Method for realizing laser effect on common paper

A common paper and laser technology, applied in papermaking, textiles and papermaking, special visual effect coating, etc., to achieve low requirements and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

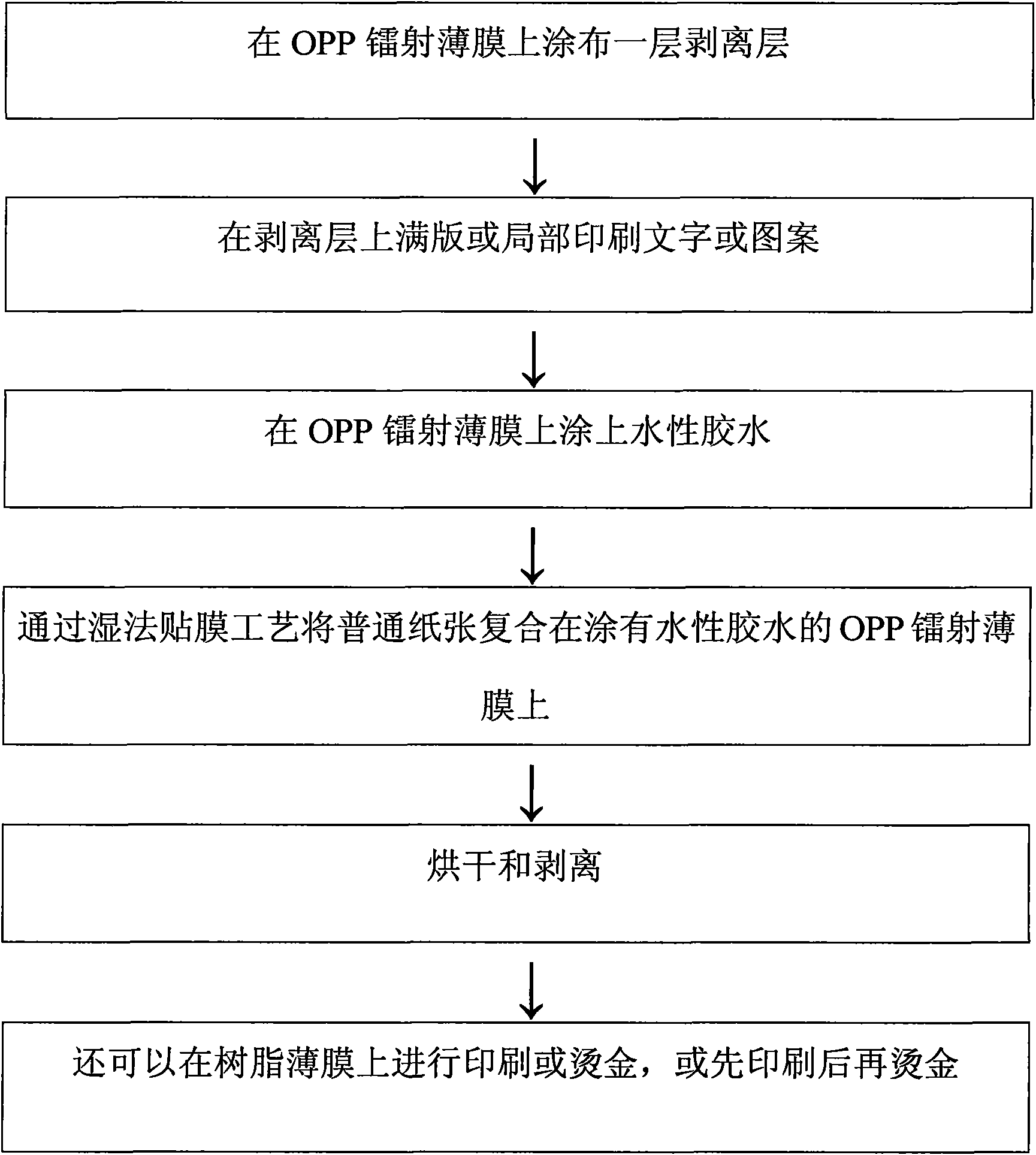

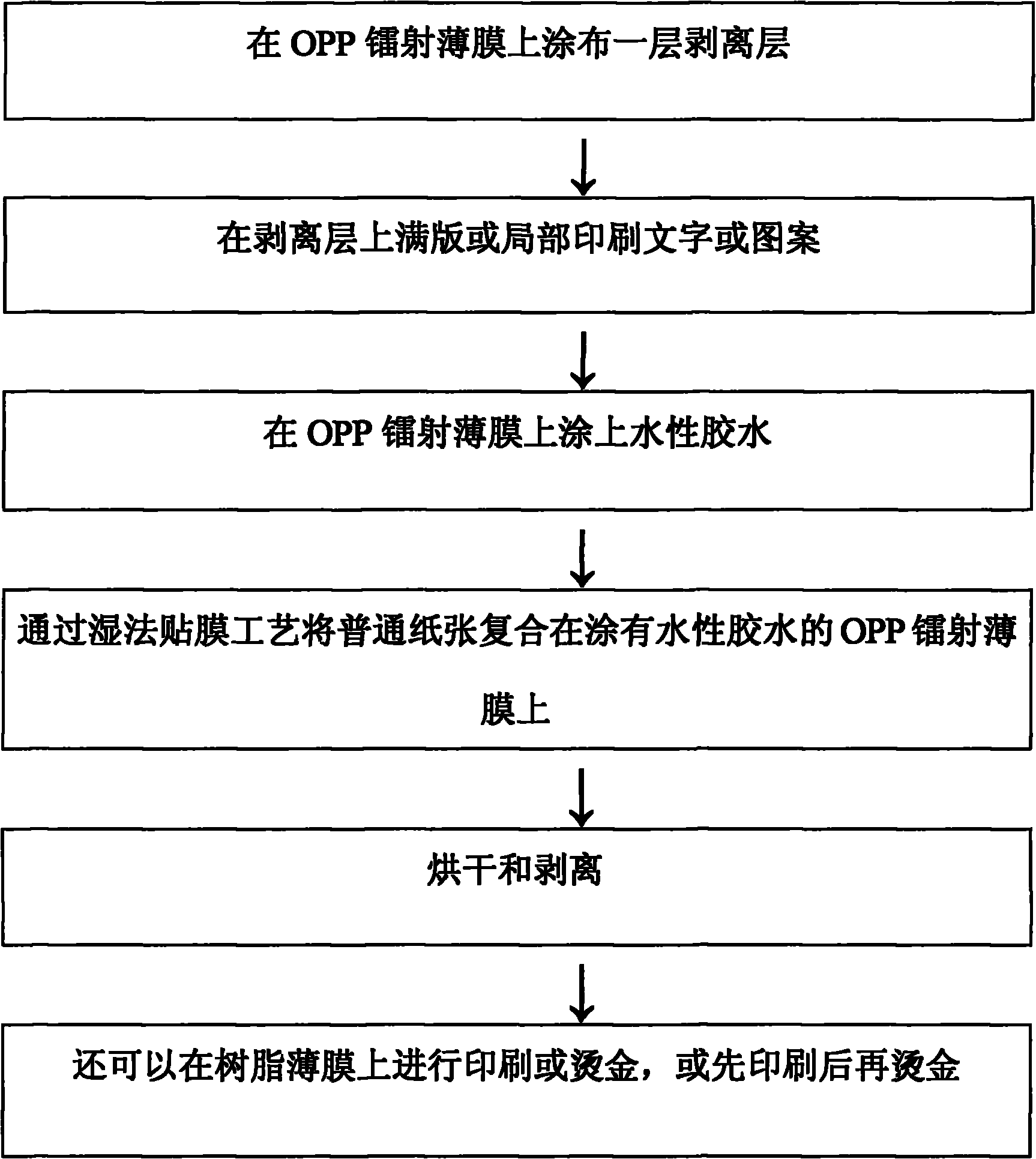

Method used

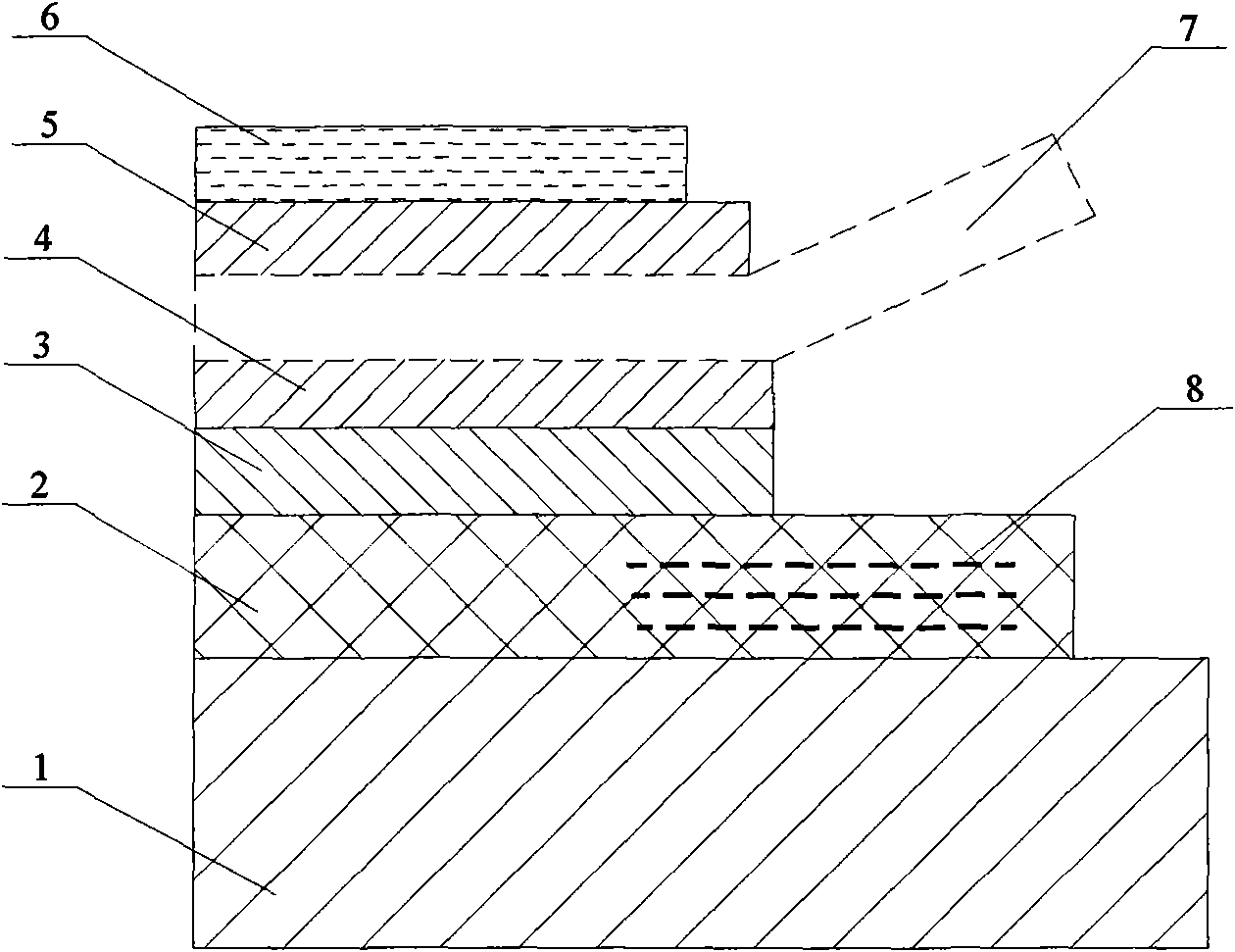

Image

Examples

Embodiment 1

[0048] The present invention comprises the component of following mass percentage:

[0049] Strippable styrene-methyl methacrylate copolymer water-based resin, 56.9%;

[0050] Copolymerized film-forming resin of waterborne methyl acrylate and butyl acrylate, 42.9%;

