Three-dimensional graphene frame material, microporous layer, gas diffusion layer and preparation method thereof

A frame material, graphene technology, applied in fuel cells, electrical components, structural parts, etc., can solve the problem of insufficient cathode water return performance of materials, achieve water management and performance improvement, and achieve high-speed conduction and high conductivity. and hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

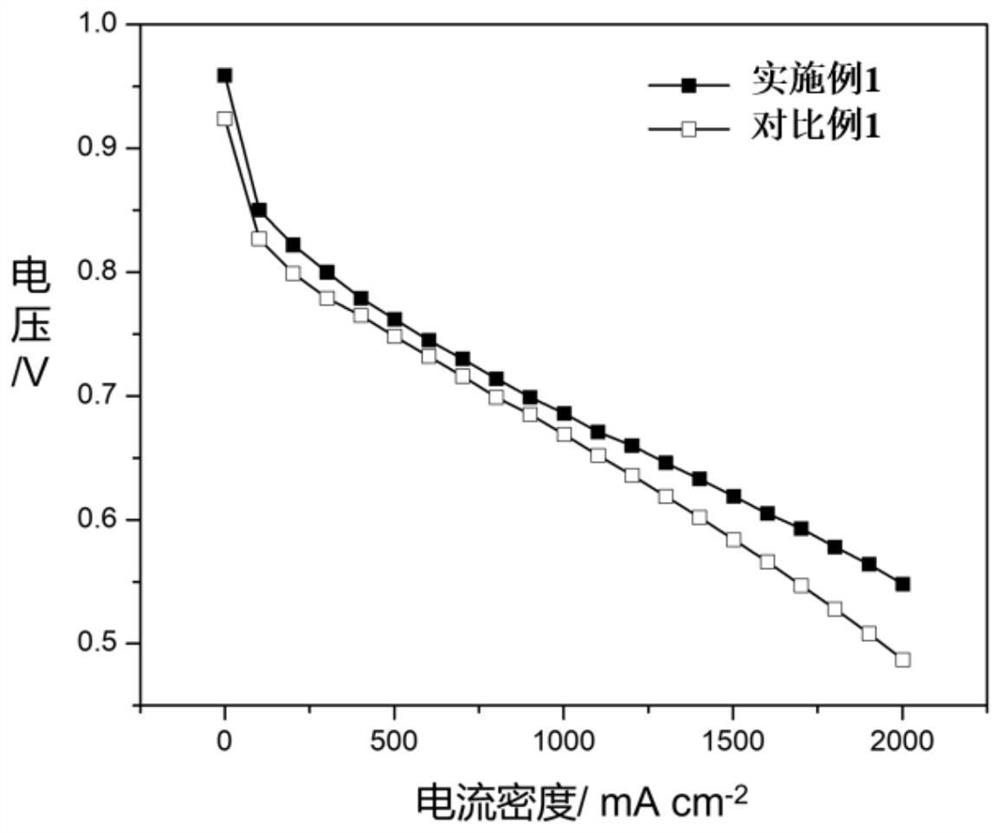

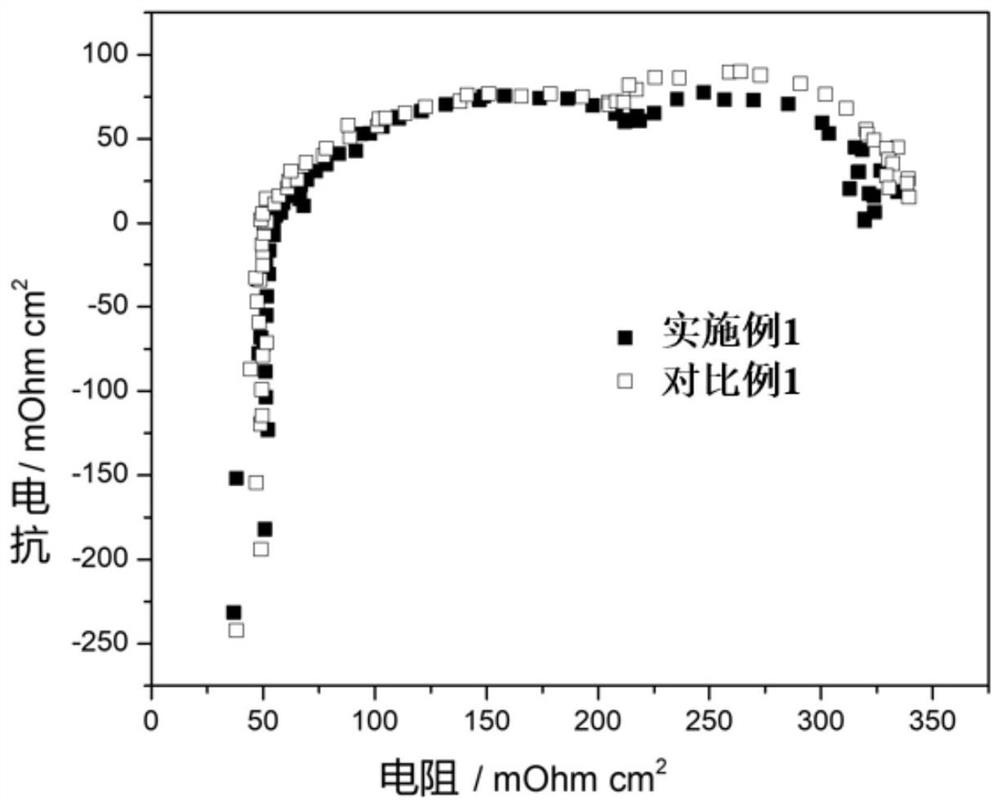

Embodiment 1

[0088] A kind of composite microporous layer containing 3DGF, its preparation method is as follows:

[0089] 1. Under an ice-water bath, first pour 20g of concentrated sulfuric acid solution into a reaction bottle containing 1g of graphite powder, add 2g of potassium permanganate solid, mix well; stir and react at 15°C for 20min; heat up to 35°C and continue Stir and react for 30 minutes; slowly add 10 g of deionized water, and continue to stir and react for 20 minutes; add 15 g of hydrogen peroxide for reduction reaction to reduce the unreacted oxidant, making the solution bright yellow. Filtrate while hot, wash with HCl and deionized water until the filtrate is free of sulfate ions, and finally configure a graphene oxide (GO) aqueous solution with a certain mass concentration (0.1-2mg / mL).

[0090] 2. Take 50 mL of the graphene oxide aqueous solution (1 mg / mL) prepared in the previous step, add 200 mg of vitamin C, and carry out a cross-linking reaction at 40 ° C for 12 hour...

Embodiment 2

[0098] A kind of composite microporous layer containing 3DGF, its preparation method is as follows:

[0099] 1. the preparation method of graphene oxide aqueous solution is as described in embodiment 1;

[0100] 2. Use ethylene glycol to carry out cross-linking, and other conditions are as above-mentioned embodiment 1, obtain GO gel;

[0101] 3. The GO gel was quickly frozen under liquid nitrogen, and then placed in a freeze dryer for freeze-drying;

[0102] 4. Carry out high-temperature heat treatment, the experimental conditions are identical with embodiment 1, obtain three-dimensional graphene framework powder material 3DGF-2;

[0103] Steps 5-8 were all as described in Example 1 to obtain the microporous layer prepared by 3DGF-2 and the assembled fuel cell, and perform performance tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com