Vertical-type polishing machine for myotonin

A polishing machine and barley technology, applied in grain finishing, grain processing, application, etc., can solve problems such as inability to polish barley rice grooves, poor appearance, etc., and achieve a simple structure, high degree of automation, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

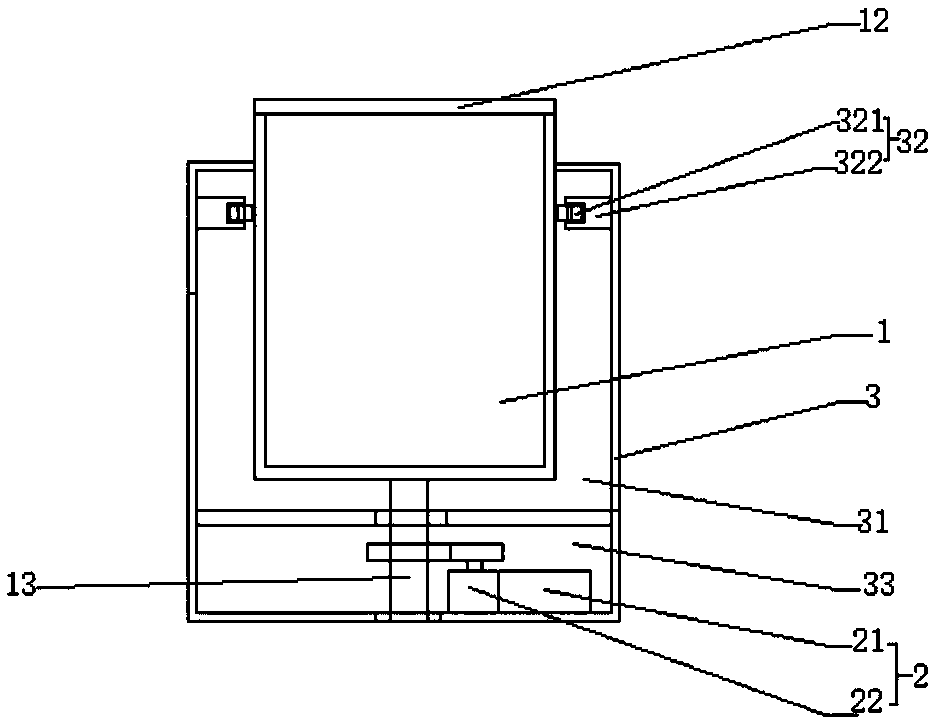

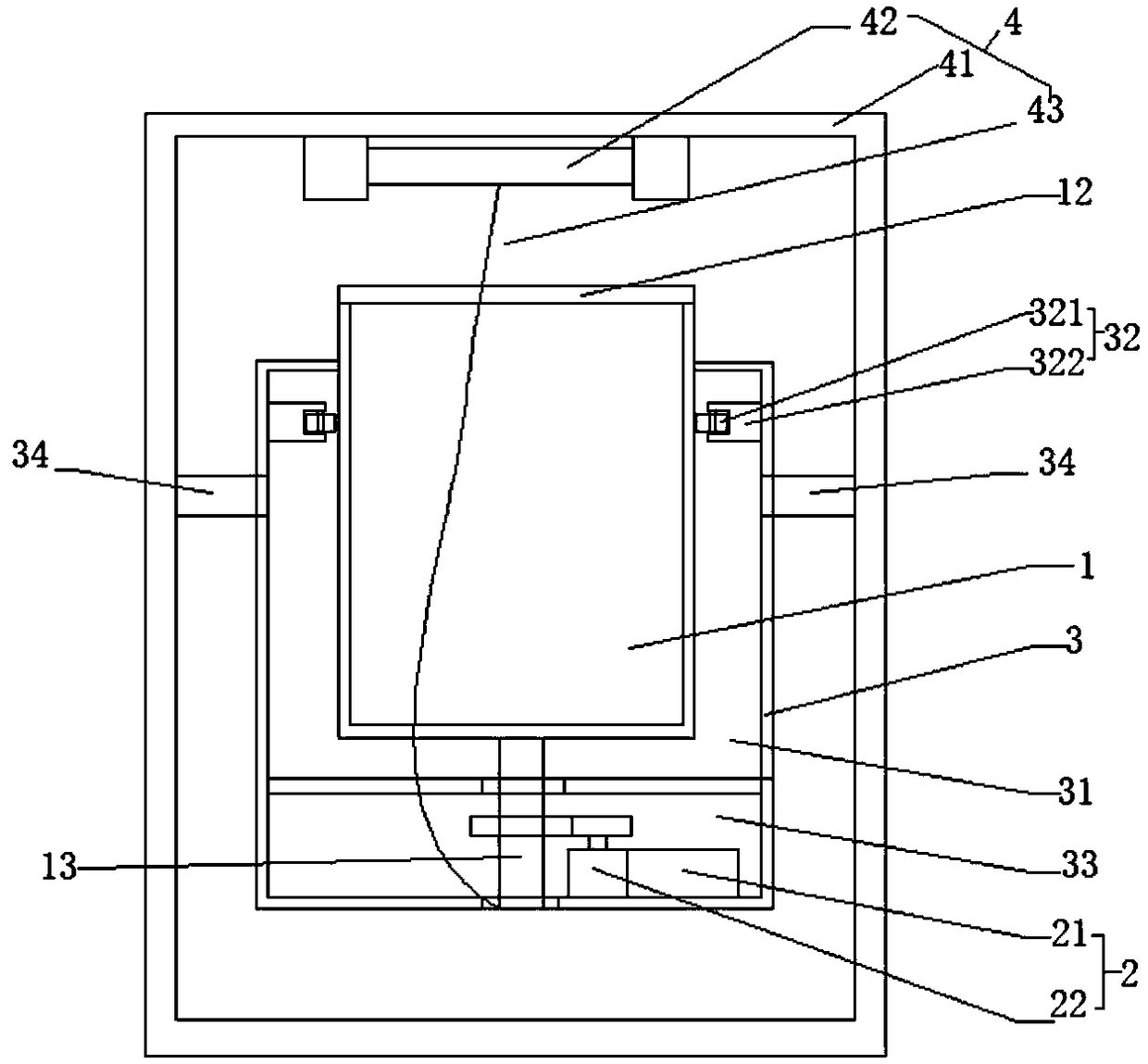

[0034] Such as image 3 As shown, with embodiment 1, the difference is that the above technical solution also includes a bracket 4, the bracket 4 is a square frame 41 open on both sides, the housing 3 is placed in the square frame 41, and The two ends of the outer wall of the housing 3 are respectively horizontally connected with rotating shafts 34 corresponding to the side walls on both sides of the square frame 41, and the ends of the two rotating shafts 34 that are far away from each other extend horizontally to the corresponding The side walls of the square frame 41 are rotatably connected. It has a simple structure and is convenient for feeding and unloading the polishing cylinder. After polishing, an external force is applied to push the lower end of the housing to rotate upwards until the opening of the polishing cylinder faces downward to pour out the barley.

[0035] In the above technical solution, the support 4 also includes a lifting device 42 and a connecting rop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com