Patents

Literature

72results about How to "Achieve visual effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display device

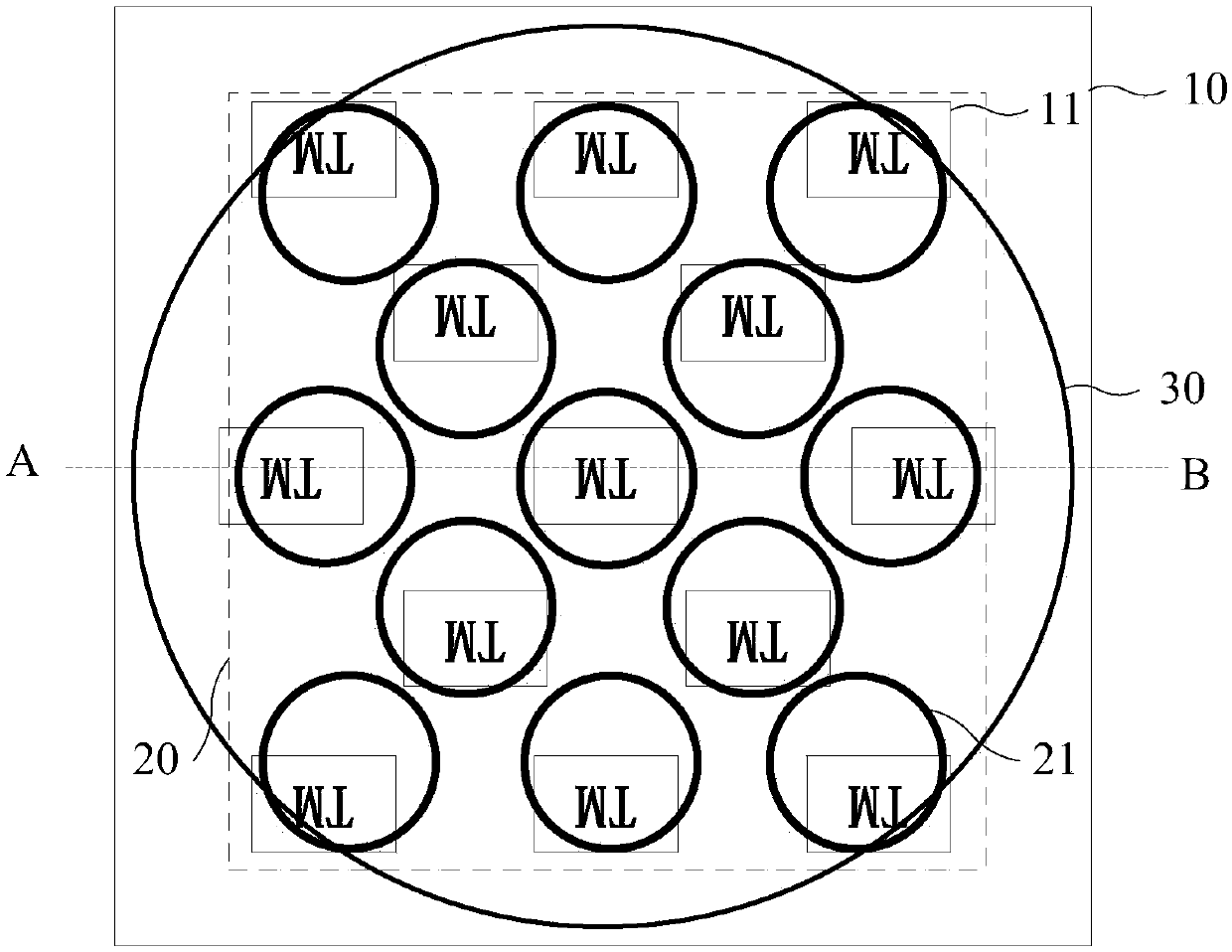

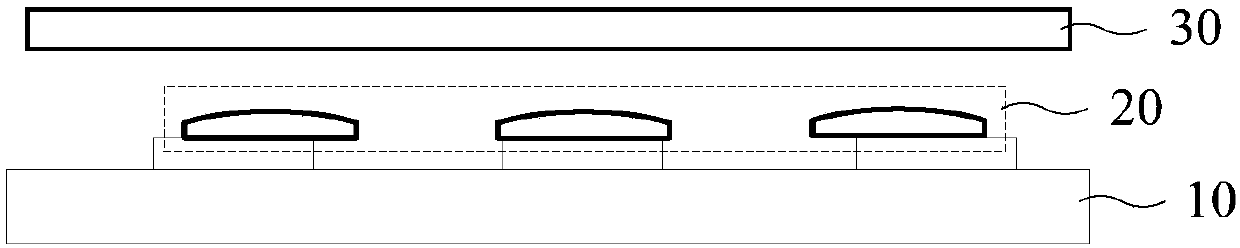

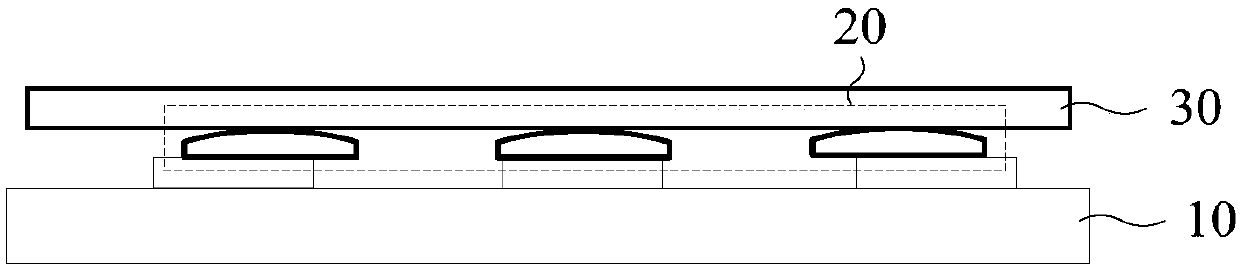

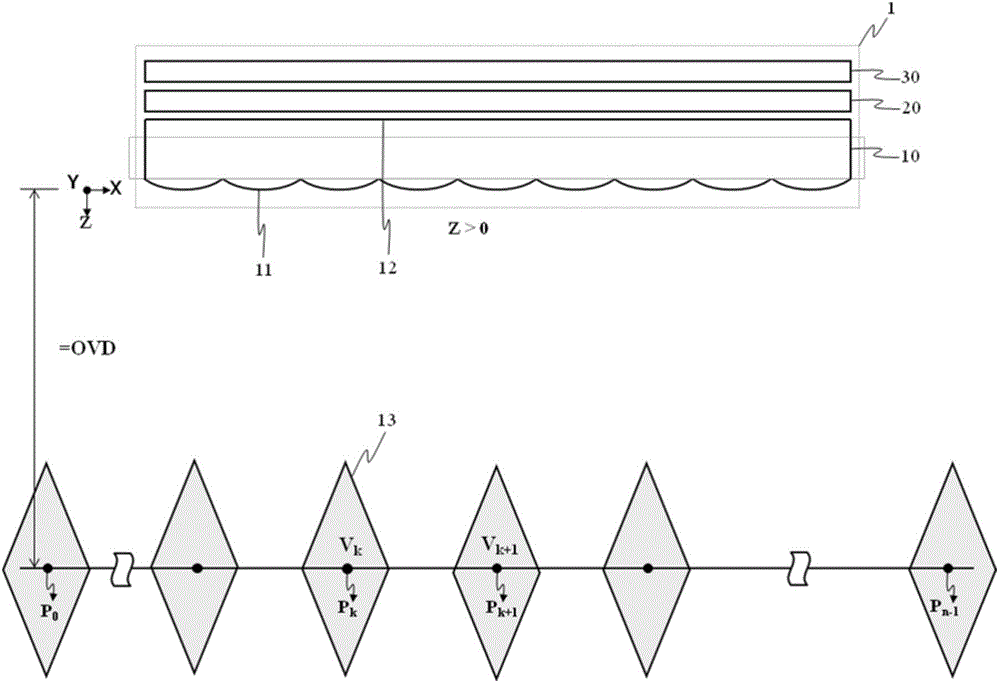

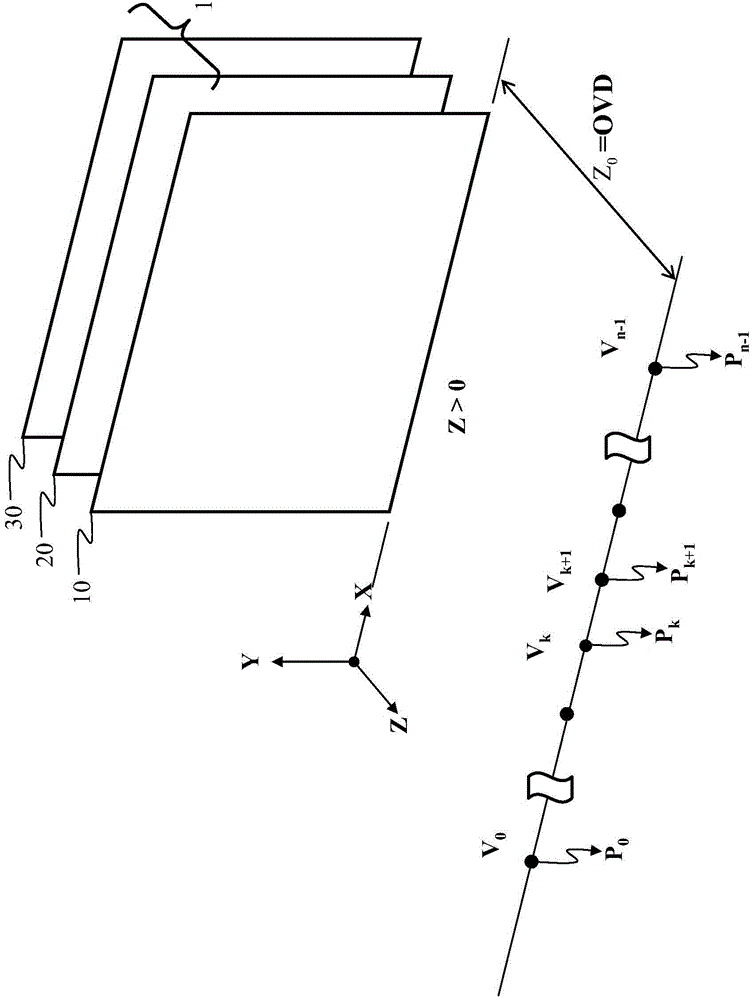

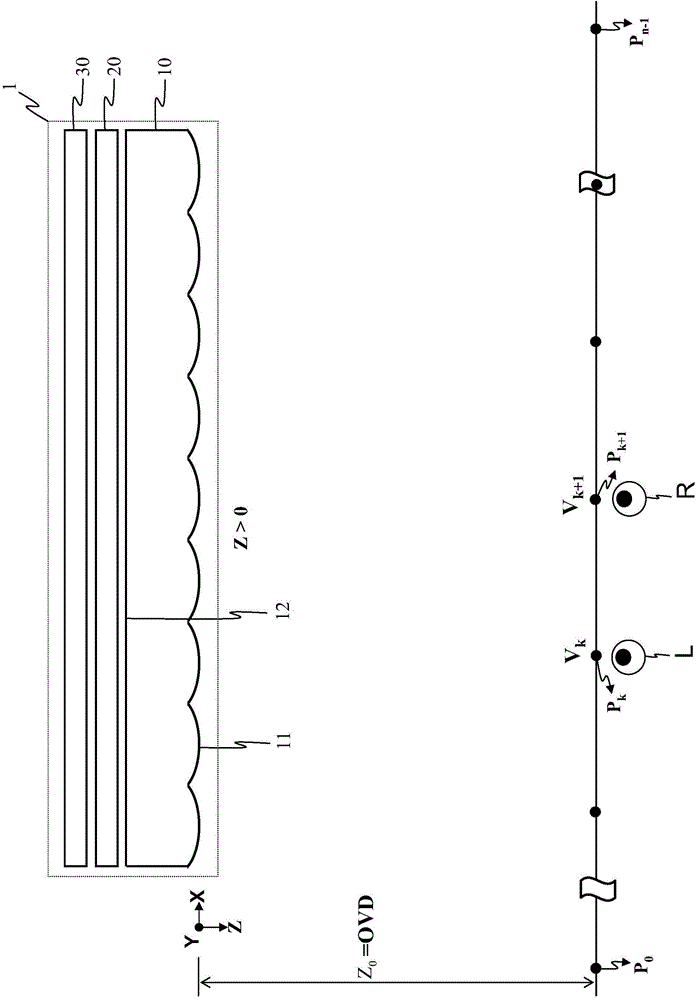

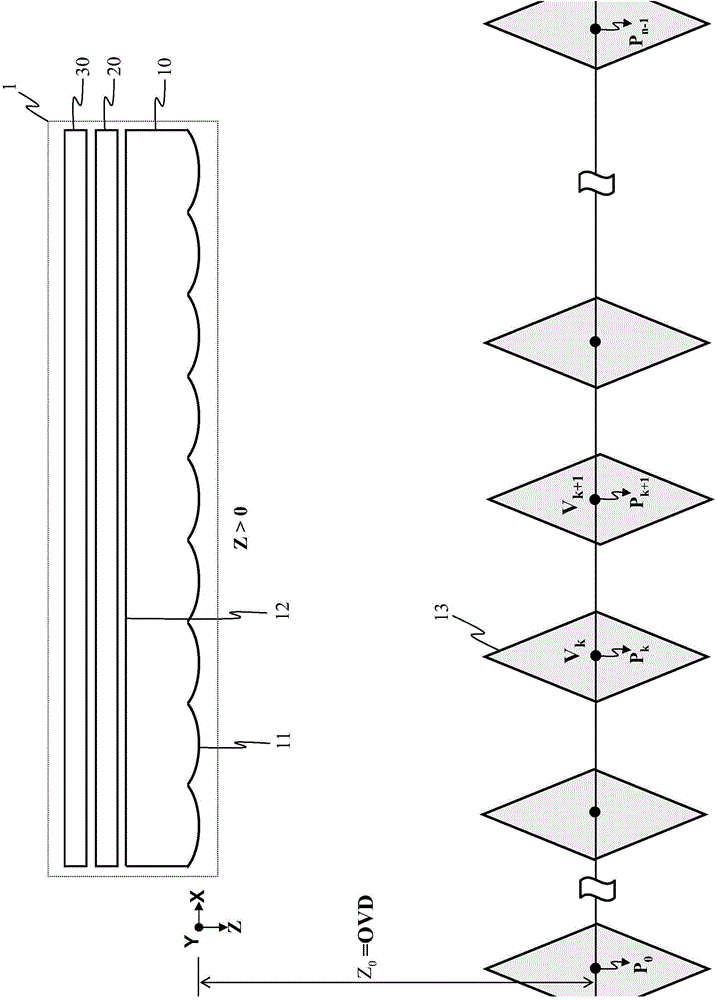

PendingCN107688243AStereo Dynamic Visual EffectsRealize multi-layer floating displayNon-linear opticsLensExit sideDisplay device

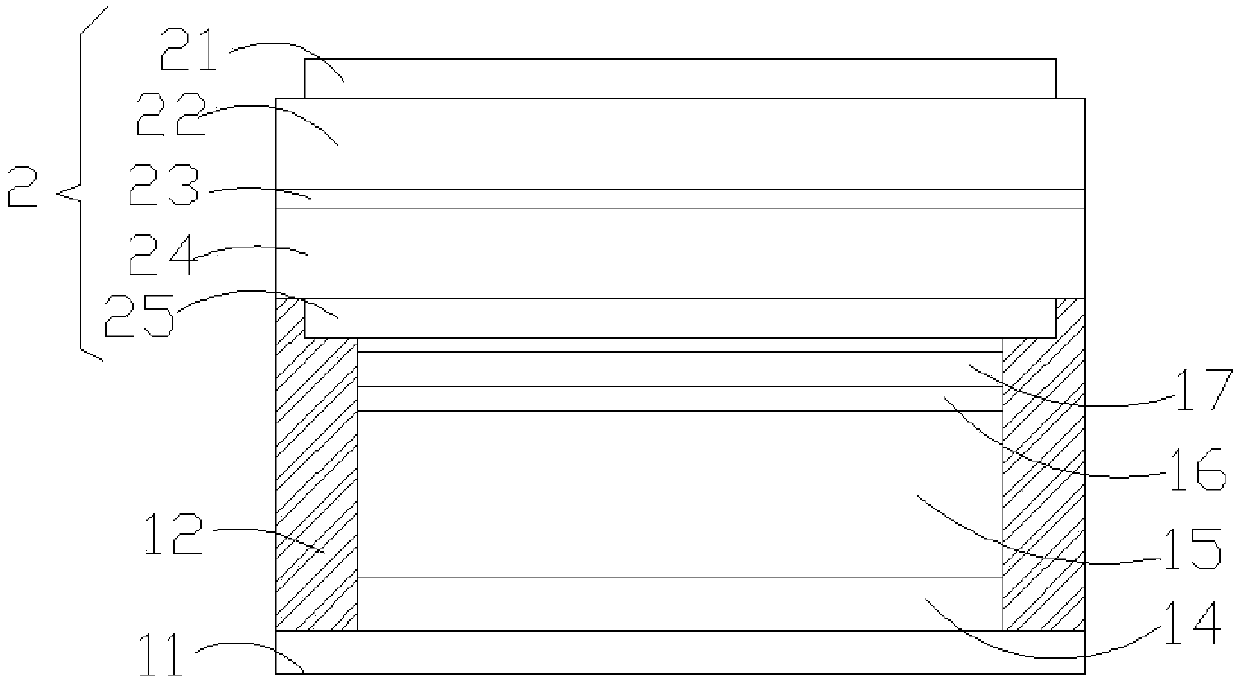

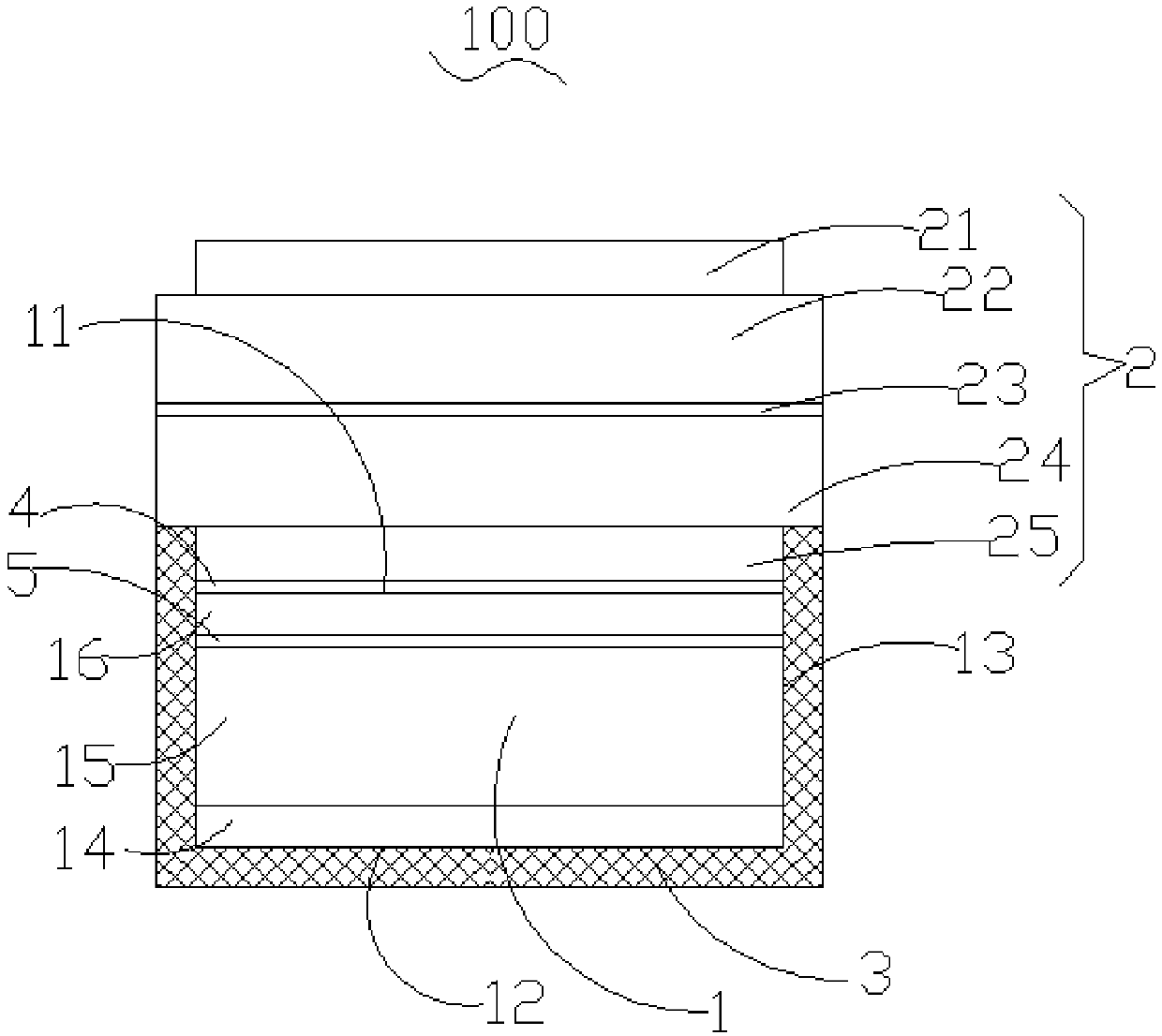

The invention discloses a display device. The display device comprises a display panel, a micro-lens group and a liquid lens, wherein the micro-lens group is positioned above a light exiting side of the display panel and comprises a plurality of micro-lens units; the micro-lens units are in one-to-one correspondence to the display units; the distance from the center of each micro-lens unit to thecenter of the corresponding display unit is gradually increased from the center of the display panel to the edge of the display panel; the liquid lens is arranged on the side, which is away from the display panel, of the micro-lens group, and is used for changing the phase of incident light to realize multi-layered displaying of suspended images. According to the technical scheme provided by the embodiment, the distance from the suspended images shown by the display device to the display panel is variable, multi-layered suspended display of the display device is realized, and thus, the three-dimensional dynamical visual effect is achieved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

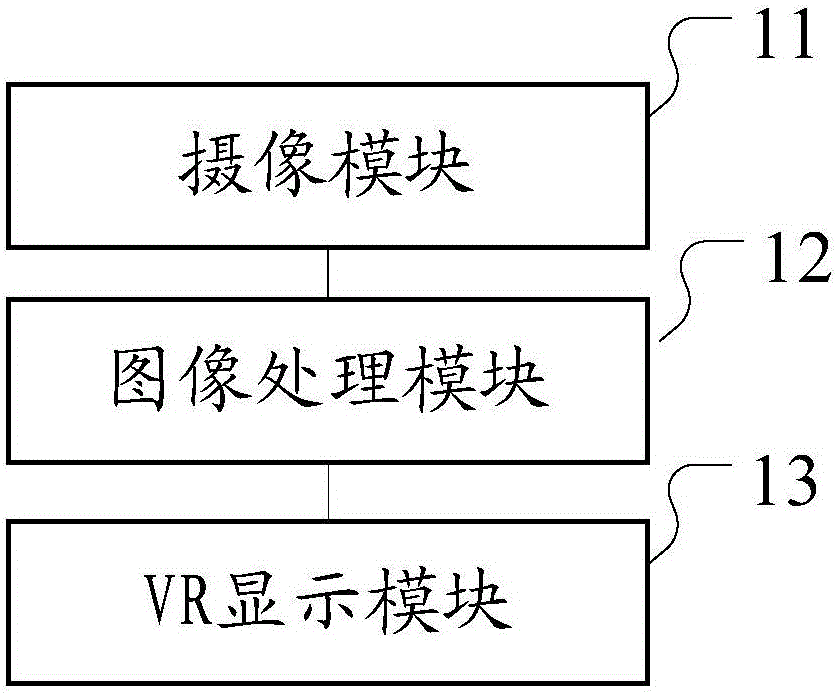

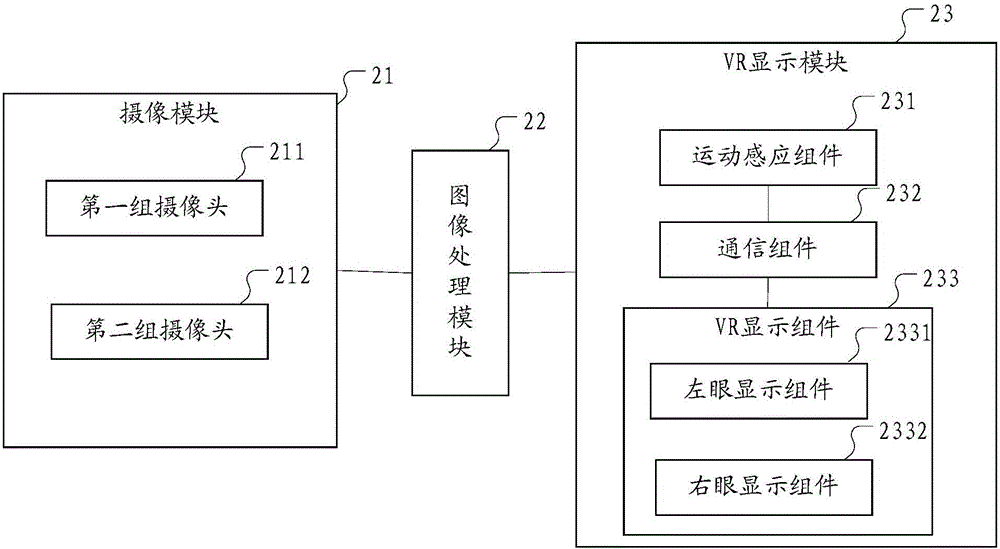

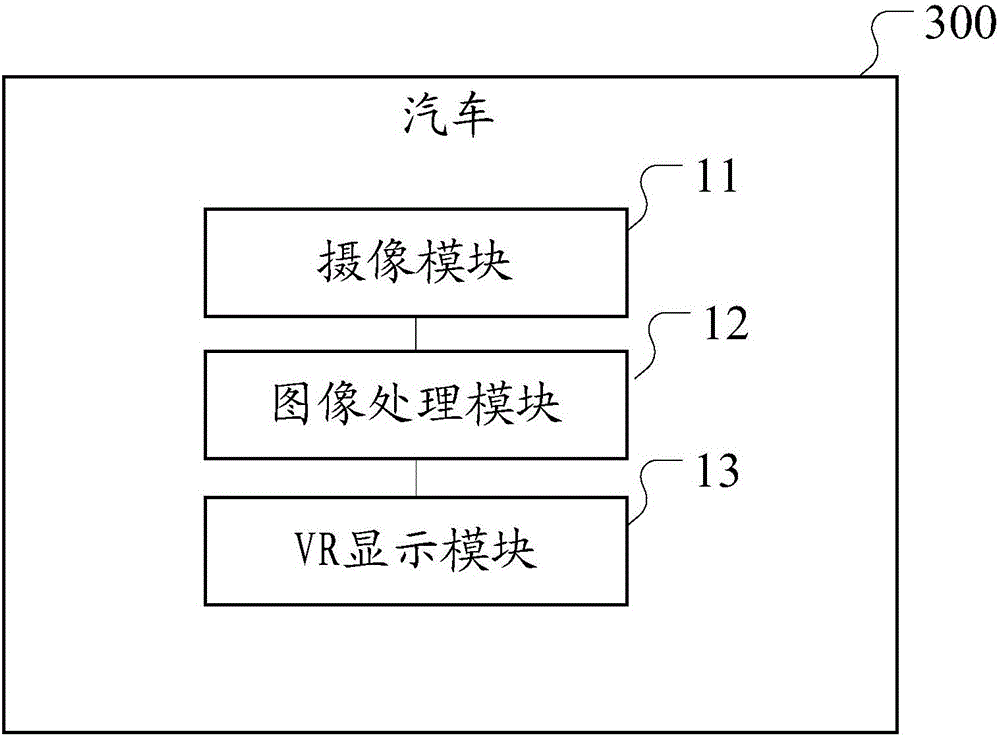

Automobile-based VR display device and method and automobile

InactiveCN106339980AFlexible switchingEasy to driveGeometric image transformationSteroscopic systemsImaging processingComputer graphics (images)

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

Process for inlaying precious metal and precious stones on purple sand and ceramic product

The invention discloses a process for inlaying precious metal and precious stones on a purple sand and ceramic product. The purple sand and ceramic products inlaid with golden silks, precious stones and bas-relief precious metal can be produced in batch through a specific manufacturing process, are clear in patterns and distinct in boundary lines after the purple sand and ceramic products are processed into finished products. Especially the purple sand and ceramic product inlaid with the golden silk, the precious stones and the bas-relief precious metal is elegant in appearance and integrates practicability and art into a whole; for highlighting the effect of the inlaying process and achieving the aesthetic feeling of a visual effect, the patterns of the purple sand and ceramic product and the bas relief decoration are in varied forms; the purple sand and ceramic product can be manufactured into various shapes according to the creation requirements and also can be inlaid with materials such as gold, diamond, crystal, sapphire and hetian jade and the like, so that the purple sand and ceramic product can be contracted in consistency, can be controlled and is not cracked in sintering.

