Screw wheel structure

A technology of helical wheel and helical blade, which is applied in the fields of liquid, fluid transportation, and mechanical processing. It can solve the problems of affecting the transmission efficiency, being easily stuck between the helical blade and the inner wall of the pipe, and not being able to fit, so as to achieve a good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

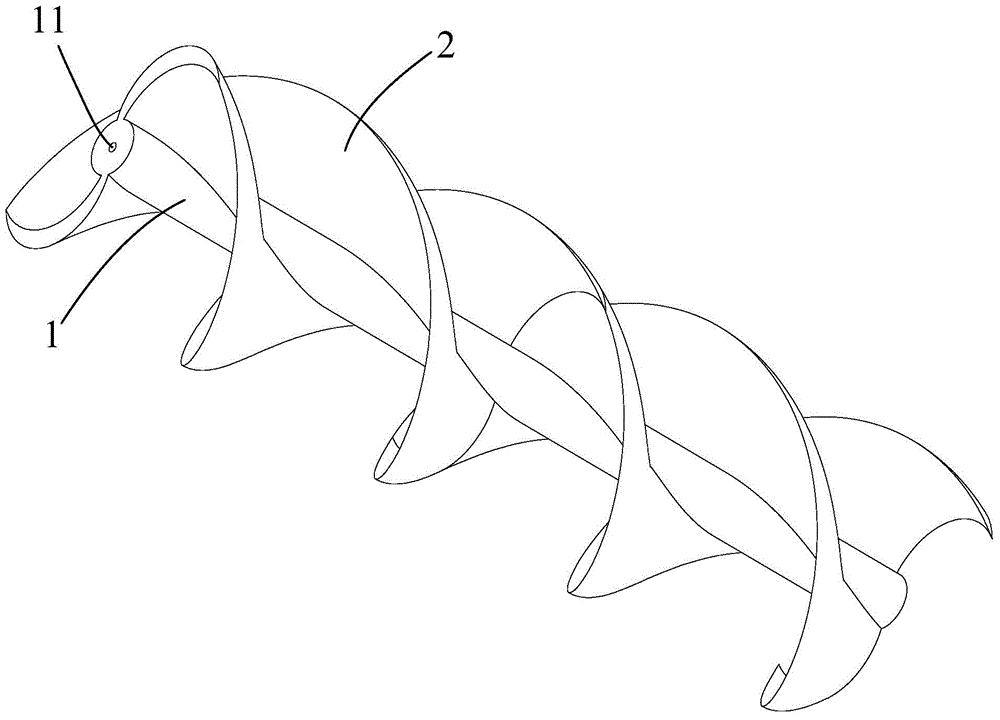

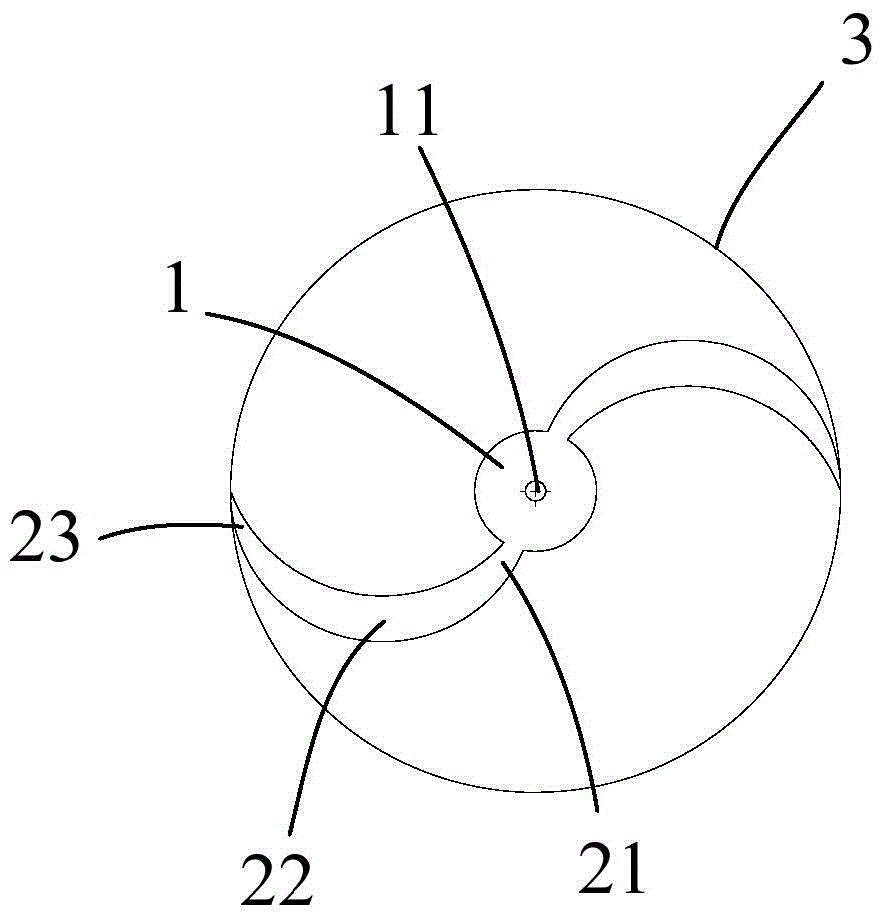

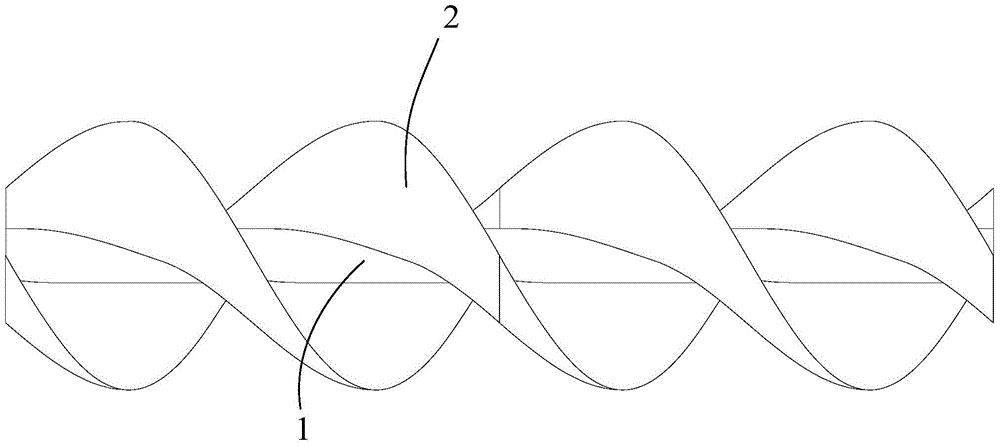

[0029] like Figure 1 to Figure 3 As shown, the present invention provides a helical wheel structure, including a central shaft 1, on which two helical blades 2 are arranged, and the two helical blades 2 spiral alternately on the central shaft 1, and the two helical blades 2 are opposite to each other. The central axis 1 forms a central symmetry. It forms a central symmetry, and realizes uniform stress during transmission or large hole processing. Each helical blade 2 forms at least one complete circle on the central axis 1, and the projection of the helical blade 2 on the central axis 1 is a projection circle 3. The inner edge 21 of the spiral blade 2 is connected to the central shaft 1, and the thickness of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com