Method and device for improving electric spark high-speed piercing finished surface integrity

A high-speed perforation and surface machining technology, applied in electric machining equipment, accessories, metal machining equipment, etc., can solve the problems of low machining efficiency, poor surface integrity of the workpiece, large surface roughness value, etc., to reduce the heat-affected zone, The effect of preventing workpiece burn and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

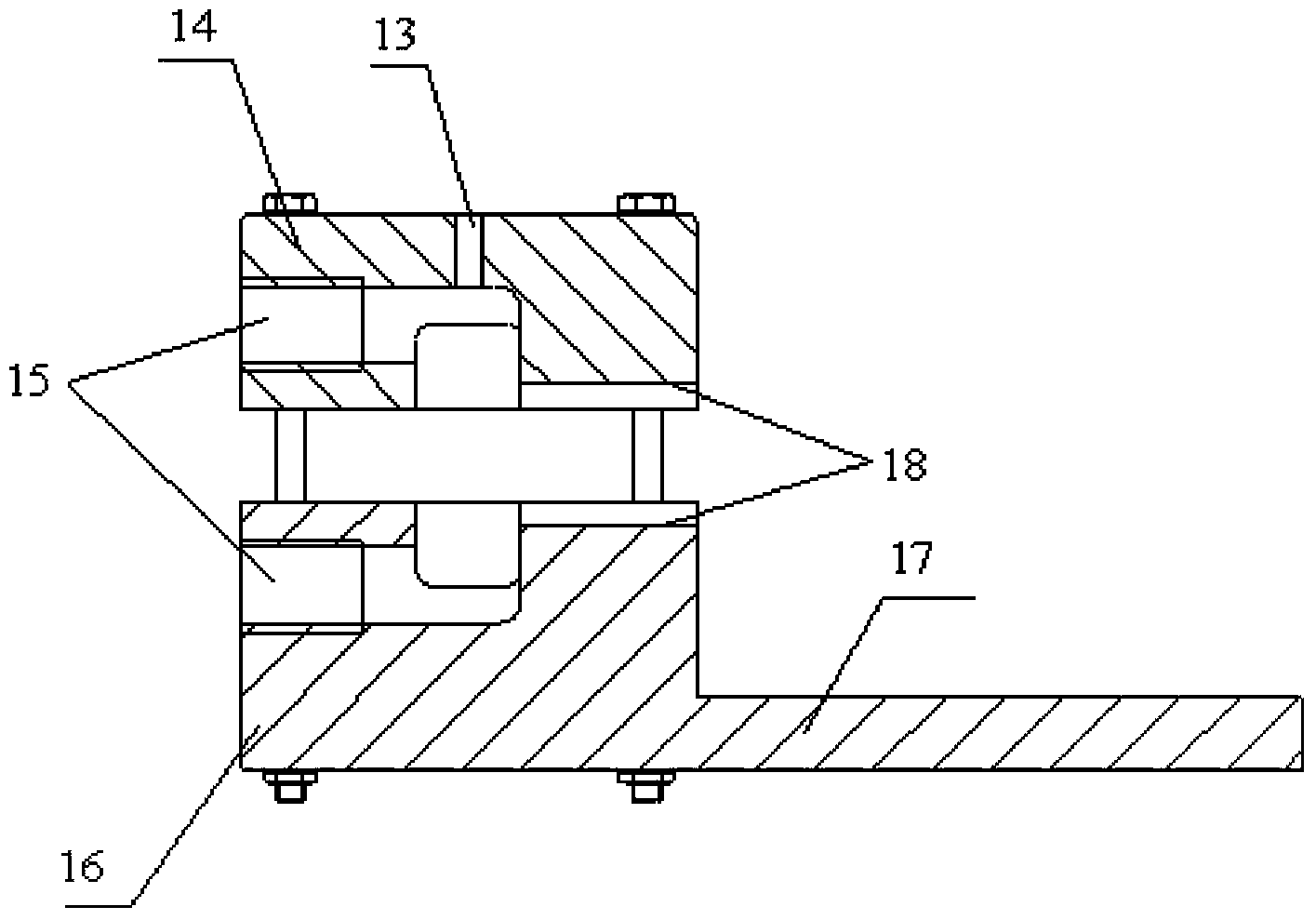

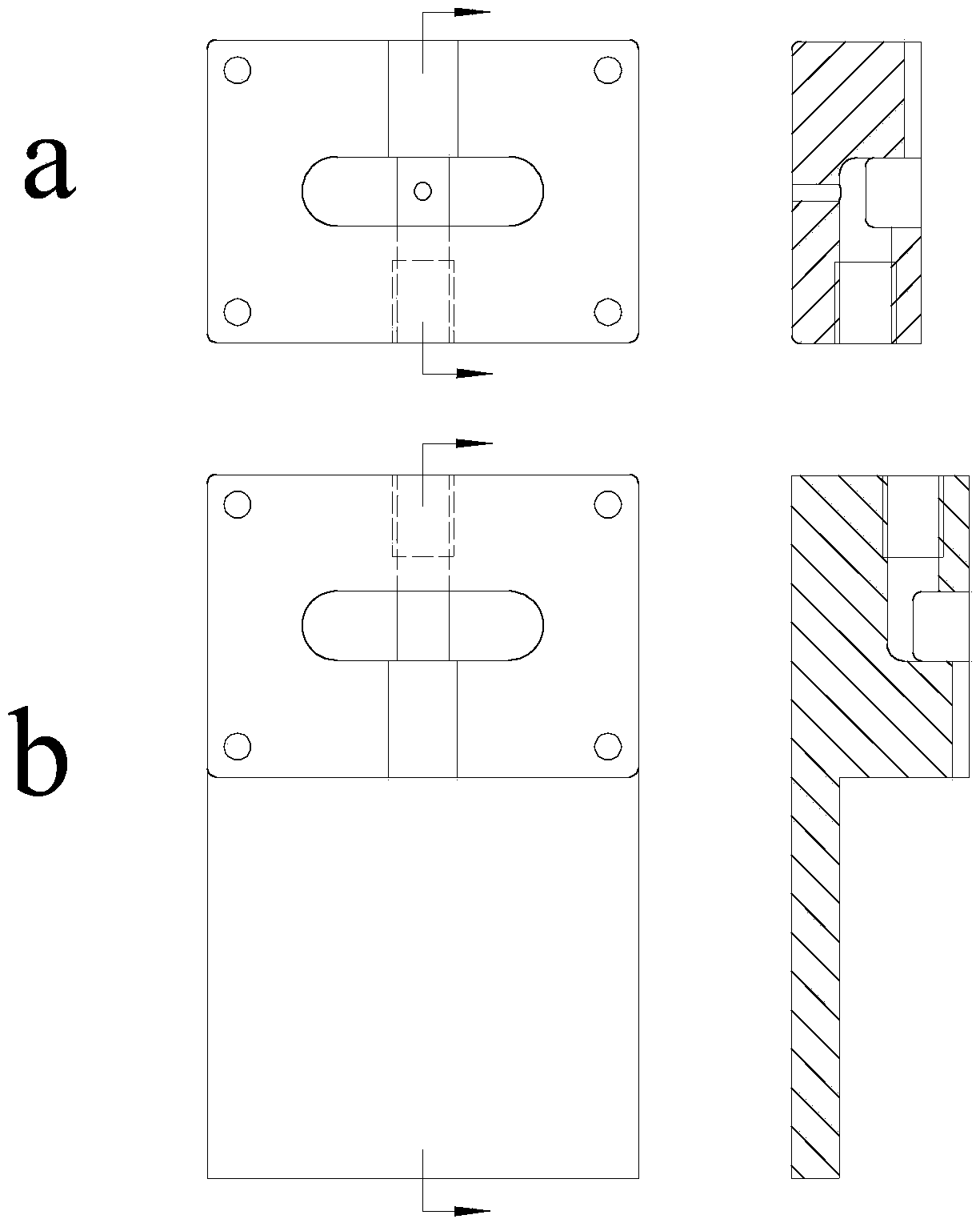

[0036] A device for improving the surface integrity of electric discharge high-speed perforation machining, the structure of the fixture 6 is as follows figure 2 , the clamp 6 includes an upper guide block 14 and a lower guide block 16, the upper guide block 14 and the lower guide block 16 are hollow after clamping, and the upper guide block 14 and the lower guide block 16 are respectively provided with water mist inlets 15 And the chip removal groove 18, the top surface of the upper guide block 14 is also provided with a tool electrode inlet 13, the tool electrode inlet 13, the water mist inlet 15 and the chip removal groove 18 are all connected to the cavity. The lower guide block 16 is arranged on the base 17, and the above-mentioned upper and lower guide blocks 14, 16 and the base 17 are insulating materials. The structure of the upper guide block and the lower guide block of the fixture is as follows image 3 a and image 3 as shown in b.