Owner:孙绪强

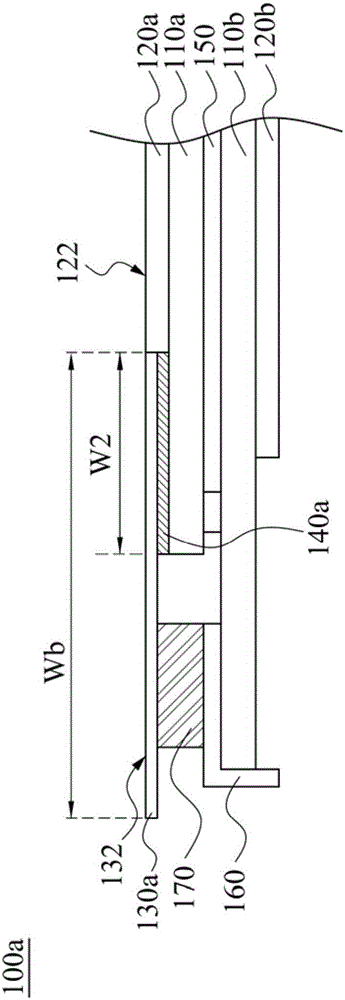

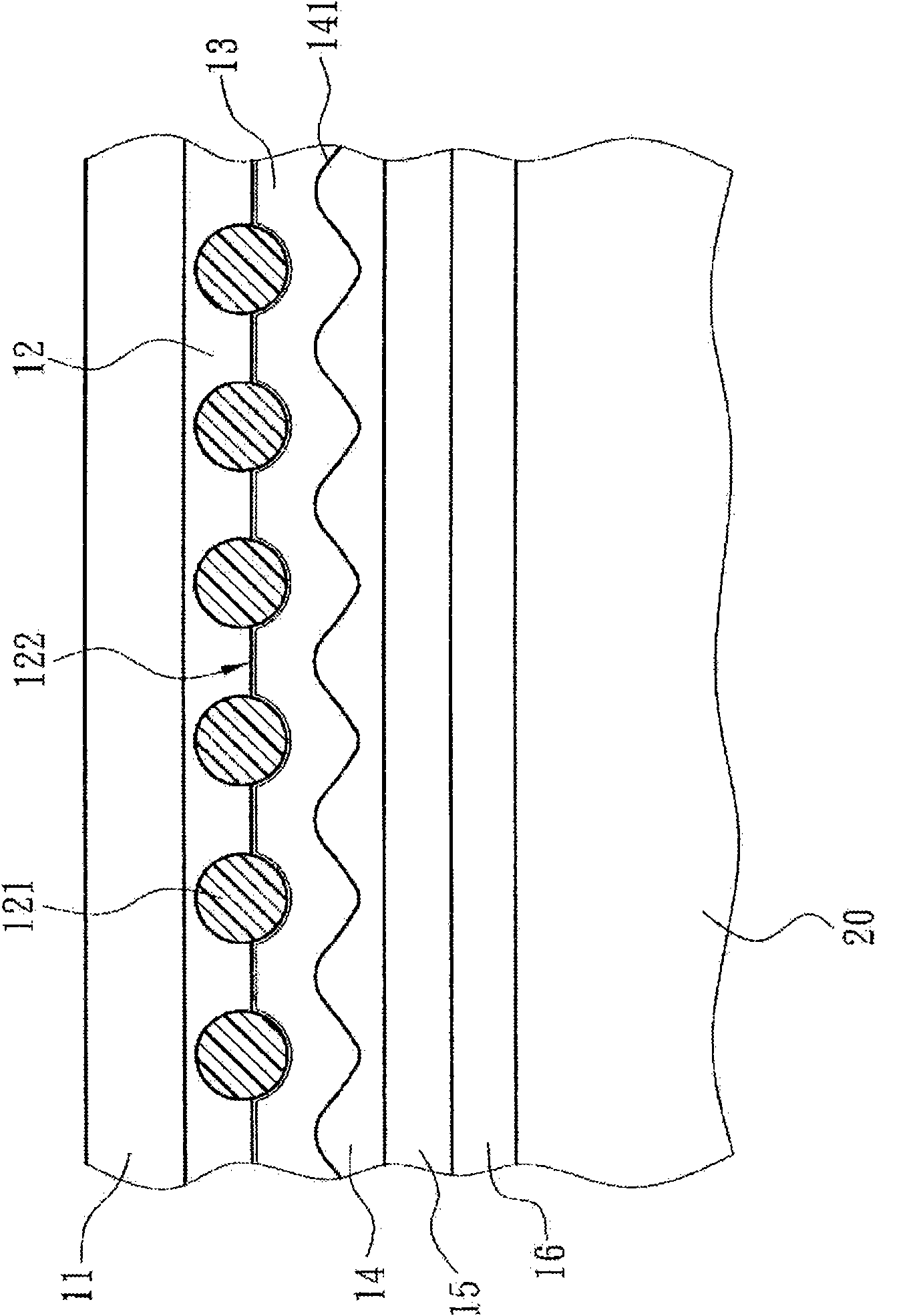

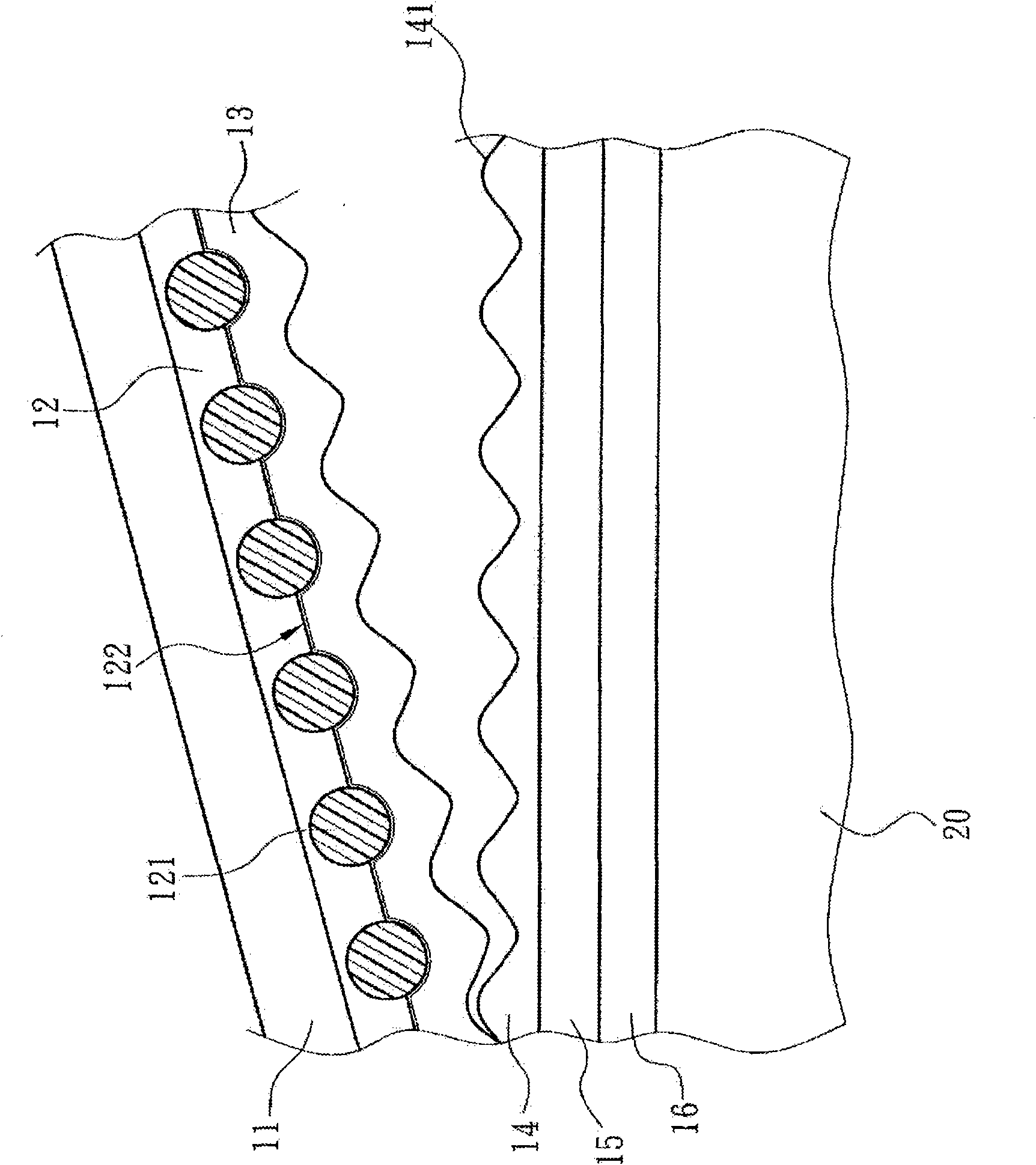

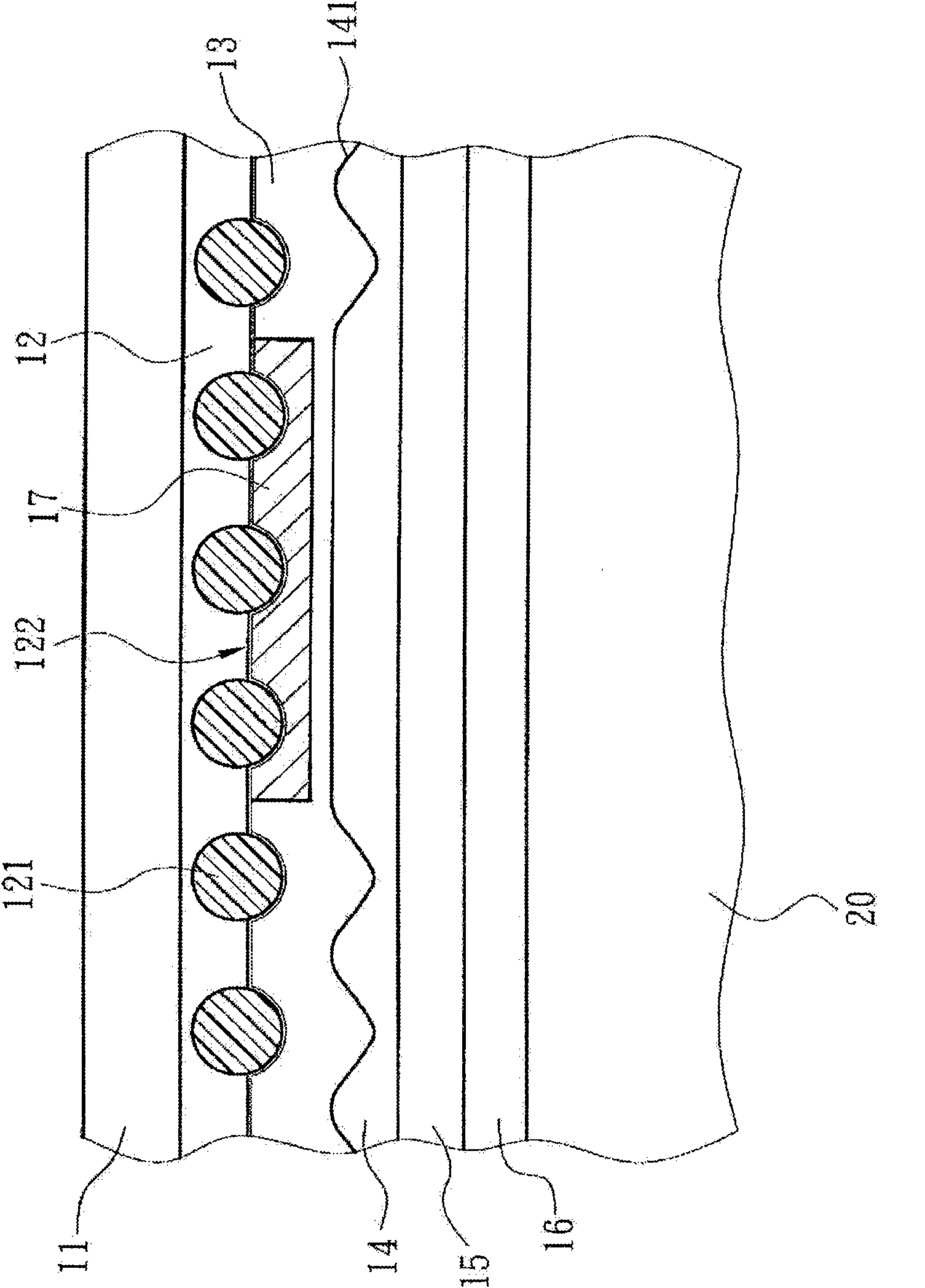

Display device

Owner:AU OPTRONICS CORP

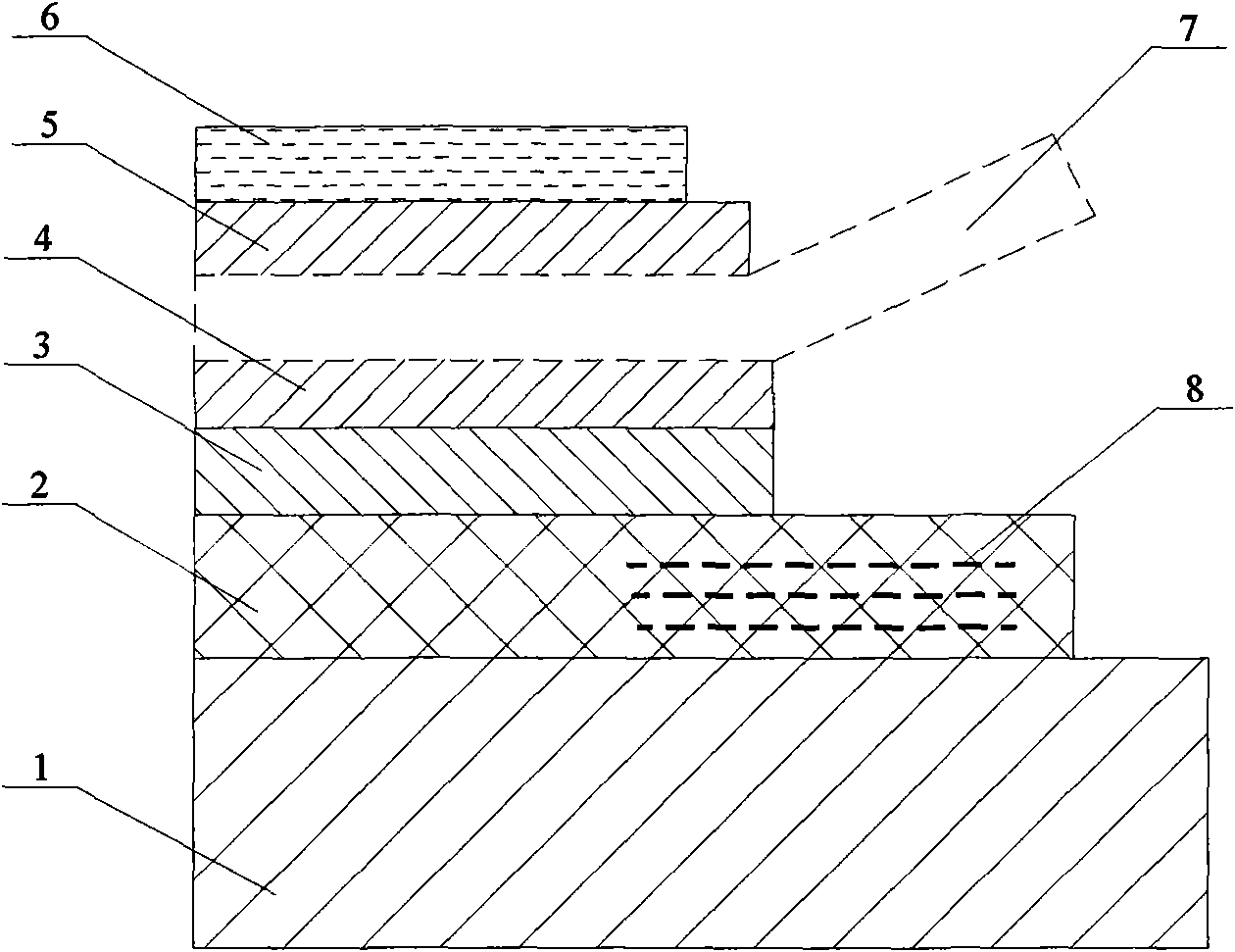

Decorative film, manufacture method for decorative film and manufacture method for additional decorative forming subject

InactiveCN102069674AAchieve visual effectDecorative surface effectsSynthetic resin layered productsBiochemical engineeringPellicle membrane

