Automatic calibration method for driving motor rack of new energy automobile

A technology for new energy vehicles and drive motors, which is used in engine testing, machine/structural component testing, electrical testing/monitoring, etc. Occupy engineer resources and other issues to achieve the effect of continuous operation and unattended operation, saving engineer resources and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

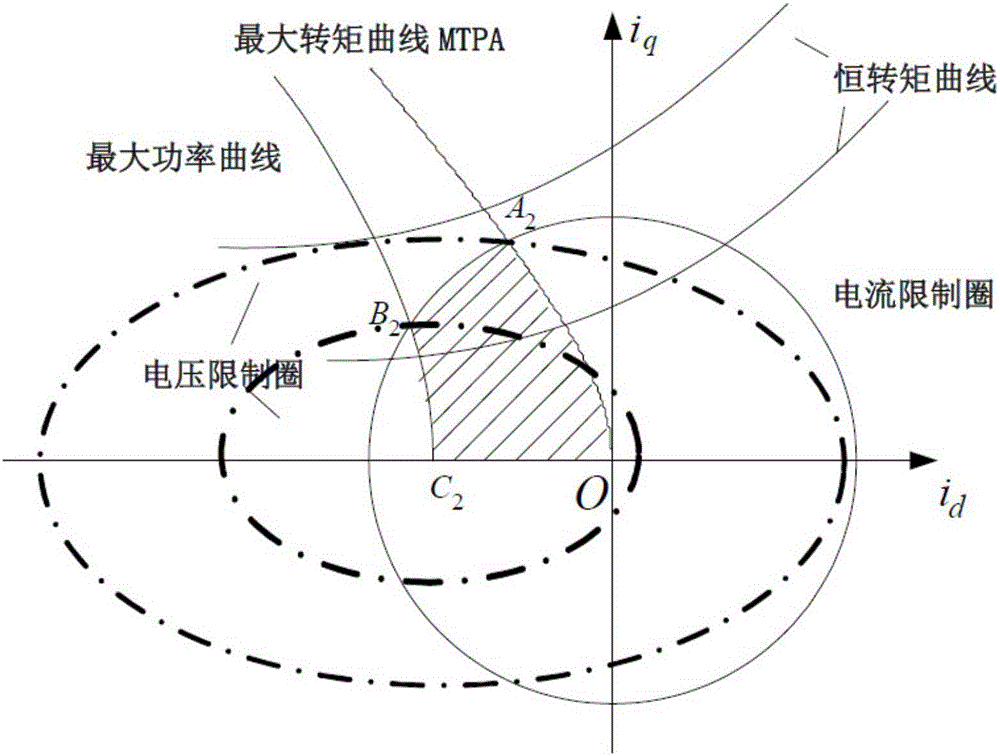

[0026] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

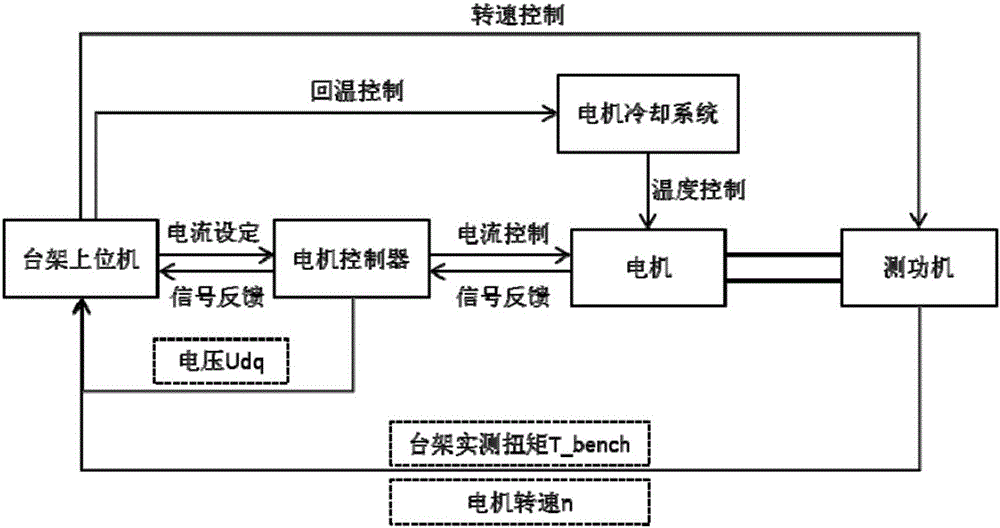

[0027] figure 2 The principle of the system implementing the method of the present invention is briefly shown. See figure 2 , the system is mainly composed of a bench PC, a motor controller, a motor, a motor cooling system, and a dynamometer. The operation of the system involves speed control, temperature return control, temperature control, current setting, current control, signal feedback, Bench measured torque T_bench and motor speed n and other working processes.

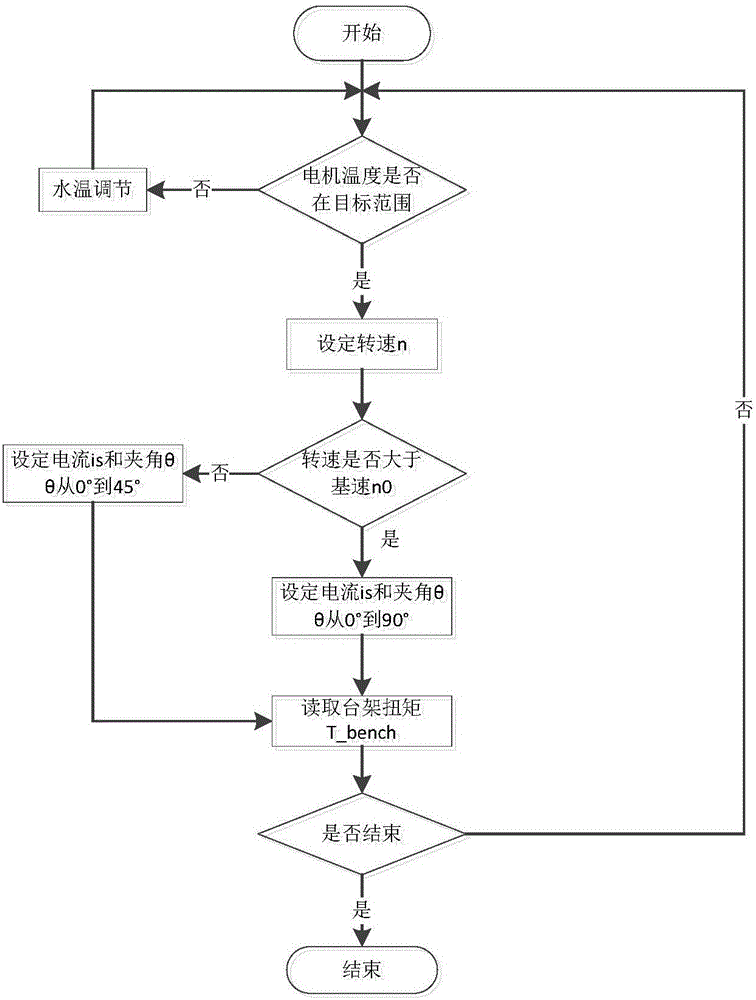

[0028] Please refer to image 3 with Figure 4 ,in image 3 shows the detailed steps of the testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com