Longitudinal cutting turning and milling compound machine tool

A compound machine tool, turning and milling technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high failure rate, low failure rate, poor performance of auxiliary accessories and electrical accessories, etc., to avoid vibration and reduce operating noise. , The effect of fast and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the examples.

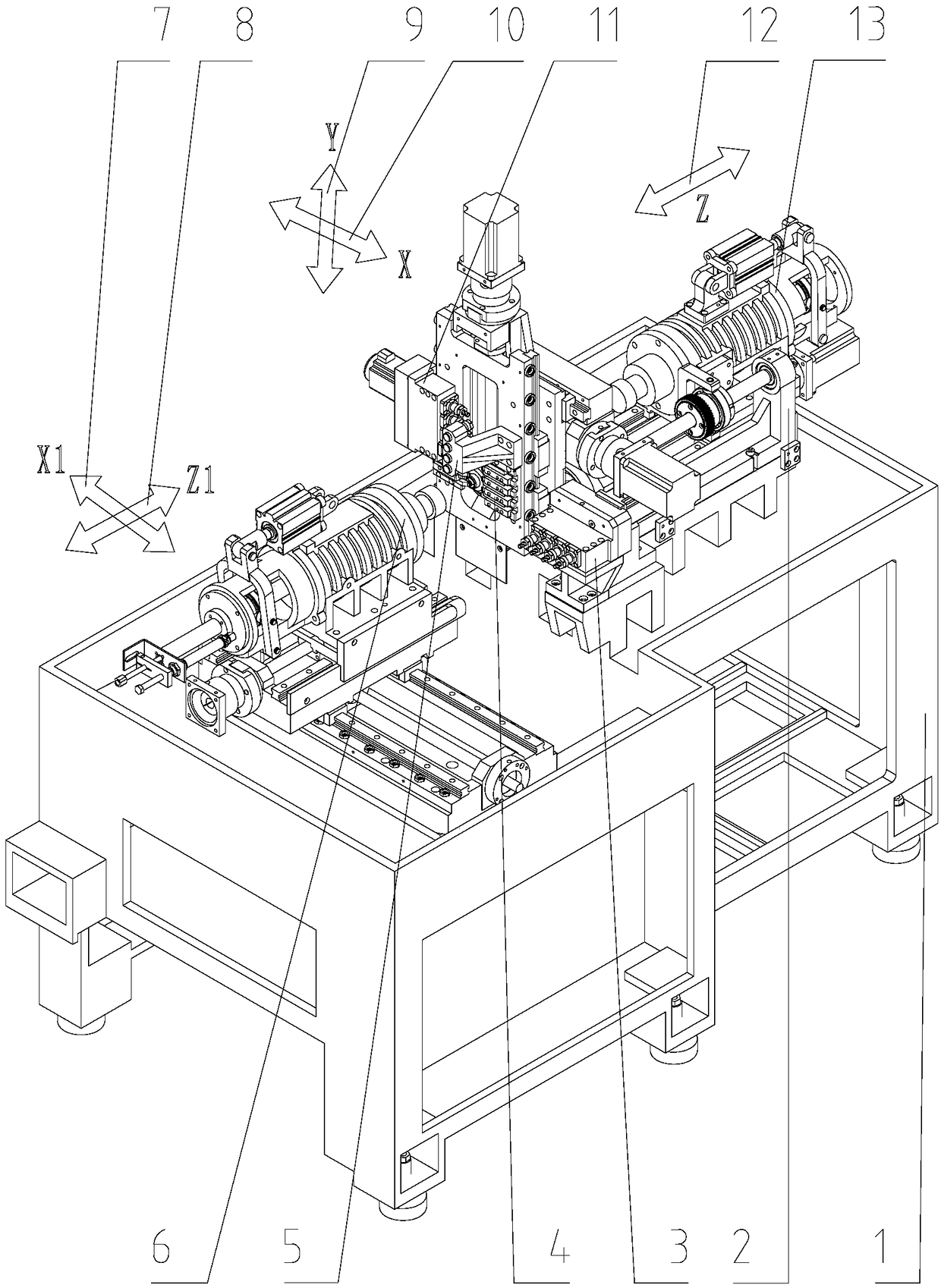

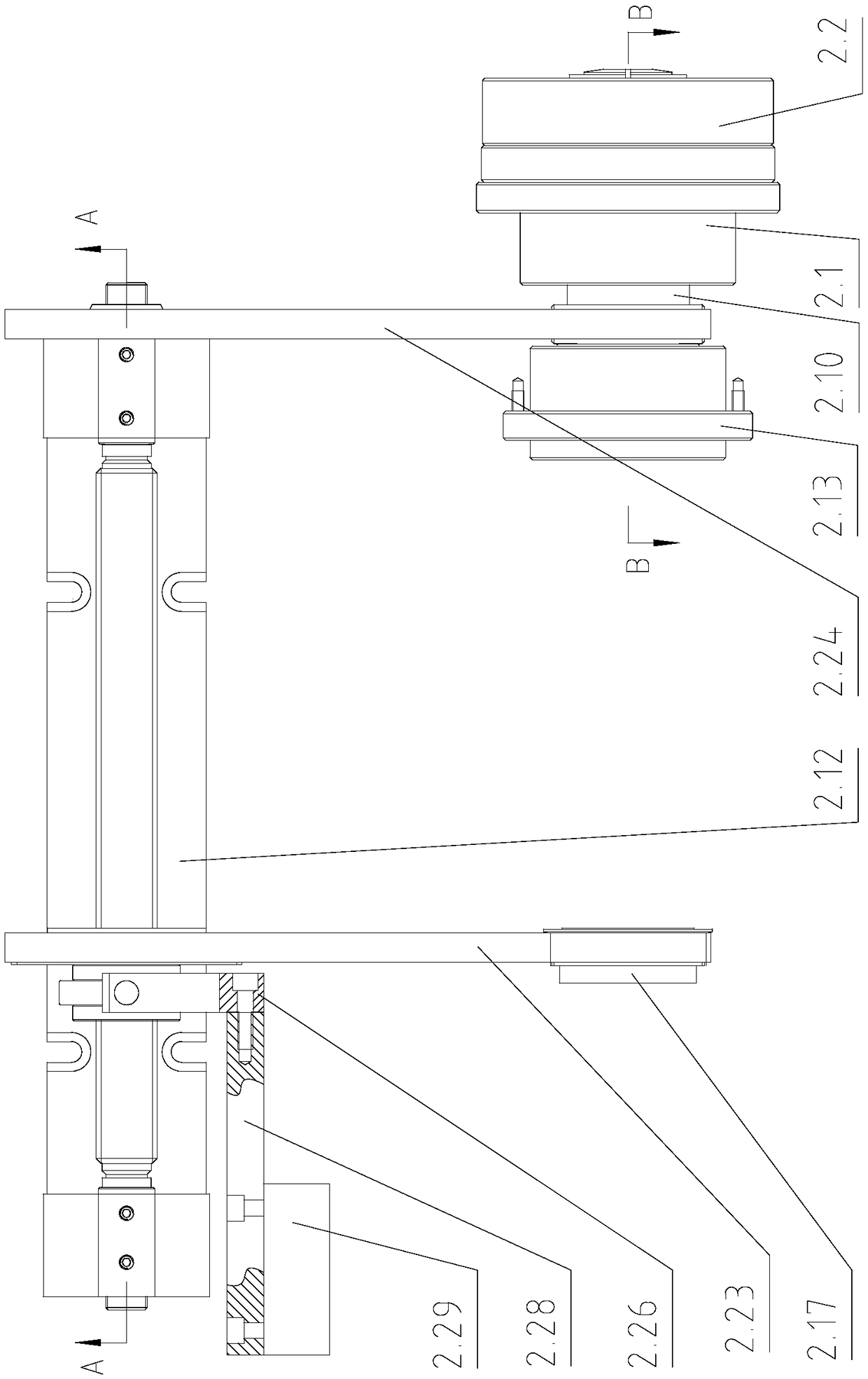

