Grinding tool with high tangential grinding force and low normal grinding force

A technology of tangential grinding force and normal grinding force, which is applied to the parts of grinding machine tools, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of easy blocking of abrasive tools, poor surface integrity of grinding workpieces, Frequent cutting burns and other problems, to achieve high surface integrity, good grinding surface integrity, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

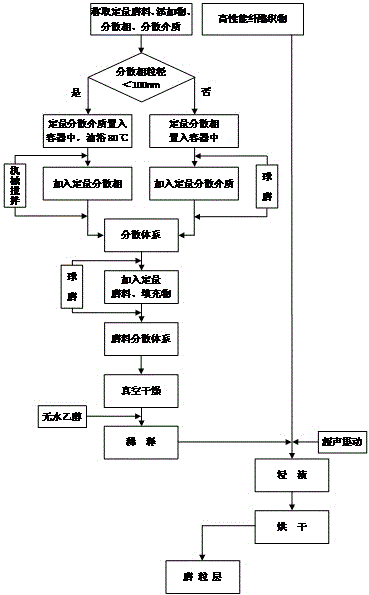

[0018] Specific implementation mode one: combined with figure 1 with attached figure 2 Describe in detail the specific implementation of the abrasive layer in the present invention:

[0019] (1) Refer to the attached figure 1 , Abrasives [1.1] choose metal oxide abrasives, silicon carbide, garnet and other ordinary abrasives or superabrasives (cubic boron oxide and diamond), with a particle size of 1-200 μm. The oxidant and activator in the filler [1.2] are selected from sodium peroxide, sodium hypochlorite, potassium permanganate or calcium peroxide. PH regulator selects sodium carbonate, potassium carbonate or sodium bicarbonate etc. for use. The binder [1.3] is made of ceramics, metal, resin or rubber. The dispersed phase [1.4] is selected from calcium carbonate, silicon dioxide, polystyrene or polymethyl methacrylate (PMMA), etc., and the particle size is less than 1 μm. The dispersion medium [1.5] is organic matter (ethylene glycol (EG), propylene glycol (PG), butyl...

specific Embodiment approach 2

[0021] Specific implementation mode two: combined with attached image 3 , detailing the specific implementation of making an abrasive belt grinding tool with high tangential grinding force and low normal grinding force. Abrasive layer-Ⅲ is made according to the method described in the specific embodiment 1, the primer [3.2] is made of resin, and the abrasive grain layer-Ⅲ and the tape base [3.1] are bonded together by the primer [3.2], and then placed Put it into a drying oven, the temperature is controlled at 170-190 ° C, and the time is 0.5-10 h. The abrasive grain layer-Ⅲ is consolidated on the belt base [3.1] to make an abrasive belt grinding tool [3.3].

specific Embodiment approach 3

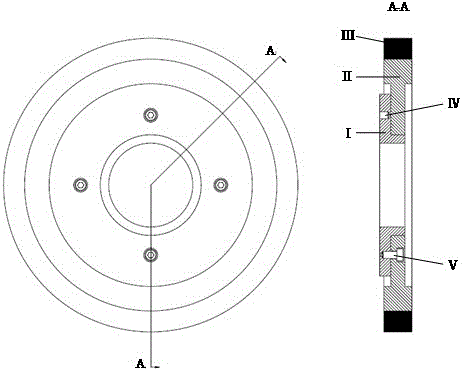

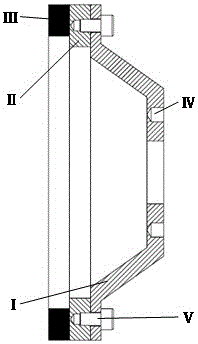

[0022] Specific implementation mode three: combined with attached image 3 And attached Figure 4 , detailing the specific implementation of making a parallel grinding tool and a cup-shaped grinding tool with high tangential grinding force and low normal grinding force:

[0023] (1) Abrasive layer-Ⅲ is made according to the method described in specific embodiment 1. After the resin is applied on the surface of the abrasive layer-Ⅲ, it is wound layer by layer along the outer ring of the matrix ring-II, and the abrasive layer is slowly processed by a machine. Layer-III is tensioned, and then the substrate ring-II wrapped with abrasive layer III is placed in a drying oven, the temperature is controlled at 170-190°C, and the holding time is 0.5-10h, so that the abrasive layer-III Consolidated on the matrix ring-II;

[0024] (2) Assemble the matrix ring-II with the abrasive layer-III bonded on the mating ring-I, attach image 3 The parallel grinding tool shown uses 4 hexagon soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com