Owner:SIPIX CHEM

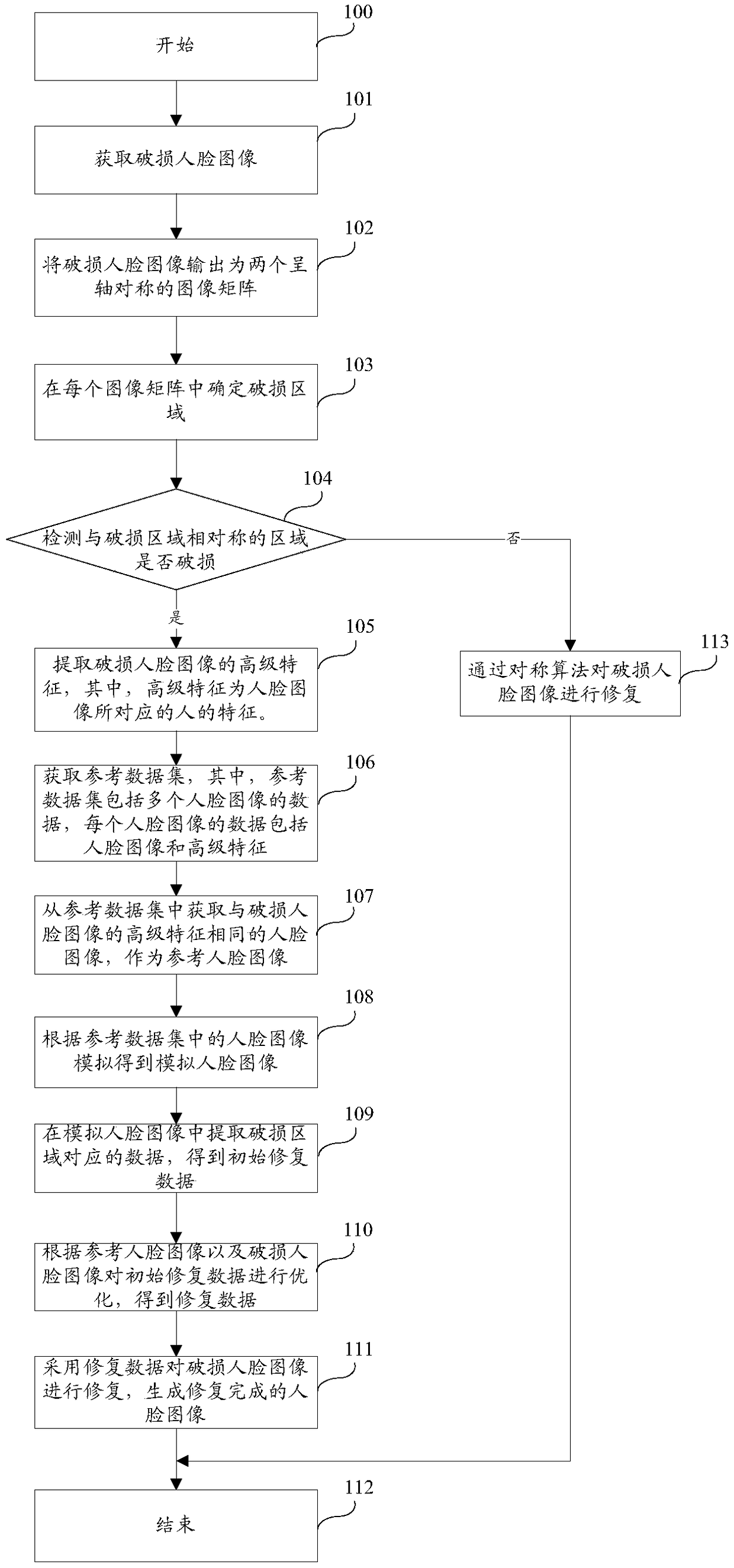

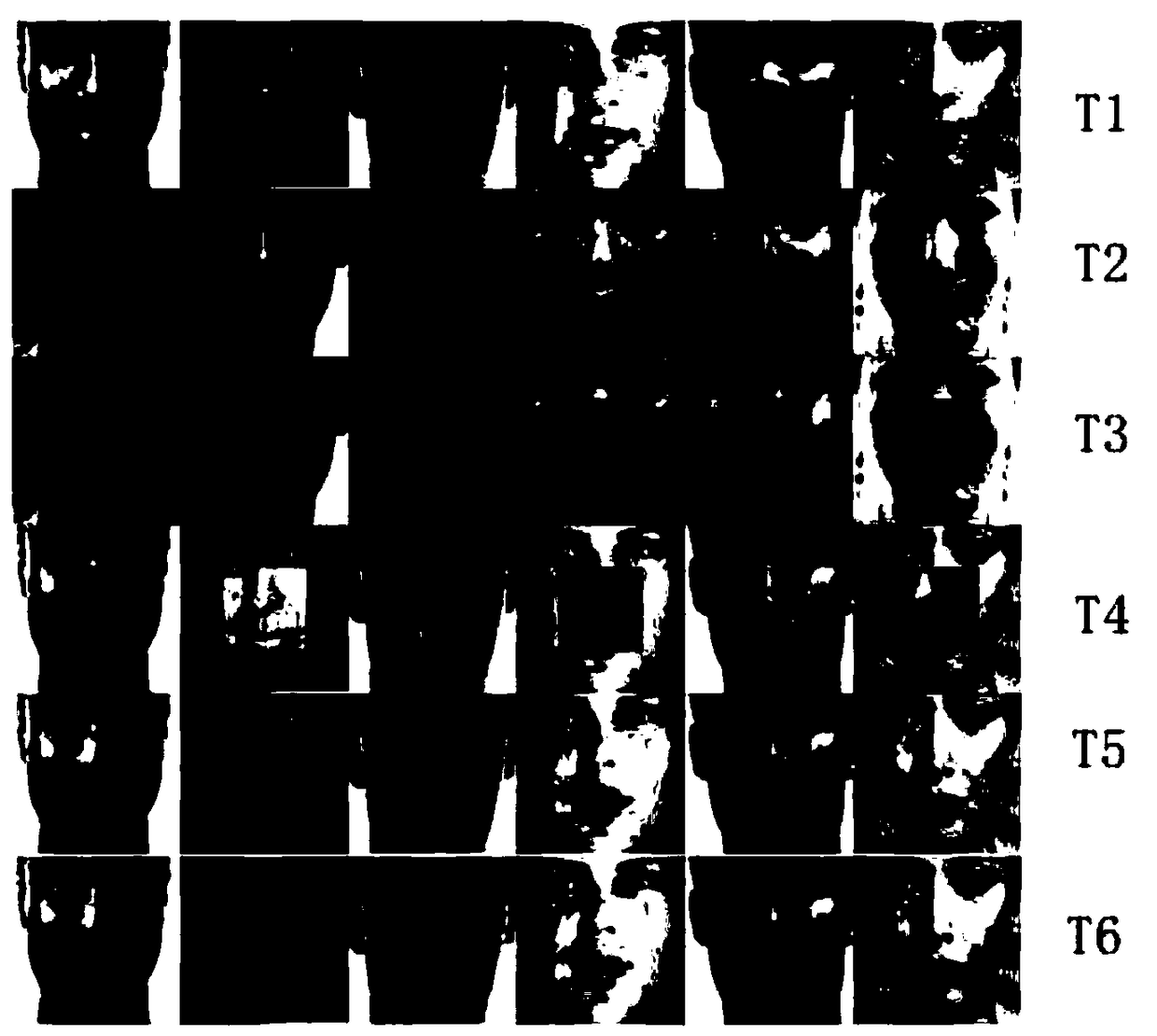

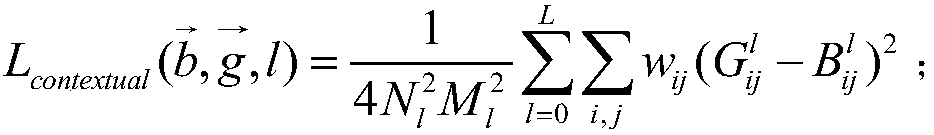

Face repairing method based on advanced features

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

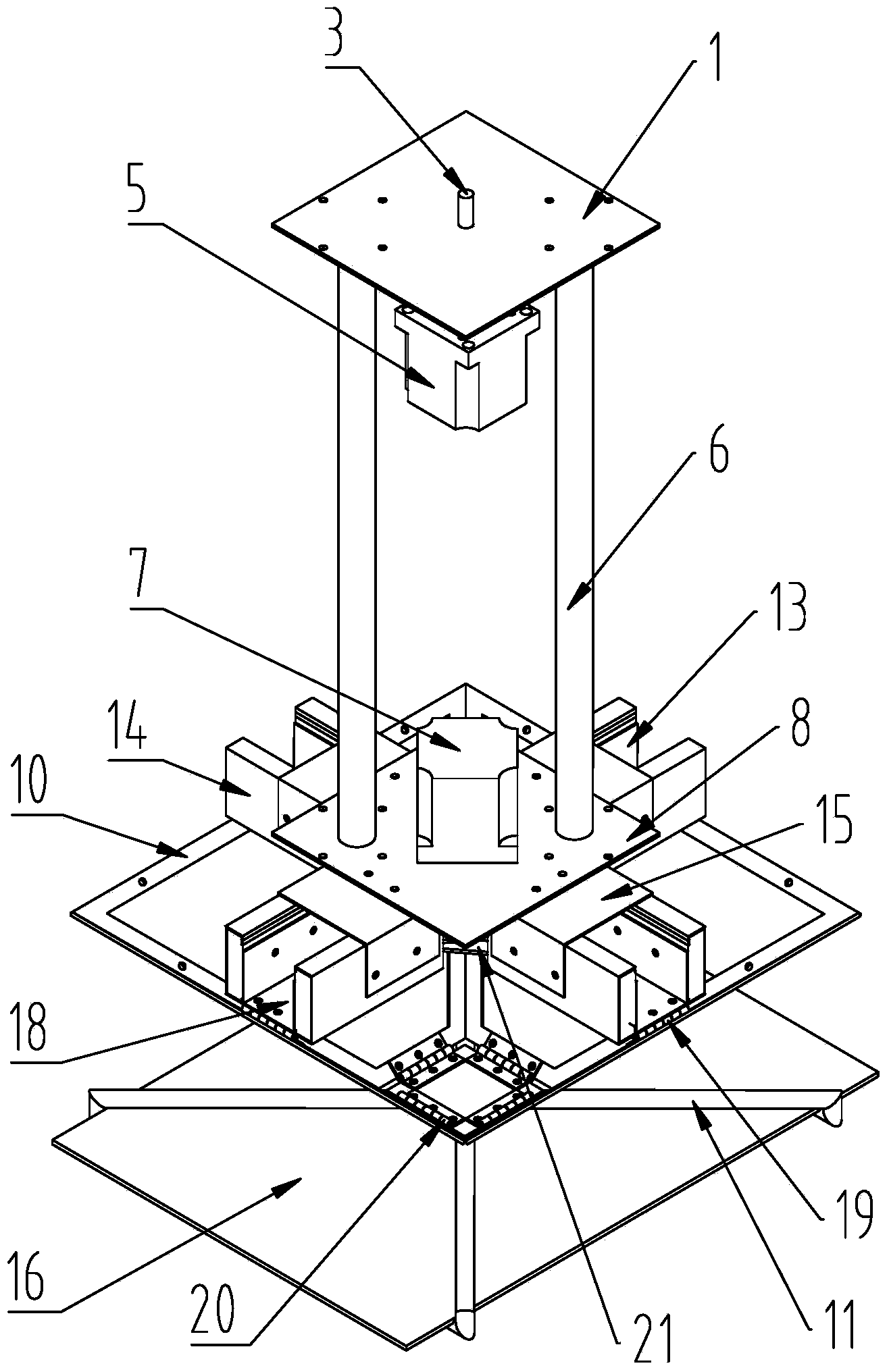

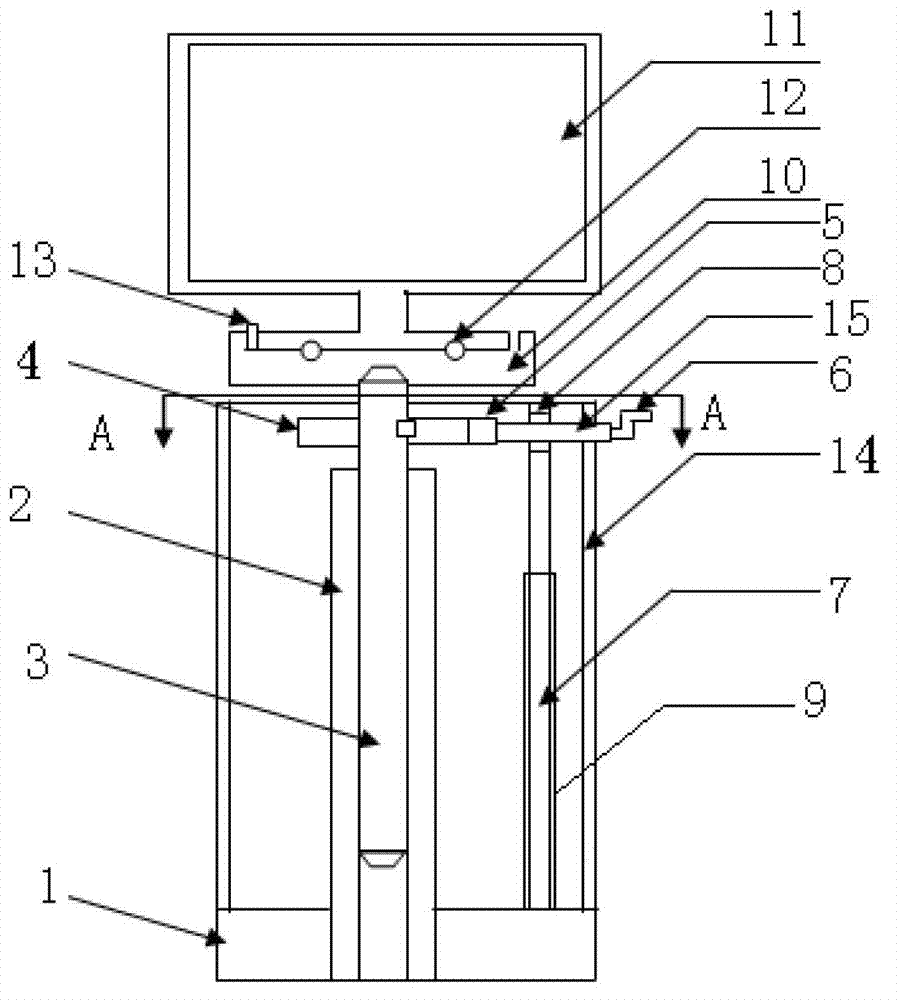

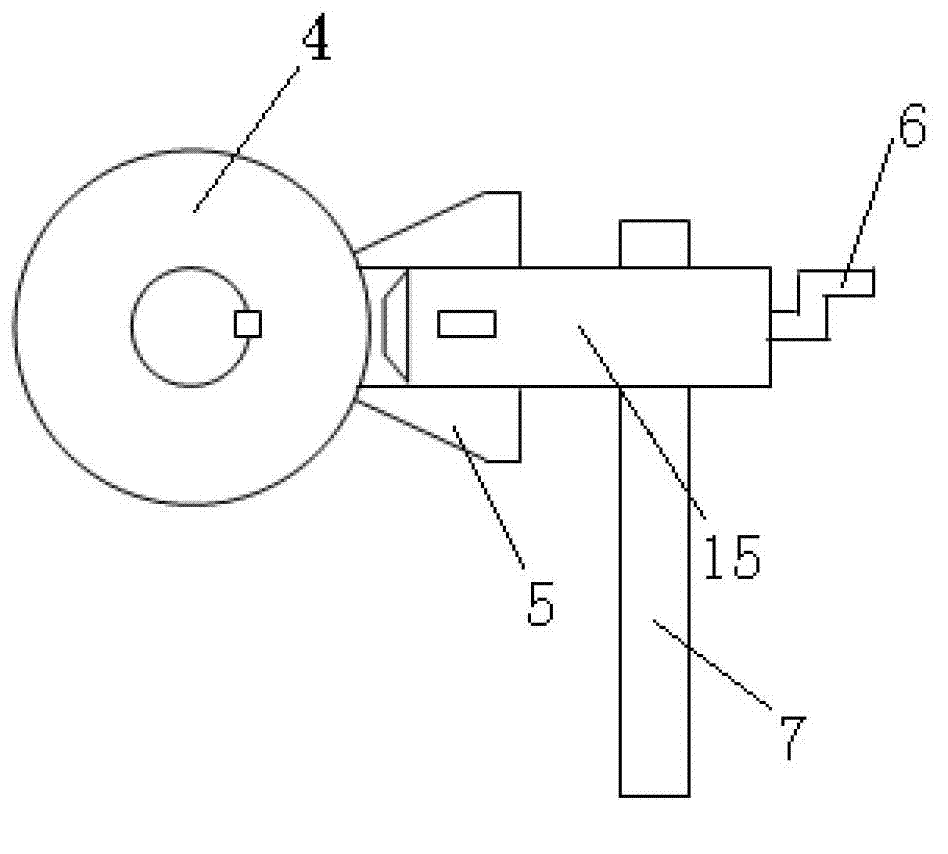

Stereoscopic image display machine based on interactive teaching

InactiveCN104143272ASame teaching experienceSolve the problem that only two-dimensional plane projection can be performedProjectorsElectrical appliancesLiquid-crystal displayComputer graphics (images)

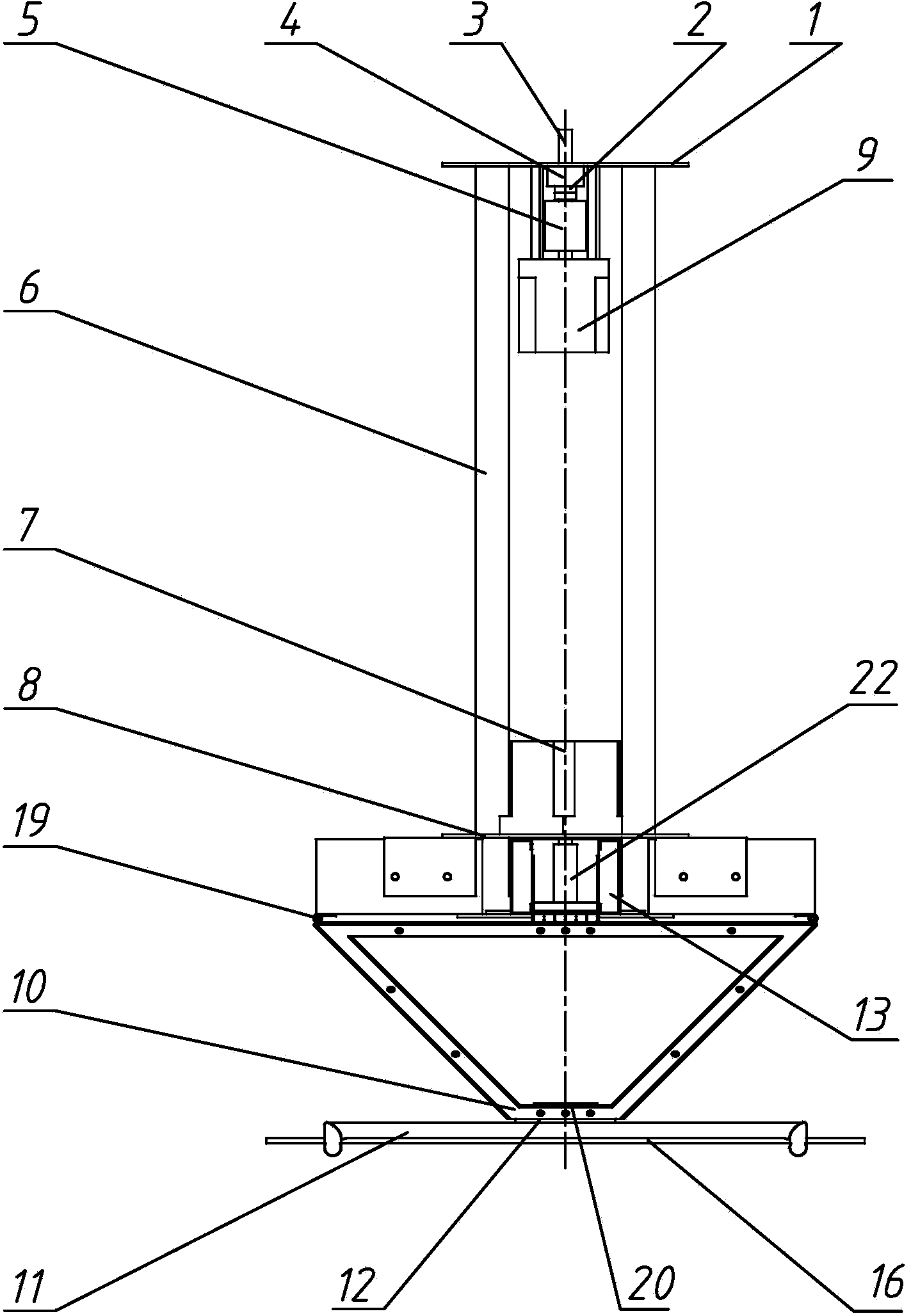

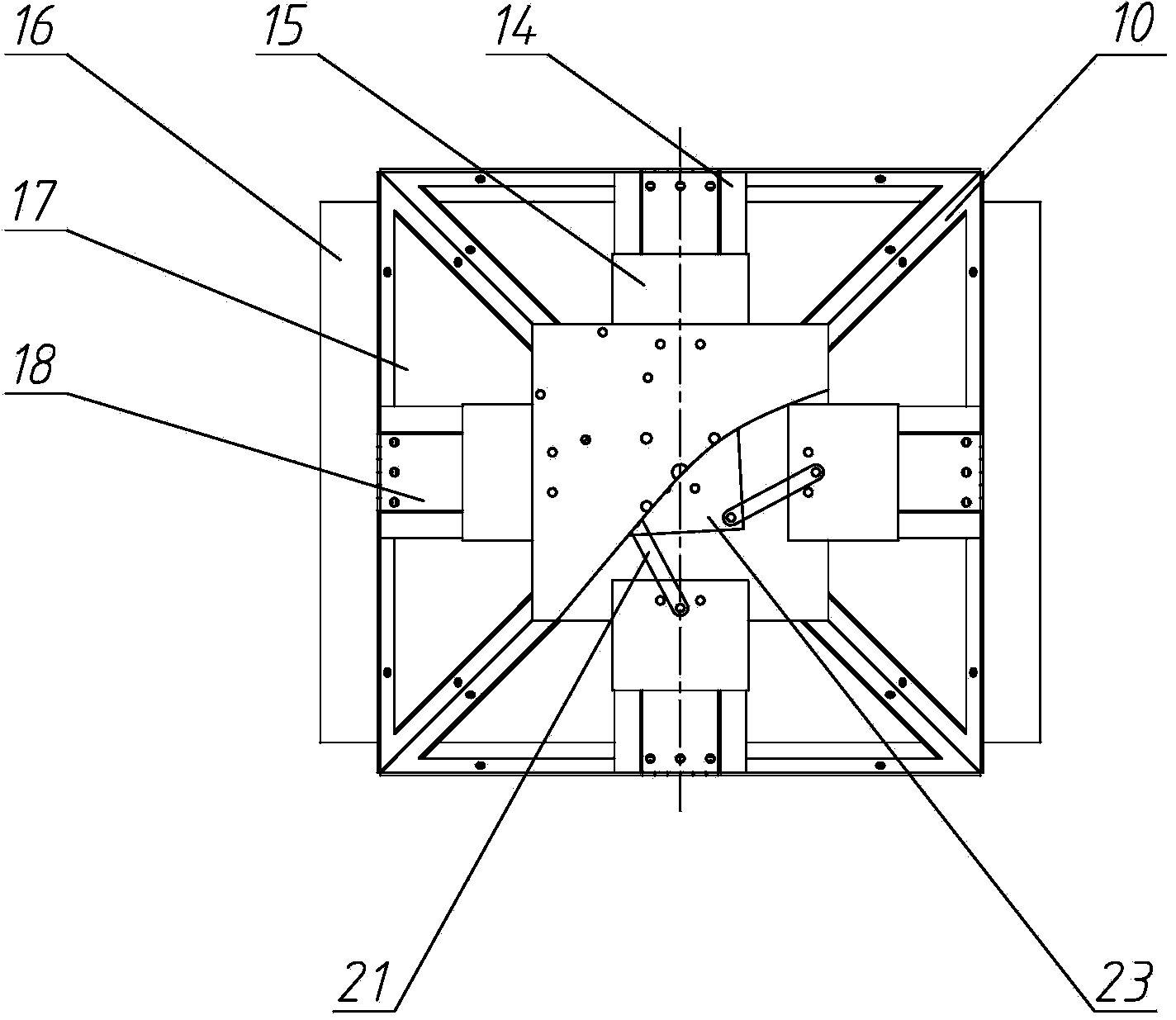

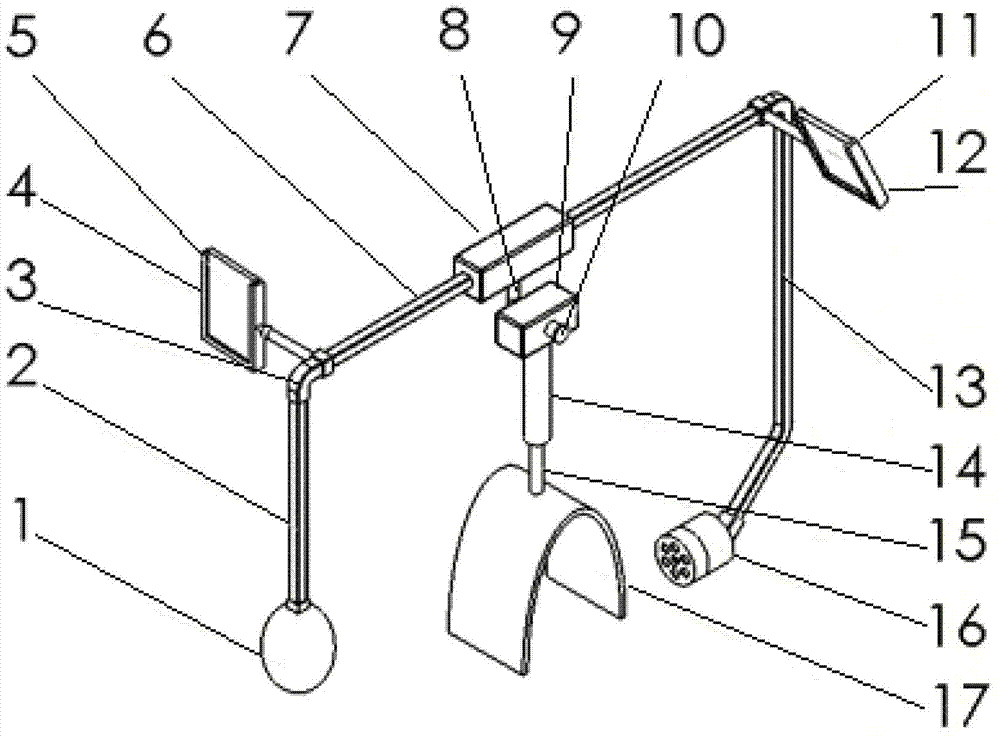

The invention discloses a stereoscopic image display machine based on interactive teaching. The stereoscopic image display machine is formed by arranging an imaging part, a folding part, a rotating part and a lifting part in sequence from bottom to top. During working, a linear push rod motor of the stereoscopic image display machine lowers the stereoscopic image display machine to be flush with a sight line in height; afterwards, a stepping motor of the stereoscopic image display machine is controlled to make a square crank drive a connecting rod to rotate, so that a guide rail elongates, and a trapezoidal frame and an organic glass plate fixedly connected to the trapezoidal frame are opened to form an angle of 45 degrees with the horizontal plane; next, the stepping motor of the stereoscopic image display machine is controlled to make the stereoscopic image display machine rotate, meanwhile, an LCD is turned on, and at this time, a stereoscopic image of the four different surfaces of a presented object can be seen at a position in a classroom through the stereoscopic image display machine. When not used, the stereoscopic image display machine is folded and lifted to a ceiling to achieve the purpose of saving space of the classroom. Besides, the stereoscopic image display machine has the advantages of being low in cost, multifunctional, high in service performance and the like.

