Shot peening strengthening surface integrity prediction method based on BP neural network

A BP neural network and surface integrity technology, applied in neural learning methods, biological neural network models, predictions, etc., can solve the complex model establishment process, cannot predict residual stress, and does not consider the correlation of input parameters of neural network prediction models, etc. problem, achieve the effect of reducing physical tests and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] This embodiment is the surface integrity prediction of gear shot peening, including the following steps:

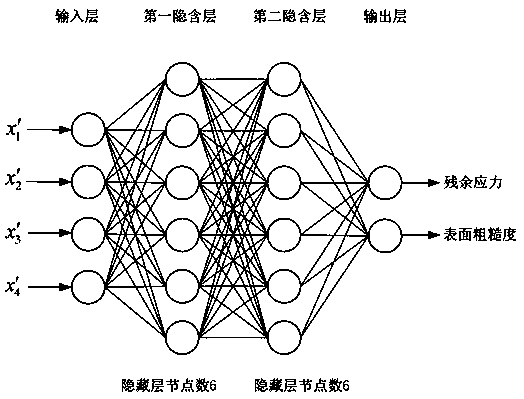

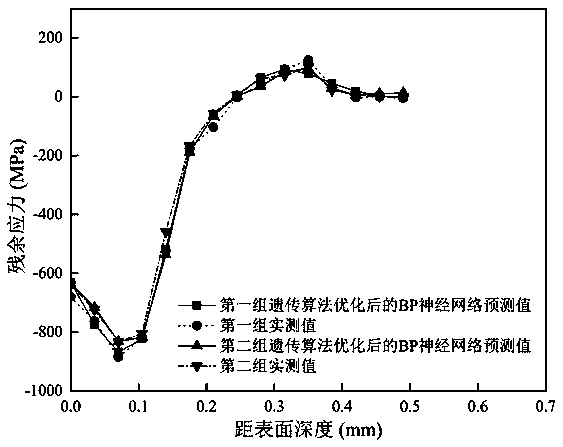

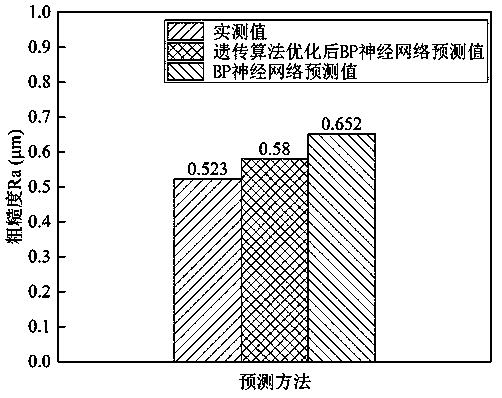

[0022] S1. Collect and sort out the shot peening test data. By analyzing the process parameters and surface integrity evaluation indicators that affect the shot peening performance during the shot peening process, the shot peening process parameters and material parameters are used as input parameters. After shot peening, the surface of the material is complete. The residual stress and surface roughness in the property parameters are the output parameters; and the input data is preprocessed, the preprocessing includes: deleting outliers, supplementing default values, performing feature dimensionality reduction on the data set, and normalizing the data Divide the test data into training set and test set according to appropriate proportion.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com