Decorative film, manufacture method for decorative film and manufacture method for additional decorative forming subject

A decorative film and a manufacturing method technology, applied in the field of decorative films, can solve the problems of uneven distribution of matting particles, poor compatibility of matting particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

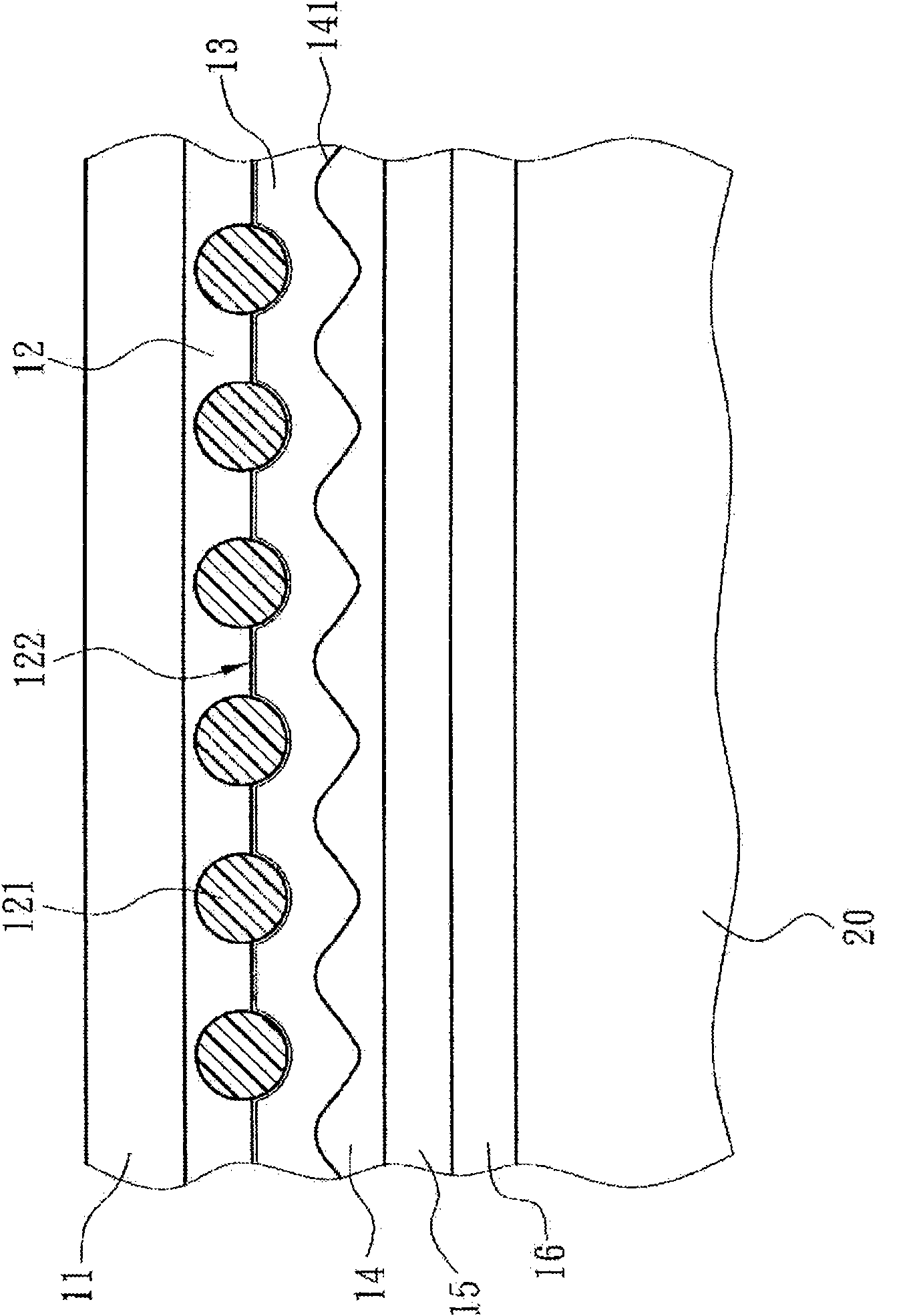

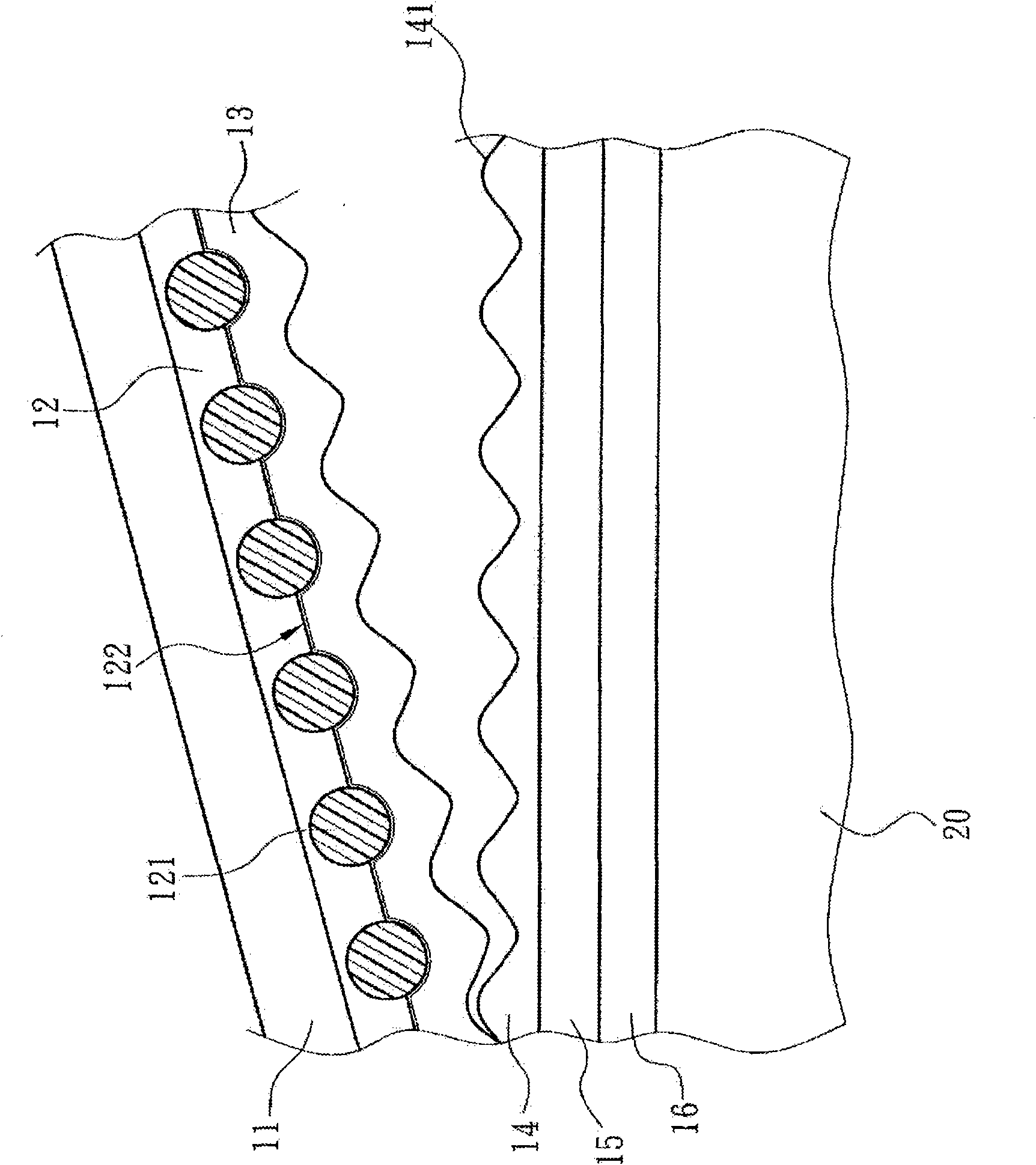

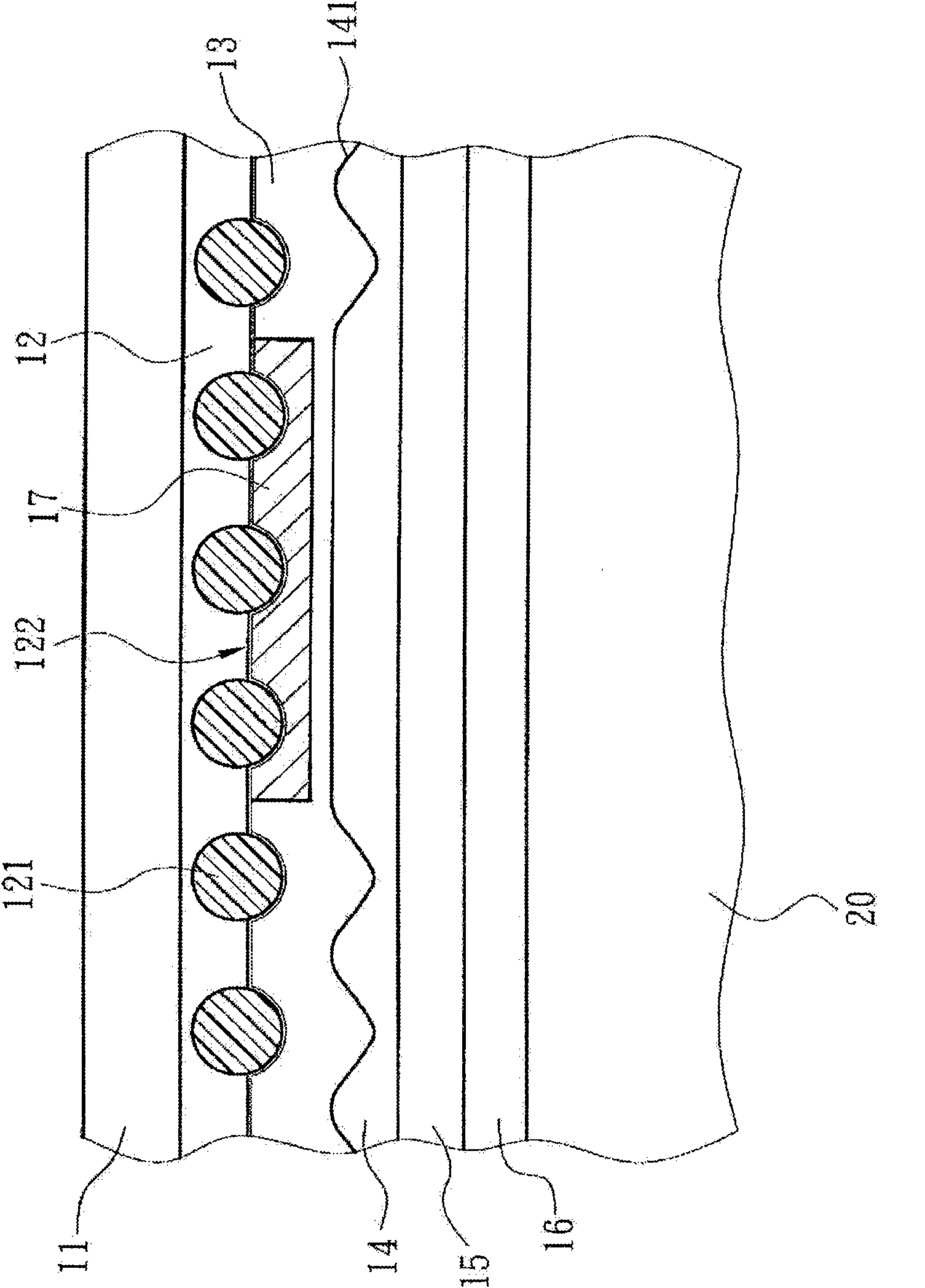

Image

Examples

Embodiment 1

[0064] In this embodiment, according to adding different proportions of atomized particles in the atomized layer, the surface gloss value of the protective layer or the release layer is adjusted.