Owner:XI AN JIAOTONG UNIV

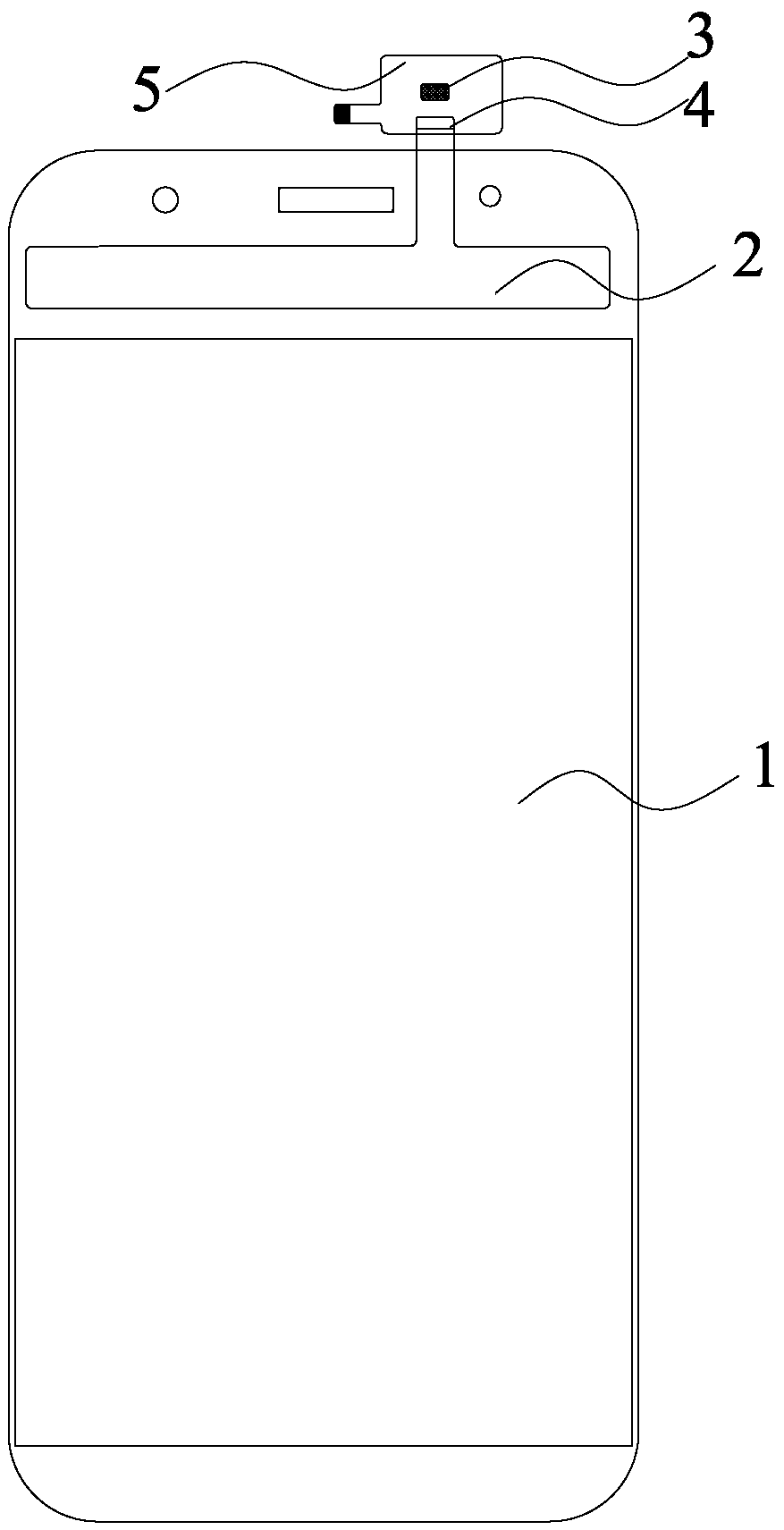

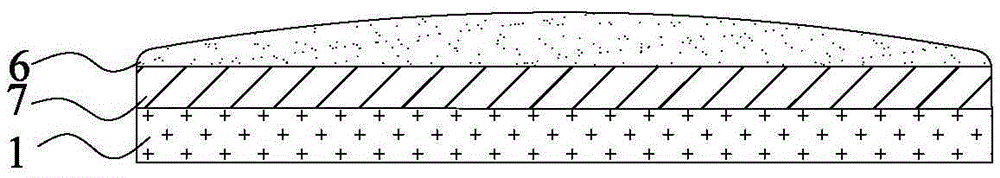

GG monolayer multipoint borderless touch screen and preparation process thereof

InactiveCN105511681AGood light transmissionImprove clarityInput/output processes for data processingSputteringGlass cover

The invention relates to the technical field of touch screens and particularly relates to a GG monolayer multipoint borderless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical adhesive layer and ITO conductive glass, wherein a border wiring area of the ITO conductive glass comprises a transverse wiring area arranged at one end of the touch screen, the ITO conductive glass is provided with a monolayer multipoint electrode pattern of single-end outgoing line, and an FPC is mounted in the transverse wiring area in a press-fitting manner and is connected with an IC chip. According to the GG monolayer multipoint borderless touch screen and the preparation process thereof, the FPC is mounted in the transverse wiring area at one end of the touch screen in the press-fitting manner, and original left and right longitudinal wiring areas are canceled, so that longitudinal sides of the touch screen do not need wiring, and thus, a borderless visual effect is built; ultraviolet illumination is adopted during magnetron-sputtering ITO film plating, so that the photoelectric properties of the ITO conductive glass are improved, only one-time FPC press-fitting is required during preparation, the process is simple, the yield of products is high, and excellent properties and production stability for the touch screen can be guaranteed.

Owner:深圳市欣联科技有限公司

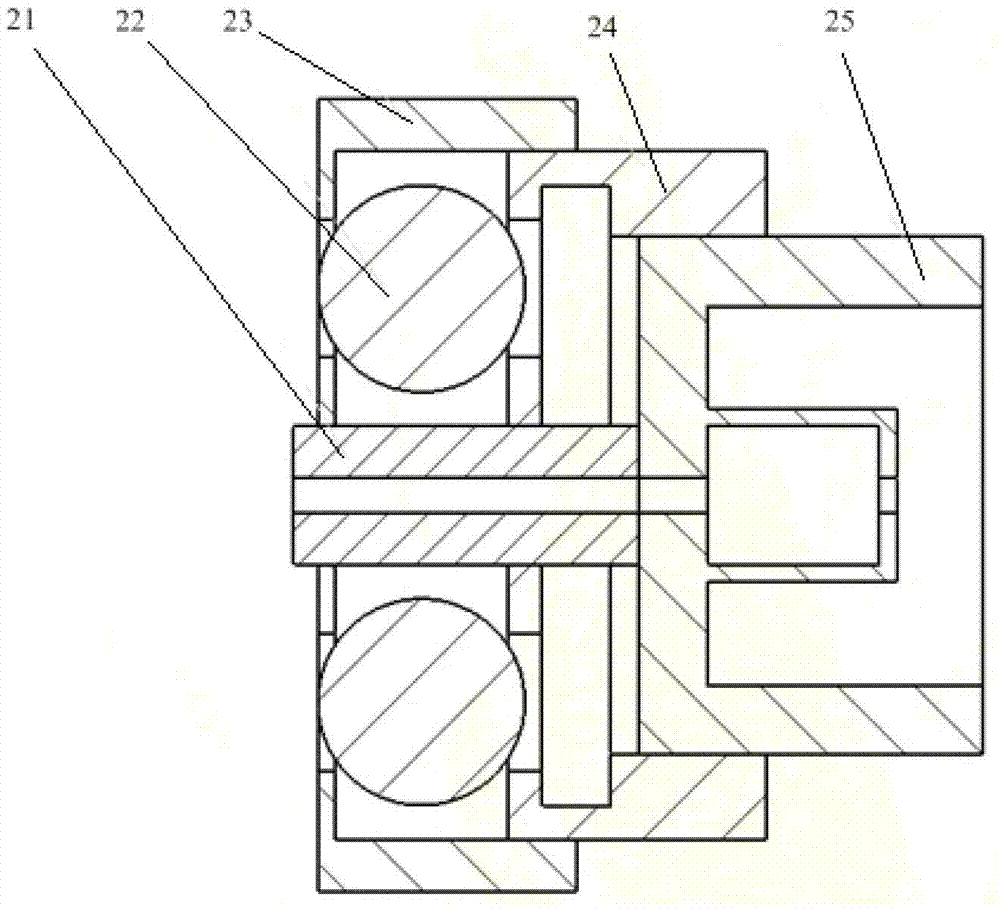

Healthcare universal lifting instrument for computer monitor

The invention discloses a healthcare universal lifting instrument for a computer monitor. The healthcare universal lifting instrument comprises a base, a main lead screw sleeve is arranged on the base, a main lead screw is fittingly mounted in the main lead screw sleeve, a bevel gear wheel is fixedly mounted at the upper end of the main lead screw, a bevel pinion is fittingly mounted on one side of the bevel gear wheel, a rotary shaft of the bevel pinion is driven by a handle, one end of the rotary shaft penetrate through a support rod, the rotary shaft is in running fit with the support rod by a bearing, a guide sleeve matched with the support rod is arranged on the base, a tray is fixedly mounted at an end of the main lead screw, and the computer monitor is rotationally mounted on the tray. The healthcare universal lifting instrument is reasonable in structural design, compact in structure, simple in principle, low in cost, good in safety performance and high in adjustment efficiency and has a function of effectively protecting the cervical vertebra and the visual range of eyes of a user, the visual angle and the vertical position of the monitor can be adjusted as needed, fatigue of cervical vertebra of the user due to the fact that the user uses a computer for a long time can be reduced, requirements of ergonomics are met completely, the computer monitor can be shifted easily in all directions, and a freewheeling visual effect can be realized.

Owner:张小伟

GF single-layer multi-touch frameless touch screen and preparation process thereof

ActiveCN105426014AImprove antiknock performanceReduce reflectionInput/output processes for data processingGlass coverEngineering

The invention relates to the technical field of touch screens, in particular to a GF single-layer multi-touch frameless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical glue layer and an ITO conductive film, wherein the wiring area of an ITO conductive film frame comprises a transverse wiring area arranged at one end of the touch screen, single-layer multi-touch electrode patterns realizing single-end wiring are formed on the ITO conductive film, a FPC (flexible printed circuit) is pressed on the transverse wiring area, an outgoing line of the ITO conductive film is connected with an IC (integrated circuit) chip through the FPC, and the tempered glass cover plate is provided with an anti-explosion layer and an anti-reflective layer. According to the GF single-layer multi-touch frameless touch screen, the FPC is pressed on the transverse wiring area at one end of the touch screen, so that wires are not required to be arranged on longitudinal edges of the touch screen, and a flameless visual effect is realized; the GF single-layer multi-touch frameless touch screen has good photoelectric performance, stability and anti-explosion capacity, FPC pressing only needs to be performed once in the preparation process, the process is simple, the yield of products is high, and the good performance and the production stability of the touch screen can be guaranteed.

Owner:DONGGUAN PINGBO ELECTRONICS

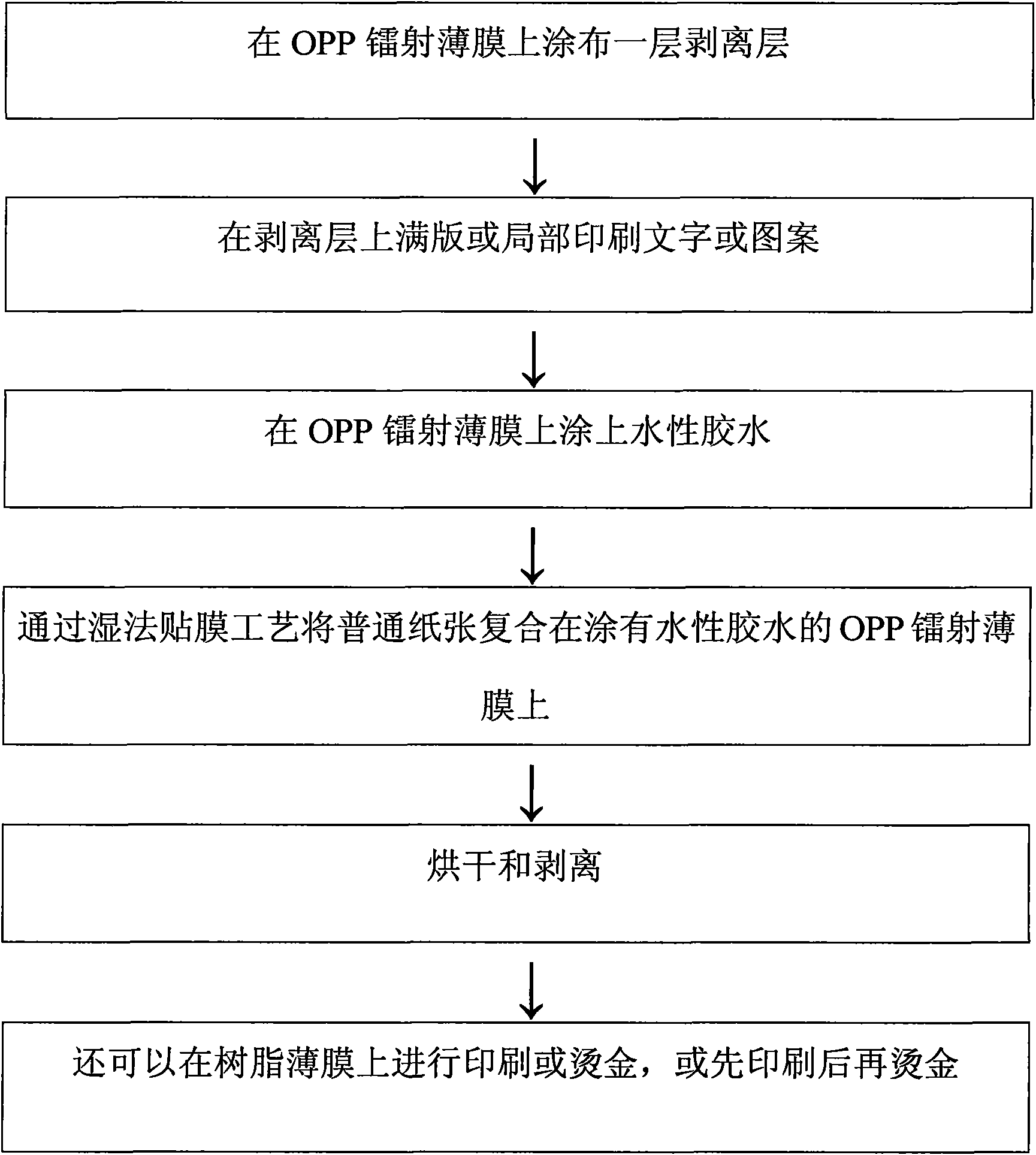

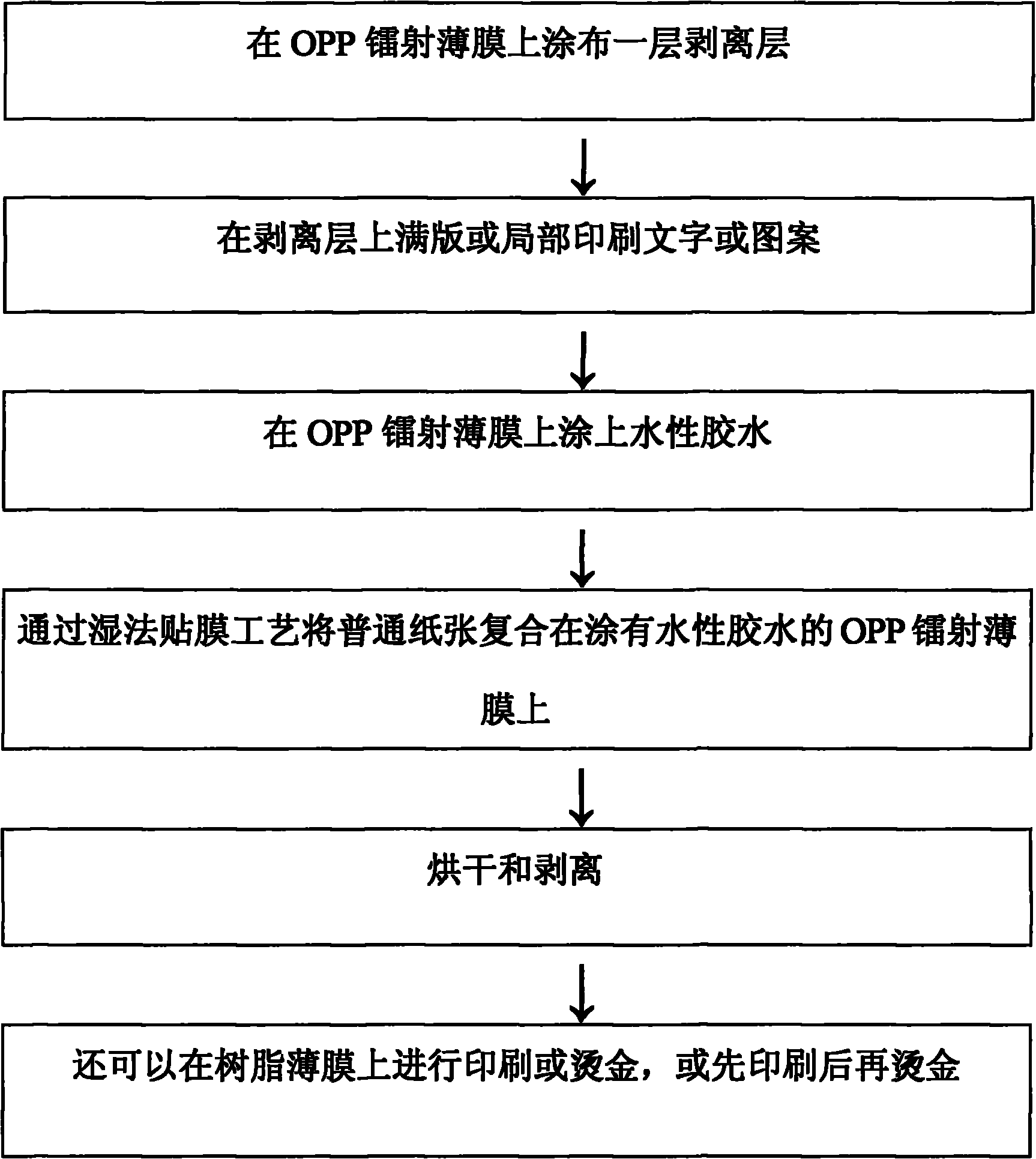

Method for realizing laser effect on common paper

InactiveCN101906737ALower requirementSolve the disadvantage that the laser effect cannot be reproduced againNon-fibrous pulp additionSpecial visual effect coatingsWater basedEngineering

The invention discloses a method for realizing laser effect on common paper. The method can realize full or local effect according to the actual requirement and comprises the following steps of: coating a stripping layer on an OPP laser film; printing characters or patterns fully or locally on the stripping layer; coating a layer of water-based glue on the OPP laser film; stitching the common paper on the OPP laser film coated with the water-based glue by a wet film coating process; and finally drying and stripping, so that the characters or patterns on the paper shows strong laser effect. The method realizes the laser effect on the paper without a vacuum aluminum plating process, has low requirement on the paper, and can not only achieve the visual effect of electrochemical aluminum gilding, but also can solve the problem of the conventional first hot printing process that the steps of printing positioning and cold transfer of the laser film cannot be leapfrogged; and besides, energyis saved and consumption is reduced to the greatest degree, the material is more environmental-friendly, the operation is simple and easy, and the method is particularly applicable to internal liningpaper for cigarettes, tipping paper, internal paper, beer labels, medicine packaging boxes, food packaging boxes and the like.

Owner:张明

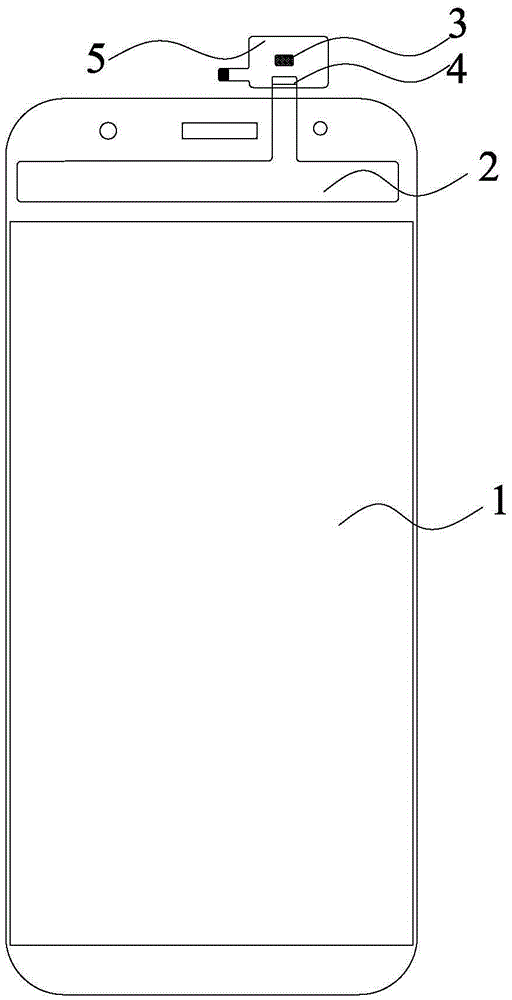

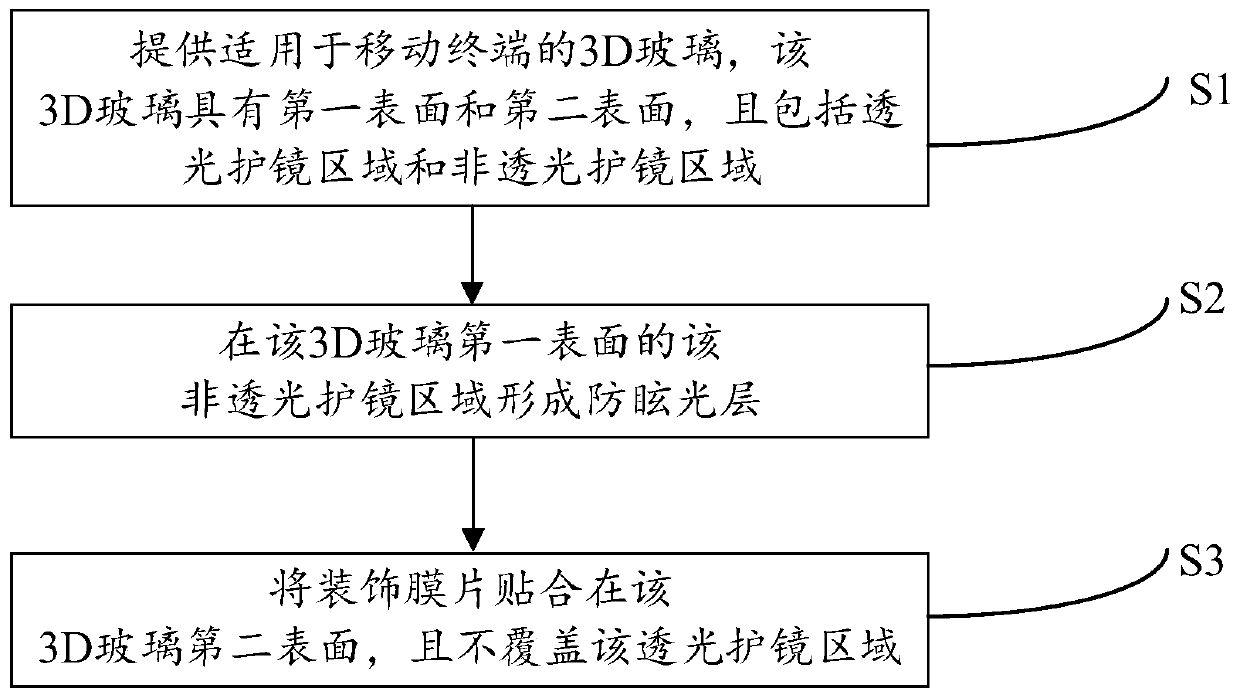

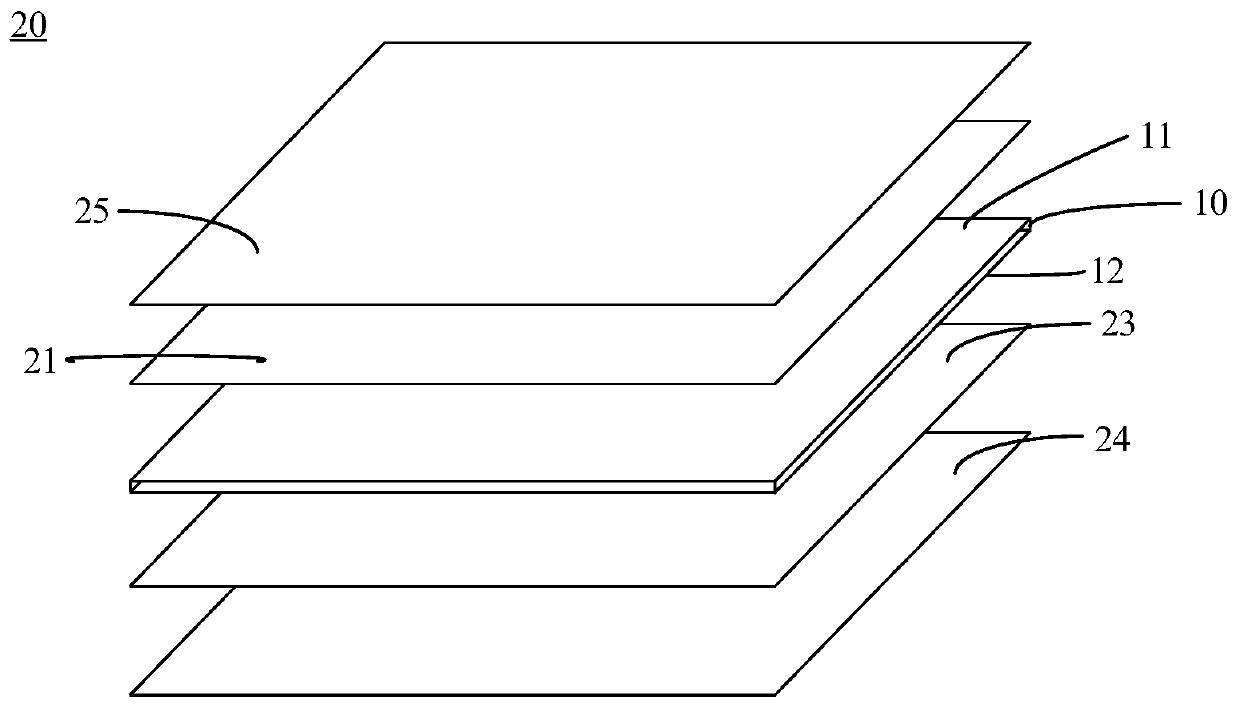

Manufacturing method of glass rear cover, glass rear cover and mobile terminal

InactiveCN111314509AImprove integrityImprove aestheticsSynthetic resin layered productsPattern printingProtective glassesEngineering

The invention discloses a manufacturing method of a glass rear cover, the glass rear cover and a mobile terminal. Firstly, 3D glass suitable for a mobile terminal is provided; the 3D glass is providedwith a first surface and a second surface, the lens comprises a light-transmitting lens protection area and a non-light-transmitting lens protection area. An anti-glare layer in the non-light-transmitting protective glass area is formed on the first surface of the 3D glass; and finally, the decorative membrane is attached to the second surface of the 3D glass. The light-transmitting protective glass area is not covered; the light-transmitting protective glass area of the glass rear cover can be used as a protective glass of the camera. The non-light-transmitting protective glass area of the glass rear cover serves as a machine shell, the glass rear cover is made to be a whole, the integrality and attractiveness of the mobile terminal can be improved, in addition, the anti-dazzle layer canachieve comparison of the matte visual sense and tactile sense of the surface of the glass rear cover, and the membrane layer can further achieve various visual effects.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

