General-purpose mechanical camshaft gear manufacturing device

A technology for camshaft gears and general machinery, which is applied in the direction of valve devices, mechanical equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of strengthening the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

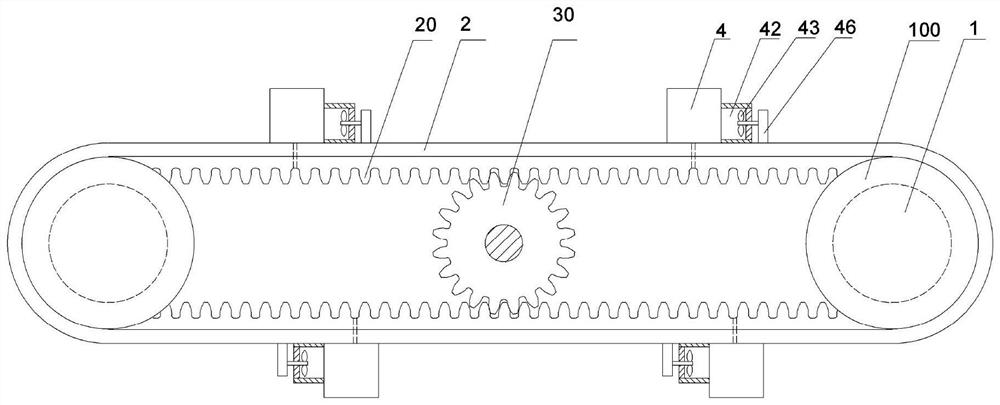

[0029] like figure 1 and figure 2 As shown, the general-purpose mechanical camshaft gear manufacturing device of this embodiment includes a moving mechanism for driving the camshaft gear 30 to move and a tooth groove grinding mechanism for grinding the tooth grooves of the camshaft gear 30 .

