Botanical seedling culturing machine

A seedling raising machine and plant technology, applied in the field of seedling raising machines, can solve the problems of incompleteness, lack of multi-layer precise control of crop seedling raising, high-quality seedling raising on an industrial scale, difficulty in large-scale, intensive industrialized high-quality seedling production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

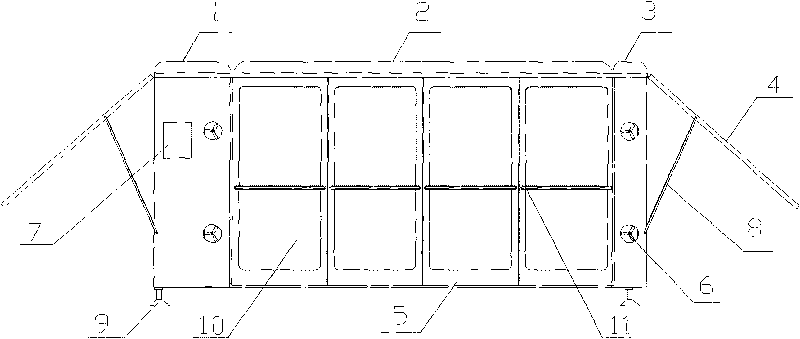

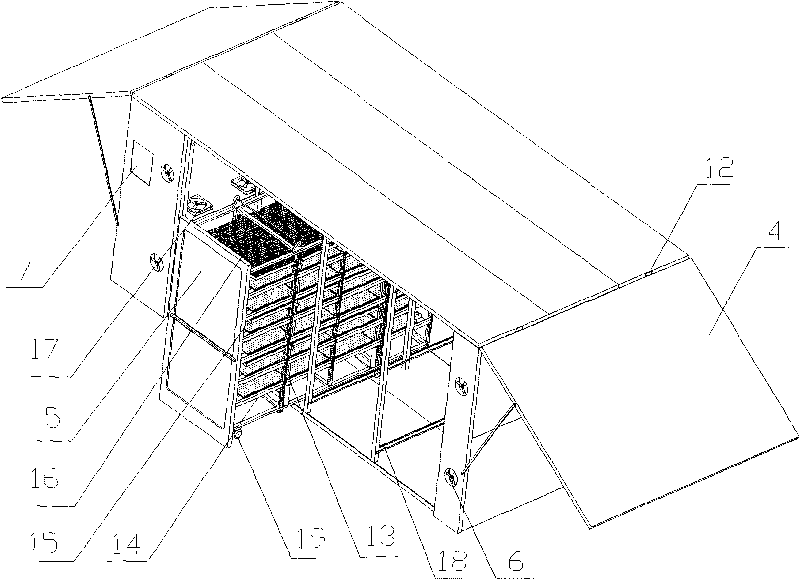

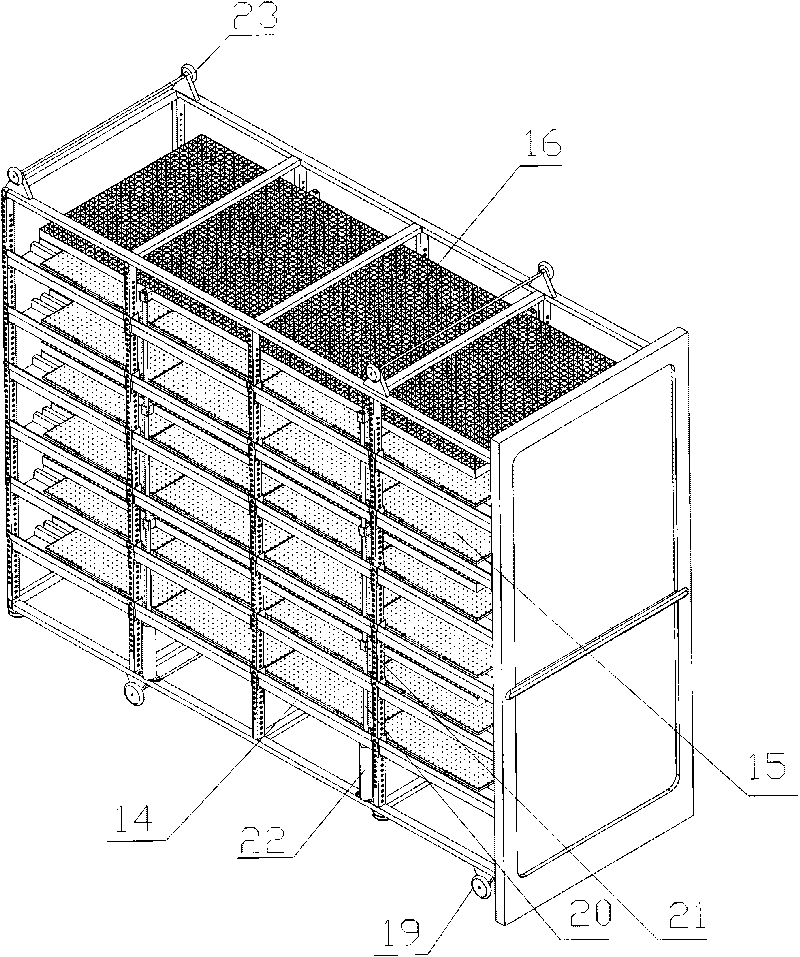

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8, including main engine section 1, auxiliary engine section 3, cultivation working section 2 and foldable double-wing solar panel 4, the main engine section 1, auxiliary engine section 3 and cultivation working section 2 are all cabinets, the main engine section 1, cultivation The working section 2 and the auxiliary machine section 3 are connected in sequence, and there is an airflow balance partition between the sections; each section is equipped with a temperature sensor, a humidity sensor, an air pressure sensor, and a monitoring instrument, a testing instrument, and a testing instrument interface; The main engine section is provided with a control system and water pumps, air compressors, air conditioners, and preheaters electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com