Method and fixture for polishing tooth surface of worm by using numerical control lathe

A technology of CNC lathe and worm tooth surface, applied in the direction of components with teeth, gear teeth, gear cutting machines, etc., can solve the problems of uneven tooth surface polishing, low efficiency, etc., to facilitate promotion, improve efficiency, and improve quality stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

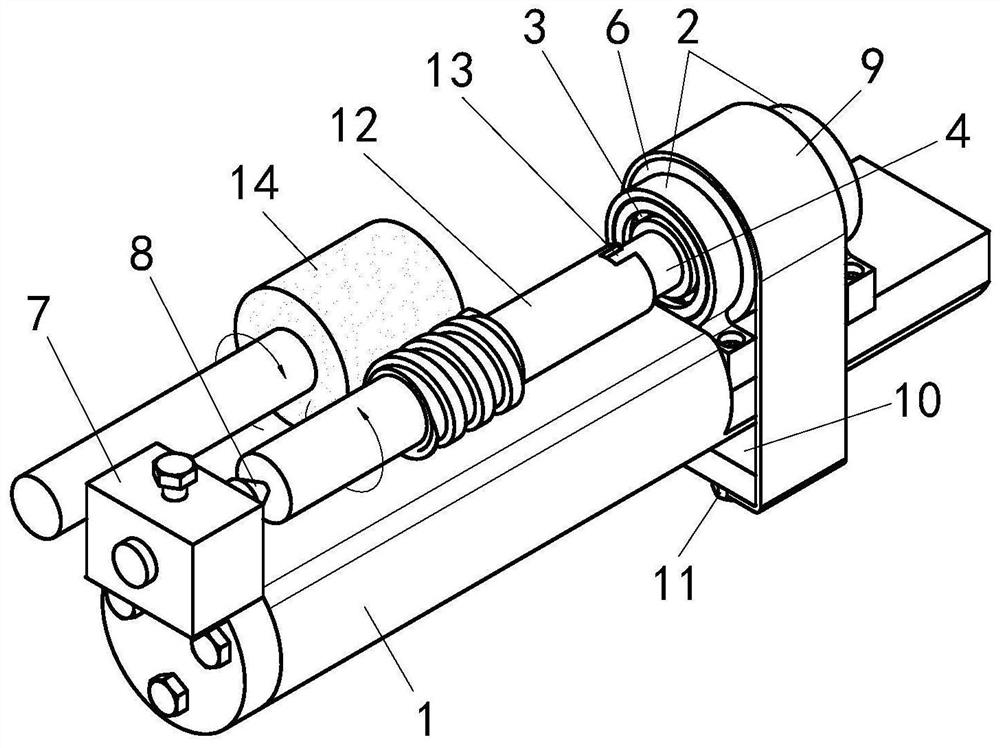

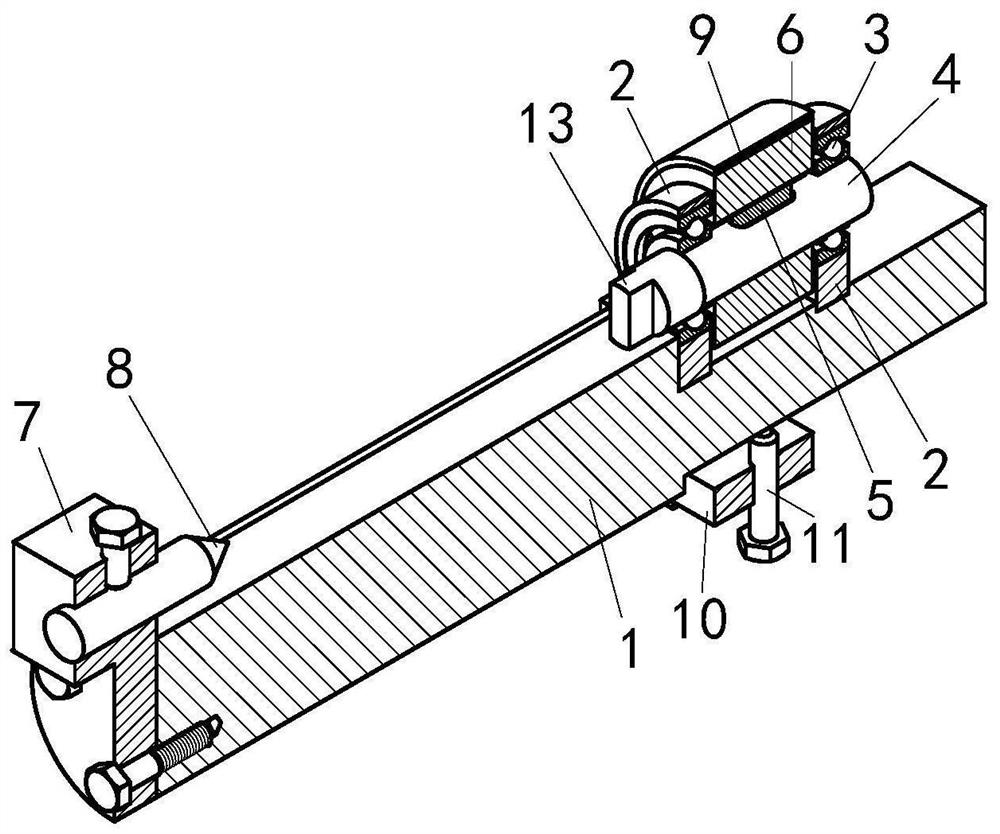

[0016] A method of polishing the tooth surface of a worm by using a numerically controlled lathe of the present invention, such as figure 1 As shown, the method is that the worm 12 is clamped on the tool rest of the CNC lathe by a clamp, and then the polishing wheel 14 is clamped on the headstock of the CNC lathe, and the polishing wheel 14 is driven by the CNC lathe to rotate; 12 translates and contacts the high-speed rotating polishing wheel 14, and polishes the tooth surface of the worm 12 through the friction between the polishing wheel 14 and the tooth surface of the worm 12. After the worm 12 clamped on the CNC lathe tool holder contacts with the polishing wheel 14, the worm 12 rotates relative to the polishing wheel 14 under the friction of the polishing wheel 14, and the linear speed of the worm 12 rotation is smaller than that of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com