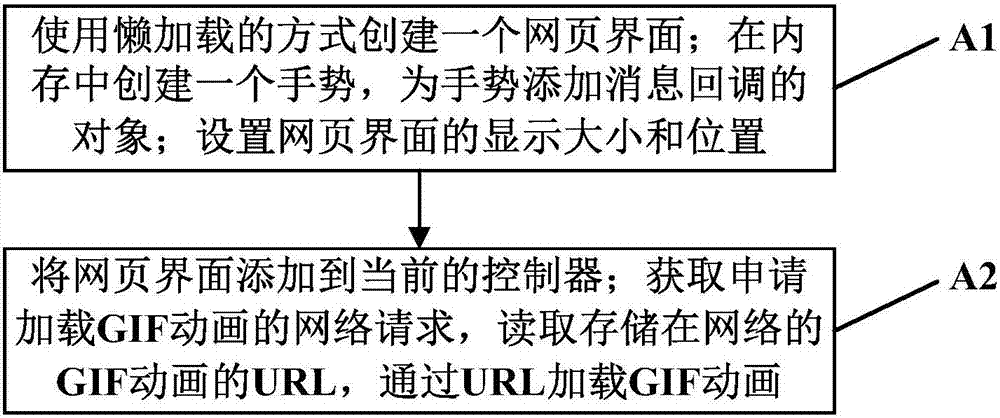

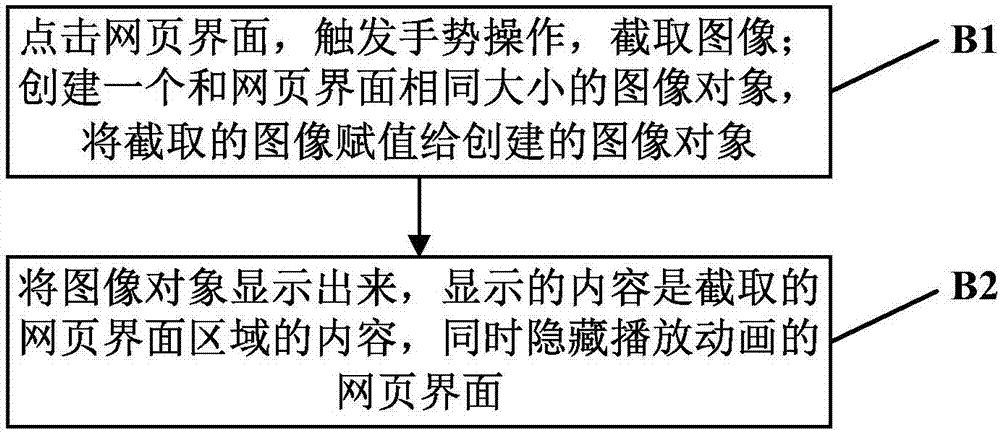

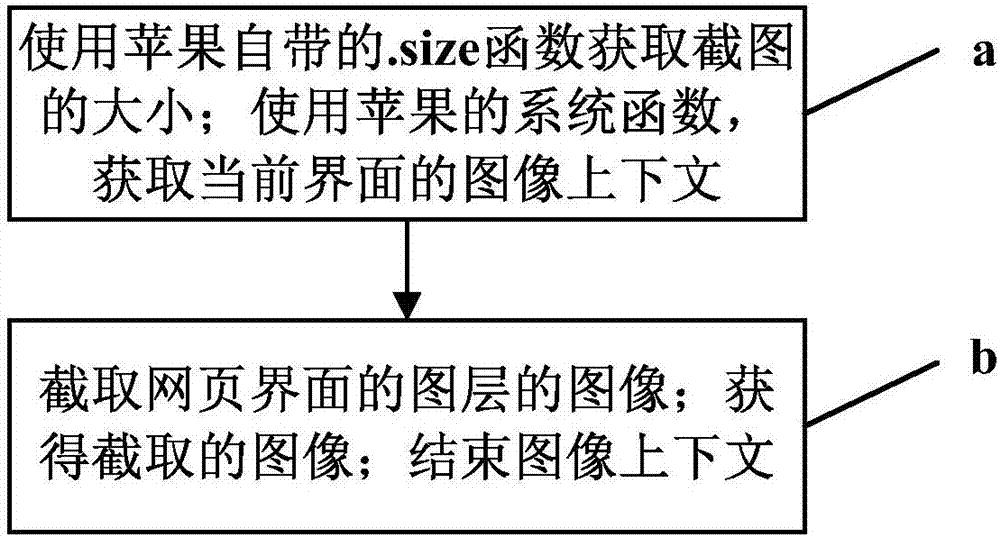

Method and apparatus for loading GIF animation in iOS

ActiveCN107038219AWill not cause a surgePrevent crashSpecial data processing applicationsInput/output processes for data processingAnimationThe Internet

The present invention discloses a method and an apparatus for loading the GIF animation in the iOS, and relates to the field of Internet mobile application development. The method comprises the following steps: creating a webpage interface by using lazy loading; creating a gesture in the memory, and adding a message callback object for the created gesture; setting the display size and the display position of the web page interface; adding the web page interface to the current controller; and obtaining a network request to load the GIF animation, reading the uniform resource locator URL of the GIF animation stored in the network, and loading the GIF animation through the URL. According to the method and apparatus disclosed by the present invention, without caching the loaded animation, the memory is released after being used up, and when loading the GIF animation, memory surge cannot occurs, so that system crashed can be avoided.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

Transfer glue with lasering effect

InactiveCN101906277AAchieve laser effectAchieve visual effectNon-macromolecular adhesive additivesHydrocarbon polymer adhesivesPulp and paper industryFood packaging

The invention relates to transfer glue, which is transfer glue with lasering effect, comprising the following components by mass percent as follows: 5639-64.85 of peelable water borne resin, 34.8-43.9% of water borne coating resin, 0.1-0.2% of defoamer and 0.1-0.2% of wetting leveling agent. By using the invention, the lasering effect on paper is realized without vacuum aluminizing devices and process; and the invention has low requirement on paper and can realize strong lasering and printing effects on any common paper, thereby saving the production cost to a maximum extent, realizing the visual effect of gilding alumite and solving the problem that printing positioning and cool transfer lasering thin film can not leapfrog in the traditional process of gilding before printing. The lasering effect is realized on lightweight papers to save energy and reduce consumption to a maximum extent, the materials are more environmental friendly and the operation is simple and easy to access. Theinvention is in particular suitable for lining paper for tobacco, cork paper, internal paper, beer mark, medicine packaging box, food packaging box and the like.

Owner:张明

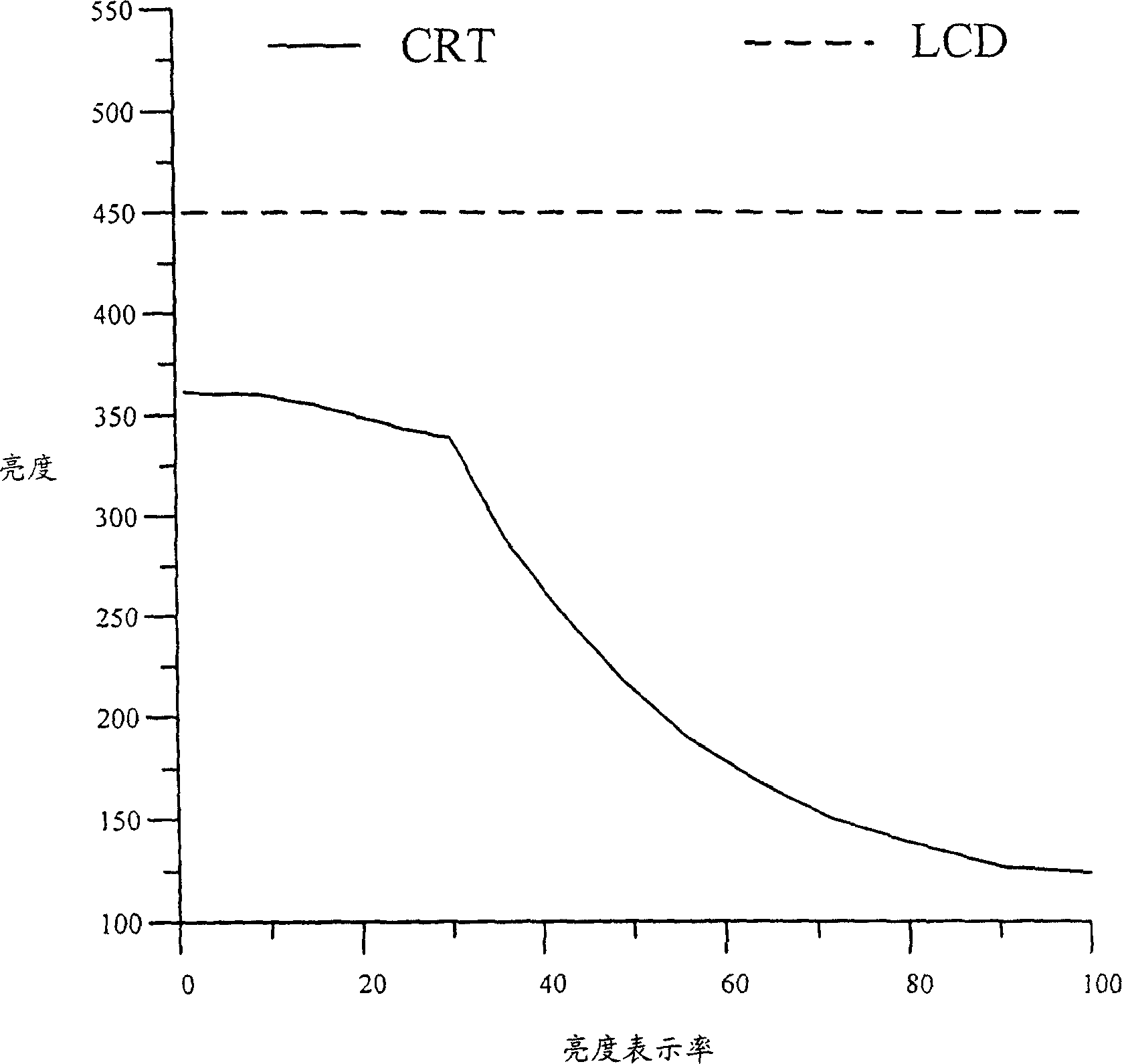

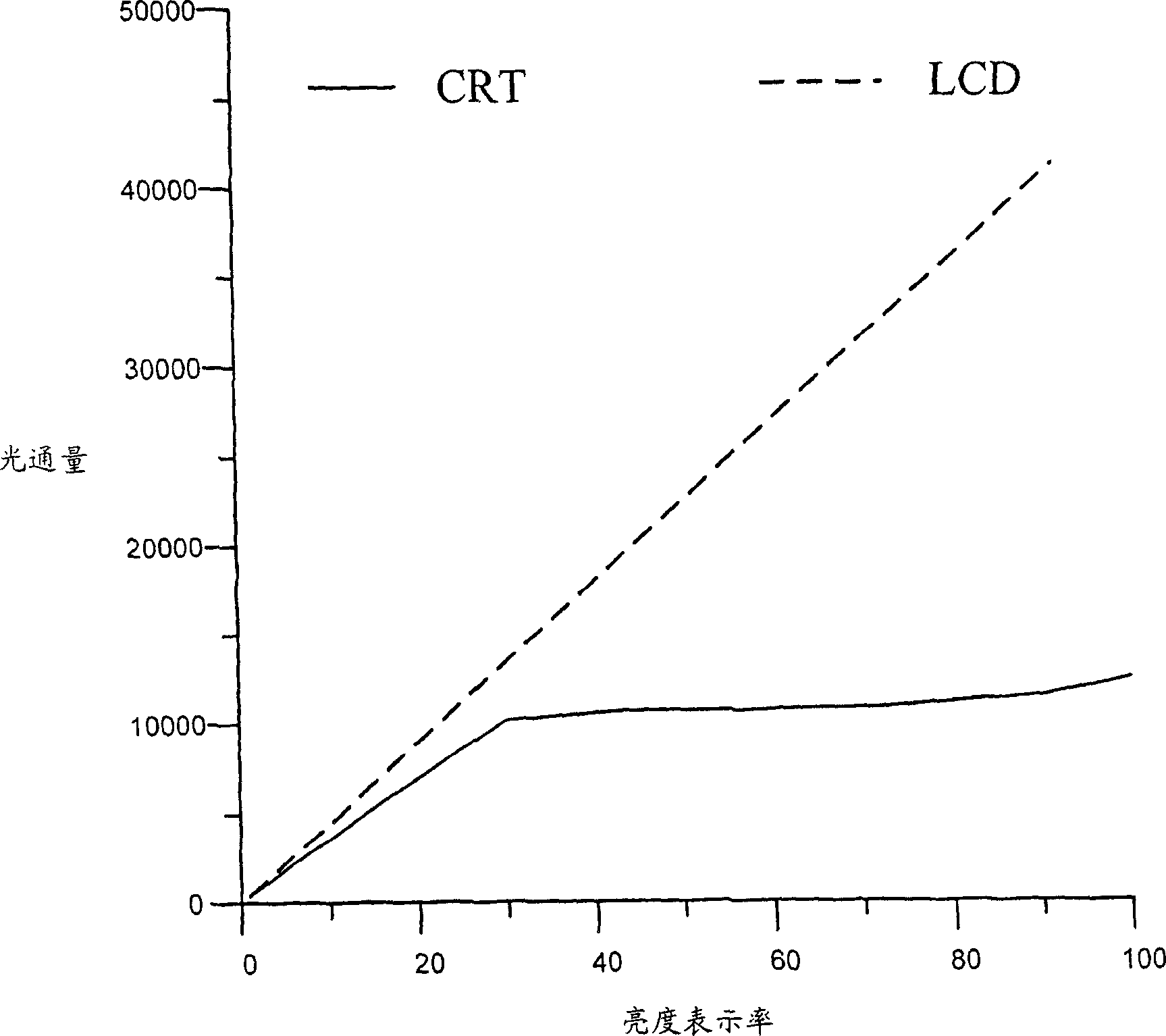

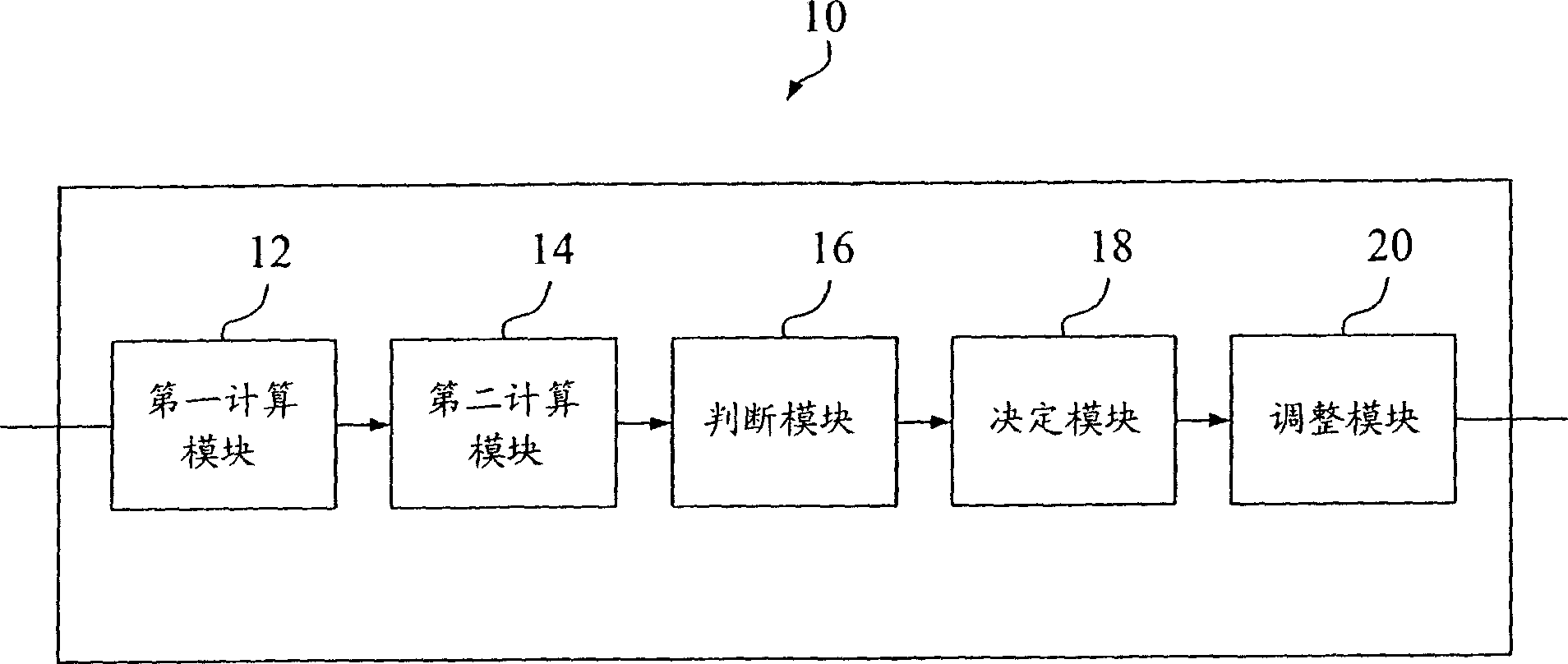

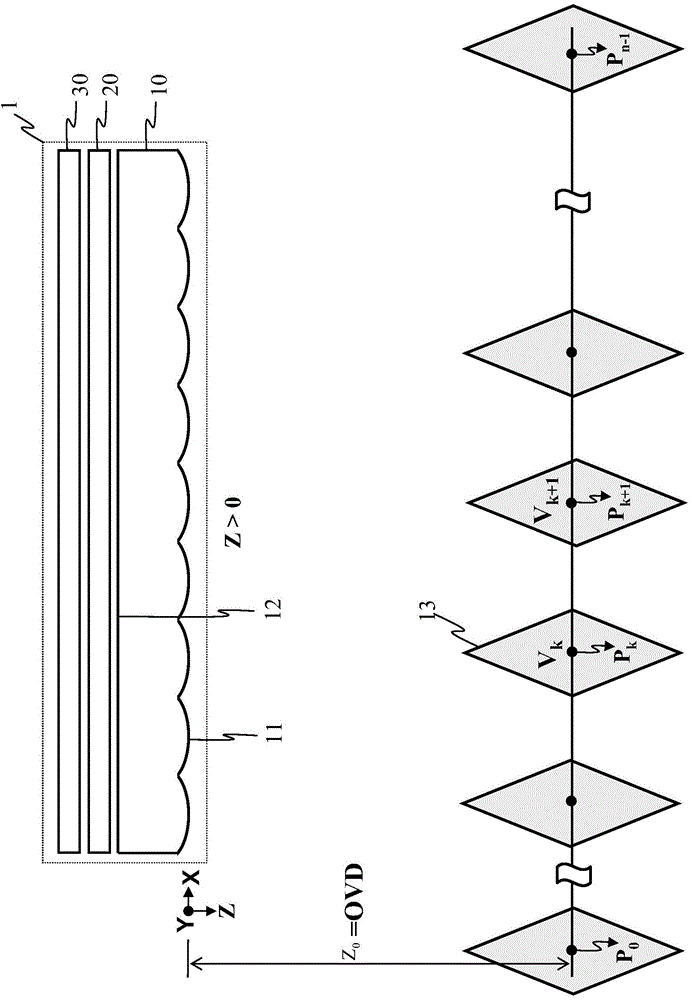

Brightness adjuster and adjusting method

ActiveCN1855208AAvoid drastic changesEnhance contrastCathode-ray tube indicatorsElectric light circuit arrangementComputer moduleComputer science

A brightness adjustment installment for a display system, adjust the No.i image brightness of the inputting image list which includes some images and every image consists of some pixels. The installment includes: a first computational module computes a present brightness indicative rate of the No.i image, a second computational module computes a indicative rate of average brightness, a judgment module chooses an indicative rate of the outputting brightness between the indicative rate of the present brightness and the indicative rate of the average brightness, a confirming module which saves some groups of brightness indicative rate and the corresponding gain value, and determine the gain value which correspond to the output brightness indicative rate, a adjustment module which multiply the gray-scale value of every pixel in the No.i image and the gain value of the outputting brightness indicative rate to completes the adjustment of the brightness.

Owner:QUANTA COMPUTER INC

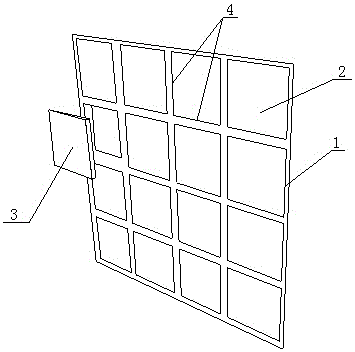

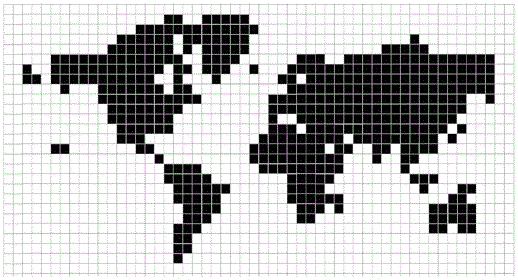

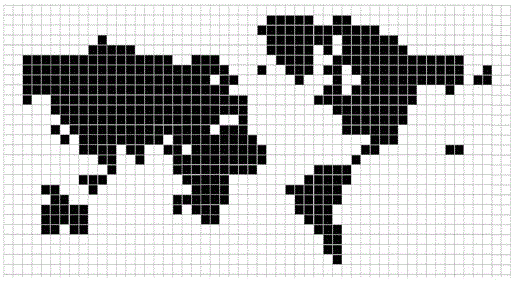

Grated wall with double-sided mosaic pattern decoration effect and method for making grated wall

The invention relates to a grated wall with a double-sided mosaic pattern decoration effect and a method for making the grated wall. The grated wall comprises a grating frame body, wherein the grating frame body consists of a closed grating outer frame and a plurality of gratings arranged in the grating outer frame; each grating is filled with fillers with one or more colors; and a color block is formed on each of the front surface and back surface of each grating through the filler. The grated wall has the benefits that after the gratings are filled with the fillers with different colors, various artistic walls with double-sided mosaic pattern decoration effects can be made according to various color blocks; the types of building partition walls are added, the artistic effects of building decoration are enriched, and flexible diversified choices are provided for modern home decoration; and the grated wall is simple, convenient and feasible, thereby having good market prospects.