[0051] Polysiloxane-polyether copolymer defoamer, 0.1%;

[0052] Polyetheroxane wetting and leveling agent, 0.1%.

Embodiment 2

[0054] Strippable styrene and butyl methacrylate copolymer water-based resin, 64.8%;

[0055] Copolymerized film-forming resin of waterborne methyl acrylate and butyl acrylate, 34.8%;

[0056] Polysiloxane-polyether copolymer defoamer, 0.2%;

[0057] Polyetheroxane wetting and leveling agent, 0.2%.

Embodiment 3

[0059] Strippable styrene-butyl methacrylate copolymer water-based resin, 58.3%;

[0060] Copolymerized film-forming resin of waterborne methyl acrylate and butyl acrylate, 41.4%;

[0061] Polysiloxane-polyether copolymer defoamer, 0.15%;

[0062] Polyetheroxane wetting and leveling agent, 0.15%.

[0063] Water-based glue in the present invention has the following advantages:

[0064] First, the OPP laser film on it is easy to peel off;

[0065] Second, it has a good binding force to the paper under it;

[0066] Third, flake reflective materials can be added to enhance the laser effect;

[0067] Fourth, it has good flexibility and moderate hardness, which can prevent shedding and napping caused by multiple printings;

[0068] Fifth, the water-based glue has good dimensional stability after drying and curing, which can ensure a strong laser effect;

[0069] Sixth, the water-based glue has good printing adaptability after film formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com