Method for predicting low-cycle fatigue life of titanium alloy material based on surface integrity

A technology of surface integrity and low cycle fatigue, applied in the direction of applying stable tension/pressure to test the strength of materials, it can solve the problems of high performance parameters and inability to meet the needs of engineering development, and achieve simplified prediction models and rapid low cycle fatigue. Effects of life prediction, improved stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

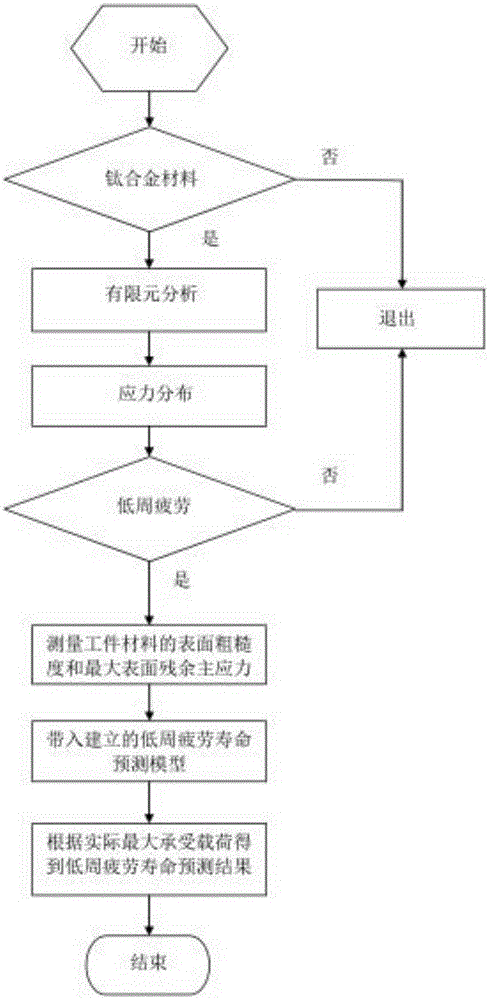

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

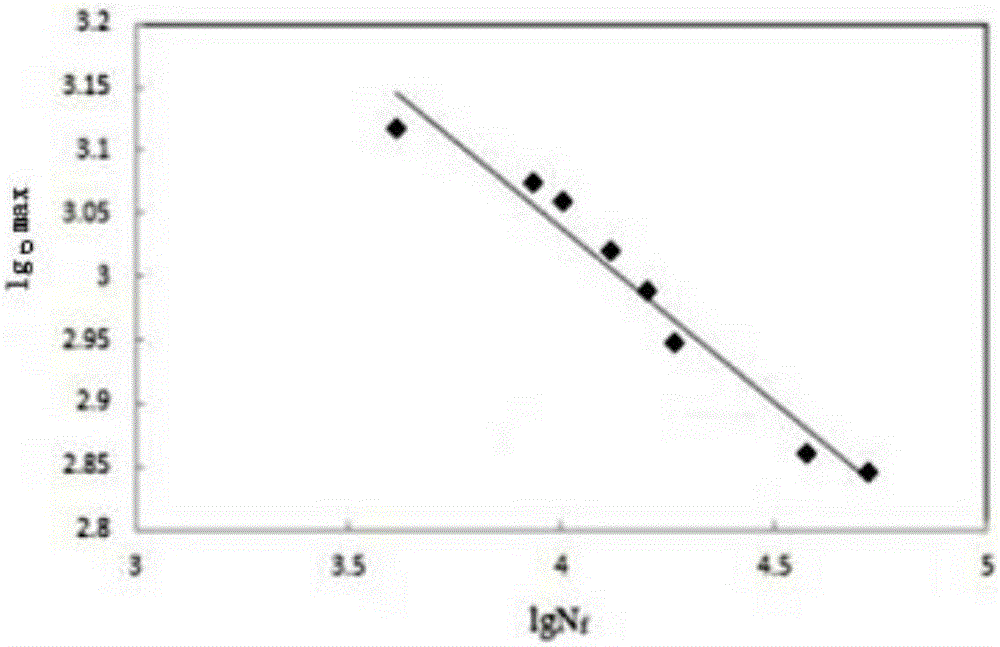

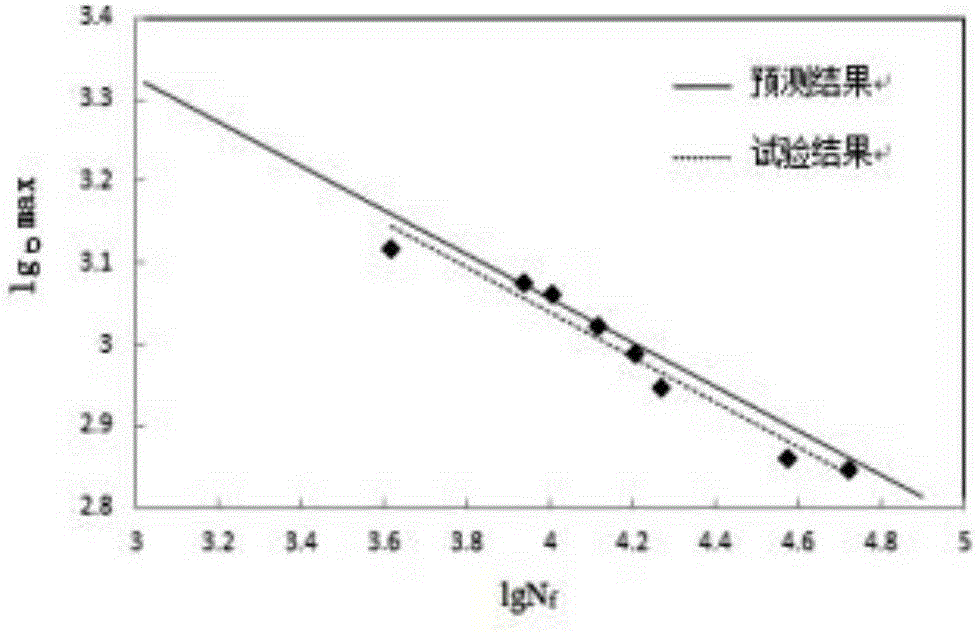

[0026] The invention is a method for predicting the low cycle fatigue life of titanium alloy materials based on surface integrity, the process of which is as follows: figure 1 As shown, the implementation steps of the present invention are described in detail below with the TC4-DT titanium alloy material as an example:

[0027] Step 1: It is judged that TC4-DT is a new type of titanium alloy material, so you can go to step 2;

[0028] Step 2: Perform finite element analysis on the structure of TC4-DT workpiece to obtain its stress distribution and judge whether it is low cycle fatigue;

[0029] Step 3: It is found that the TC4-DT workpiece structure produces plastic strain at the dangerous point, so it can be judged that it is low cycle fatigue, and enter step 4;

[0030] Step 4: Set different cutting parameters, including cutting speed, fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com