Polishing machine suitable for gears with different bore diameters

A processing machine and gear technology, which is applied to gear cutting machines, components with teeth, gear tooth manufacturing devices, etc., can solve the problems of iron filings being easy to splash, safety hazards, and affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

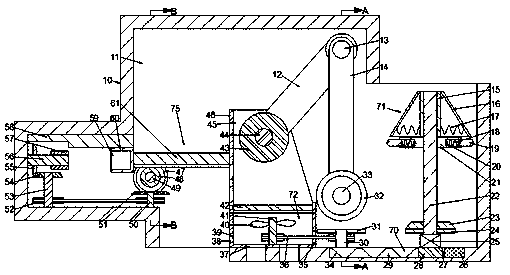

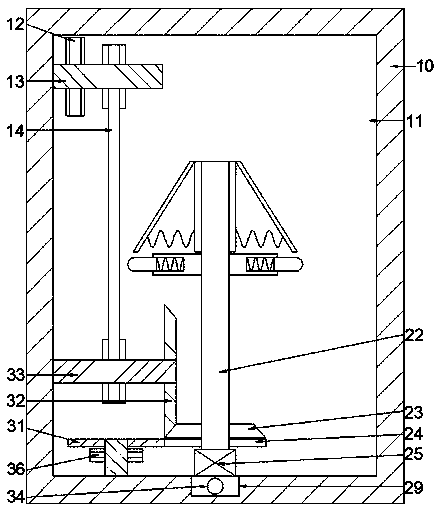

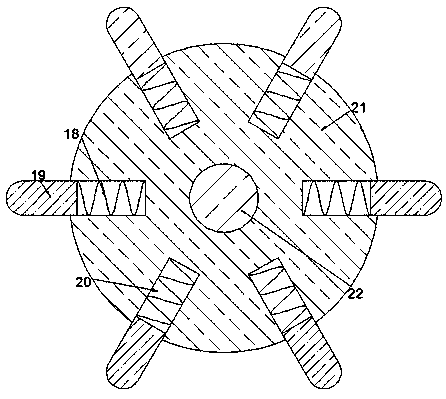

[0020] Such as Figure 1-4 As shown, a grinding machine suitable for gears with different apertures includes a working box 10 and a working chamber 11 arranged in the working box 10. The right side of the working chamber 11 opens upward, and the working box 10 is fixed Be provided with moving device 70, described moving device 70 comprises the conductive magnet 28 that is provided with slide, described moving device 70 can make described conductive magnet 28 slide left and right, described conductive magnet 28 upper end surface is fixedly provided with motor 25, described The upper end surface of the motor 25 is rotated to be provided with a motor shaft 22, and the motor shaft 22 is fixedly provided with a fixed plate 21, and the fixed plate 21 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com