Combined method for producing abrasive cloth flap disc automatically

An abrasive cloth disc and combined technology, which is applied in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve problems such as low production efficiency and unstable product quality, so as to improve production efficiency and shorten running time. , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the following, the present invention will be further explained through embodiments with reference to the drawings:

[0058] Preferred embodiment

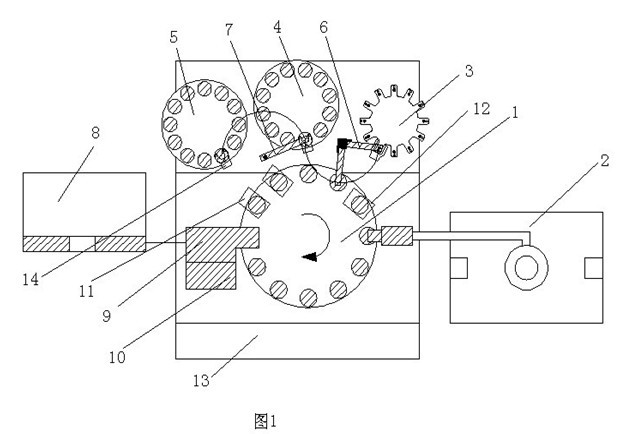

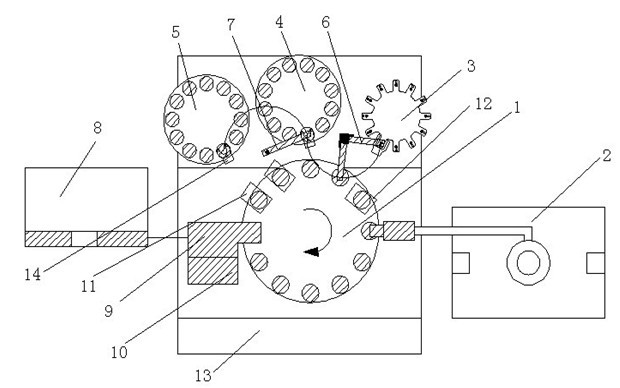

[0059] Such as figure 1 As shown, below we describe the working principle of the entire device: a combined automatic production method of emery cloth discs, in this method the following devices are used:

[0060] Main turntable 1, sizing system 2, pallet loading turntable 3, emery cloth page wheel loading turntable 4, cover loading turntable 5, robot one 6, robot two 7, feeding mechanism 8, planting device 9, cutting device 10, shaping device 11. The thickness measurement mechanism 12 and the control system 13 controlling the operation of the above-mentioned devices, in which:

[0061] The main turntable 1 contains multiple stations, and the main turntable 1 drives the tray to reach each station in turn within a 360° range;

[0062] Gluing system 2 is used to evenly inject adhesive into the tray on the main turntable 1;

[0063] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com