A glass microstructure processing method

A glass microstructure and processing method technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of large surface roughness, affecting the performance of glass microstructures, micro-crack damage, etc., to improve the surface quality. , The effect of reducing subsurface damage and surface roughness and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

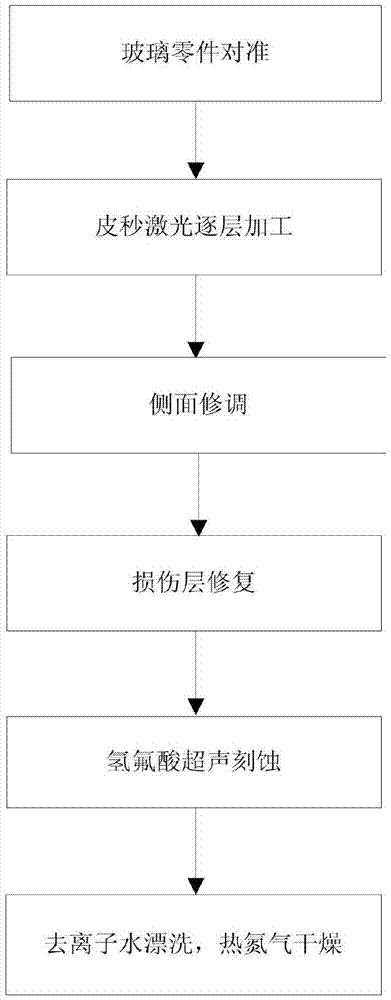

[0026] The present invention as figure 1 shown in the following steps:

[0027] The first step is to adjust the position of the glass parts.

[0028] Put the glass part to be processed into the processing tool, observe it through the CCD alignment device, and adjust the X, Y, Z axis and the rotation axis around the Z axis to make the part at the processing origin.

[0029] The second step is to use picosecond laser layer-by-layer material removal processing technology to process glass parts.

[0030] Use the laser with a wavelength of 355nm to 1064nm, a power of 10W to 50W, and a pulse frequency of 5ps to 25ps to process glass parts layer by layer, and scan the laser on the glass surface through a vibrating mirror to realize the processing of the required graphics. After each layer is processed, adjust the Z axis, and then repeat the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com