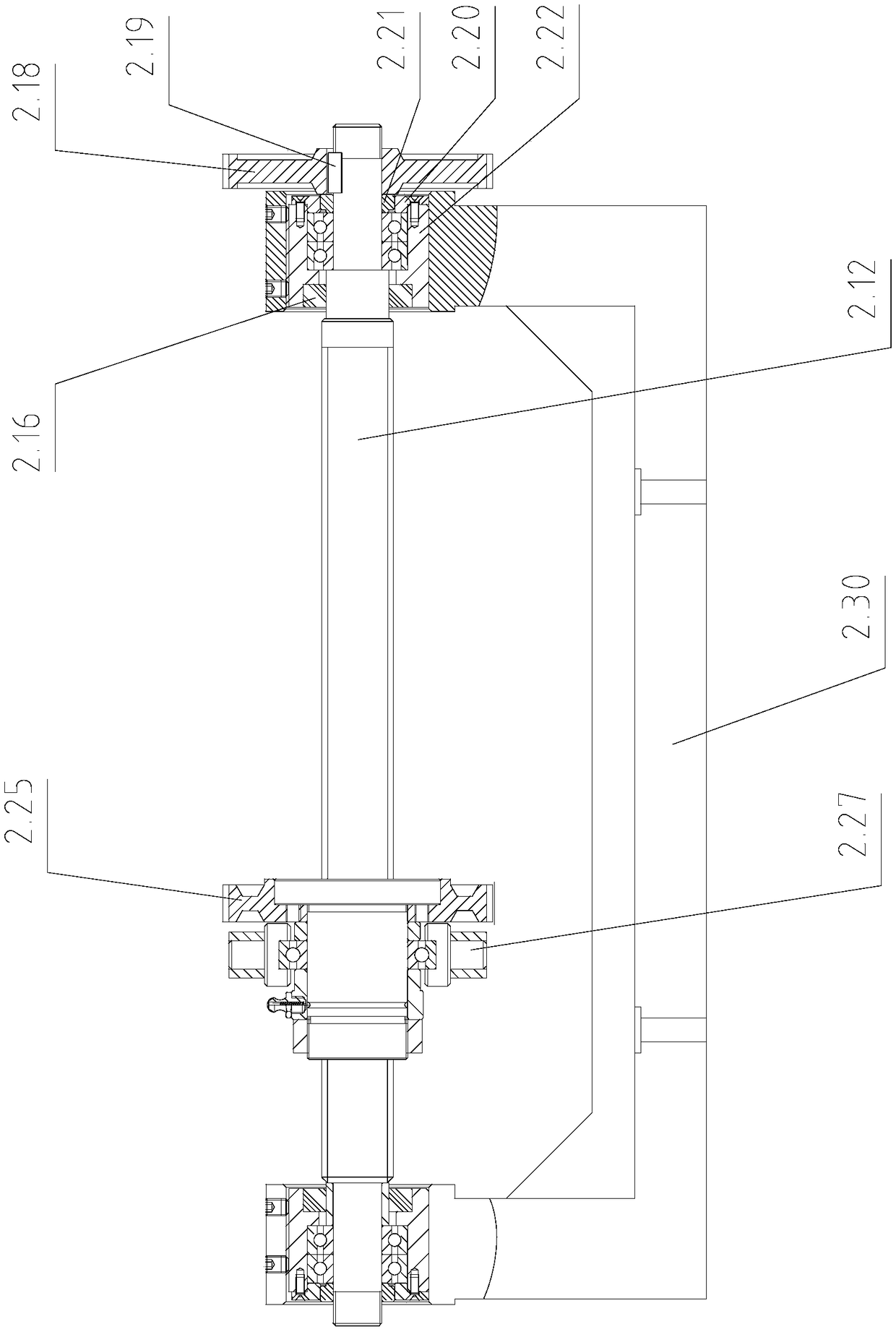

[0043] A longitudinal cutting type turning and milling compound machine tool, including a machine base 1, a synchronous guide sleeve system 2, a tool system, a drive system and a transmission system.

[0044] The base 1 supports the whole machine, and many components are installed directly or indirectly on the base 1. The key point of its design is to ensure the rigidity and stability of the whole machine, and at the same time meet the requirements of sheet metal installation and electrical installation. Requirements, but also to collect coolant and iron filings.

[0045] The drive system includes a main shaft assembly 13 and a sub-spindle assembly 6. The main shaft assembly 13 includes a headstock slide plate 13.1. The headstock slide plate 13.1 is provided with a main shaft housing 13.2. Cylinder base 13.4 and rear position box 13.9 are arranged, cylinder base 13.4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com