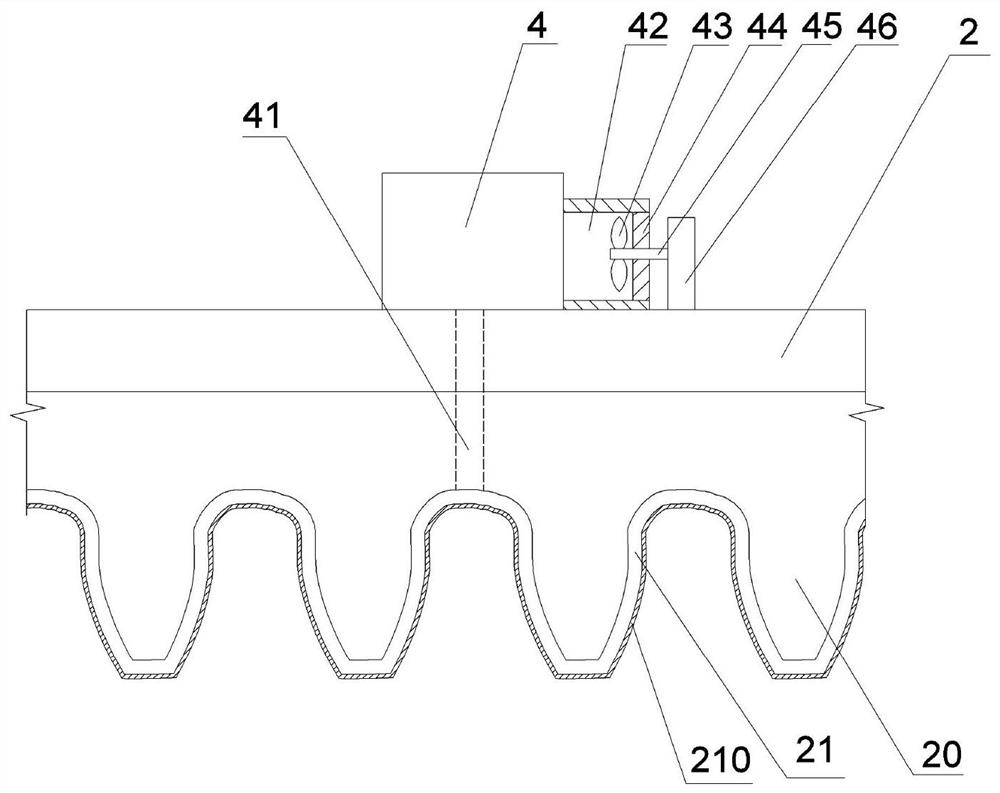

[0030] The cogging grinding mechanism includes two rotating rollers 1 and a belt 2 wound on the two rotating rollers 1. The rotating roller 1 is connected with a servo motor (not shown in the figure) to drive the rotating roller 1 to rotate, thereby driving the belt 2 Movement on two rotating rollers 1. The inner side of the belt 2 is provided with grinding teeth 20 which can mesh with the tooth grooves of the camshaft gear 30. The grinding teeth 20 are bonded with an air bag 21 wrapping the grinding teeth 20. The outer surface of the air bag 21 is provided with a grinding layer 210. The grinding layer 210 is Similar to the structure of sandpaper, the outer edge of the rotating roller...

Embodiment 2

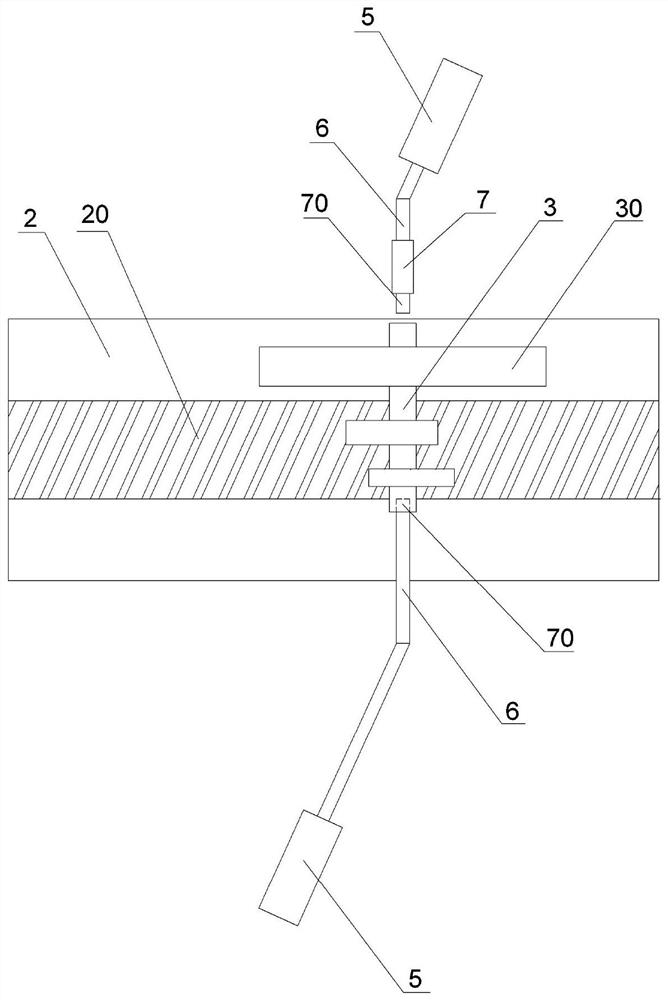

[0044] The difference between this embodiment and Embodiment 1 is that: Image 6 and Figure 7 As shown, this embodiment is used for grinding two camshaft gears 30 (of course, more than two camshaft gears 30 can also be polished according to actual needs), and each camshaft 3 is connected with a support rod 6 for support and positioning Each support rod 6 is connected with a connecting rod 8, and then the connecting rod 8 is fixed by the output rod of the linear motor 5 to drive each camshaft gear 30 to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com