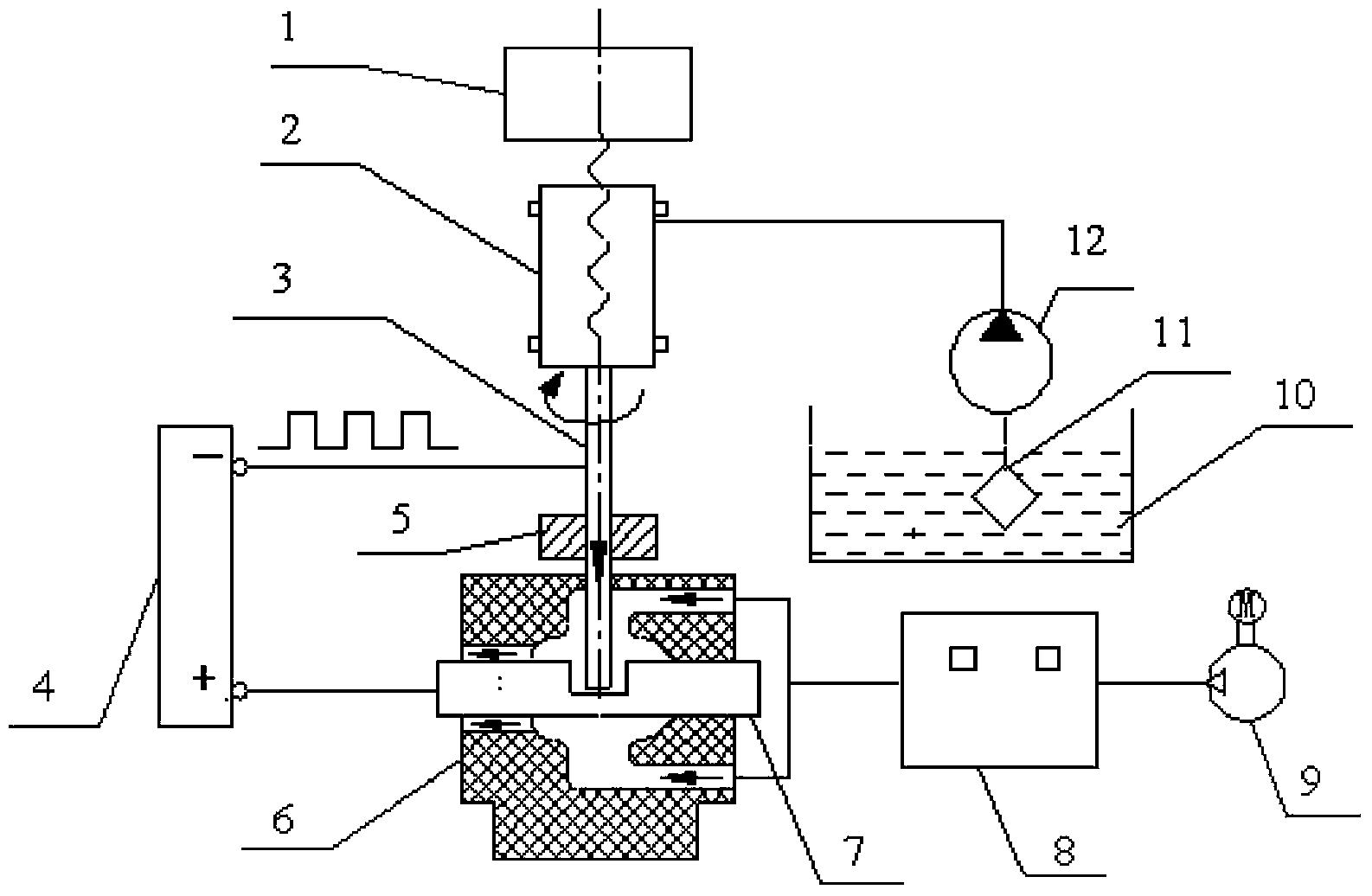

[0037] The schematic diagra...

Embodiment 2

[0045] like figure 1 and figure 2 As shown, a device for improving the surface integrity of EDM high-speed perforation machining is different from Example 1 in that the material of the workpiece 7 used is Q235 (thickness 7mm), the discharge pulse width is 40μs, and the duty ratio is 5:3. , The open circuit voltage is 80V, the average current is 28A, the high-speed flushing pressure is 5MPa, the water mist pressure is controlled at 0.6MPa, the flow velocity of the water mist on the surface of the workpiece is 67 m / s, and the gas-liquid volume ratio is 200:1.

[0046] In this embodiment, the average processing time of small holes with a diameter of 2mm and a depth of 7mm is about 31s, while the average processing time of the same material and ordinary high-speed EDM under the same processing parameters is about 38s, and the processing efficiency is increased by about 18.42%. The surface morphology was observed by a 3D video microscope, and the surface integrity was significan...

Embodiment 3

[0049] like figure 1 and figure 2 As shown, a device for improving the surface integrity of EDM high-speed perforation machining is different from Example 1 in that the material of the workpiece 7 used is a single crystal silicon ingot (thickness 5.5mm), and the resistivity is 0.01Ω. cm, the discharge pulse width is 40μs, the duty ratio is 5:3, the no-load voltage is 80V, the average current is 28A, the high-speed flushing pressure is 5MPa, the water mist pressure is controlled at 0.6MPa, and the flow rate of water mist on the surface of the workpiece is 100m / s , The gas-liquid volume ratio is 200:1.

[0050] In this embodiment, the average processing time for small holes with a diameter of 2mm and a depth of 5.5mm is about 5s, while the average processing time for the same material and ordinary high-speed EDM under the same processing parameters is about 6s, and the processing efficiency is increased by about 16.67%. , the surface morphology was observed through a three-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com