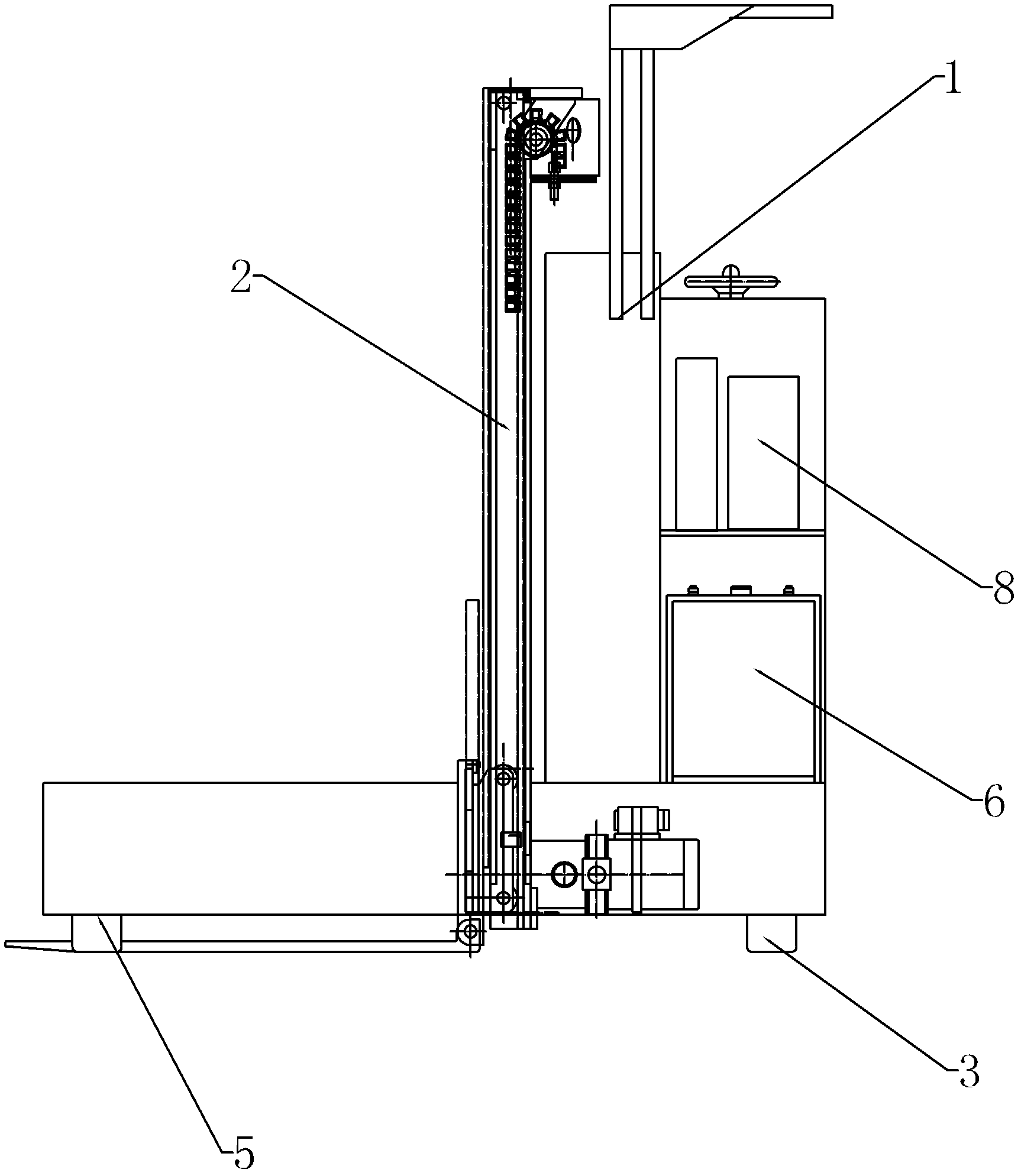

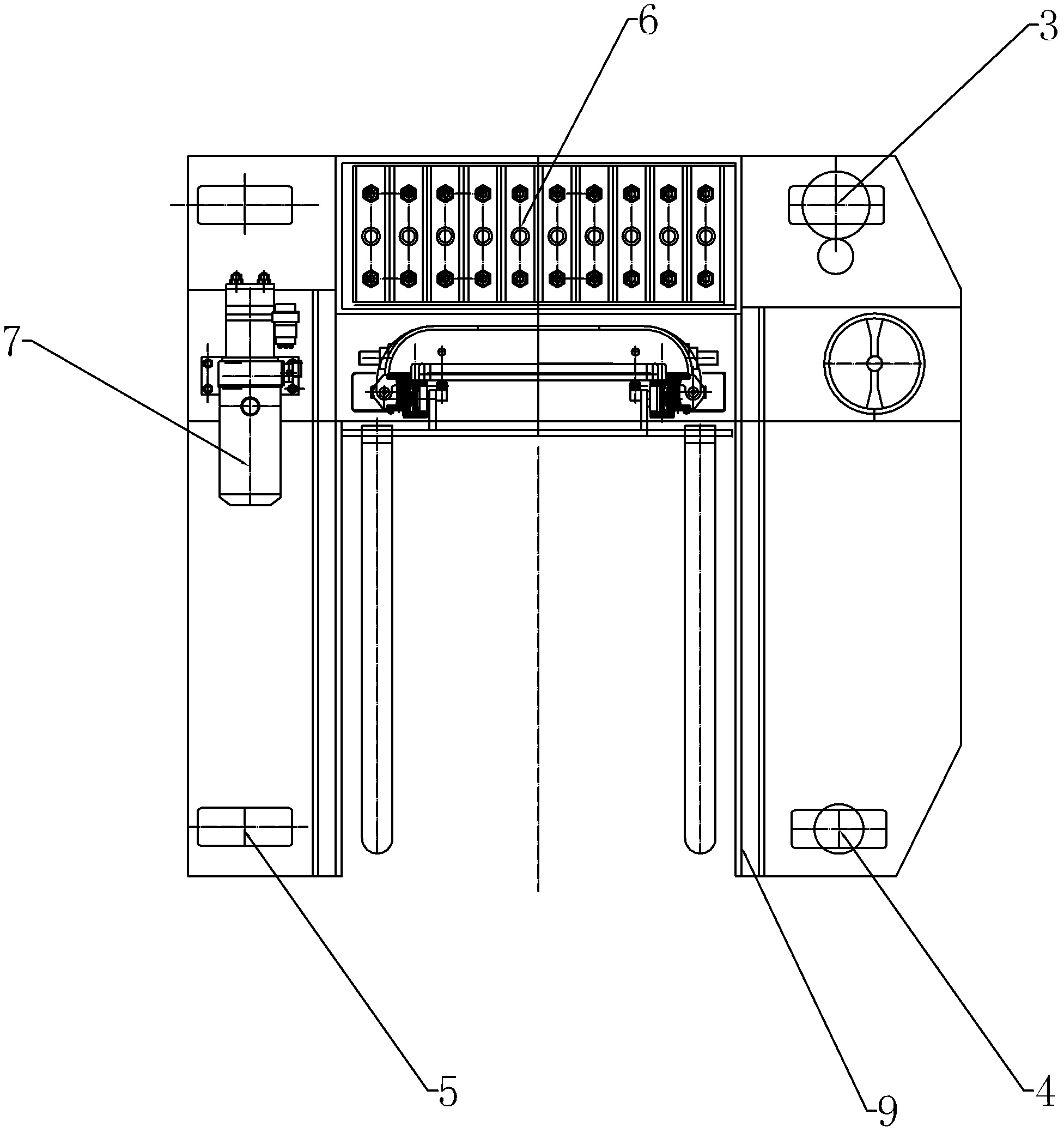

[0024] Such as Figure 1~2 As shown, the present invention mainly comprises car body 1 and door frame 2, and door frame 2 is installed in the front of car body 1. A storage battery 6 , a hydraulic power pack 7 and a main controller 8 are installed in the vehicle body 1 . The four corners of the lower end of the vehicle body 1 are sequentially connected with a driving wheel 3 , a steering wheel 4 and two follower wheels 5 . The storage battery 6 adopts three sets of lithium power batteries or four sets of maintenance-free lead-acid batteries to provide all working and control power.

