Gear wheel pump

A gear pump and gear technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of difficulty in disassembly and assembly, and achieve the effects of reliable transmission, easy disassembly, and high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

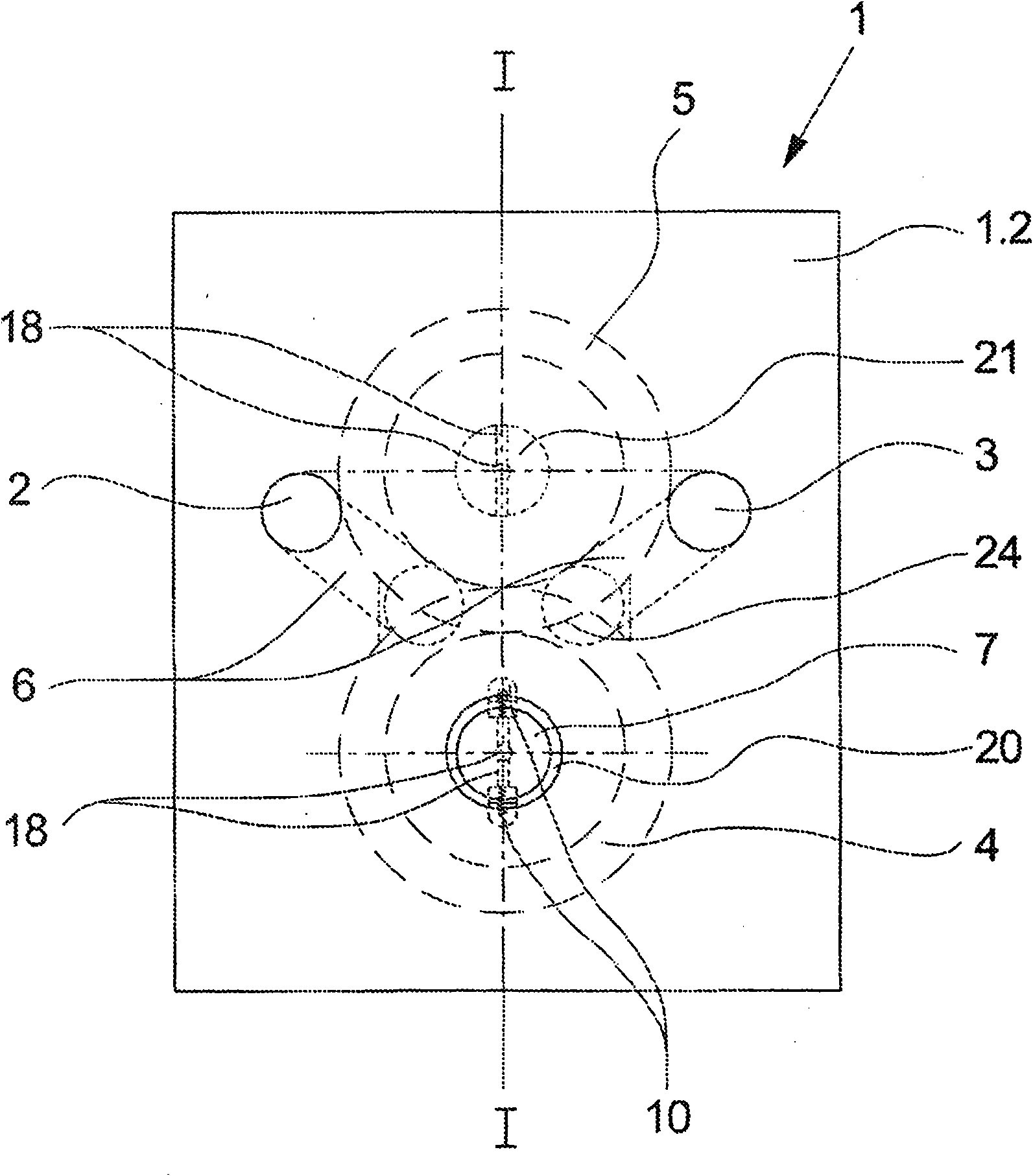

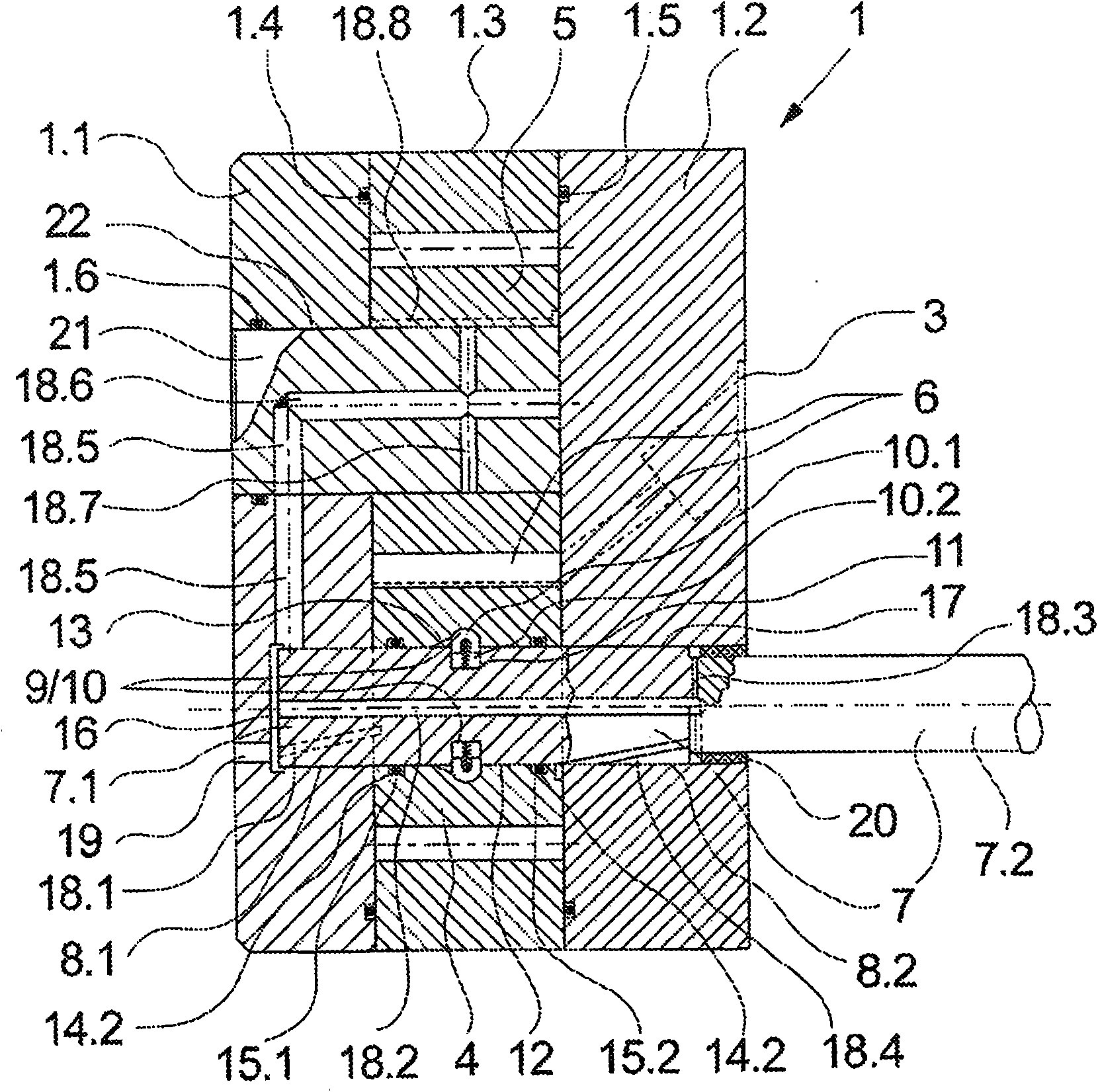

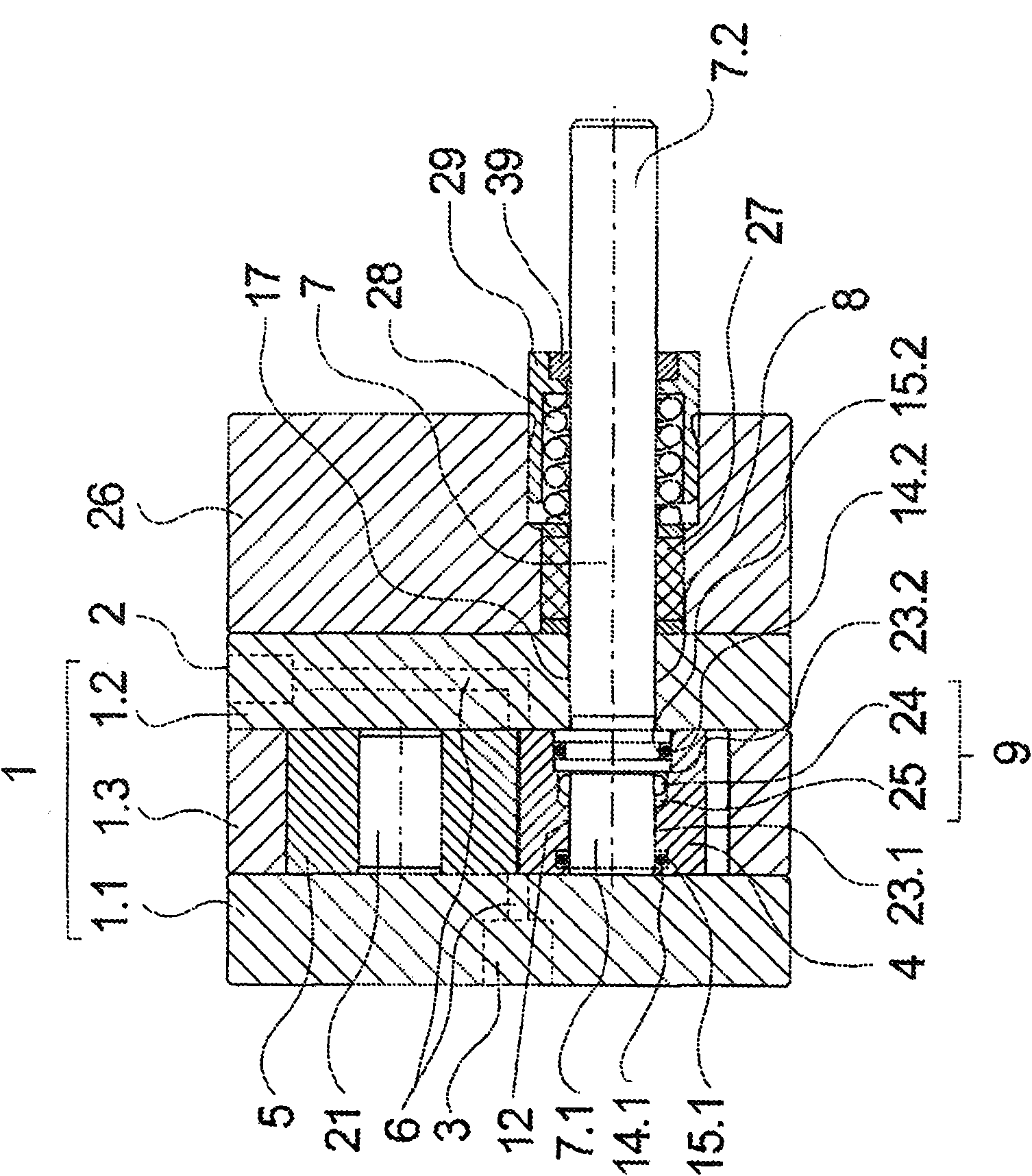

[0033] figure 1 and figure 2A first embodiment of the gear pump of the present invention is shown. figure 1 A front view of the gear pump is shown here, while figure 2 A cross-sectional view of the gear pump is shown. In this regard, the following description applies to both figures, where no particular emphasis is made on one of the figures.

[0034] The gear pump has a pump housing 1 which is multi-part and has housing plates 1.1 and 1.2 and an intermediate plate 1.3 held between the housing plates 1.1 and 1.2. A sealing ring 1.4 and 1.5 is provided on the end faces of the housing plates 1.1 and 1.2, by means of which the gaps between the intermediate plate 1.3 and the housing plates 1.1 and 1.2 are sealed towards the outside.

[0035] The intermediate plate 1.3 has respective openings for the two intermeshing gear wheels 4 and 5. In the overlapping region of the gear wheels 4 and 5, a delivery channel system 6 is formed in the housing parts, which is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com