Swing type ultrasonic vibration drill

An ultrasonic vibration and shaking head technology, which is applied in portable drilling rigs, boring/drilling, drilling/drilling equipment, etc., can solve problems such as poor processing precision, achieve safe operation, broad application prospects, and large application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

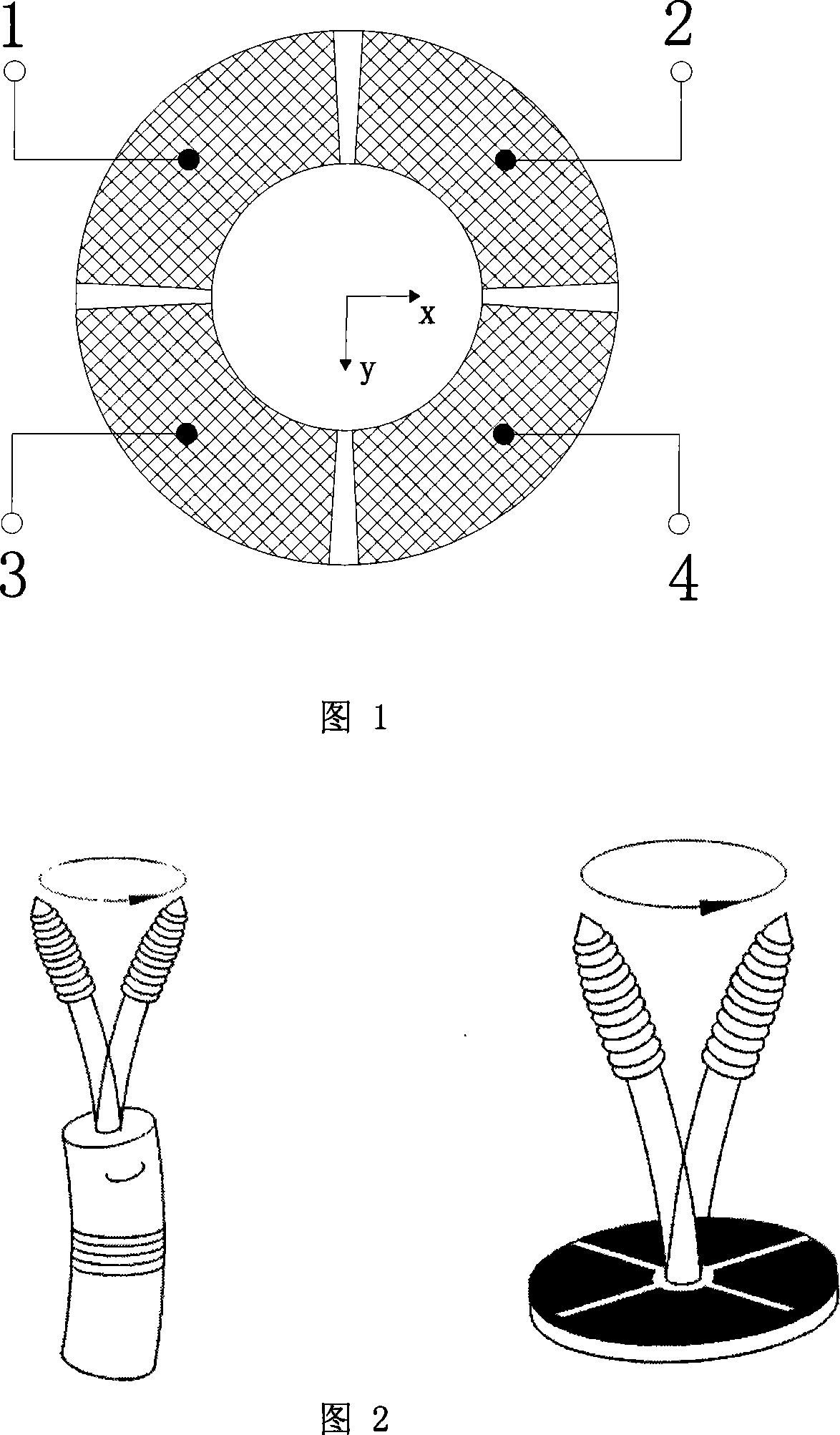

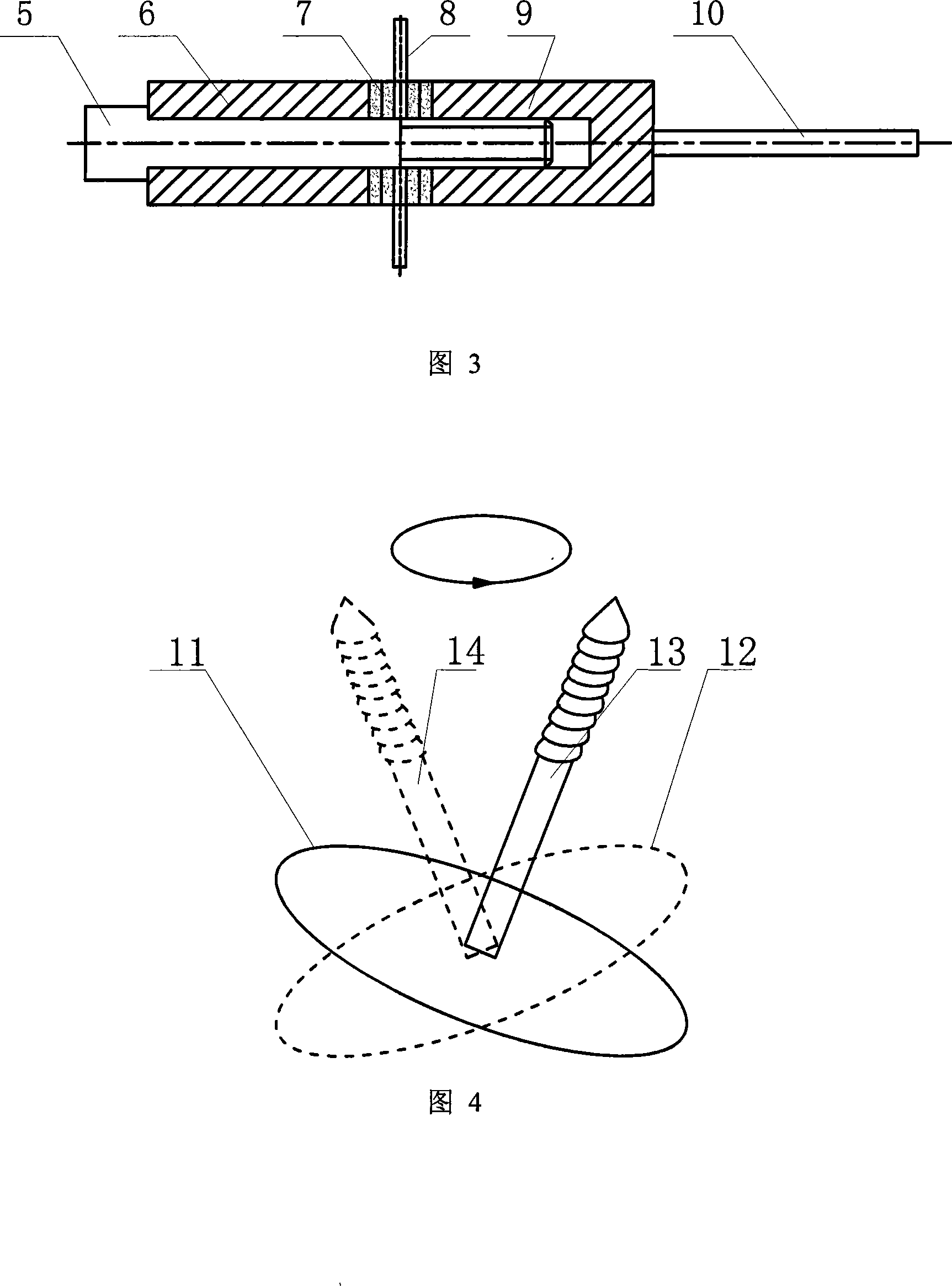

[0017] The working principle and specific implementation of the oscillating head ultrasonic vibration drill will be described below based on the four fan-shaped electrode partitions of the piezoelectric ceramic ring shown in FIGS. 1 to 4 as an example.

[0018] As shown in Figures 1 to 4, the oscillating head ultrasonic vibration drill of the present invention is mainly composed of a stator assembly, a rotor and a drill bit, and is characterized in that: the stator assembly is a piezoelectric ceramic ring polarized in one axial direction 7 is fixed on the stator plate 8, and the stator plate 8 acts as a flange. The first and second stator bodies 6 and 9 are pressed on both sides of the stator plate 8 to provide a certain pre-pressure. The surfaces of the piezoelectric ceramic ring 7 are respectively Four fan-shaped electrodes with even partitions are plated; the stator rod is a rod-shaped rotor, the bottom is fixed near the center of the end of the second stator body, and a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com