Manufacturing method of imitation leather layered shoe heel

A manufacturing method and a layered technology, applied in the field of shoe heel manufacturing, can solve the problems of uneven distribution of glue, bulges formed by the glue flowing to the edge, waste, etc., to increase the sense of hierarchy and beauty, improve work efficiency, ensure The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

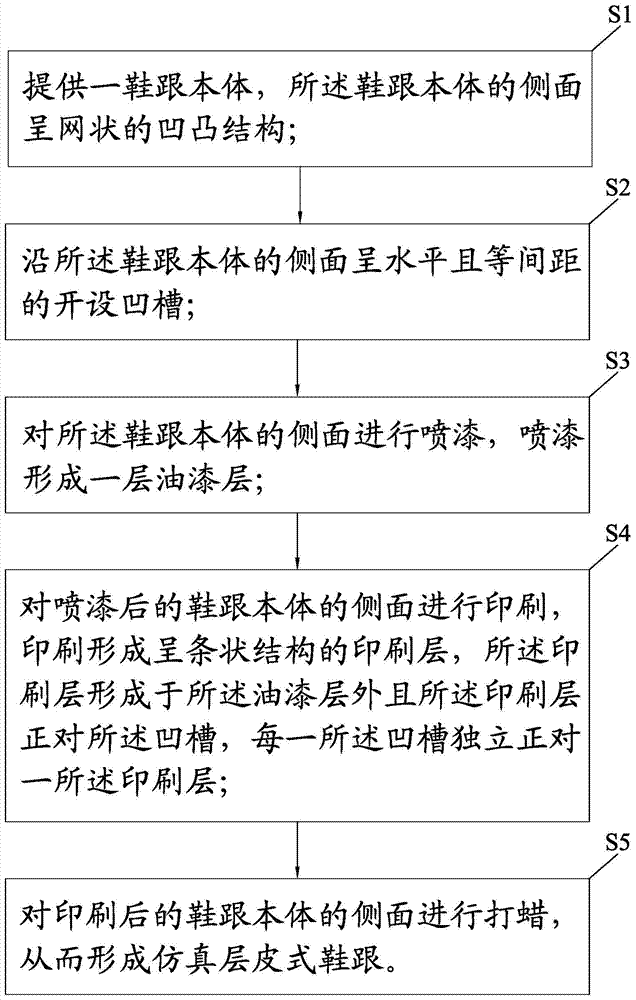

[0019] Such as figure 1 As shown, the present invention provides a kind of manufacturing method of artificial layer leather type heel, and it comprises the steps:

[0020] S1: providing a heel body, the side of the heel body has a mesh-shaped concave-convex structure;

[0021] S2: grooves are formed horizontally and equally spaced along the side of the heel body;

[0022] S3: spraying paint on the side of the heel body to form a layer of paint;

[0023] S4: Print the side of the heel body after painting to form a strip-shaped printing layer, the printing layer is formed outside the paint layer and the printing layer is facing the groove, each The groove is independently facing one of the printing layers;

[0024] S5: waxing the side of the printed heel body to form a simulated leather heel.

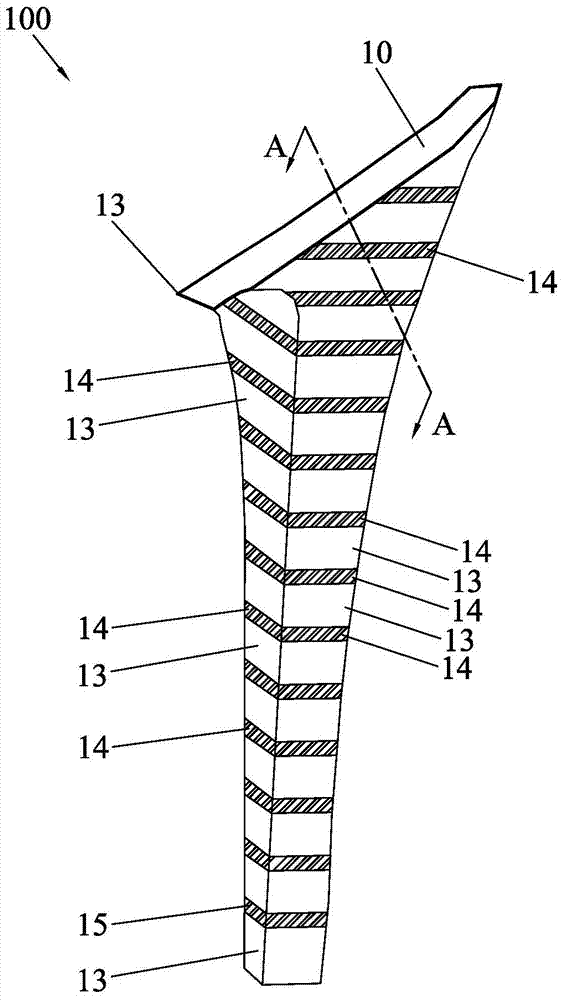

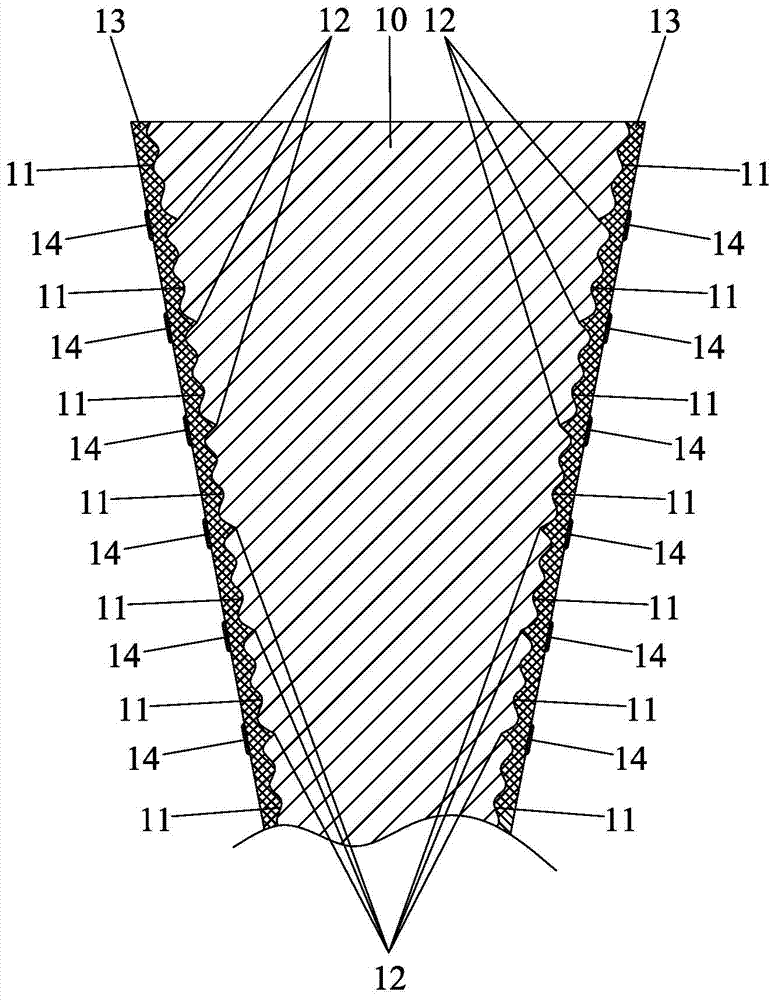

[0025] combine Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com