Pipeline defect surface integrity detection device and detection method

A technology of surface integrity and detection device, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficulty in accurately judging the degree of pipeline damage and different detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

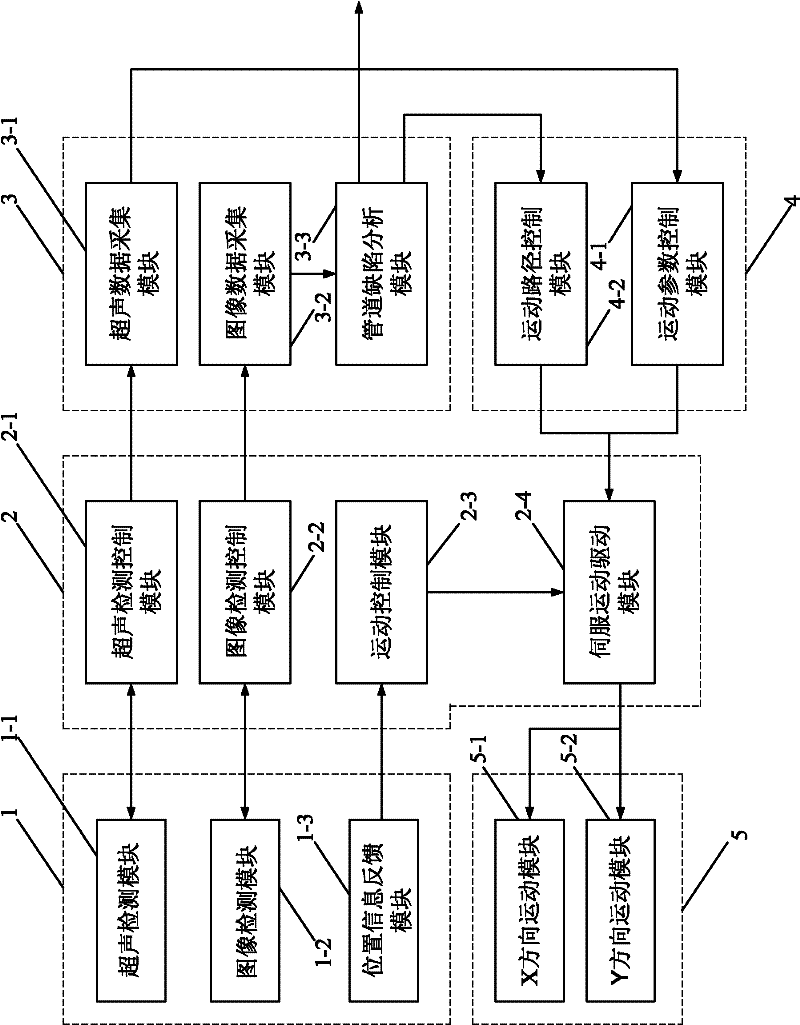

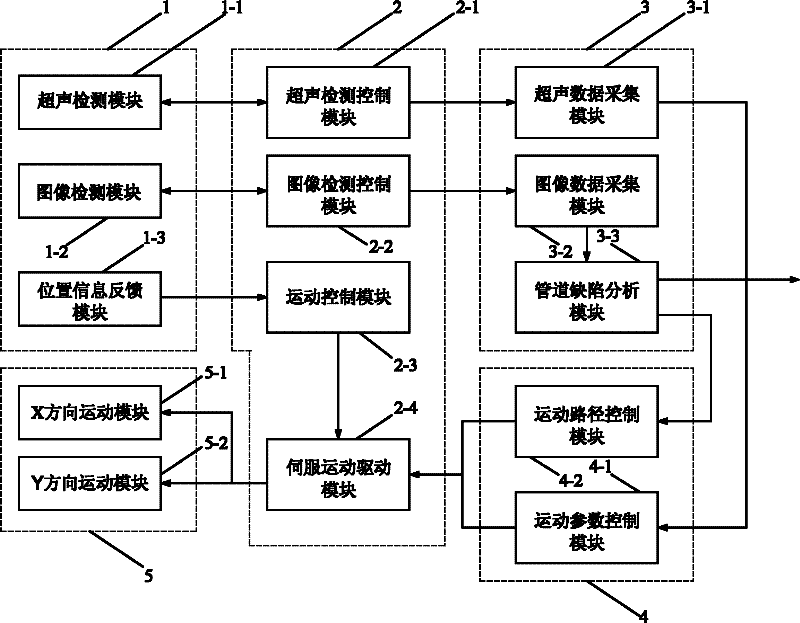

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is made up of detection component 1, control component 2, data acquisition component 3, motion control component 4 and motion execution component 5; The detection data signal input and output terminals are connected, and the image detection data signal output and input terminals of the detection component 1 are connected with the image detection data signal input and output terminals of the control component 2; the position information data output terminals of the detection component 1 are connected with the position information data of the control component 2 The input end is connected, and the ultrasonic acquisition data output end of control assembly 2 is connected with the ultrasonic acquisition data data input end of data acquisition assembly 3, and the image acquisition data output end of control assembly 2 is connected with the image acquisition data input end of data acqu...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the first difference between this embodiment and the specific embodiment is that the detection component 1 is composed of an ultrasonic detection module 1-1, an image detection module 1-2, and a position information feedback module 1-3; the ultrasonic detection module The output and input end of the ultrasonic detection data signal of 1-1 is the output and input end of the ultrasonic detection data signal of the detection component 1; the output and input end of the image detection data signal of the image detection module 1-2 is the image detection data of the detection component 1 Signal output and input terminals; the position information data output terminal of the position information feedback module 1-3 is the position information data output terminal of the detection component 1 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that the control assembly 2 is driven by the ultrasonic detection control module 2-1, the image detection control module 2-2, the motion control module 2-3 and the servo motion The module 2-4 is composed; the ultrasonic detection data signal input and output end of the ultrasonic detection control module 2-1 is the ultrasonic detection data signal input and output end of the control assembly 2; the image detection data of the image detection control module 2-2 The signal input and output end is the image detection data signal input and output end of the control assembly 2; the position information data input end of the motion control module 2-3 is the position information data input end of the control assembly 2; the motion control module 2 The servo drive control signal output end of -3 is connected with the servo d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com