Turbine expansion refrigeration high-speed grinder

A turbo expander and high-speed grinding technology, which is applied in the manufacture of tools, superfinishing machines, grinding/polishing equipment, etc., can solve problems such as unstable machining accuracy, high cost of processing consumables, and little experience in grinding and polishing, and achieve Low processing cost, good stability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

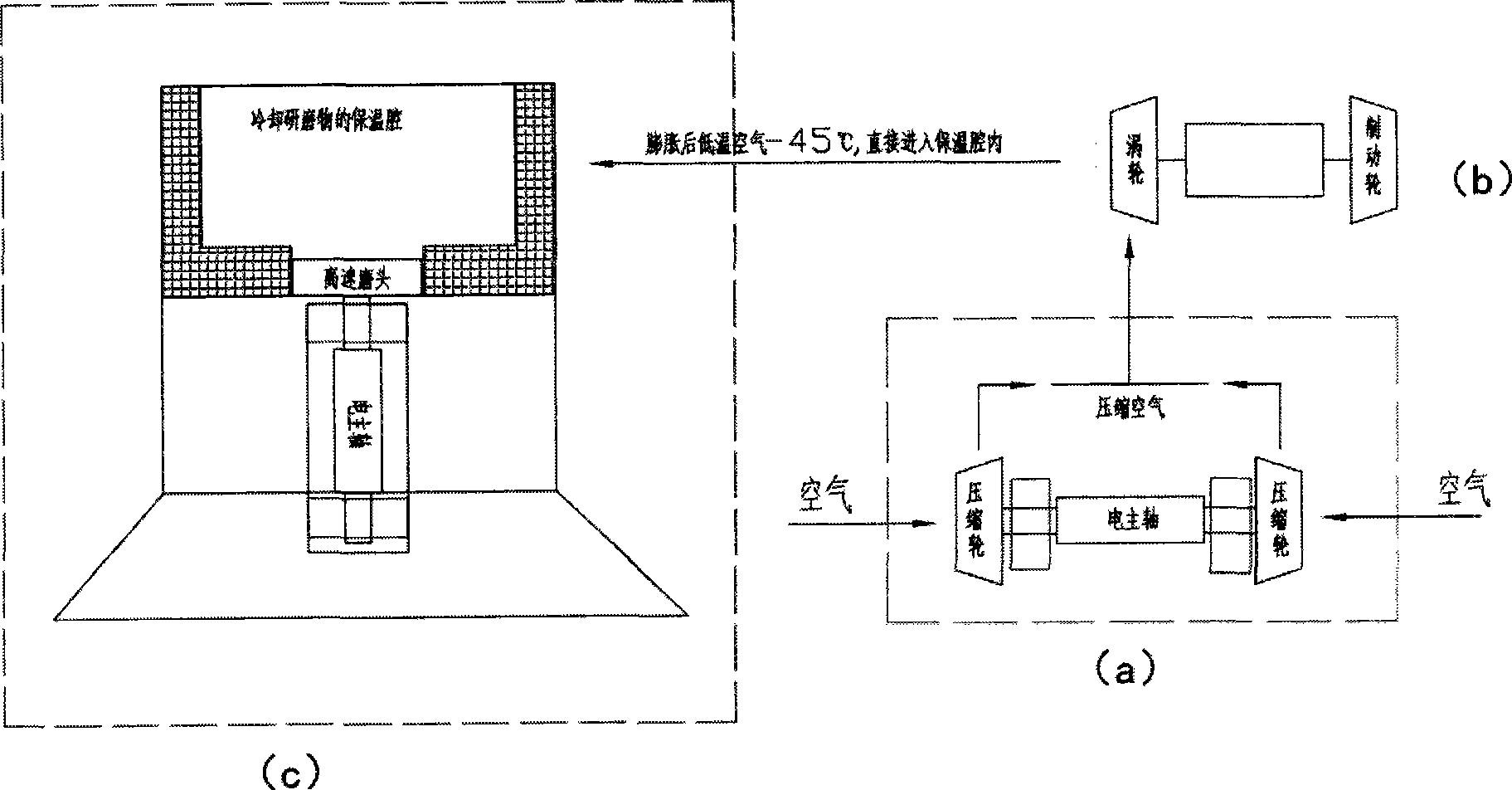

[0013] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the turboexpansion refrigeration high-speed grinder is composed of three parts: a high-speed compressor (a), a turboexpander (b) and a high-speed motor grinder (c). The air is passed into the high-speed compressor (a), the output compressed air enters the turbo expander (b), and then the expanded low-temperature air (-45°C) is directly passed into the insulation chamber of the high-speed motor grinder (c) , In the heat preservation cavity, the electric spindle is used to drive the high-speed grinding head to realize the cooling and grinding of the object. The high-speed compressor (a) is supported by an air bearing, with a rotating speed of 6000rpm, a pressure of 4MPa, and 700m3 / h. The turboexpander (b) is supported by air bearings and used for refrigeration, and its temperature is adjustable within the range of 0 to -60°C. The high-speed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com