Method for machining micro-mechanical quartz tuning fork gyro sensitive structure

A quartz tuning fork and sensitive structure technology, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems that cannot meet the accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] The present invention will be further described below with reference to the accompanying drawings and embodiments.

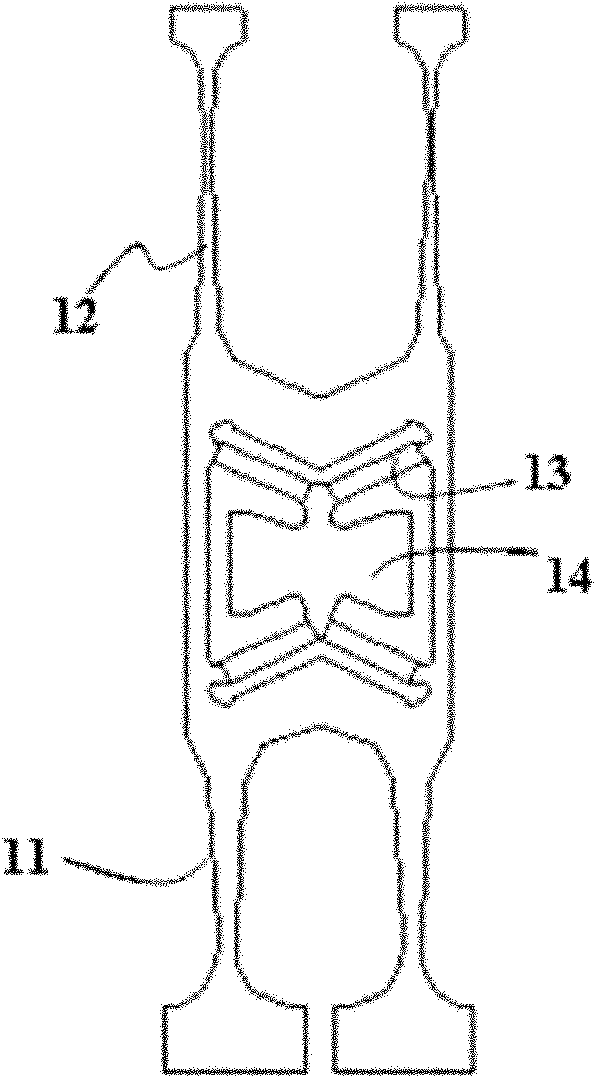

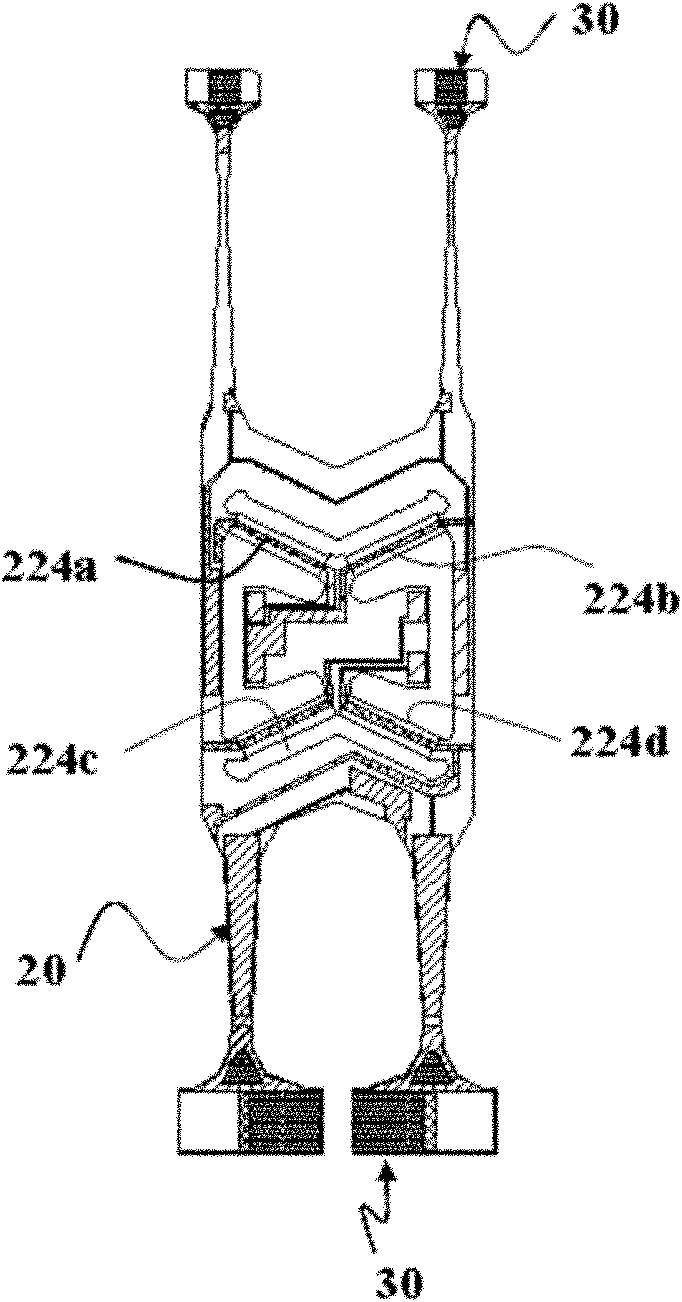

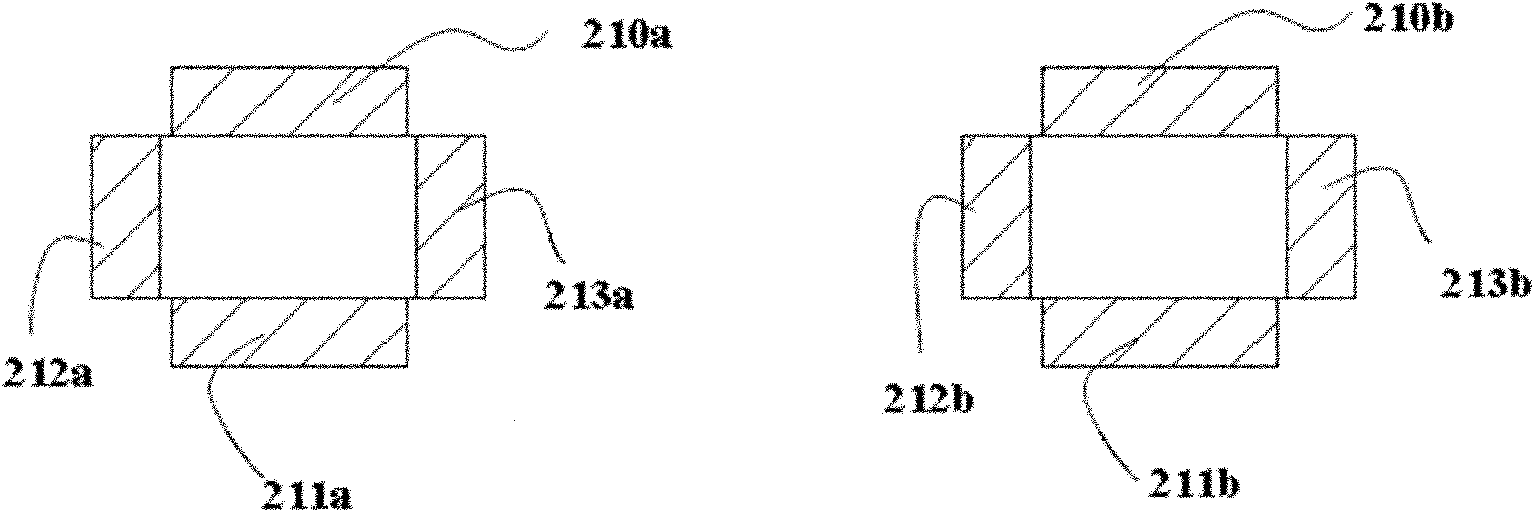

[0055] The H-shaped quartz tuning fork is a three-dimensional quartz structure, and the three-dimensional structure is usually processed by a multi-layer mask combined with photolithography and etching processes in micromachining. In order to improve the machining accuracy of the gold balance mass, it is necessary to process the gold balance mass by gold electroplating. In order to improve the machining accuracy of the surface electrode, the surface electrode pattern must be transferred to the surface of the tuning fork structure by photolithography before the quartz structure is corroded. Therefore, it is necessary to consider the process compatibility of three-dimensional quartz structure processing, gold balance mass electroplating processing, and electrode pattern processing in the process route, and design the processing steps reasonably.

[0056] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com