Welded steel automobile hub

A technology for automobile wheels and rims, which is applied to rims, vehicle parts, transportation and packaging, and can solve problems such as unsatisfactory, superfluous effects, and unsatisfactory appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

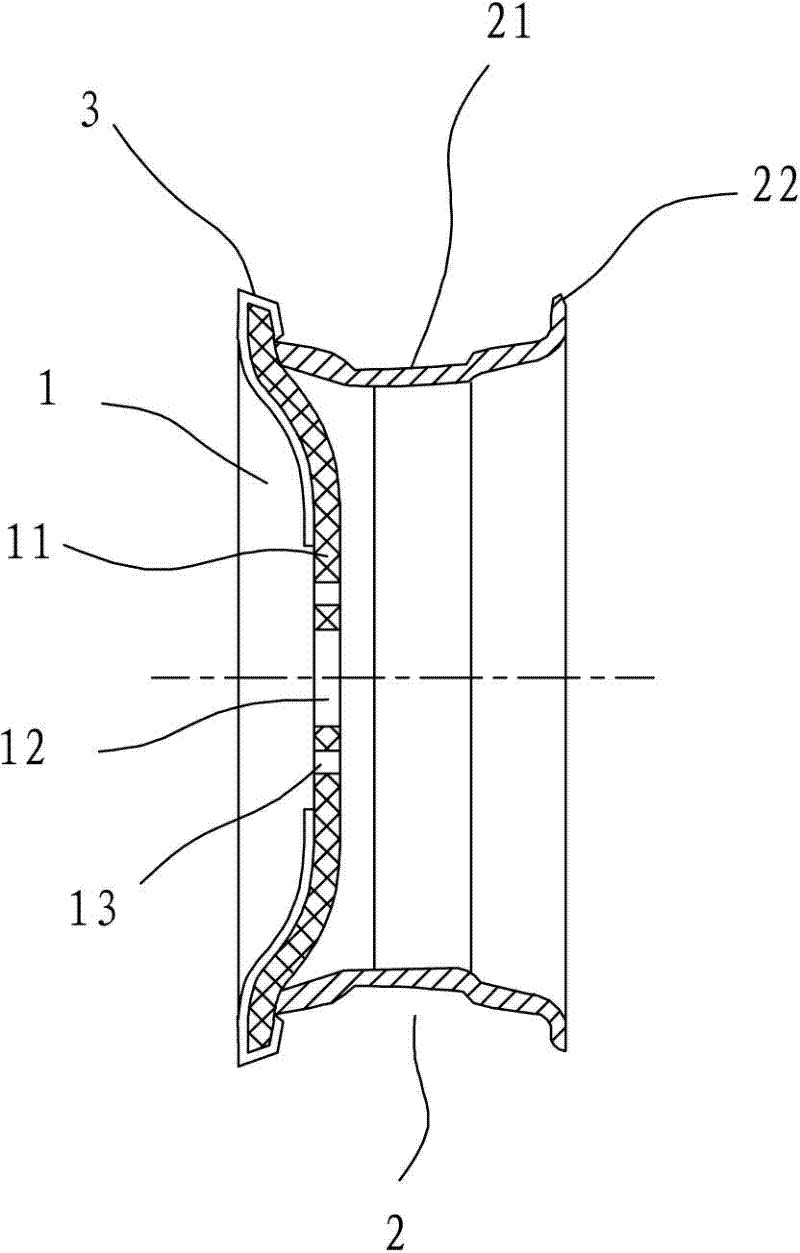

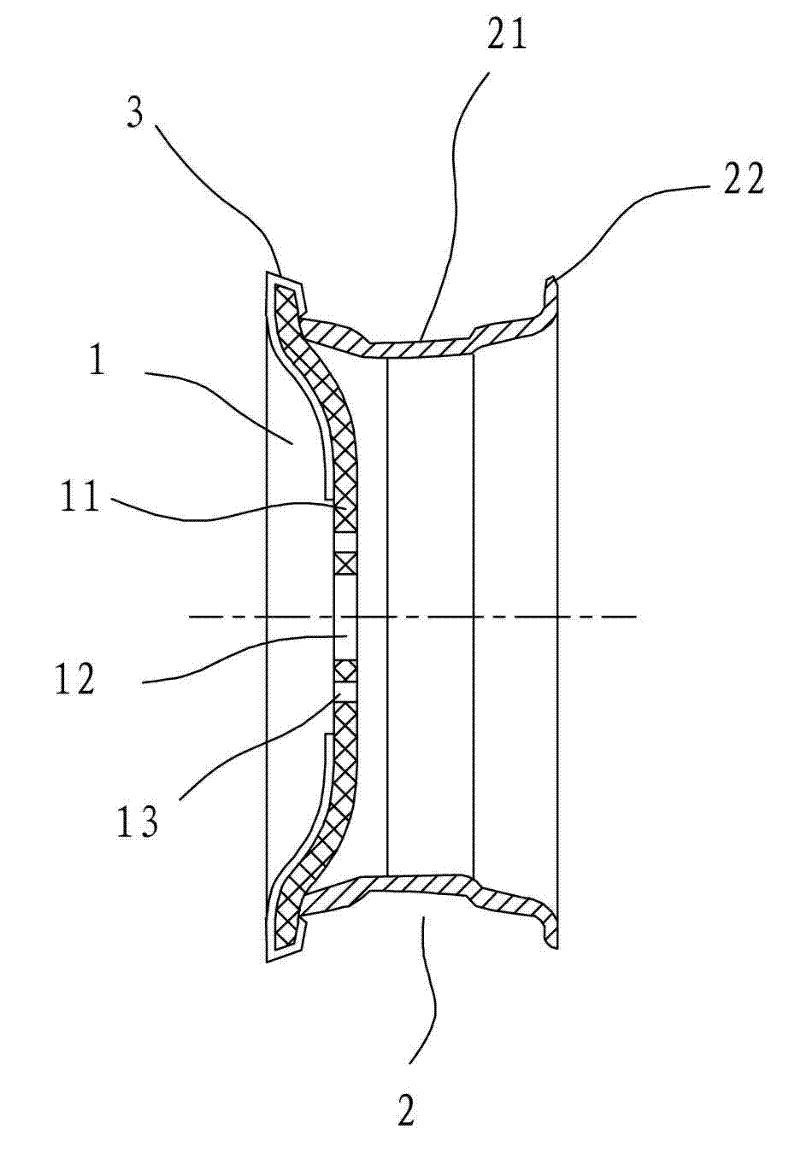

[0011] Such as figure 1 As shown, the welded steel automobile wheel hub proposed by the present invention includes a spoke 1 and a rim 2 respectively cast or forged from steel, and the two are connected by welding. Wherein, the spoke 1 includes a plurality of spokes 11 distributed radially, a center hole 12 is arranged in the center, and a plurality of mounting holes 13 are evenly distributed around the center hole 12 for fixing the hub on the axle. The rim 2 includes a rim body 21 and raised rims 22 provided on both sides of the rim body 21 for fixing the tire. The spokes 11 of the spokes 1 extend outward into an arc-shaped surface in the inner cavity of the rim 2 and are welded and fixed to the outer end surface of the rim 2 to form the entire hub.

[0012] In addition, the spoke 1 is provided with an electroplated chromium layer, or a decorative layer 3 made of stainless steel or aluminum alloy.

[0013] The wheel hub proposed by the present invention is welded by steel, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com