Machining device for machining tool

A technology for processing devices and processing tools, which is applied in the direction of thread cutting devices, manufacturing tools, metal processing equipment, etc., can solve problems such as inconsistent models, polluted air, and large demand for threaded screws, so as to reduce costs and improve accuracy and efficiency. , the effect of preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

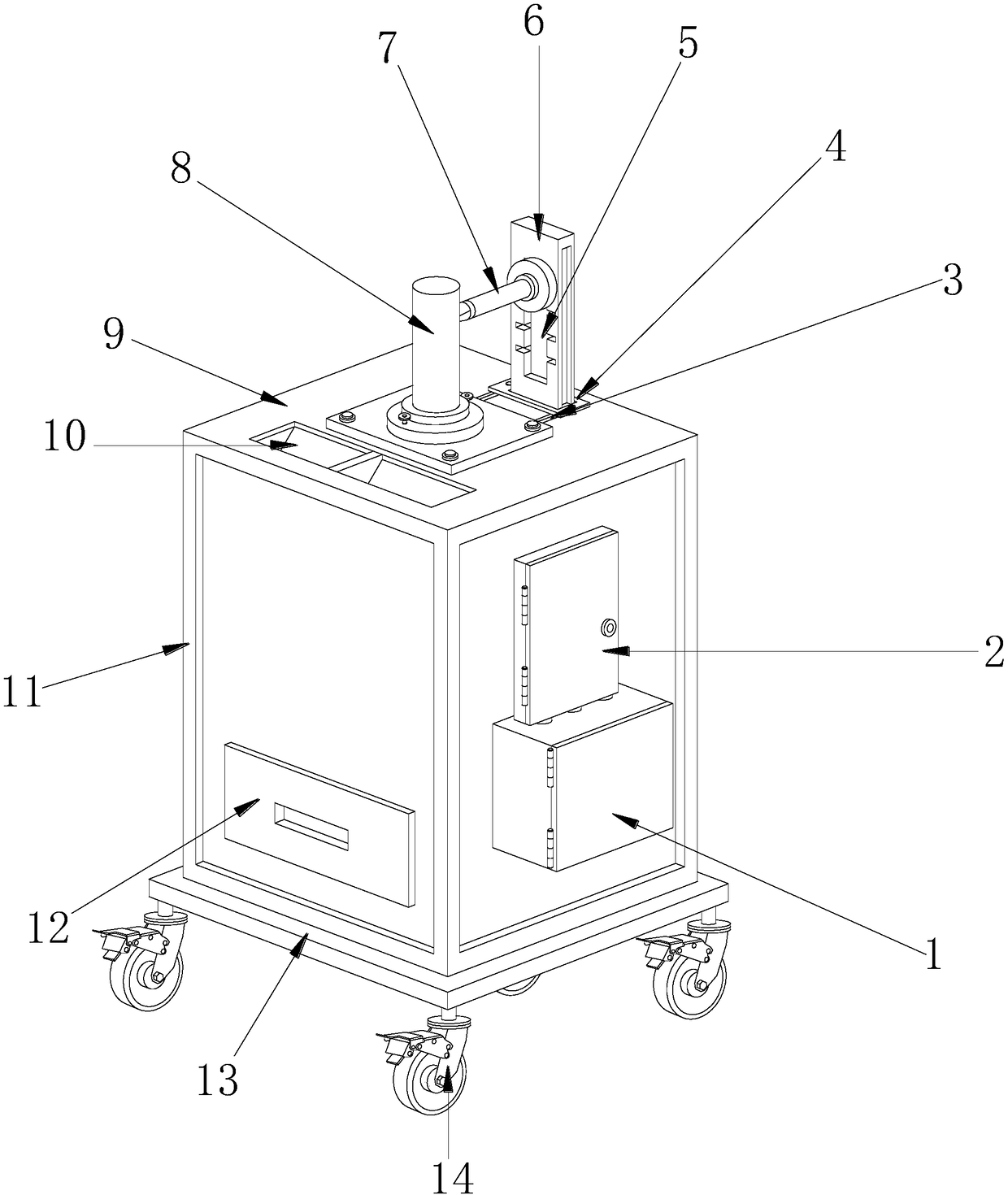

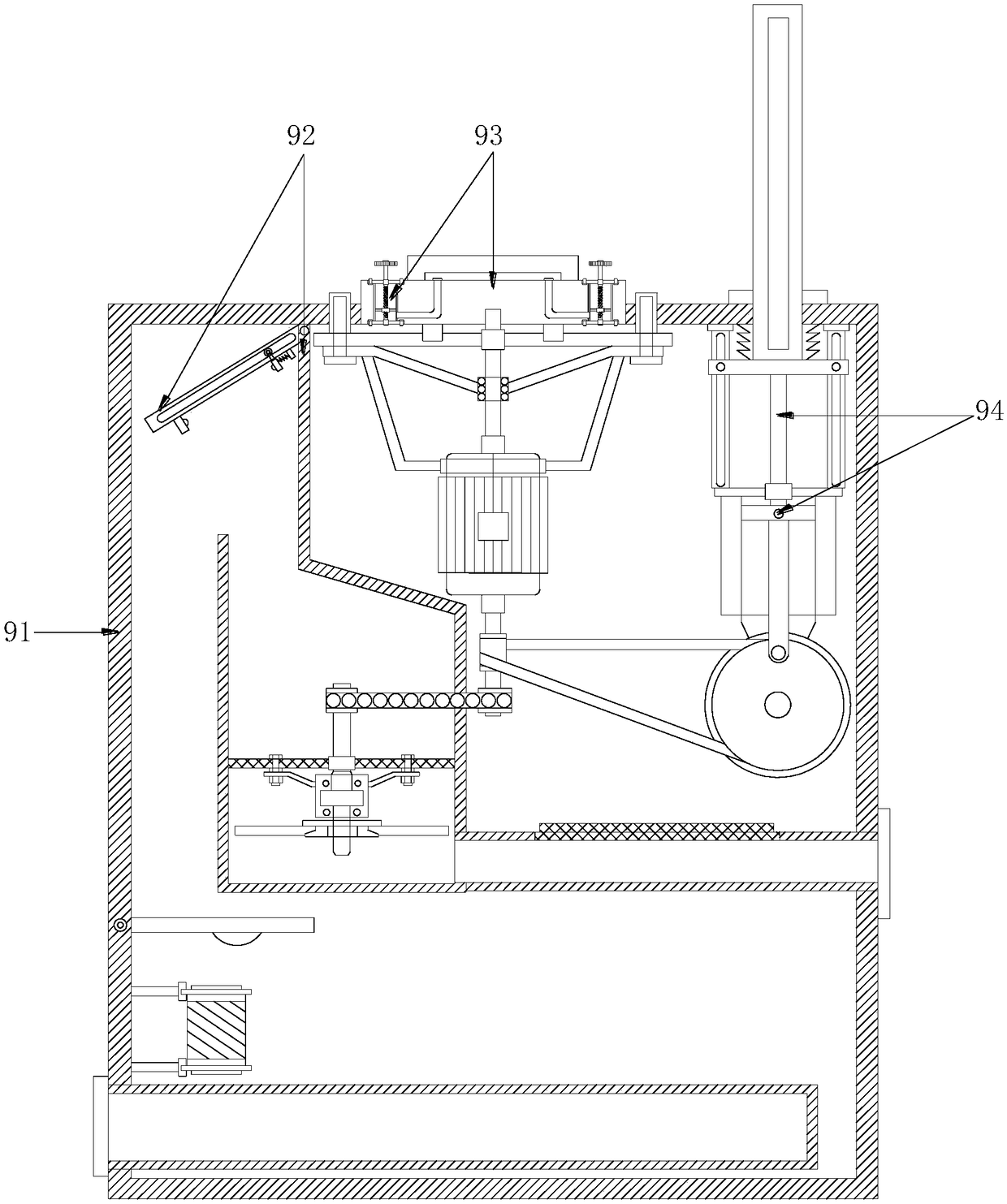