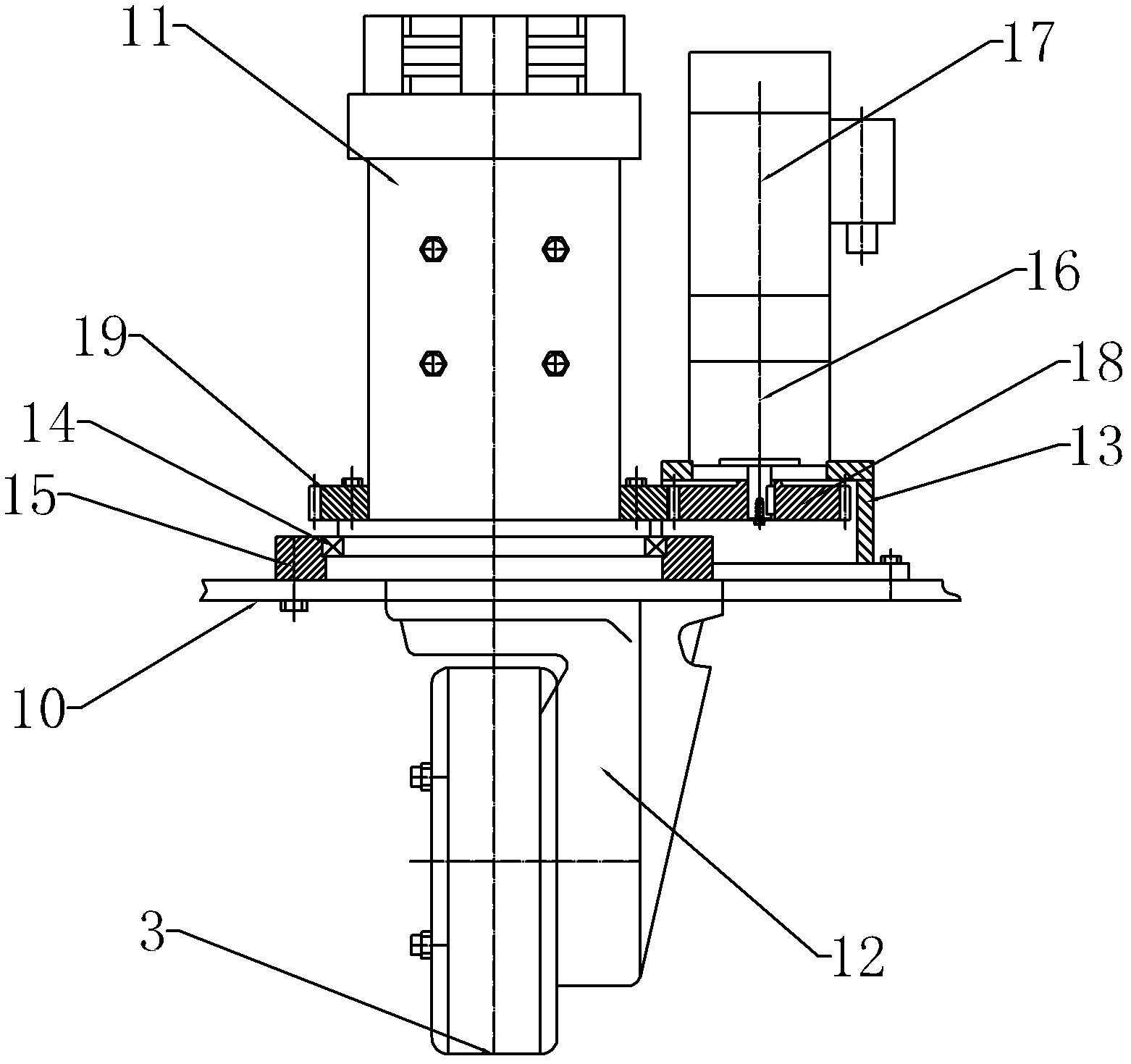

[0025] Such as image 3 As shown, the mounting plate 10 below the car body 1 is connected with a machine base 15, and the machine base 15 is connected with the travel motor 11 through the first bearing 14, and the lower end of the travel motor 11 is connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com