Non-conventional type hole combined boring mill

A special-shaped hole and boring machine technology, applied in the field of machine tools, can solve the problems of increasing the repeated positioning error of the piston and affecting the machining accuracy of the piston, and achieve the effects of avoiding machine tool vibration, avoiding the heating of the boring head, and reducing machining errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

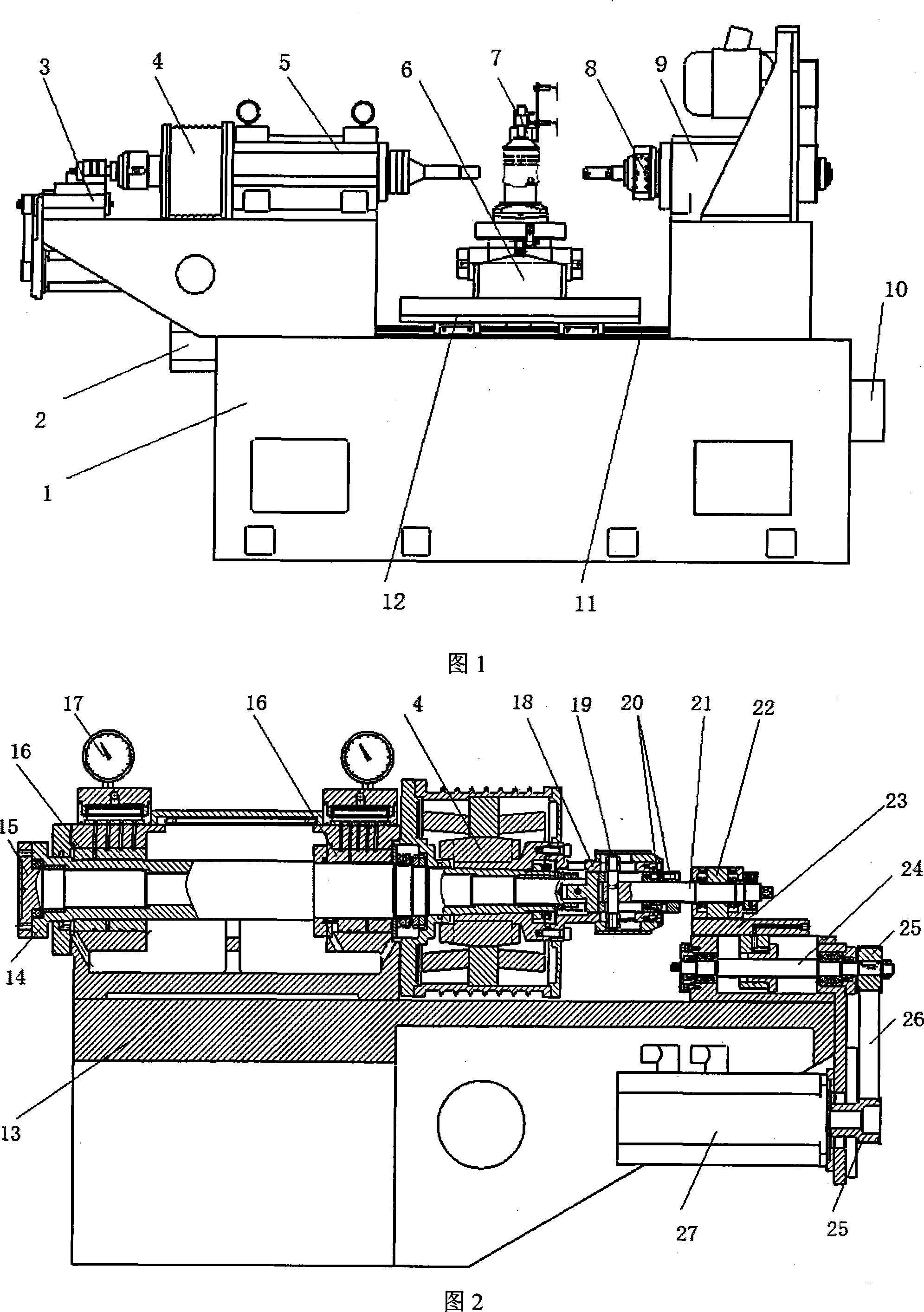

