Optical Device Structure and Processing Method of Miniature Double Parallel Reflecting Surfaces

A technology of parallel reflective surfaces and processing methods, applied in optical components, optics, optical surface grinders, etc., can solve the problems of high cost and slow speed, prevent corrosion and fall off, simplify the difficulty, and simplify the fixing and pick-and-place complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

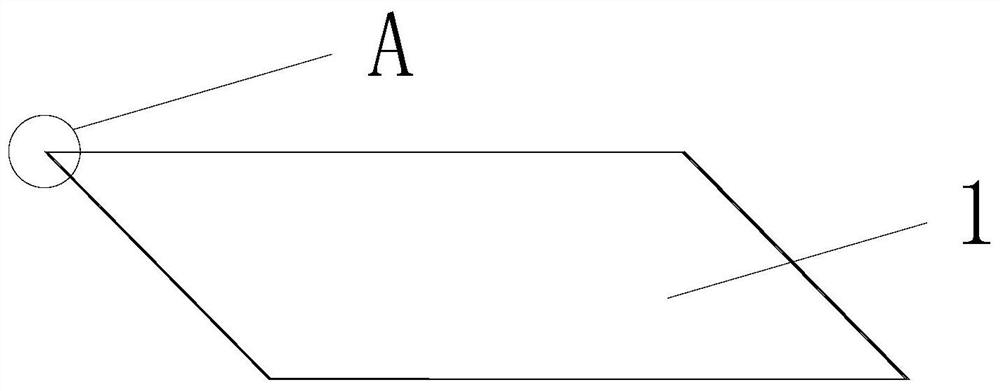

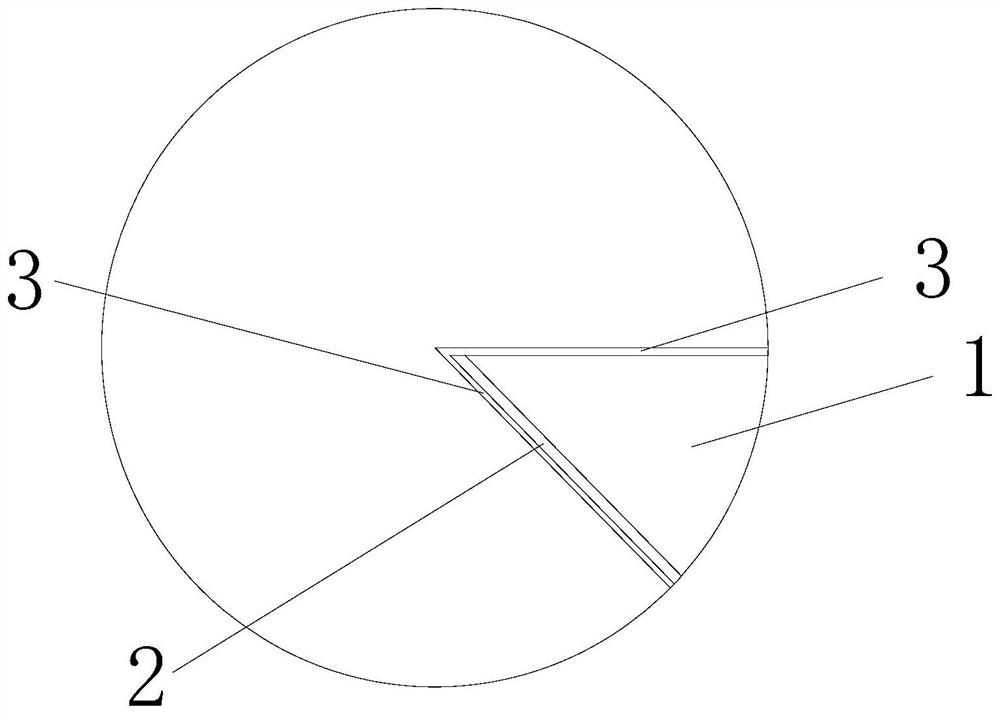

[0054] Such as figure 1 and figure 2 As shown, the present embodiment provides an optical device structure with miniature double parallel reflective surfaces, the optical device structure includes a glass body 1, the glass body 1 has two parallel slopes, and the two slopes of the glass body 1 are provided with Reflective film 2 , anti-reflective film 3 is provided on the two surfaces of the light inlet and outlet of glass body 1 and the outer surface of reflective film 2 .

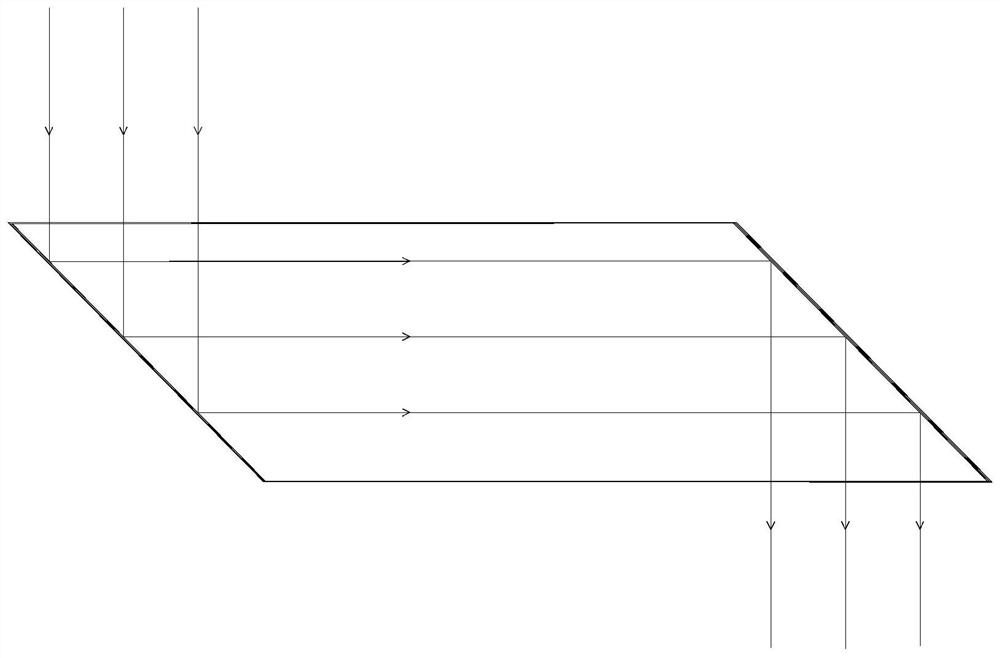

[0055] The upper and lower surfaces of the glass body 1 are used as the light inlet and outlet, from image 3 It can be seen that the direction of the arrow is the transmission direction of the light. The light in this embodiment enters from the upper surface of the glass body 1, is reflected by the reflective film 2 on the left slope, and is transmitted to the right slope on the upper surface of the glass body 1. The reflective film 2 on the right slope is used for reflection, and then output from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com