Method for detecting residual stress of multi-ceramic thermal barrier coating

A technology of thermal barrier coating and residual stress, which is applied in the direction of coating, testing material strength by applying a stable bending force, metal material coating process, etc., and can solve problems such as limited application and shallow detection depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for detecting residual stress of a multi-ceramic thermal barrier coating, the steps are as follows:

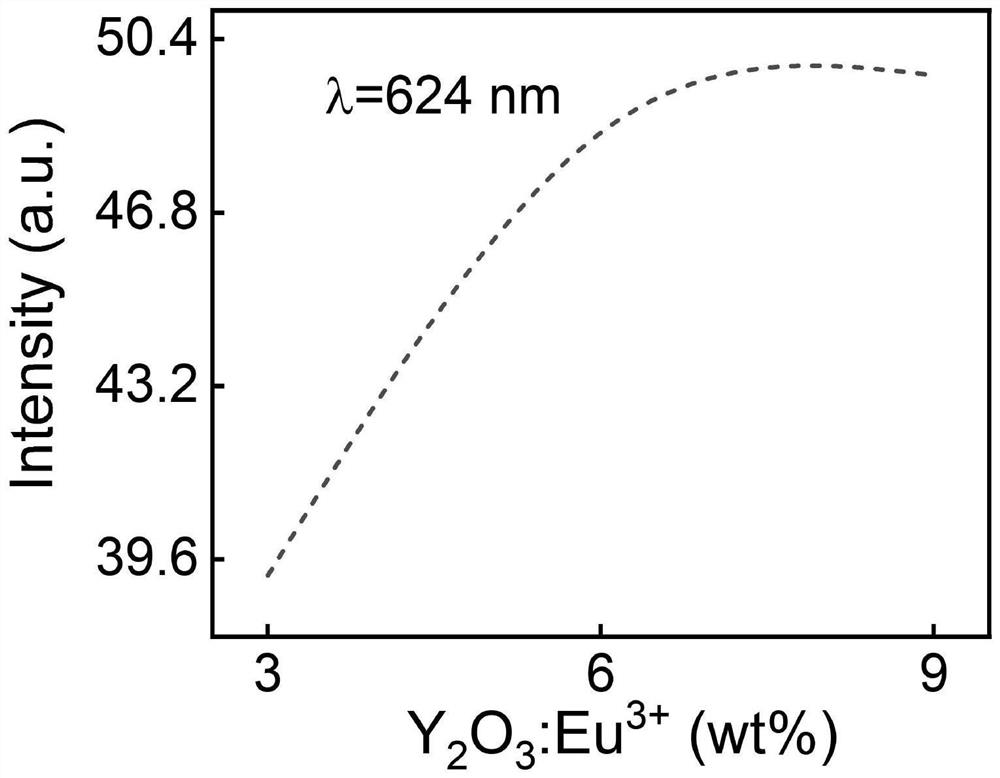

[0033] (1) Mixing: the ceramic layer material La 2 Zr 2 o 7 Fluorescent material Y with luminescent properties 2 o 3 : Eu 3+ The fluorescent powder is mixed according to the mass ratio of 6%, and the composite powder is mixed evenly by a planetary mixer to obtain a mixed ceramic powder;

[0034] The rotating speed of described mixer is 500r / min; There are zirconia mixing balls in described mixer, and the ratio of ball to material is 10:1;

[0035] (2) Spraying: sandblasting the elongated metal substrate (15cm in length, 3mm in thickness, and 5mm in width), and then using a plasma spraying system to spray the mixed ceramic powder obtained in step (1) on the metal substrate to obtain Composite coating (LZO / Y) with a thickness of 300 μm 2 o 3 : Eu 3+ );

[0036] The sandblasting used corundum sand with a particle size of 300 mesh and a blasting pressure ...

Embodiment 2

[0044] A method for detecting residual stress of a multi-ceramic thermal barrier coating, the steps are as follows:

[0045] (1) Mixing: the ceramic layer material Gd 2 Zr 2 o 7 (GZO) and Luminescent Properties Fluorescent Material Y 2 o 3 : Eu 3+ The fluorescent powder is mixed according to the mass ratio of 6%, and the composite powder is mixed evenly by a planetary mixer to obtain a mixed ceramic powder;

[0046] The rotating speed of described mixer is 500r / min; There are zirconia mixing balls in described mixer, and the ratio of ball to material is 10:1;

[0047] (2) Spraying: sandblasting the elongated metal substrate (15cm in length, 3mm in thickness, and 5mm in width), and then using a plasma spraying system to spray the mixed ceramic powder obtained in step (1) on the metal substrate to obtain Composite coating (GZO / Y) with a thickness of 300 μm 2 o 3 : Eu 3+ );

[0048] The sandblasting used corundum sand with a particle size of 300 mesh and a blasting pres...

