Bamboo ceramic grinding wheel, preparation method and application thereof

A ceramic grinding wheel and grinding wheel technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high processing equipment and process requirements, easy to cause pollution, difficult to manufacture, etc., to achieve low manufacturing cost, processing High efficiency and excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

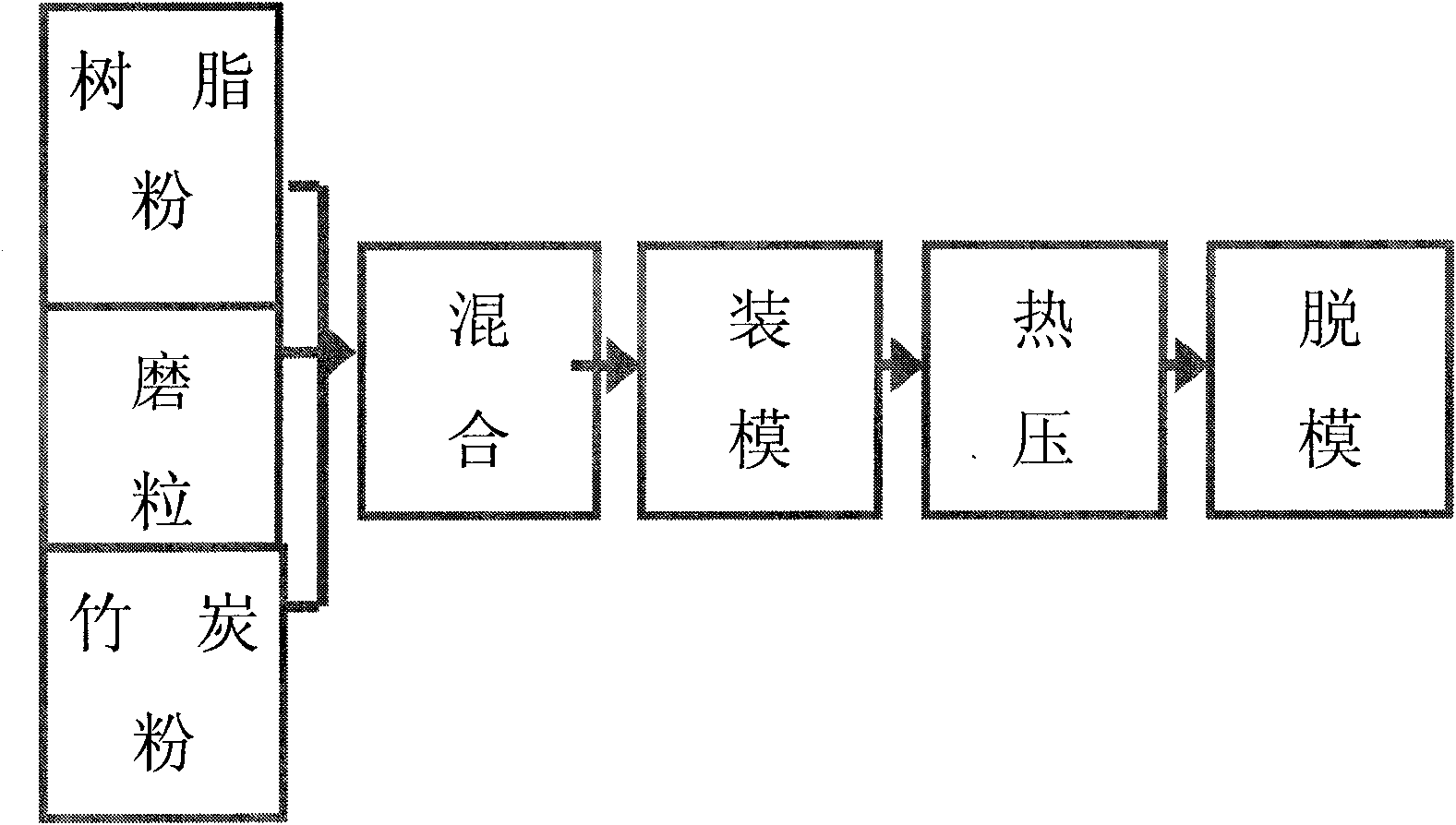

[0031] Phenolic resin (type 2123), abrasive grains (alumina 3000#) and bamboo charcoal powder (12500#) were weighed respectively and stirred with a mixer for 10 minutes according to the mass ratio of 20%:20%:60%, and mixed evenly to make The mixture; the mixture is put into the mold, and the mold is closed. Put the mold into a hot press, heat it from room temperature to 120°C for 10 minutes, apply a pressure of 20 MPa, and heat it to 240°C for 42 minutes, and apply a pressure of 40 MPa. Take out the mold and let it cool to room temperature, open the mold and take out the blank grinding wheel. Put the formed semi-finished grinding wheel into a muffle furnace, heat it up to 900°C at an average heating rate of 10°C / min under normal pressure, keep it for 2 hours, and finally cool it with the furnace to obtain bamboo ceramic grinding wheel 1, and its properties are shown in Table 1 shown.

Embodiment 2

[0033] Phenolic resin (type 2123), abrasive grains (alumina 3000#), and bamboo charcoal powder (12500#) were weighed respectively and stirred with a mixer for 10 minutes according to the mass ratio of 25%: 20%: 55%, and mixed evenly. The mixture; the mixture is put into the mold, and the mold is closed. Put the mold into a hot press, heat it from room temperature to 120°C for 20 minutes, apply a pressure of 10 MPa, and heat it to 240°C for 40 minutes, and apply a pressure of 42 MPa. Take out the mold and let it cool to room temperature, open the mold and take out the blank grinding wheel. Put the formed semi-finished grinding wheel into a muffle furnace, heat it to 900°C at an average heating rate of 10°C / min under normal pressure, keep it for 2 hours, and finally cool it with the furnace. Its properties are shown in Table 1.

Embodiment 3

[0035] Phenolic resin (type 2123), abrasive grains (alumina 3000#), and bamboo charcoal powder (12500#) were weighed respectively and stirred with a mixer for 10 minutes according to the mass ratio of 30%:20%:50%, and mixed evenly to make The mixture; the mixture is put into the mold, and the mold is closed. Put the mold into a hot press, heat it from room temperature to 120°C for 10 minutes, apply a pressure of 20 MPa, and heat it to 240°C for 42 minutes, and apply a pressure of 40 MPa. Take out the mold and let it cool to room temperature, open the mold and take out the blank grinding wheel. Put the formed semi-finished grinding wheel into a muffle furnace, heat it up to 900°C at an average heating rate of 10°C / min under normal pressure, keep it for 2 hours, and finally cool it with the furnace to get bamboo ceramic grinding wheel 3, its properties are shown in Table 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com