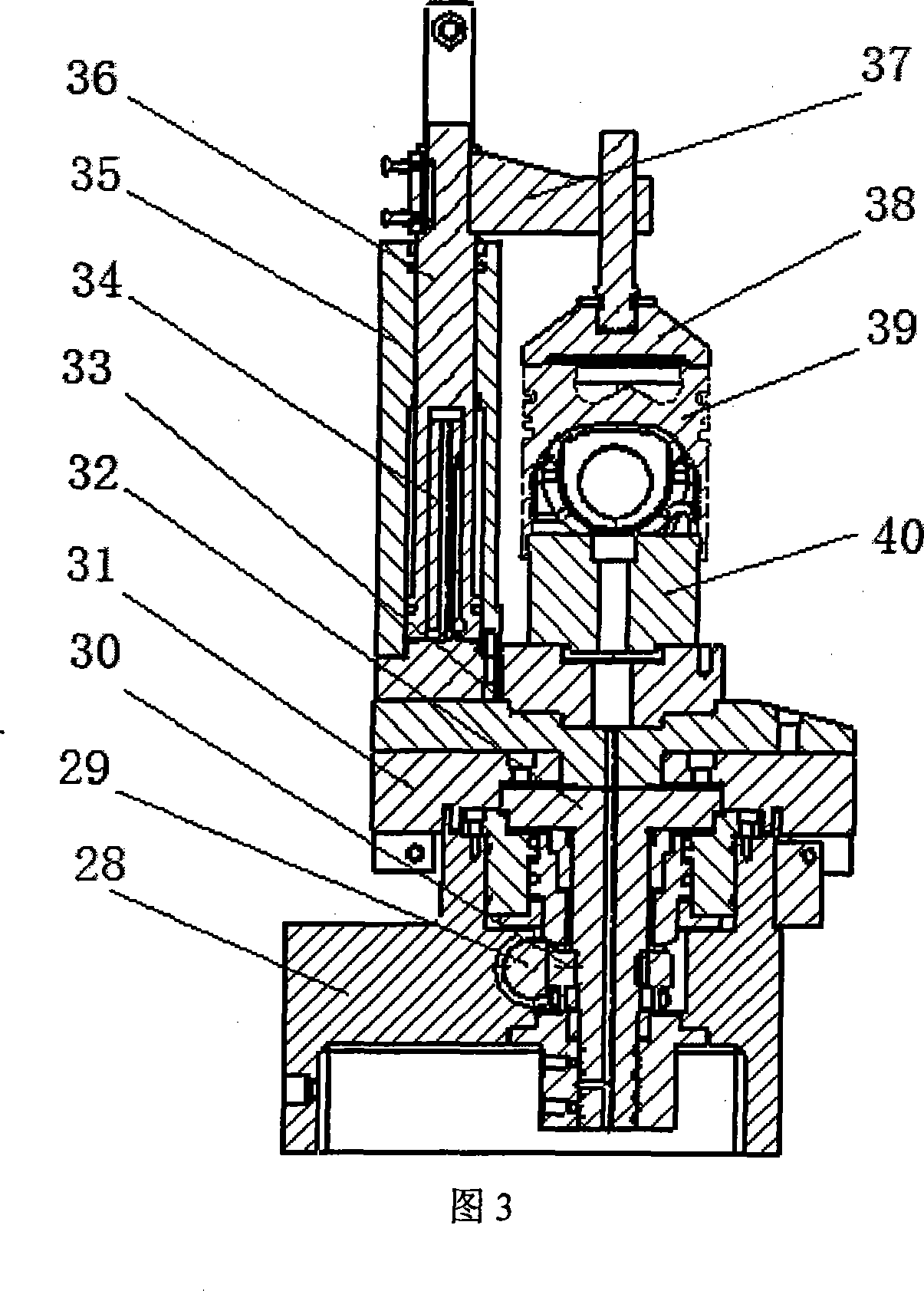

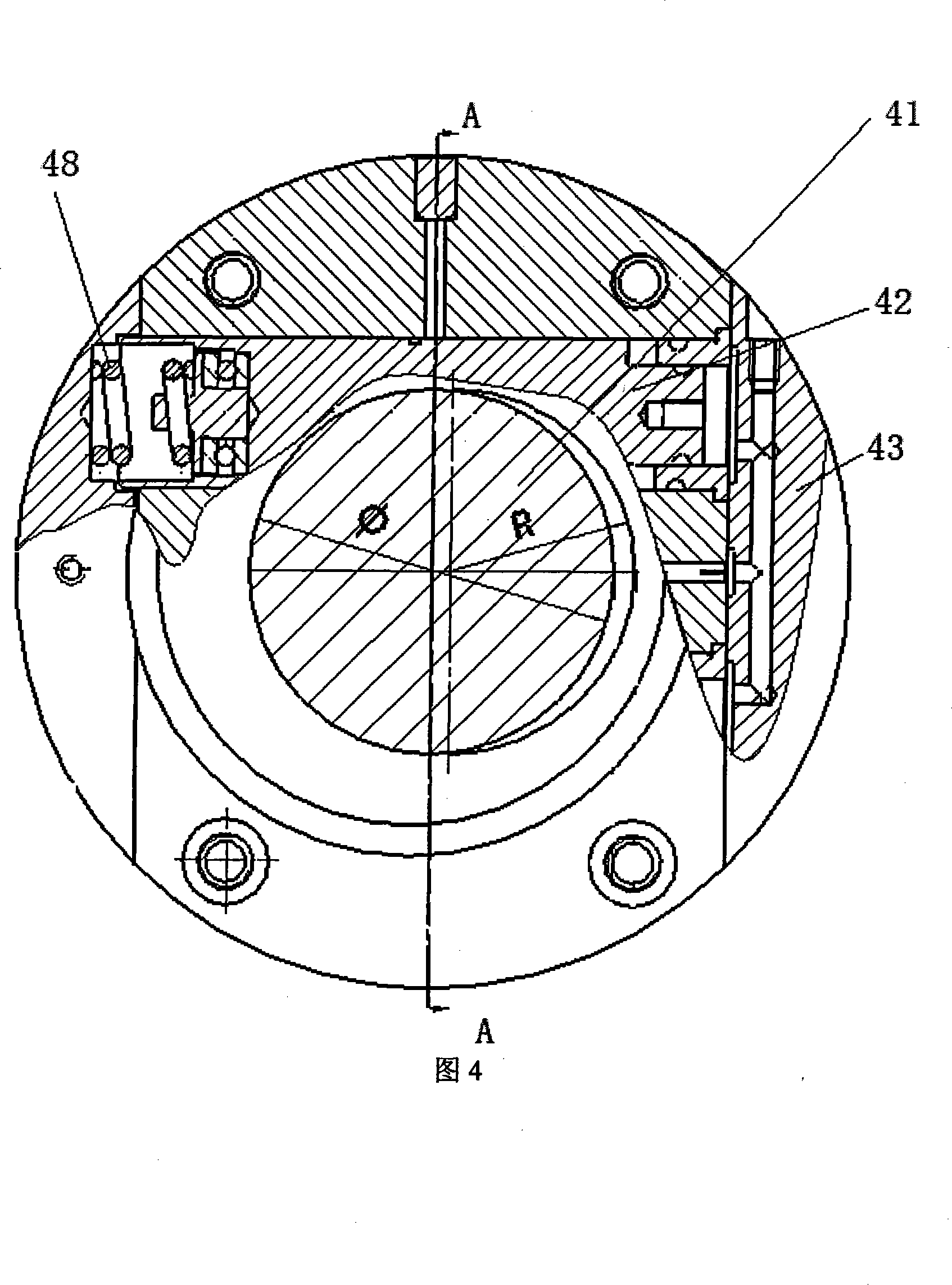

[0021] In Fig. 1, a screw transmission part 2 is installed on the left side of the machine tool base 1, and an automatic lubricating device 10 is installed on the right side. The left side of the upper part of the machine tool base 1 is sequentially equipped with a boring head radial feed mechanism 3, a spindle motor 4 and a small hole throttling type high-speed precision hydrostatic boring head 5. The upper part of the middle part of the machine tool base 1 is provided with a precision linear guide rail 11, and the precision linear guide rail 11 is provided with a machine tool slide 12, and a rotary table 6 is installed on the machine tool slide 12, and a workpiece rotary clamping mechanism 7 is provided on the rotary table 6. . On the upper right side of the machine tool base, a snap ring slot and an inner and outer chamfering spindle box 9 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com