Embodiment 3

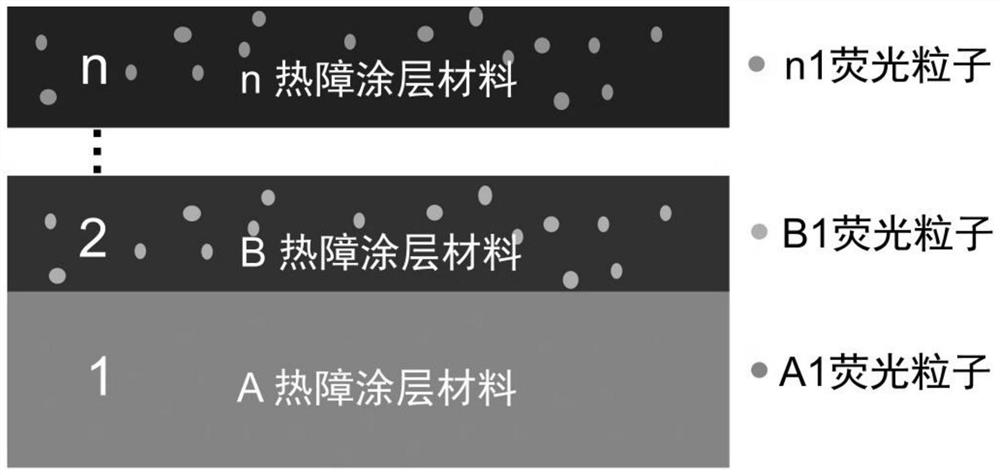

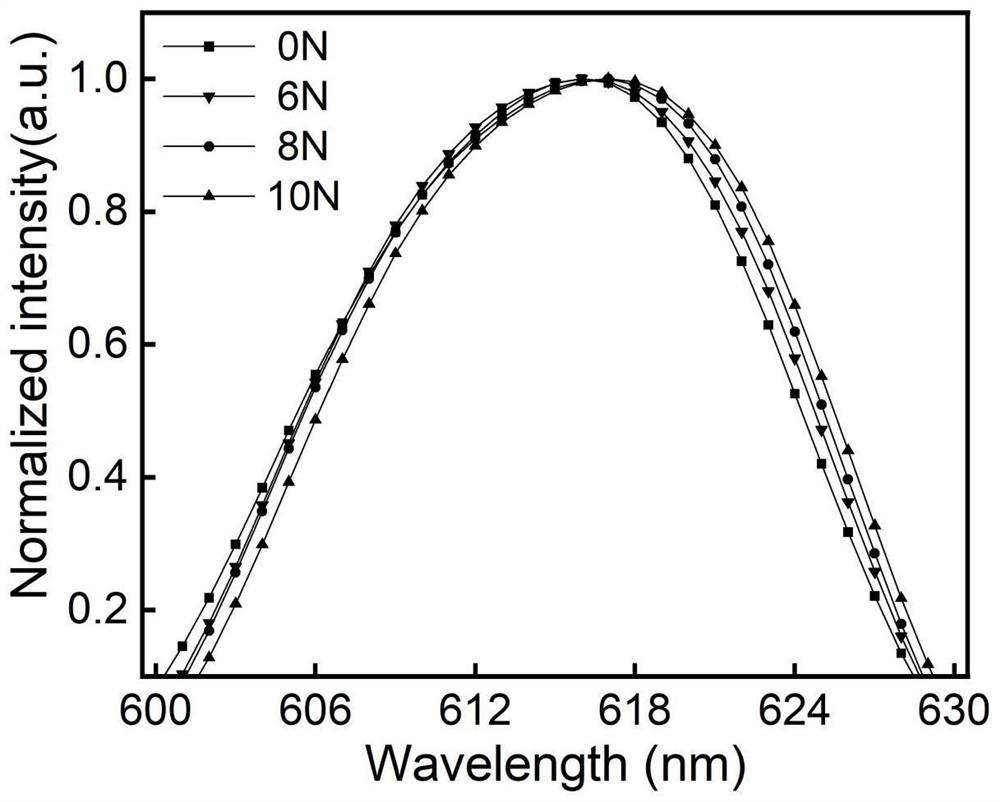

[0054] According to the method of Steps (1) to (3) of Example 1, ceramic thermal barrier coating materials of different doping systems are sequentially deposited on the metal substrate, first depositing LZO and luminescent fluorescent material Y 2 o 3 : Eu 3+ The thermal barrier coating ceramic layer mixed with fluorescent powder according to the mass ratio of 6%, followed by depositing GZO and luminescent characteristic fluorescent material Y on the composite coating according to the method of embodiment 2 steps (1)-(3) 2 o 3 : Eu 3+ Thermal barrier coating ceramic layer mixed with fluorescent powder at a mass ratio of 6%, to achieve a surface layer of GZO / Y 2 o 3 : Eu 3+ , the lower layer is LZO / Y 2 o 3 : Eu 3+ The multi-ceramic layer composite structure, each with a thickness of 150 μm. Lower LZO / Y 2 o 3 : Eu 3+ The fluorescence luminescence peak and the stress state equation are as embodiment 1, the lower layer GZO / Y 2 o 3 : Eu 3+ The fluorescence luminescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com