Owner:FUZHOU UNIV

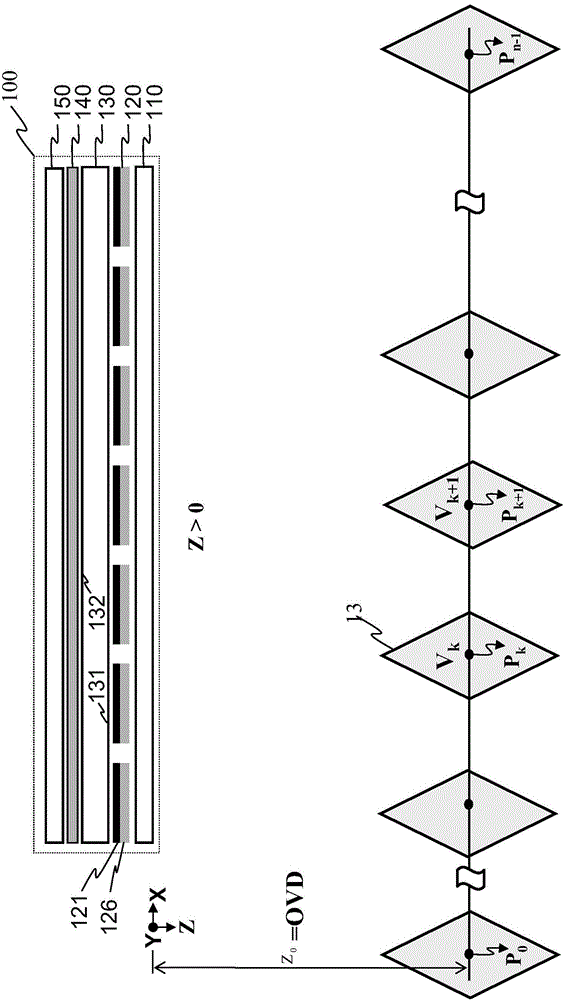

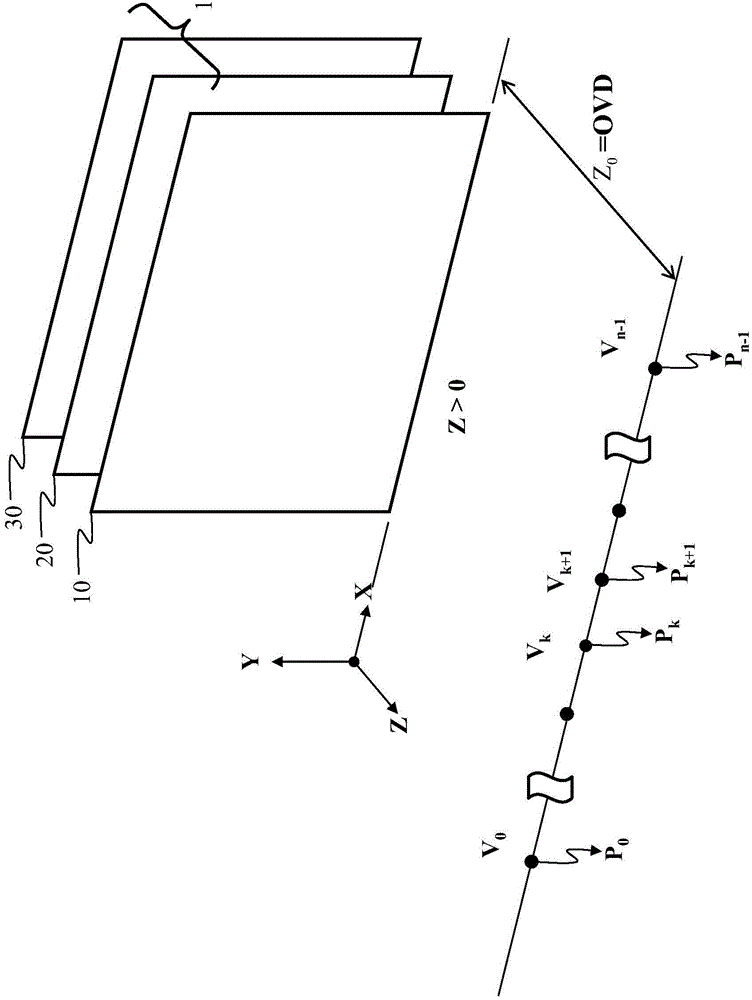

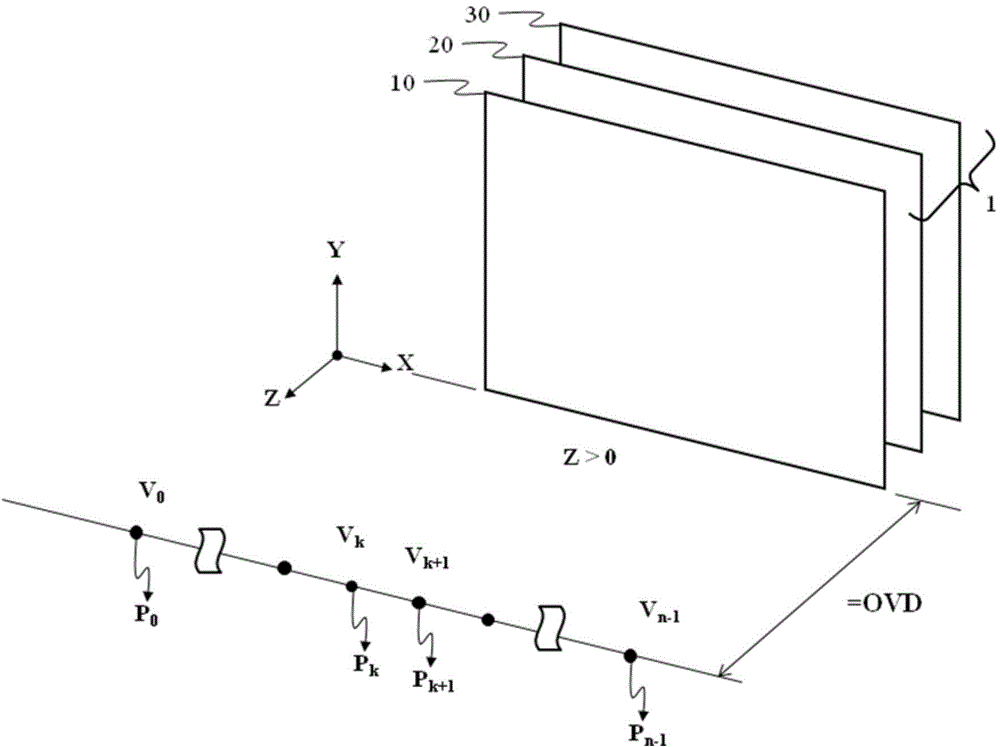

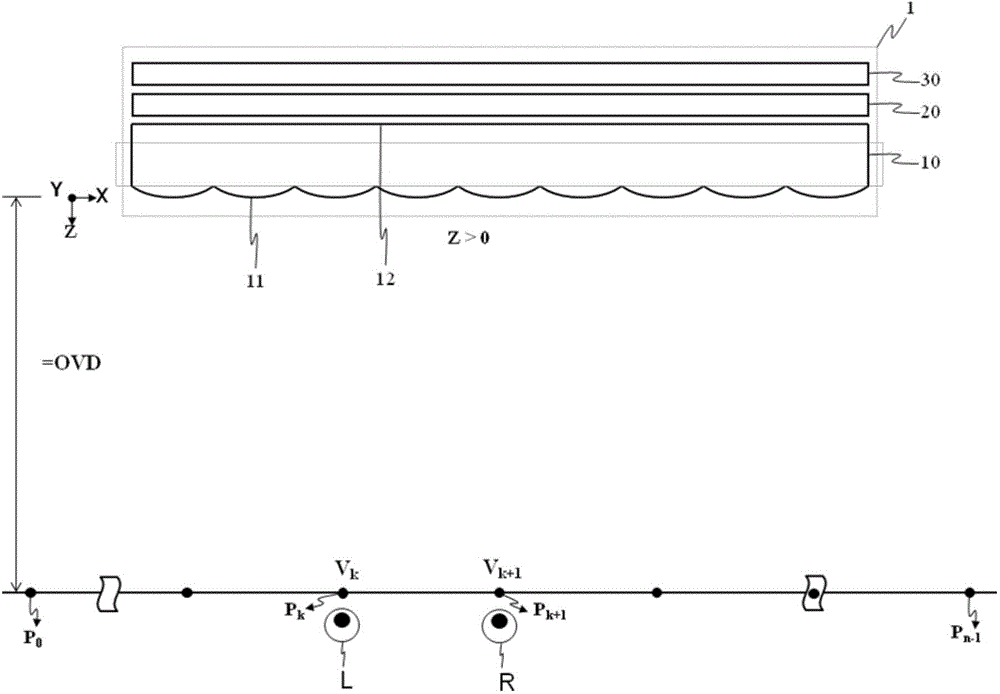

Method And Device Capable Of Displaying 2d And 3d Images Simultaneously

ActiveCN104423054AAchieve visual effectCreate unlimited advertising benefitsIlluminated signsOptical elementsGrating3d image

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Method capable of displaying 2D and 3D dynamic images simultaneously and device

ActiveCN104375275AAchieve visual effectCreate unlimited advertising benefitsProjectorsSteroscopic systemsLight sourceComputer graphics (images)

The invention discloses a method capable of displaying 2D and 3D dynamic images simultaneously and a device. A first light source, a first image face, a transparent base material, a second image face and a second light source are mainly used. The first light source projects 2D dynamic image light. The second light source projects 3D dynamic multi-visual resultant image light. A parallax grating structure is arranged on the first image face. The surface of a shading assembly in the parallax grating structure is made of materials with light reflex and light scattering. A back projection screen structure is arranged on the second image face and is made of materials with light reflex and light scattering. The first image face and the second image face are respectively arranged on two faces of the transparent base material. In addition, by use of the method of respectively projecting the 2D dynamic image light and the 3D multi-visual resultant image light on the first image face and the second image face, an objective of simultaneously displaying the 2D dynamic image and the 3D dynamic image is achieved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Device Capable Of Displaying The 2d And 3d Images Simultaneously

ActiveCN104423053AAchieve visual effectCreate unlimited advertising benefitsOptical elementsGratingComputer graphics (images)

The present invention discloses a device capable of displaying the 2D and 3D images simultaneously. According to the assembly order, the device is mainly composed of a first light source assembly, a first 2D image assembly, a parallax barrier assembly, a lens array assembly, a second 3D multi-scene synthetic image assembly and a second light source assembly, wherein the parallax barrier assembly and the lens array assembly possess the equivalent visual separation effects, for the second 3D multi-scene synthetic image assembly, the consistent optimal viewing distance and optimal viewing point can be provided, namely, the same single scene image is provided for the same optimal viewing distance and the same optimal viewing point. Therefore, by the illumination of the first light source to the first 2D image assembly , the viewers can watch the 2D images provided by the first 2D image assembly. In addition, by the illumination of the second light source assembly to the second 3D multi-scene synthetic image assembly, the viewers can watch the 3D image at the optimal viewing distance and the optimal viewing point.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

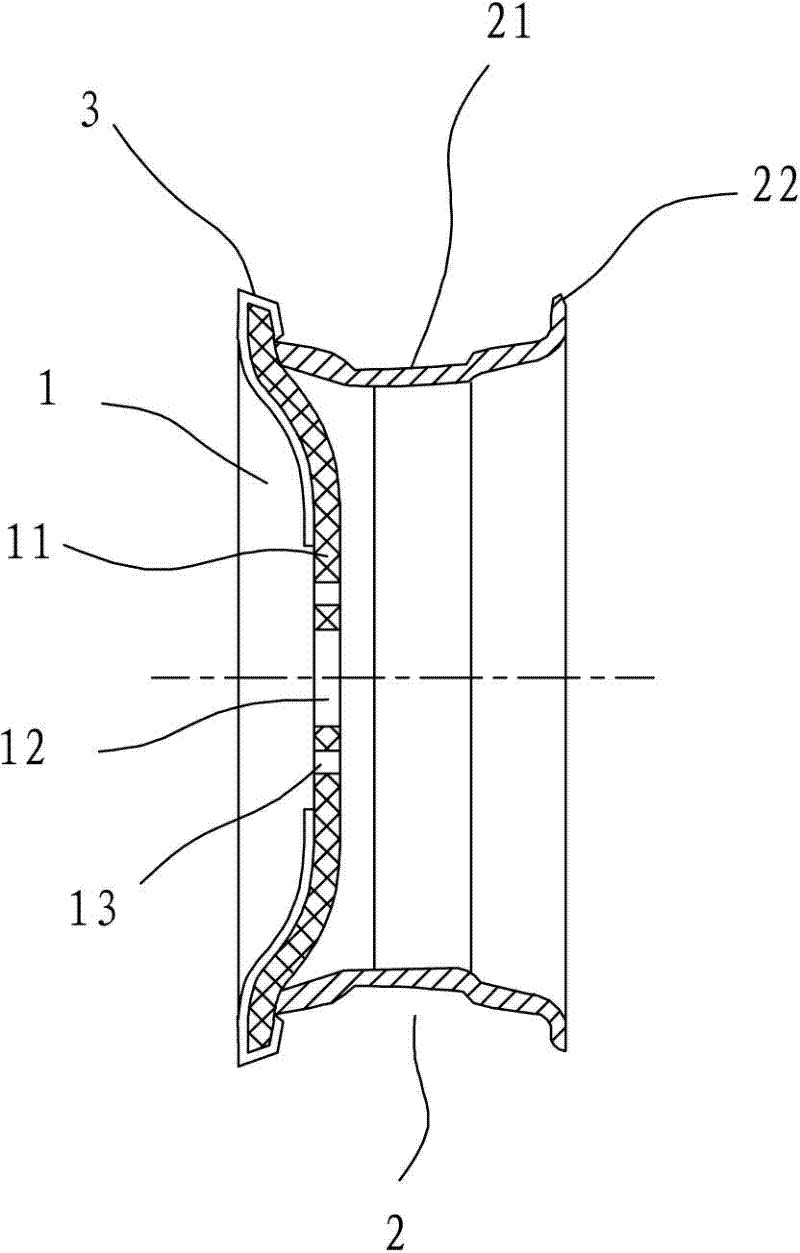

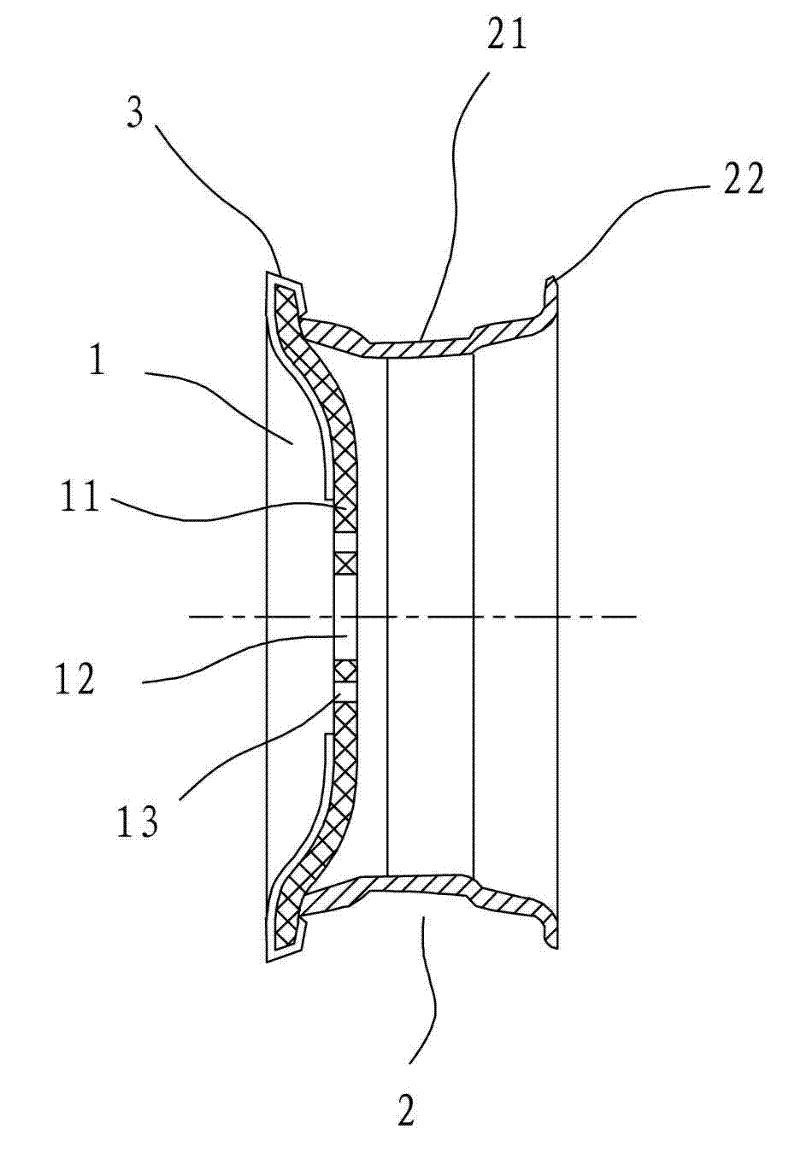

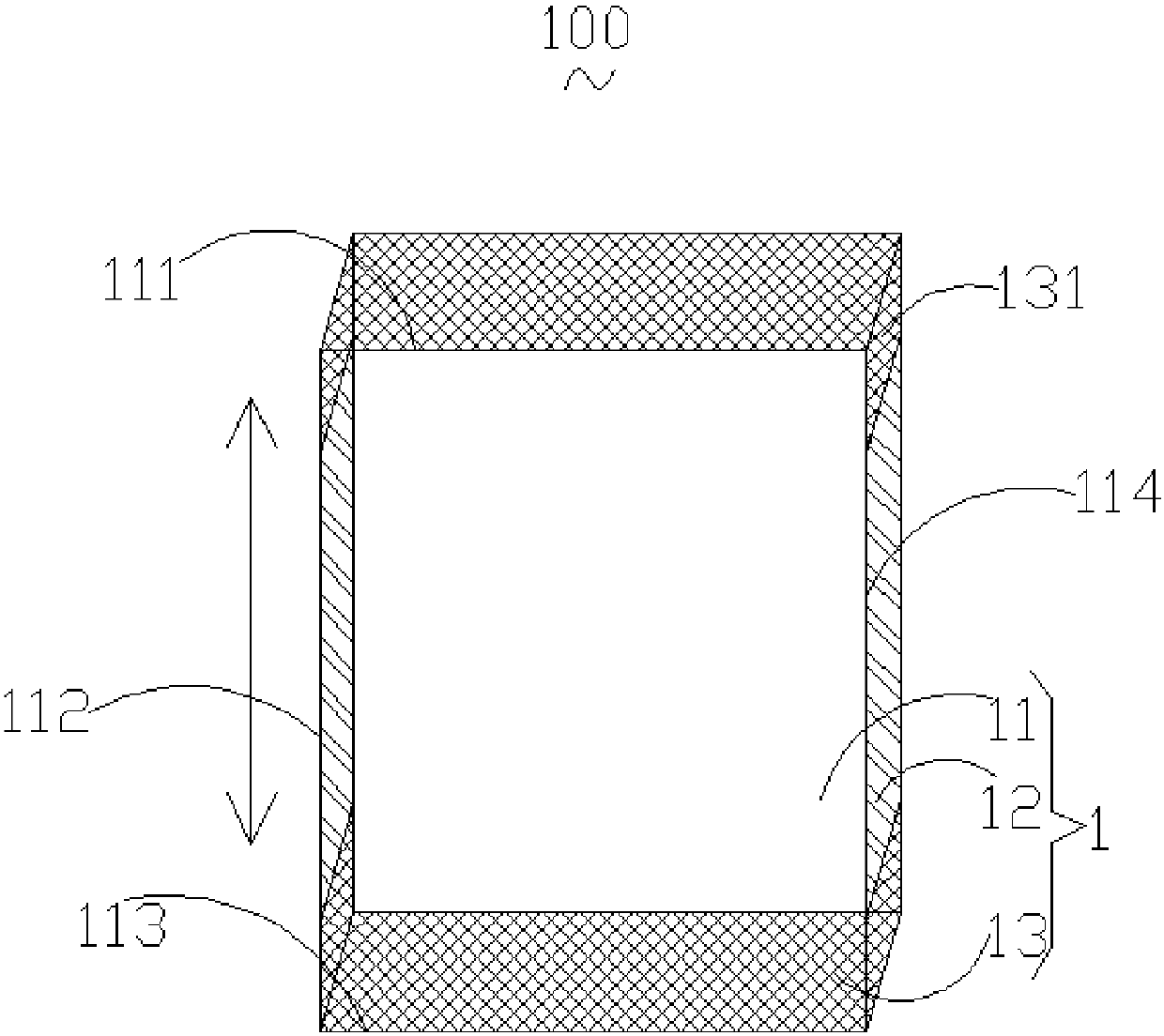

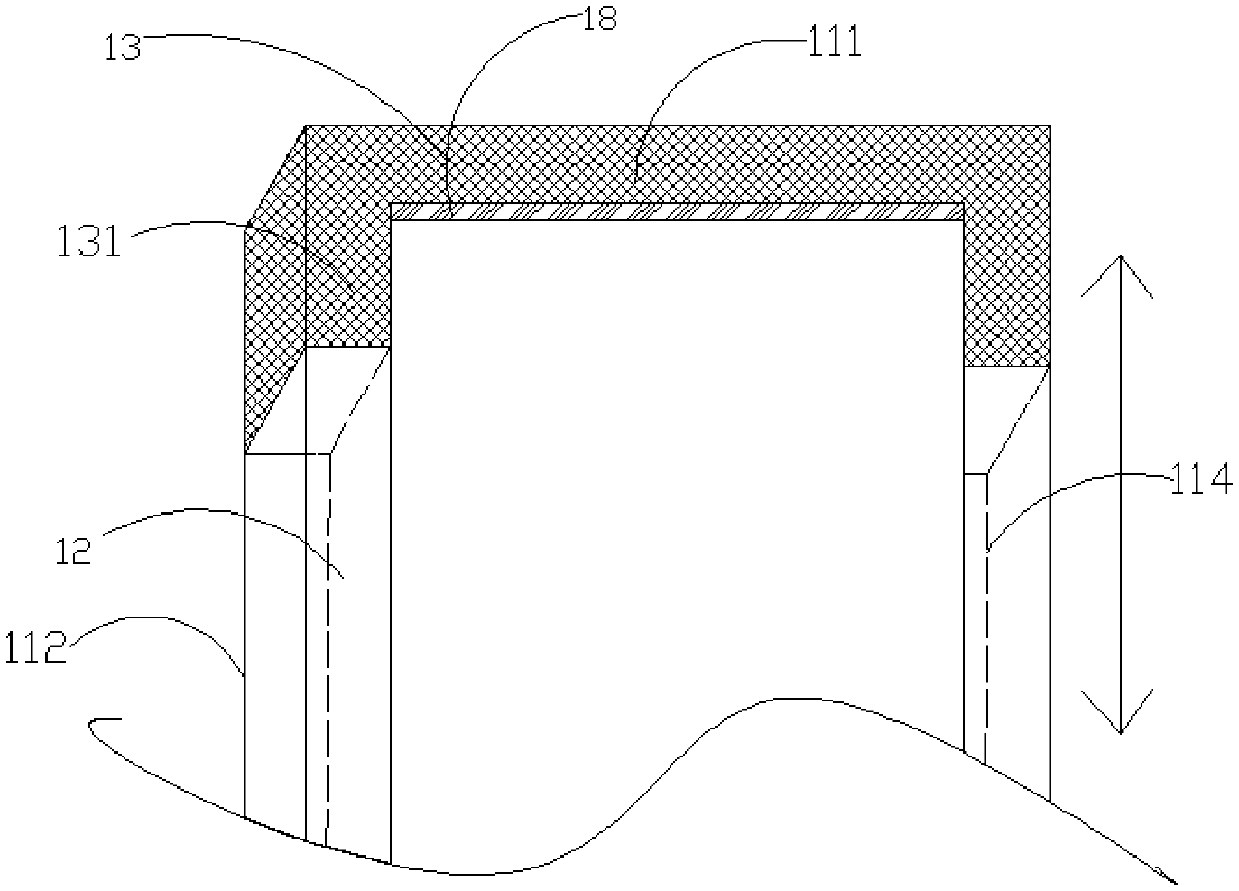

Welded steel automobile hub

The invention discloses a welded steel automobile hub, which comprises a wheel arm and a rim which are made of steel, wherein the wheel arm comprises a plurality of spokes which are radially distributed; a central hole is formed in the center of the wheel arm; a plurality of mounting holes are uniformly distributed at the periphery of the central hole; the rim comprises a rim main body and bumped wheel flanges arranged on the two sides of the rim main body; and the spokes are extended outwards inside the rim to form an arc-shaped surface and are fixedly welded on the outside end surface of the rim. The hub is formed by welding the steel, the wheel arm has a certain radian, and a decorative layer made of stainless steel or aluminum alloy is chromed or covered on the hub, so that a specific visual effect for an aluminum alloy hub can be achieved, and the cost of the hub is far lower than that of an aluminum alloy hub.

