Nail burnishing stick and preparation method thereof

A technique for polishing strips and nails, applied in manicure and pedicure tools, clothing, applications, etc., can solve problems such as environmental pollution, nails that cannot remove liver toxins in time, and human hazards, and achieve bright and clean visual effects, nails The surface is smooth and delicate, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

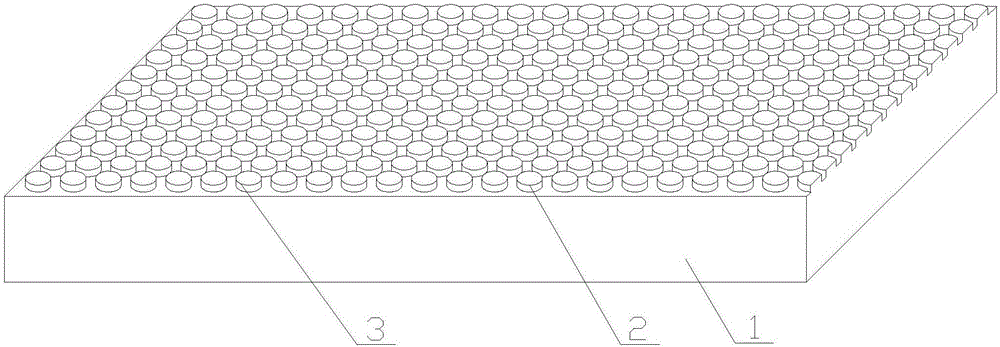

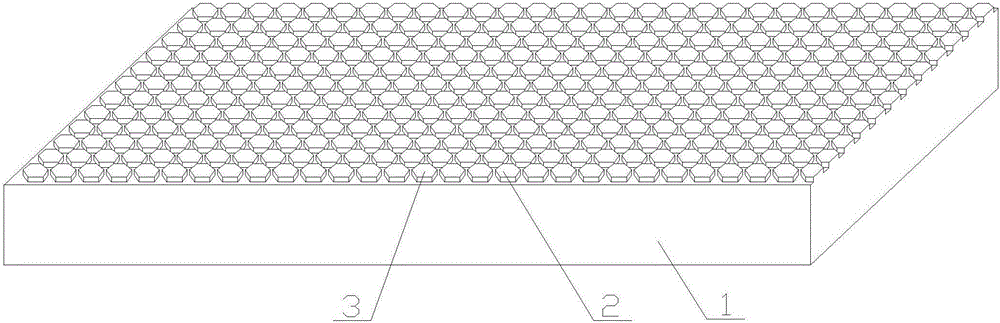

[0044] A nail polishing strip, comprising a substrate and a polishing layer, the polishing layer includes a plurality of densely distributed polishing teeth, the shape of the polishing teeth is a cylinder whose axis is perpendicular to the substrate, and the bottom of the polishing teeth is connected to the substrate in one piece. Wherein, the diameter of the polishing teeth is 205 μm, the distance between the polishing teeth is 155 μm, and the height of the polishing teeth is 20 μm. The base plate and polishing teeth are made of blue glass with a layer of chrome on top of the polishing teeth.

[0045] The preparation method of the above-mentioned nail polishing strip comprises the following process steps:

[0046] Mask plate production: Take a glass plate and coat it with a chromium film by sputtering. The chromium film includes the chromium layer in contact with the glass plate and the chromium trioxide layer outside the chromium layer, the chromium layer and the trioxide la...

Embodiment 2

[0055] A nail polishing strip, comprising a substrate and a polishing layer, the polishing layer includes a plurality of densely distributed polishing teeth, the shape of the polishing teeth is a cylinder whose axis is perpendicular to the substrate, and the bottom of the polishing teeth is connected to the substrate in one piece. Wherein, the diameter of the polishing teeth is 145 μm, the distance between the polishing teeth is 140 μm, and the height of the polishing teeth is 19 μm. The base plate and polishing teeth are made of blue glass with a layer of chrome on top of the polishing teeth.

[0056] The preparation method of the above-mentioned nail polishing strip comprises the following process steps:

[0057] Mask plate production: Take a glass plate and coat it with a chromium film by sputtering. The chromium film includes the chromium layer in contact with the glass plate and the chromium trioxide layer outside the chromium layer, the chromium layer and the trioxide la...

Embodiment 3

[0066] A nail polishing strip, comprising a substrate and a polishing layer, the polishing layer includes a plurality of densely distributed polishing teeth, the shape of the polishing teeth is a cylinder whose axis is perpendicular to the substrate, and the bottom of the polishing teeth is connected to the substrate in one piece. Wherein, the diameter of the polishing teeth is 150 μm, the distance between the polishing teeth is 150 μm, and the height of the polishing teeth is 20 μm. The base plate and polishing teeth are made of blue glass with a layer of chrome on top of the polishing teeth.

[0067] The preparation method of the above-mentioned nail polishing strip comprises the following process steps:

[0068] Mask plate production: Take a glass plate and coat it with a chromium film by sputtering. The chromium film includes the chromium layer in contact with the glass plate and the chromium trioxide layer outside the chromium layer, the chromium layer and the trioxide la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com