Error sensing compensation method for precision machining

A technology of precision machining and compensation method, applied in the direction of metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of no sensor function, achieve the effect of improving processing accuracy, solving precision machining of machine tools, and achieving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

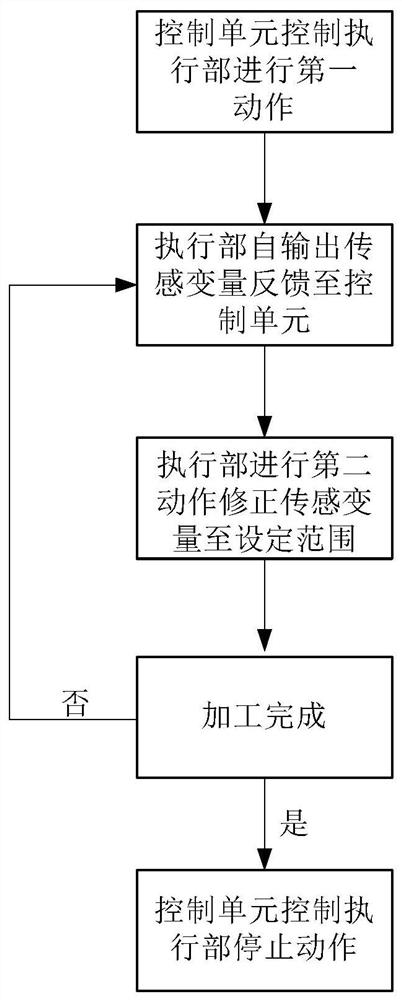

[0047] The invention provides an error sensing compensation method for precision machining, comprising the following steps:

[0048] S1: the control unit receives the processing instruction and outputs the first control command to control the executing part to perform the first action;

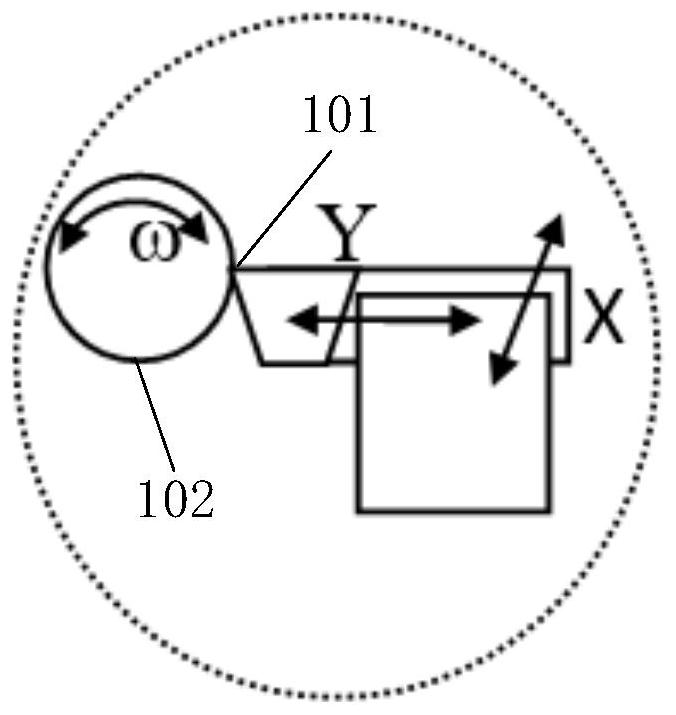

[0049] S2: During the action of the executing part, the sensing variable is self-output and the sensing variable is fed back to the control unit. The detection part of the sensing variable comes from the tool tip 101 of the tool of the executing part. The sensing variable is obtained by changing the frequency parameter.

[0050] S3: The control unit outputs the second control command to control the execution part to perform the second action, thereby correcting the sensing variable to the set range, and performing feedback and command output in real time, so that the correction of the processing sensing variable is performed in real time, thereby ensuring that the workpiece 102 machining accu...

Embodiment 2

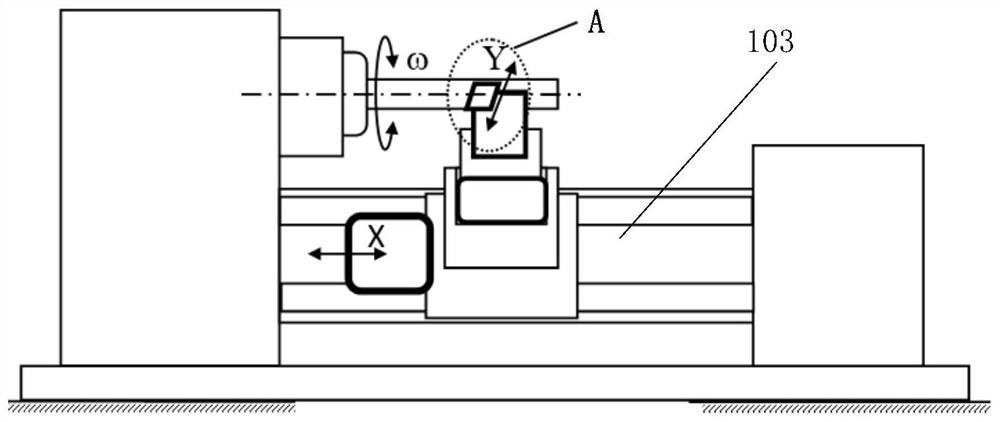

[0066] This embodiment is a preferred example of Embodiment 1.

[0067] In this embodiment, a lathe is taken as an example to describe a method for implementing error sensor compensation in the machining process of the machine tool 103 . In addition, the tool in the present invention is any one or more of piezoelectric material bodies, magnetostrictive material bodies, electromagnetic permanent magnet material bodies, shape memory alloy material bodies, electrostatic material bodies, and phase change material bodies in series. A combination of different material bodies, wherein a multi-body combination comprising the same material body, can also achieve the effects of the present invention through the arrangement of structures. Specifically, the cutting tool includes the use of materials with applied magnetic field or electric field, cold and hot deformation, fluid pressure deformation, and chemical reaction deformation, which can realize signal acquisition and then realize se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com