Owner:KAIPING ZHONGLV IND

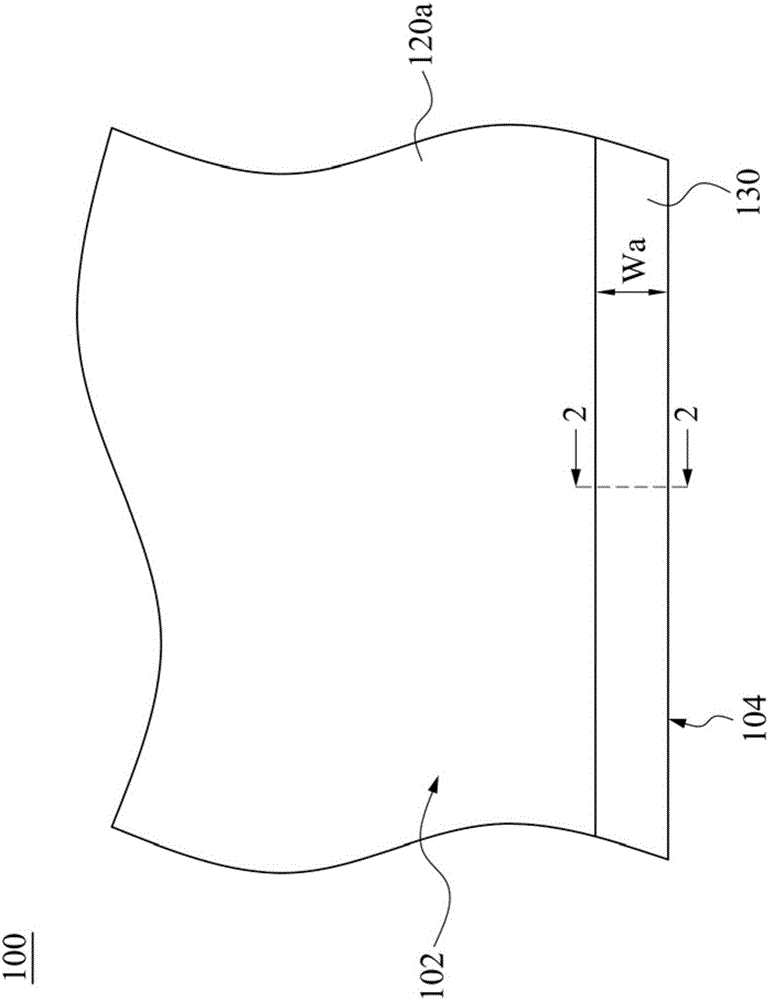

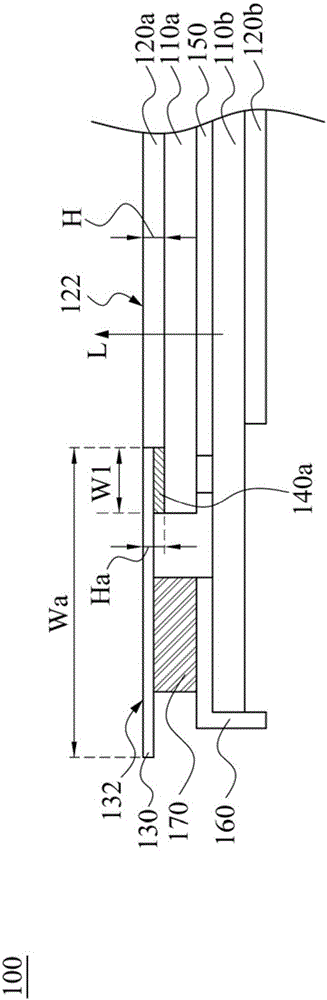

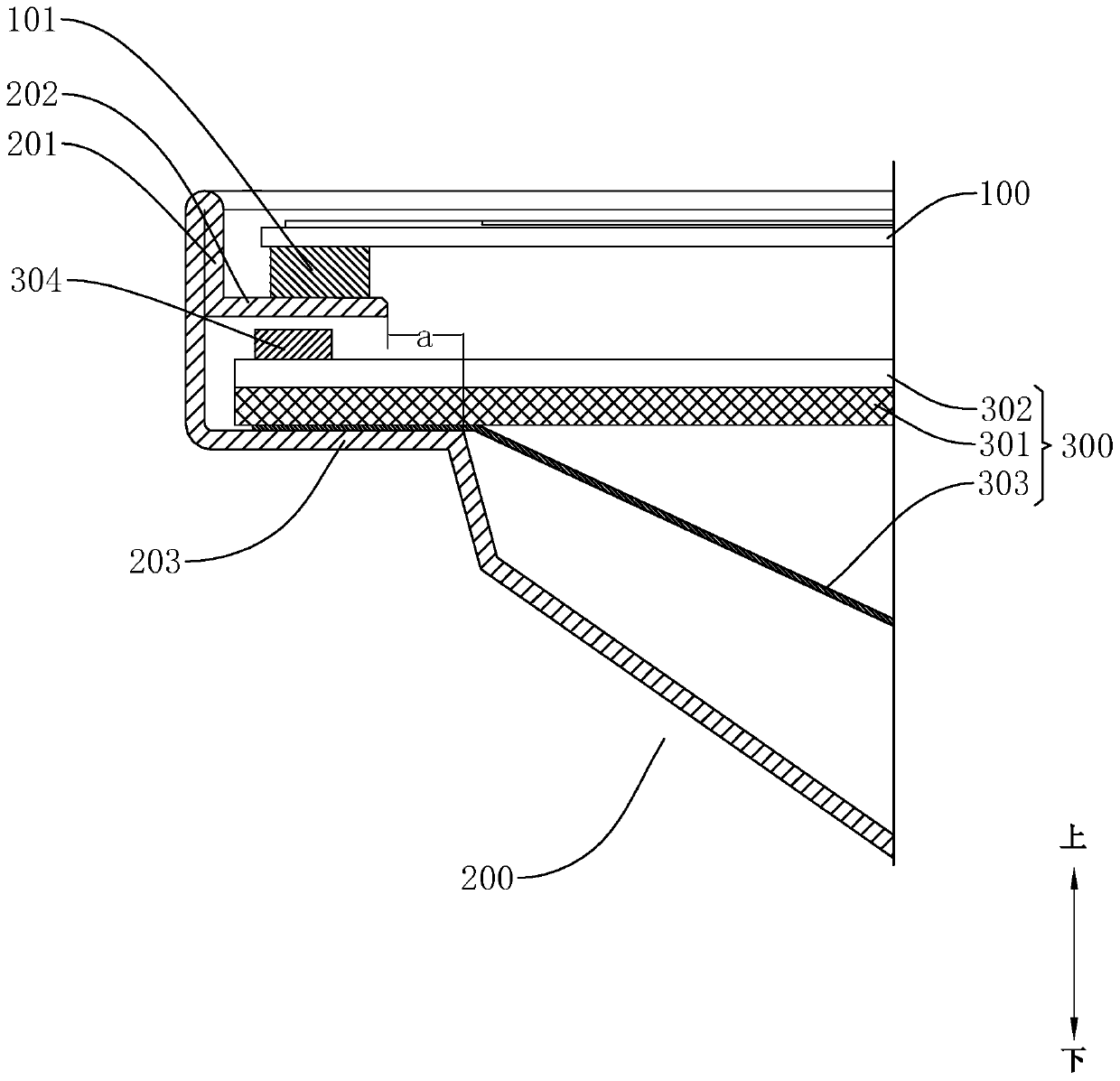

Display module and display device

InactiveCN107748466ARealize the purpose of narrow borderAvoid light leakageNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a display module. The display module comprises a backlight module and a liquid crystal display panel, and the liquid crystal display panel is arranged on the backlight module. The backlight module comprises a backboard, two opposite plastic frames and two opposite side borders, and the two plastic frames are arranged at the two opposite sides of the backboard, are connectedwith the extending sections of the two side borders and are connected between the liquid crystal display panel and the backboard. By the adoption of the display module, the borders of the display panel can become narrower, and the visual effect close to the vision effect close to a full screen is achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

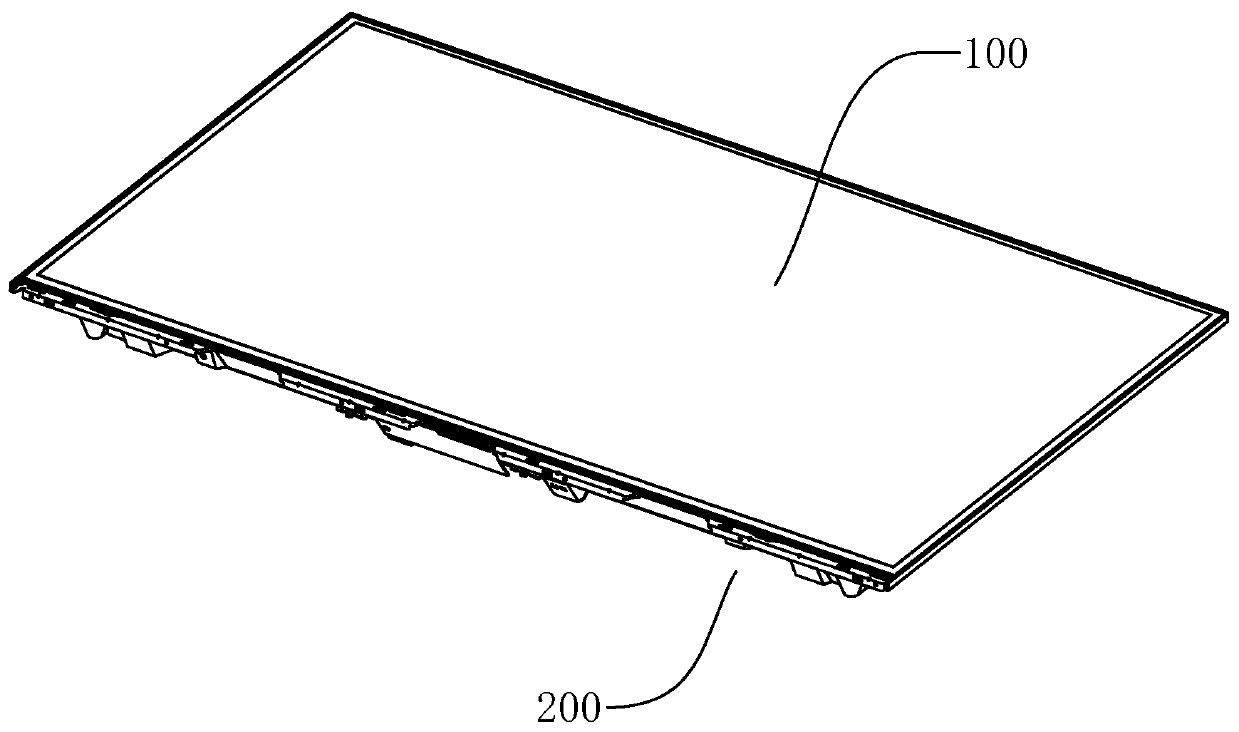

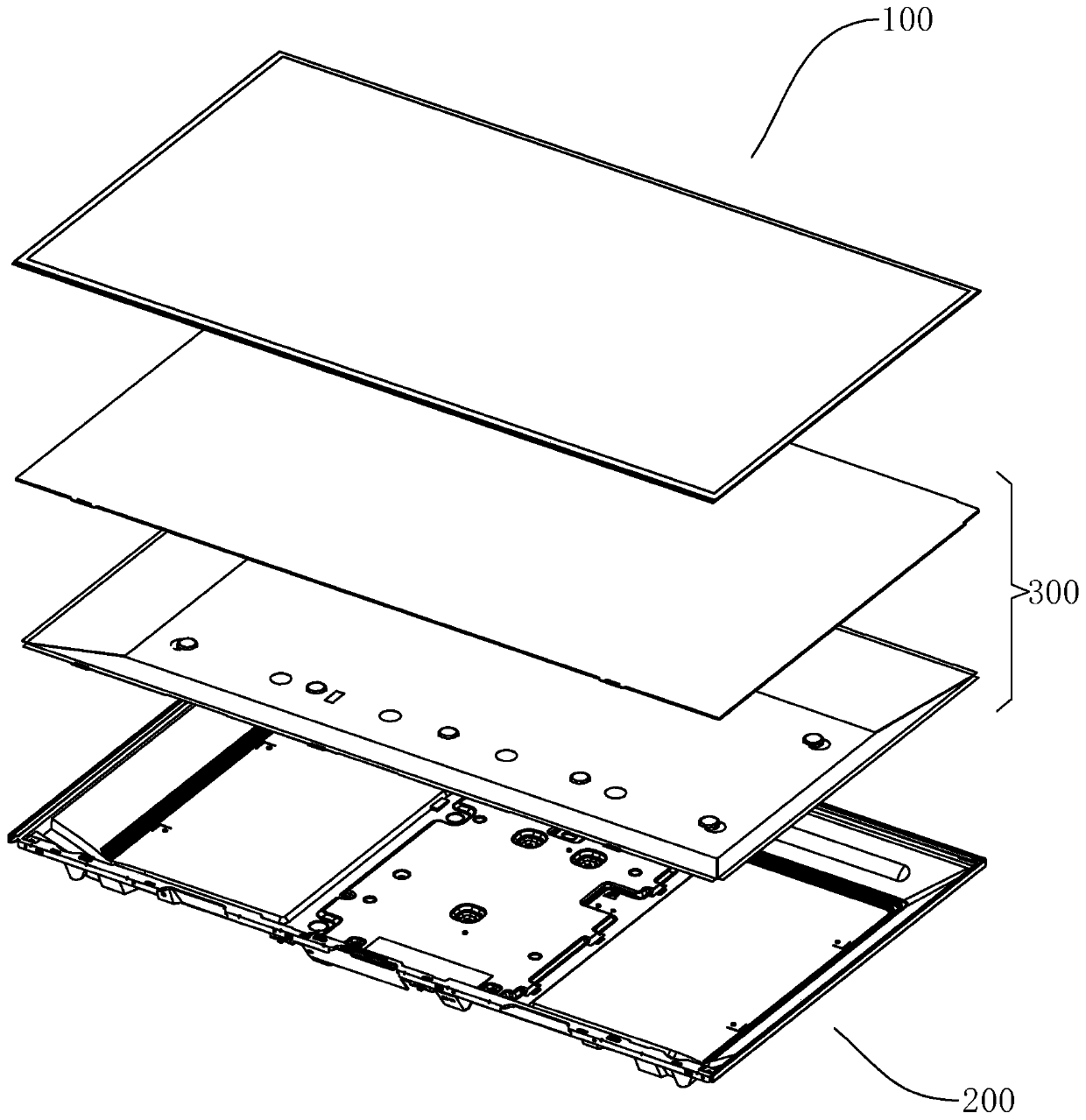

Display module and display device

InactiveCN107807476ARealize the purpose of narrow borderReduce border sizeOptical light guidesNon-linear opticsLiquid-crystal displayAdhesive

The invention provides a display module. The display module comprises a liquid crystal display panel, a backlight module and a single-side adhesive layer, wherein the liquid crystal display panel is arranged on the backlight module, the backlight module comprises a top and a bottom which are arranged oppositely and four side ends which are located between the top and the bottom, and the single-side adhesive layer is pasted into the bottom end surface and the four side end surfaces and covers the bottom end surface and the four side end surfaces. By means of the display module, the border of the display module can be narrowed, so that the visual effect of an all screen is almost achieved; moreover, the display module can be thinner and lighter.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

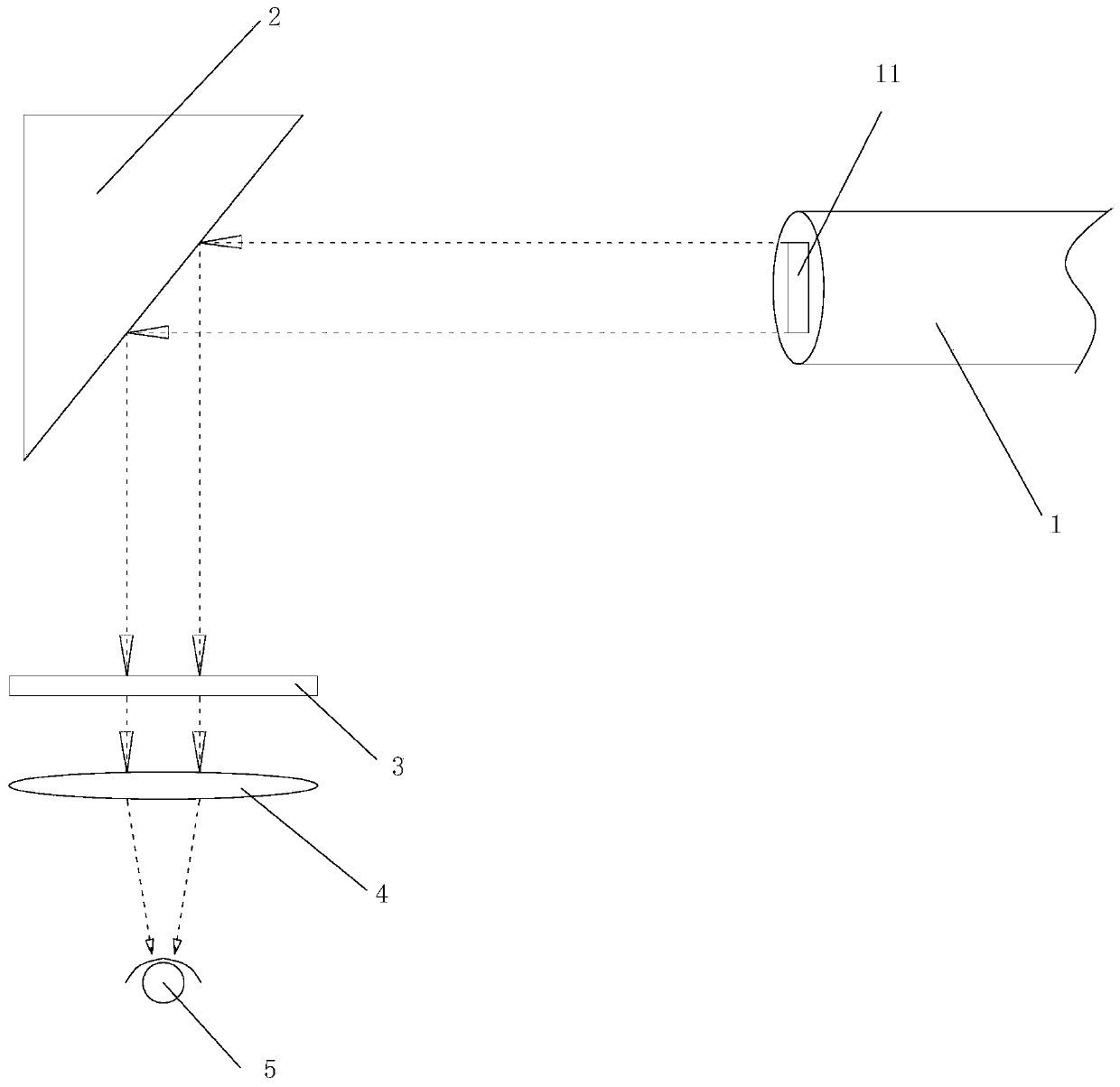

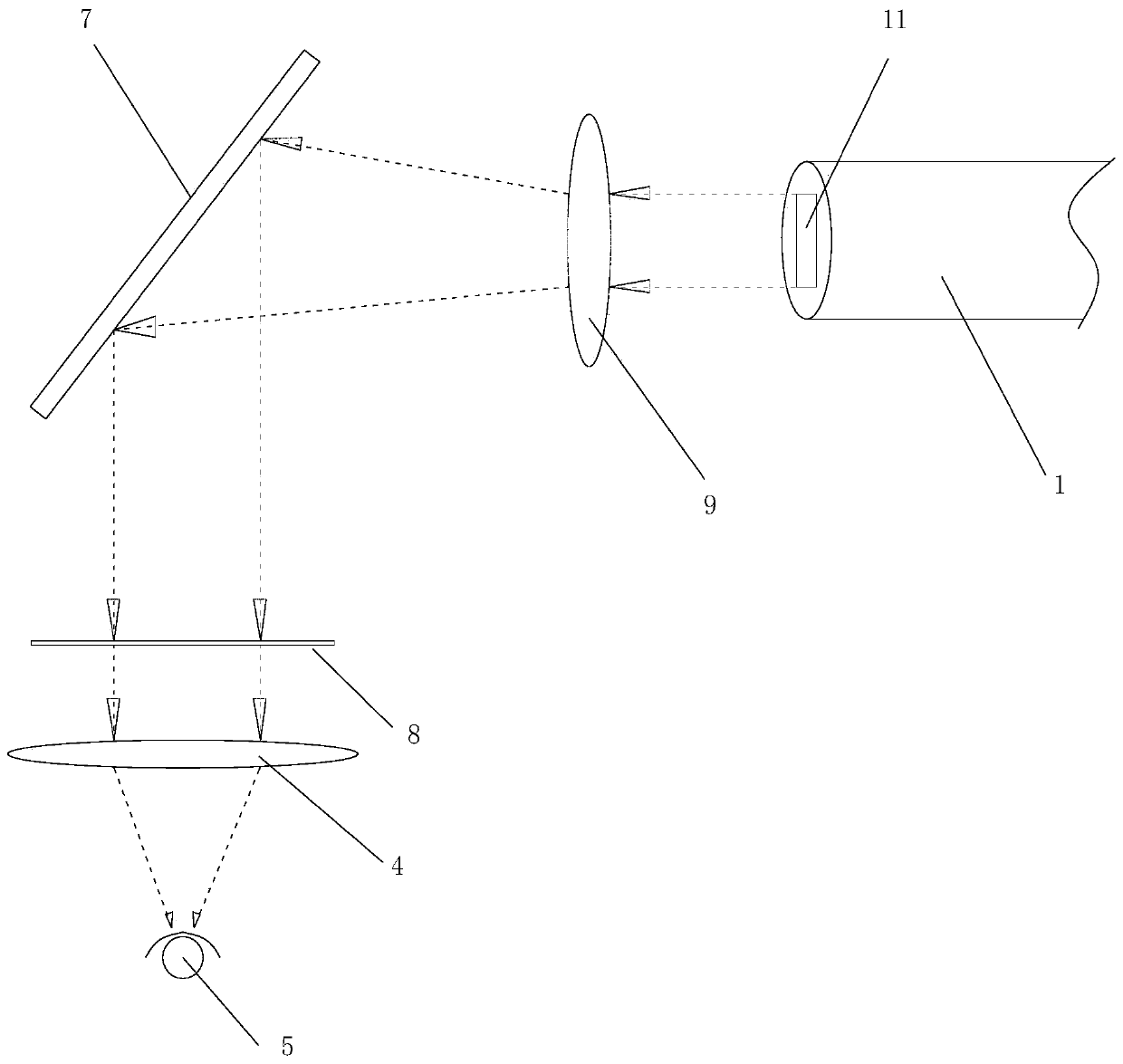

Magnetic-resonance compatible large-view-angle virtual reality optical system

InactiveCN109814261AAchieve a large viewing angleAchieve visual effectDiagnostic recording/measuringSensorsResonanceElectromagnetic environment

The invention discloses a magnetic-resonance compatible large-view-angle virtual reality optical system. The system comprises an image transmission optical fiber and an optical path system. The optical path system is located in front of a light outlet end of the image transmission optical fiber, and a curtain for imaging is arranged in the optical path system. According to the system, through thehigh-definition imaging curtain, a real image of large-view-angle optical imaging can be scattered in multiple directions, an examinee can see a large-angle scene under the complex electromagnetic environment in a magnetic-resonance cavity, the large view angle is achieved, and the system has the function of providing VR visual stimulation of division vision and three-dimensional vision of the left and right eyes.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

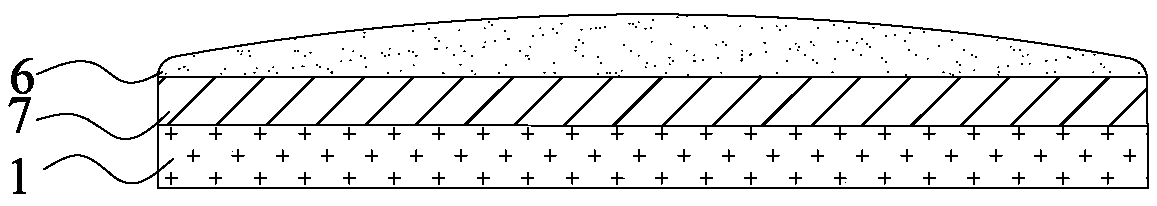

Nail burnishing stick and preparation method thereof

PendingCN106723871AAchieve visual effectGuaranteed aestheticsManicure/pedicureMedicinePolishing teeth

The invention discloses a nail burnishing stick and a preparation method thereof. The nail burnishing stick comprises a substrate and a polishing layer; the polishing layer comprises multiple polishing teeth which are densely distributed; the bottom of the polishing teeth is fixed on the substrate. The polishing stick can polish the surface of nails so that the surface of nails presents bright and beautiful color; nail surfaces can be beautified without the use of harmful nail polish or nail polish removers; manicure effect is obtained. The invention also discloses a preparation method of the nail polishing stick.