[0065] First, 4 μm atomized particles are added to the atomized layer at a ratio of 2.5%, 15% and 30%, respectively, and then the release layer, protective layer, pattern layer and adhesive layer are coated, and transferred through the complete IMR process On the substrate, the release layer and the atomized layer are finally separated from the surface of the protective layer. Use NOVO-GLOSS TRIO photometer (RHOPHOINT INSTRUMENTS) to measure the surface gloss of these protective layers at a measurement angle of 60 degrees. The measured results are shown in the following table:

[0066] Add particle size

[0067] It can be seen from the results in the above table that the 60 degree gloss value will decrease with the increase of the proportion of added particles, that is to sa...

Embodiment 2

[0069] In this embodiment, the surface gloss value of the protective layer is adjusted according to the thickness of the release layer.

[0070] First, add 4 μm atomized particles to the atomized layer at a ratio of 15%. The coating thickness of the atomized layer is 3 μm, and apply release layers with a thickness of 2 μm, 6 μm, and 8 μm on the atomized layer. , followed by coating a protective layer, a pattern layer and an adhesive layer, which are transferred to the substrate through a complete IMR process, and finally the release layer and the atomized layer are separated on the surface of the protective layer. Finally, the NOVO-GLOSS TRIO photometer (RHOPHOINT INSTRUMENTS) was also used to measure the surface gloss of these protective layers at a measurement angle of 60 degrees. The measured results are shown in the following table:

[0071] Add particle size

Release layer thickness

60 degree gloss value

4μm

2μm

17

4μm

6μm

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com