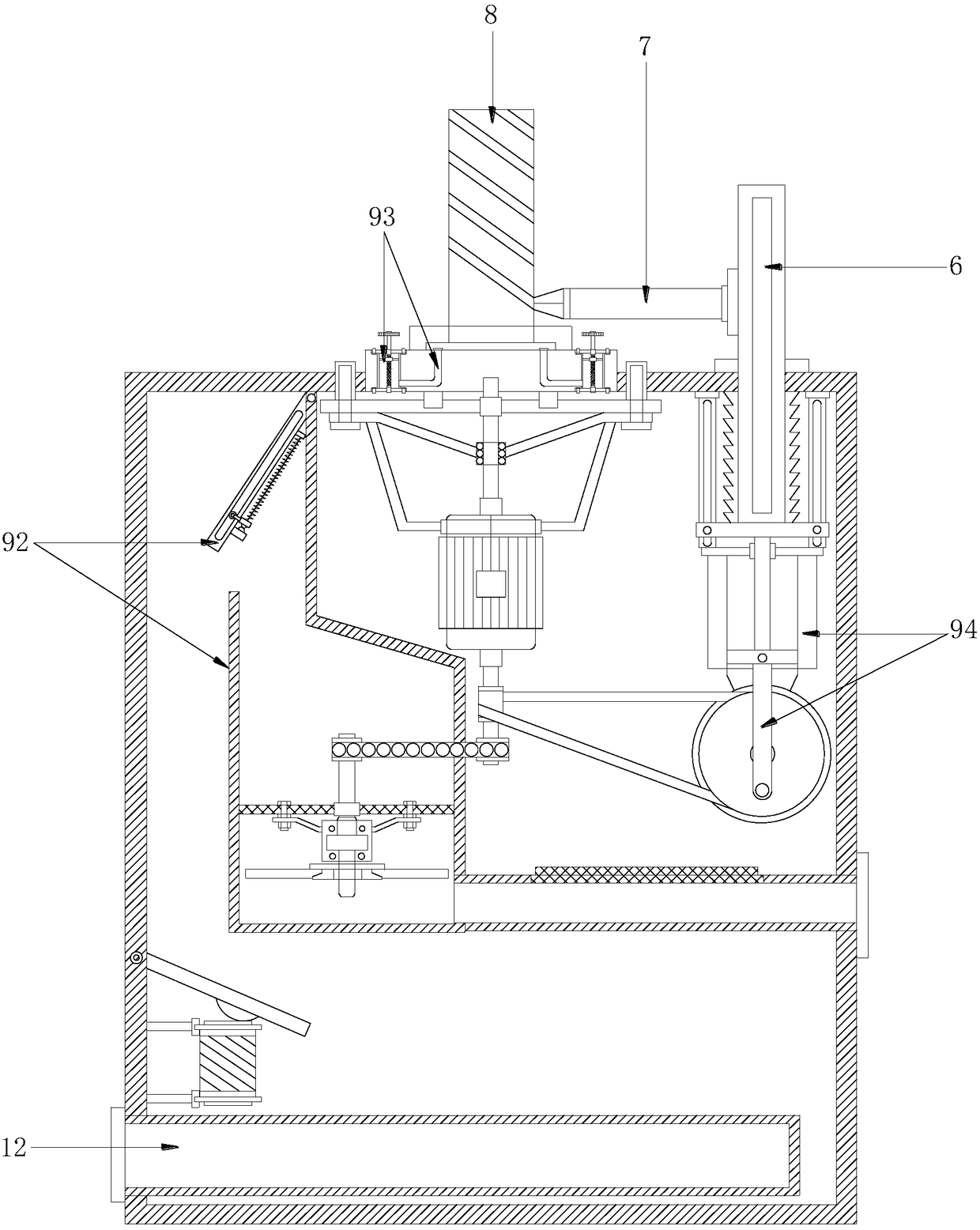

[0025] see Figure 1-Figure 6 , the present invention provides a processing device for processing tools, the structure of which includes a power distribution cabinet 1, a control cabinet 2, a horizontal slide rail 3, a longitudinal slide rail 4, a tool slot 5, a movable rectangular pillar 6, a cutting knife 7, a workpiece 8, a workpiece Thread groove processing device 9, chip feed groove 10, reinforcement frame 11, chip collecting box 12, base 13, casters 14, the bottom of the base 13 is provided with four casters 14 evenly and equidistantly and the two adopt threaded cooperation, the described The top of the base 13 is provided with a workpiece thread groove processing device 9, and the workpiece thread groove processing device 9 is vertically fixed on the groove on the top surface of the base 13, and the outer wall of the workpiece thread groove processing device 9 is provided with a reinforcement frame 11 and two The latter adopts interference fit, the bottom of the reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com