Owner:秦燕云

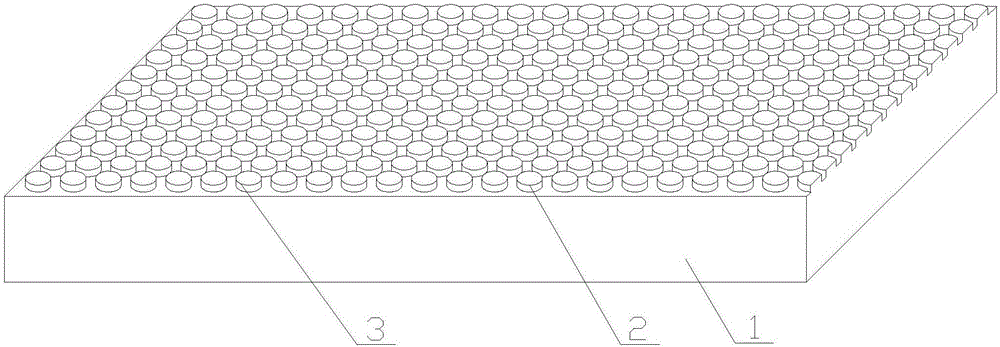

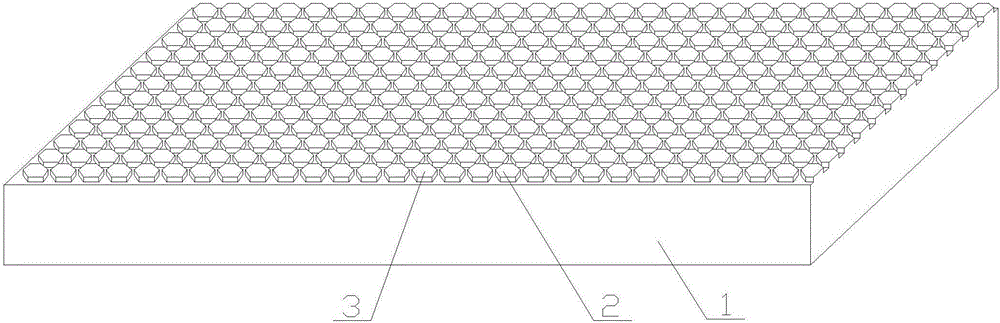

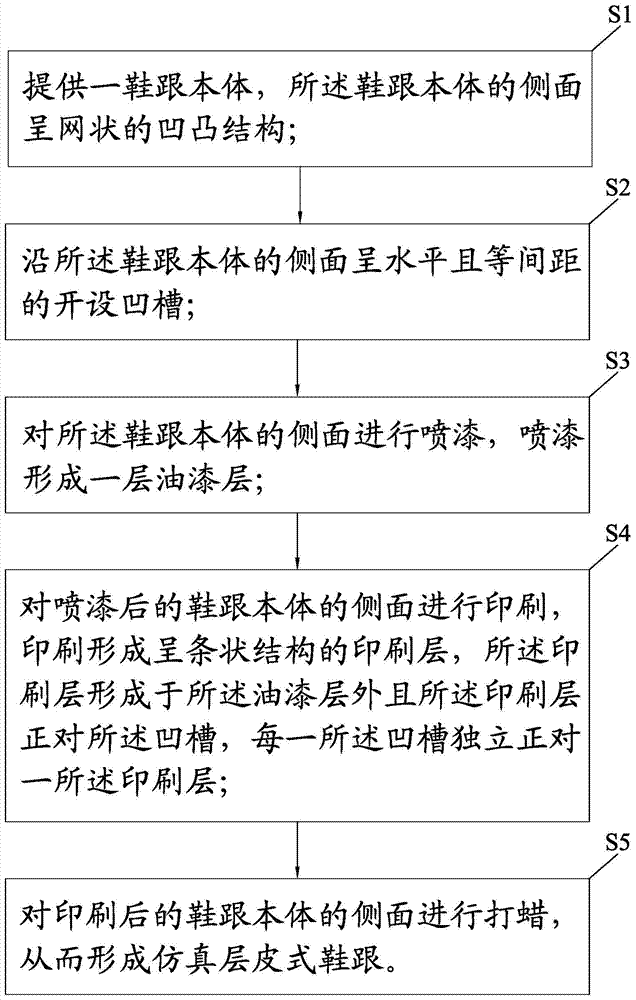

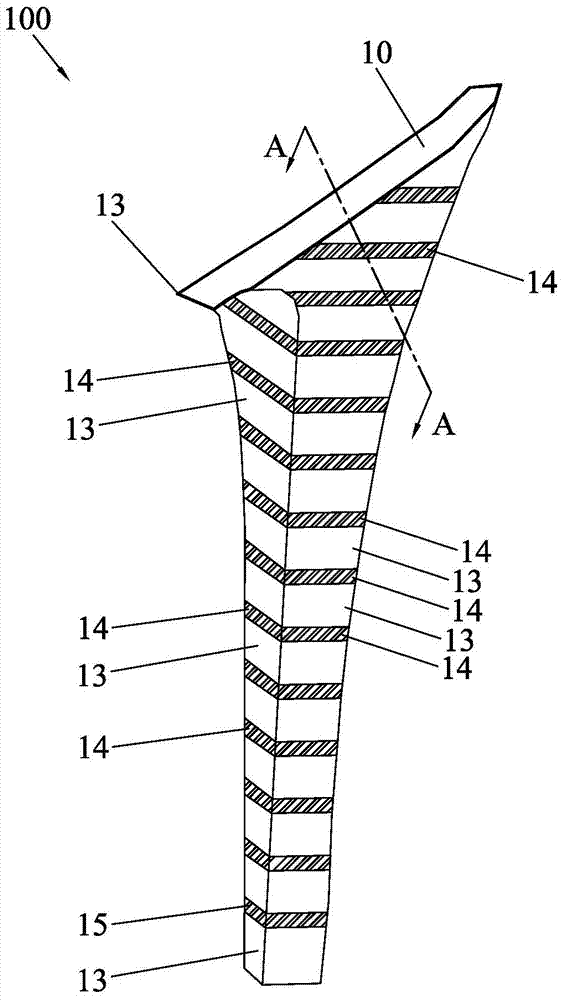

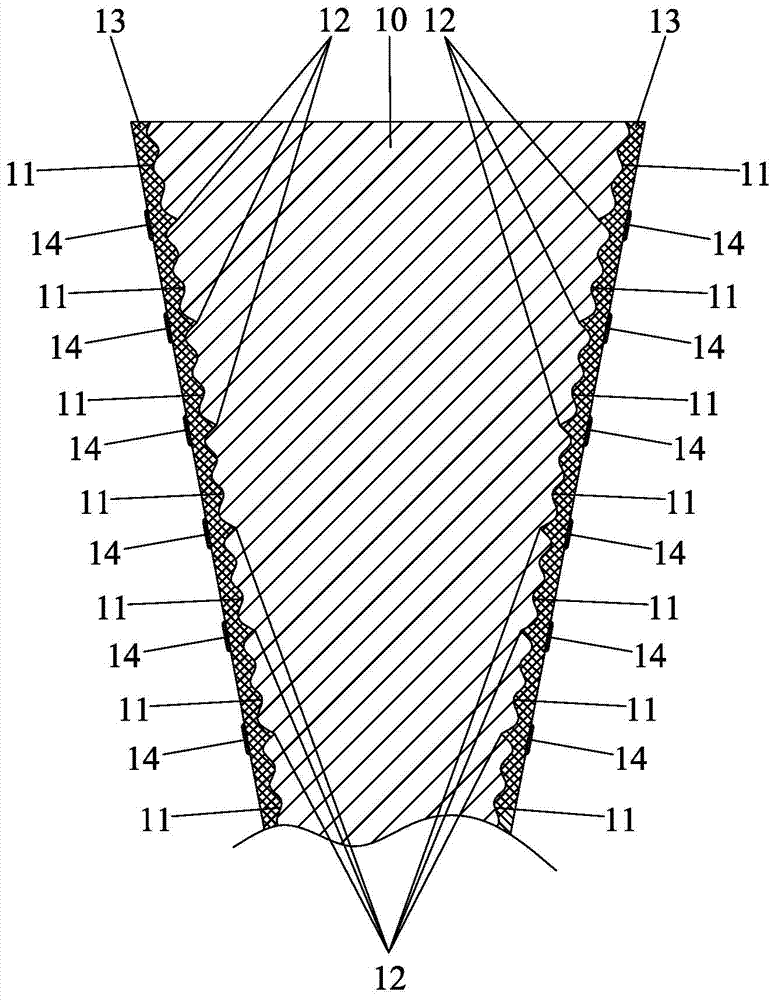

Manufacturing method of imitation leather layered shoe heel

InactiveCN104325670AGuaranteed aestheticsImprove efficiencyDomestic footwearConvex structureEngineering

The invention discloses a manufacturing method of an imitation leather layered shoe heel. The manufacturing method comprises the following steps: (1) providing a shoe heel body, wherein the side surface of the shoe heel body is provided with a net-shaped concave-convex structure; (2) engraving grooves in the side surface of the shoe heel body, wherein the grooves are horizontal and the distances between two neighbored grooves are equal; (3) spraying paint on the side surface of the shoe hell body so as to form a paint layer; (4) printing the side surface of the shoe heel body after paint-spraying to form a printing layer with a strip-shaped structure, wherein each groove is individually corresponding to one printing layer; (5) waxing the side surface of the shoe heel body after printing so as to form the imitation leather layered shoe heel. The paint layer formed by the paint spraying can be firmly and rapidly coated on the shoe heel body, the firm connection is guaranteed, and the work efficiency is improved. A beautiful imitation leather appearance can be achieved without using any real leather, the cost is effectively reduced, and the shoe heel is environment-friendly and practical. Furthermore, groves and printing layers can form regular lines on the shoe heel body, and the layering and aesthetic feeling of the shoe heel are both increased.

Owner:DONGGUAN YONGKAI SHOES +1

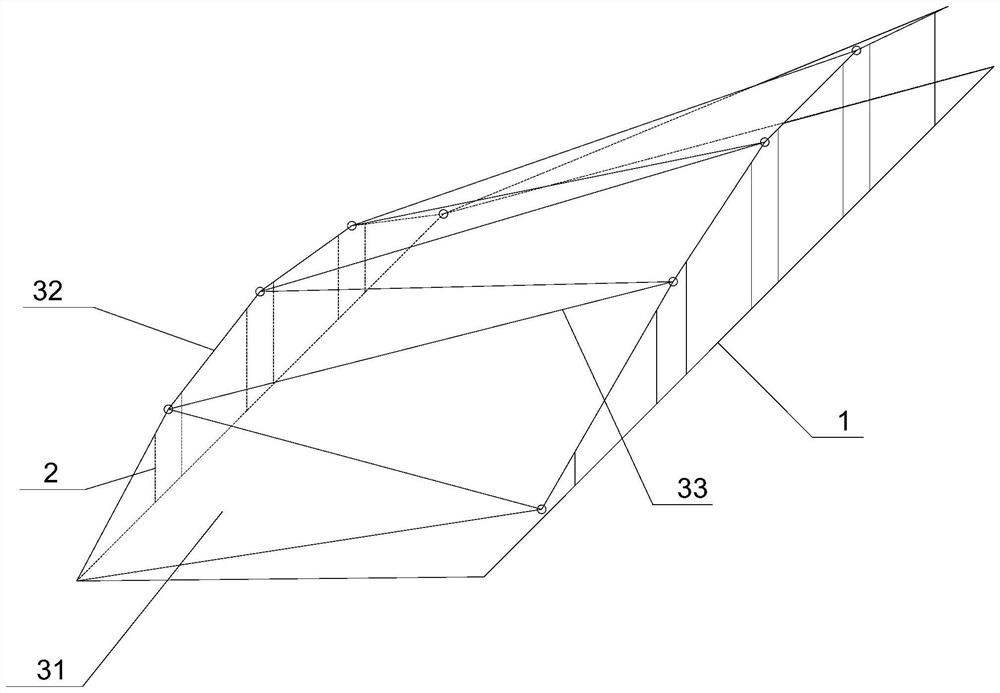

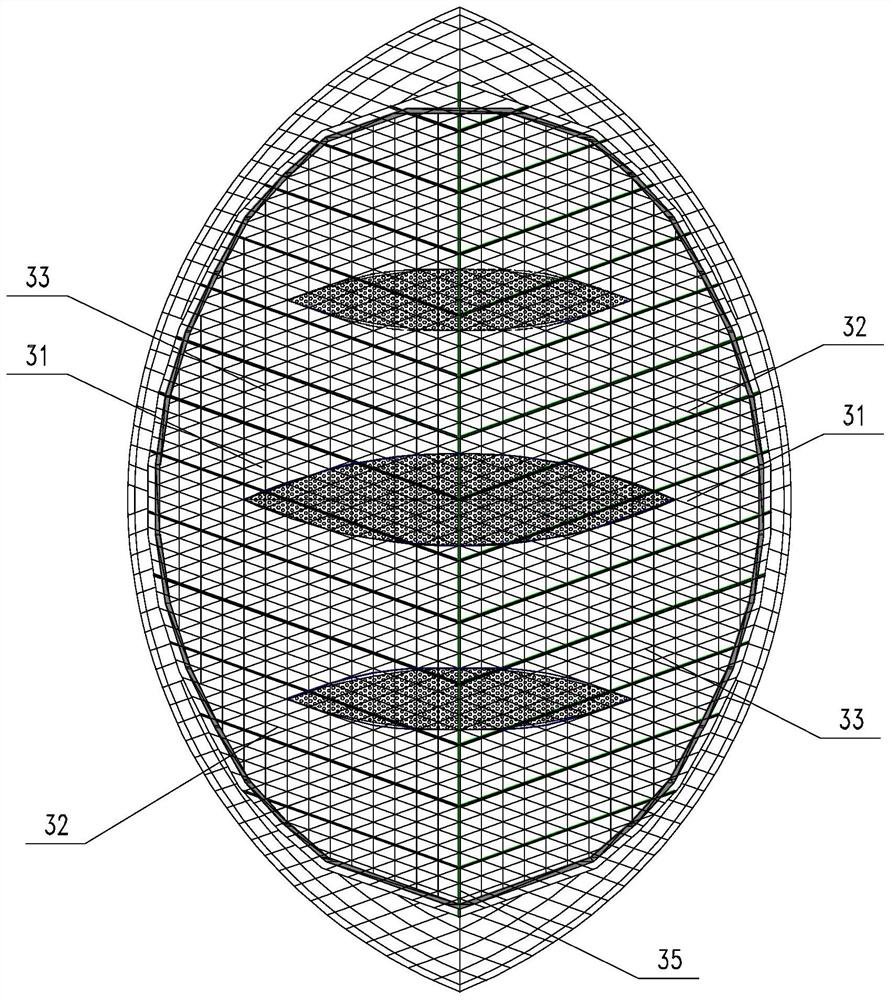

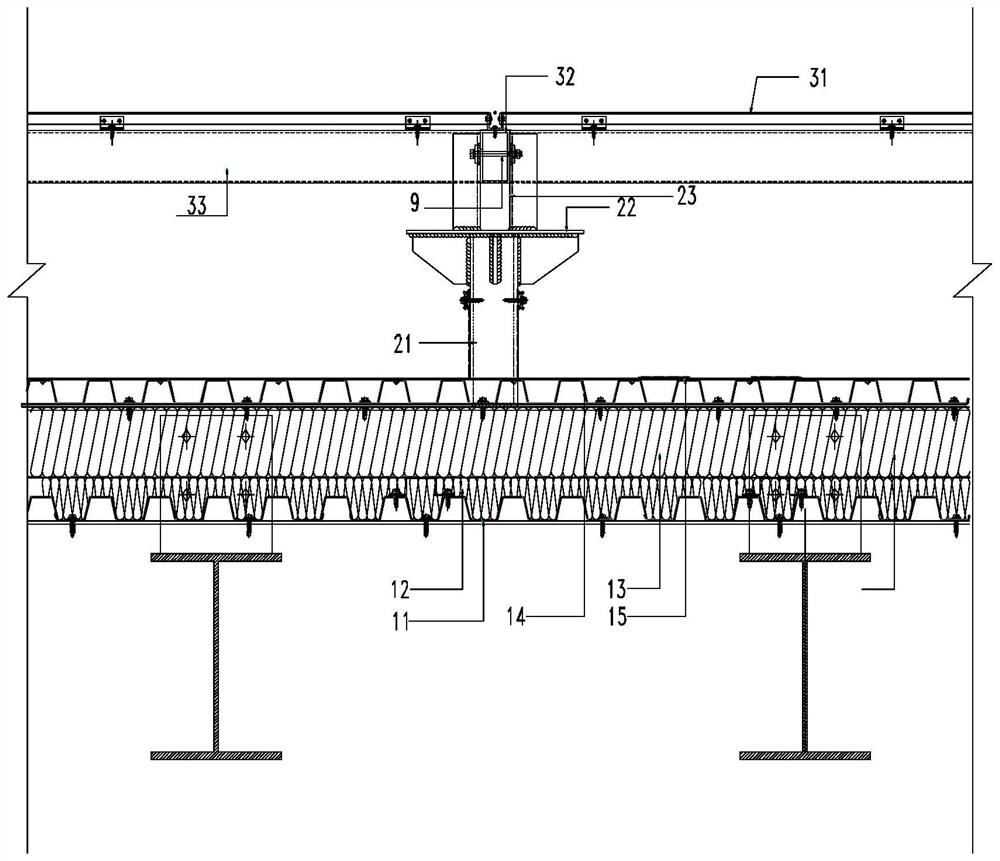

Construction method of double-layer roof curtain wall structure

PendingCN112814383AChange shapeAchieve visual effectWallsHeat proofingKeel structureMechanical engineering

The invention discloses a construction method of a double-layer roof curtain wall structure. A lower floor system is laid, a plurality of rows of curtain wall supports are arranged on the lower floor system to form a zone, and each curtain wall support comprises a short column, a short column platform and a height-adjustable stand column which are sequentially connected from bottom to top, through measuring and positioning, main keels are fixed at the required height position of the height-adjustable stand columns, the main keels are arranged on the rows of curtain wall supports, the adjacent main keels in the same row are sequentially connected to form a strip-shaped main keel structure, each main keel is supported by two curtain wall supports arranged in a spaced mode, and the connecting positions of the adjacent main keels in the strip-shaped main keel structure are connected to the two ends of the main keels in the adjacent strip-shaped main keel structure through two auxiliary keels, and a triangular grid for arranging the triangular curtain wall plate is formed. The heights of the two ends of the corresponding main keels are changed by changing the heights of the curtain wall supports, so that the angles of the triangular curtain wall plates are changed, and the overall shape of the triangular latticed frame is changed.

Owner:SHANGHAI CONSTR NO 1 GRP +1

Construction method of antique building wall

InactiveCN108331278AAchieve visual effectRealistic visual effectsCovering/liningsPolyesterWater based

The invention discloses a construction method of an antique building wall. The method comprises steps as follows: (1) stitched polyester cloth is paved and fixed on the surface of a foundation wall, and a granitic plaster wall surface is prepared on the surface of the stitched polyester cloth; (2) slurry is smeared on the granitic plaster wall surface, so that the slurry covers the granitic plaster wall surface; (3) after 4-10 days, the slurry is cleaned with a brush and a cleaning fluid, wherein the cleaning fluid comprises water and a water-based organosilicon waterproof agent. Antique construction is performed on the foundation wall, so that the foundation wall has the visual effect of an ancient building wall in appearance and has real, natural and lasting antique effects. The construction process is simple and easy to operate, environmentally friendly, pollution-free and low in cost and cannot damage the wall.

Owner:DECAI DECORATION

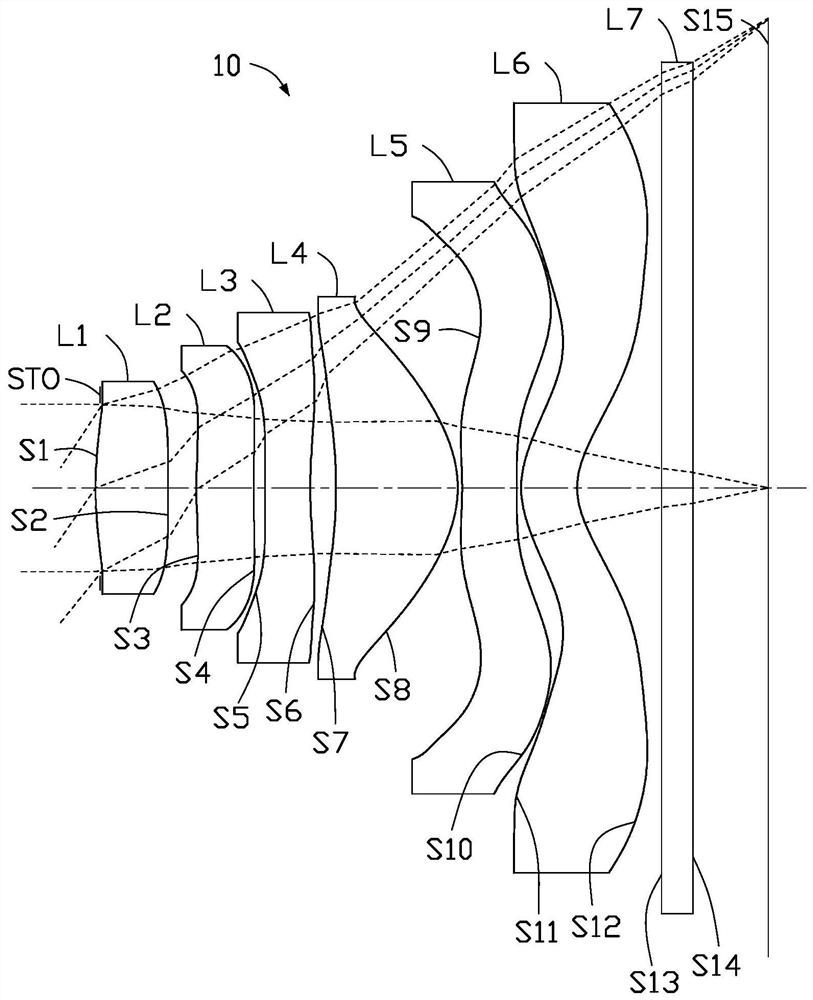

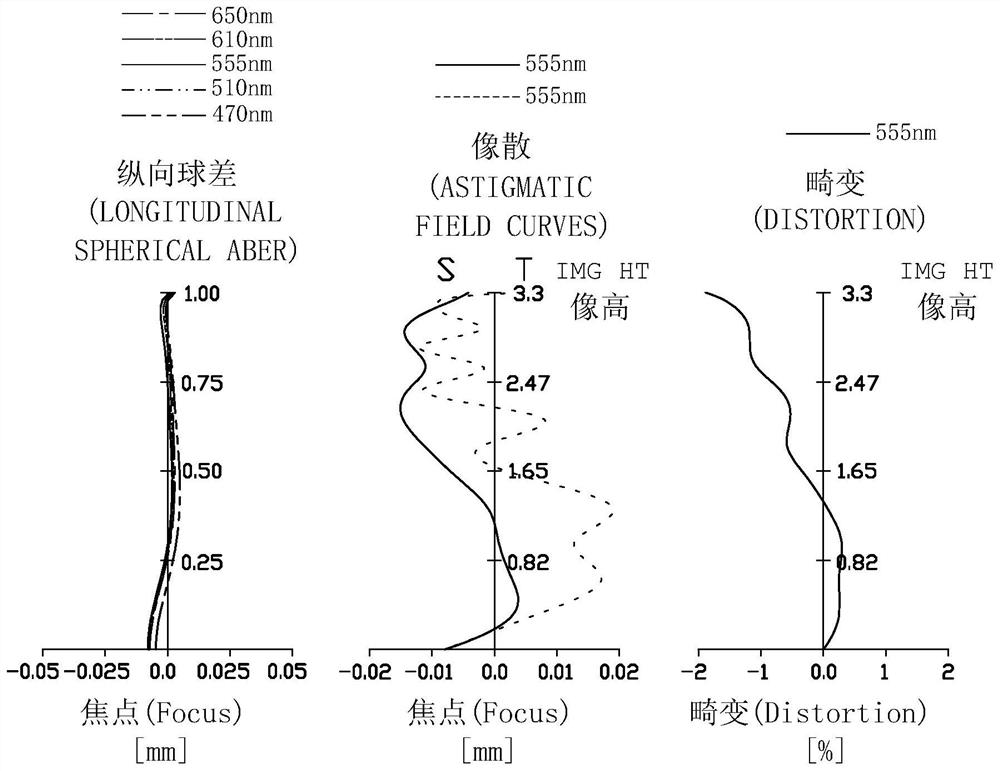

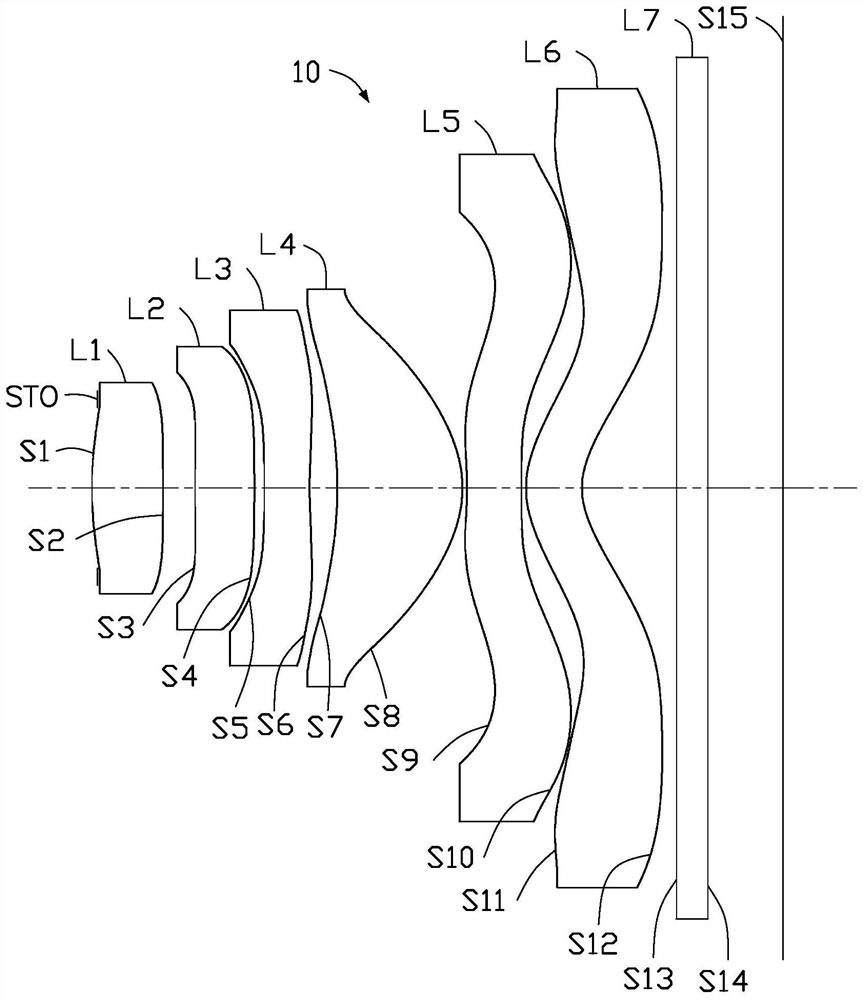

Optical imaging system, image capturing module and electronic device

The invention provides an optical imaging system, an image capturing module and an electronic device. The optical image imaging system includes, in order from an object side to an image side: a firstlens with positive refractive power, the object-side surface of the first lens being convex at an optical axis; a second lens with refractive power; a third lens with refractive power; a fourth lens with positive refractive power, the image-side surface of the fourth lens being convex at the optical axis; a fifth lens with refractive power; a sixth lens with refractive power, the object-side surface of the sixth lens being a convex surface at the optical axis, and the image-side surface of the sixth lens being a concave surface at the optical axis; the optical imaging system satisfies the following conditions: 0.5 < f1 / f26 < 1.6, wherein f26 is the combined focal length of the second lens, the third lens, the fourth lens, the fifth lens and the sixth lens, and f1 is the effective focal length of the first lens. The optical imaging system has the advantages of wide viewing angle and head miniaturization.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Human body bathing device

InactiveCN102885592AFixed, comfortable and stableAchieve visual effectBathroom accessoriesHuman bodyEngineering

The invention provides a human body bathing skincare nursing device. The human body bathing skincare nursing device comprises a spray head, a pneumatic device and a mirror plane combination, wherein the spray head comprises roll balls, a spray gun and a liquid storage device which is used for storing a bathing skincare solution, and the solution stored in the liquid storage device can reach the roll balls and the spray gun; the pneumatic device is connected with the spray head through an air pipe and provides pneumatic power for the spray head to ensure that the bathing skincare solution in the liquid storage device is moved and sprayed out of the spray head; and the mirror plane combination comprises at least two mirror planes, and the inclination angle of at least one mirror plane is adjustable. According to the human body bathing skincare nursing device, the spray head is formed by combining the roll balls and the spray gun together to achieve smearing of liquid; and a visual effect is achieved through reflection of a front mirror and a back mirror.

Owner:SHANGHAI DIANJI UNIV

Frameless liquid crystal display screen

PendingCN111505853AAchieve visual effectSimple production processNon-linear opticsLiquid-crystal displayMechanical engineering

The invention discloses a frameless liquid crystal display screen. The frameless liquid crystal display screen comprises an OC panel and a back plate, and the back plate is formed through integrated bending. The back plate is provided with an opening used for installing the OC panel, the opening of the back plate is bent inwards to form the first bearing part used for installing the OC panel, theback plate is integrally bent and formed to directly form the first bearing part, a frame does not need to be arranged, the production process is simplified, the production cost is reduced, black edges can be reduced, and the frameless visual effect is achieved.

Owner:GUANGDONG CHANGHONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com