Patents

Literature

52results about How to "Does not change properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

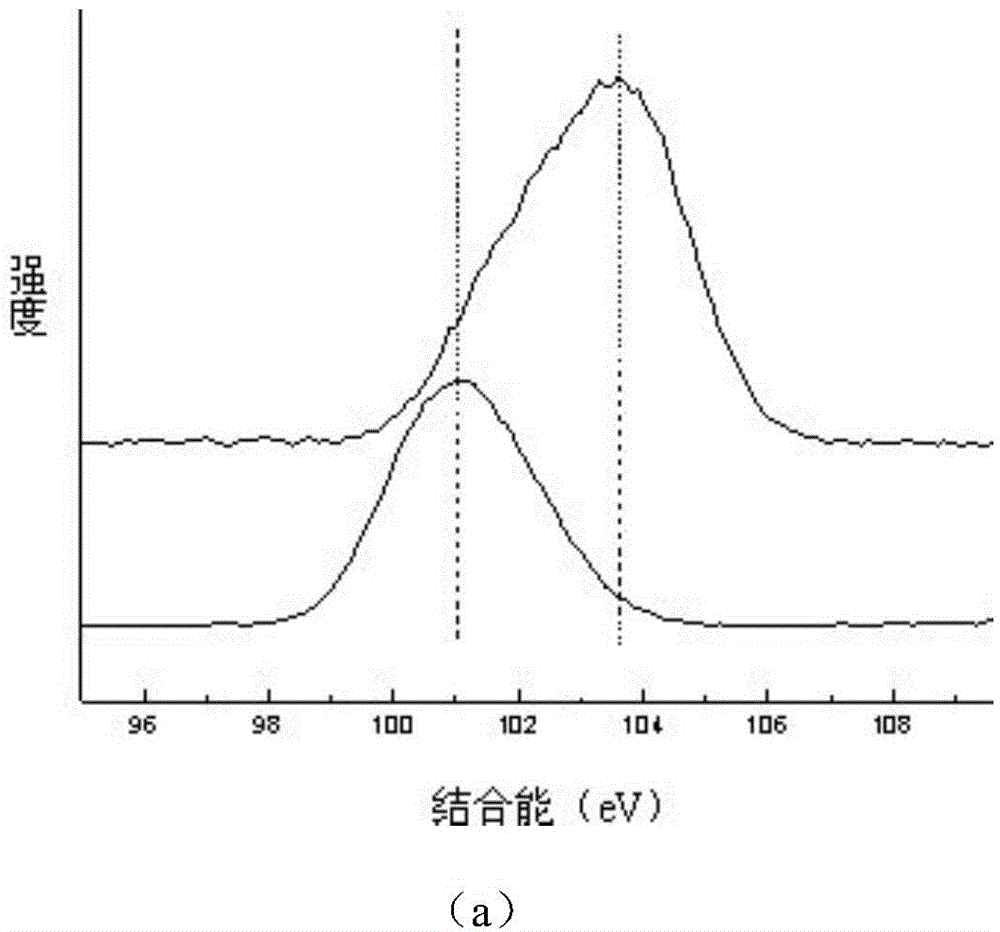

Method for preparing monolayer molybdenum disulfide quantum dots based on electronic dynamic regulation and control

ActiveCN106905966AHigh yieldPromote absorptionCatalyst activation/preparationNanotechnologyPhotoablationLaser scanning

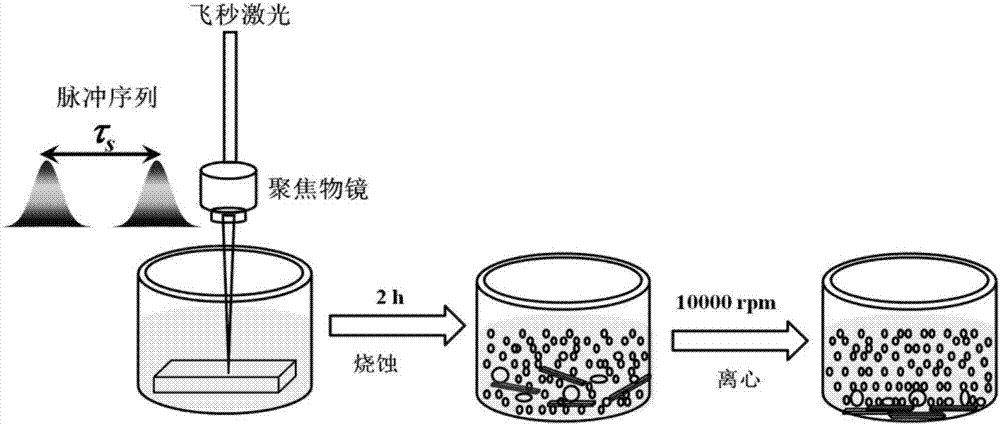

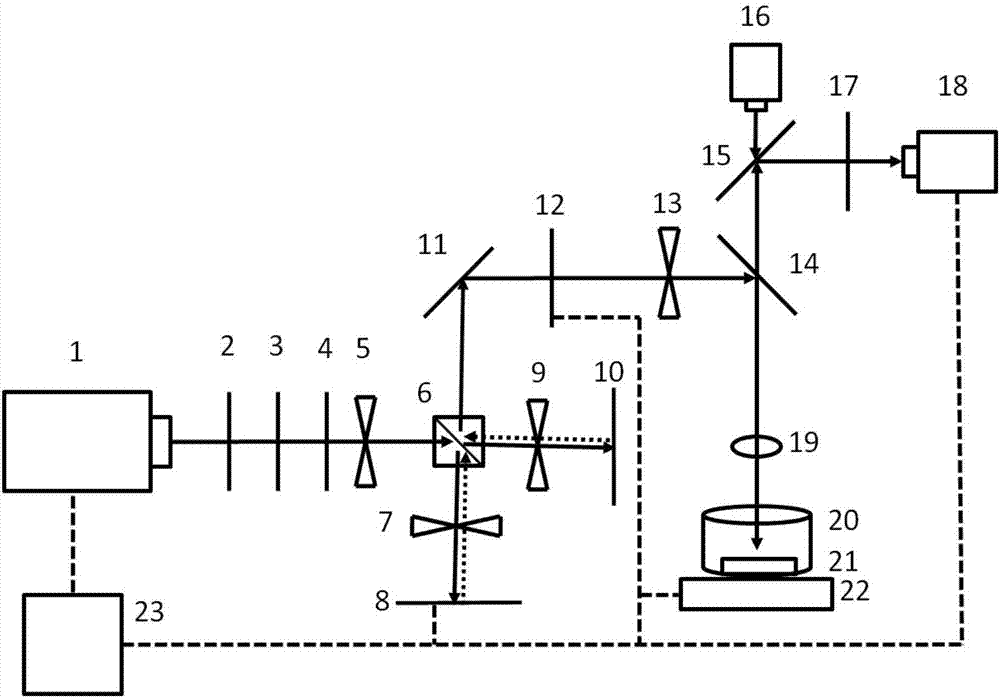

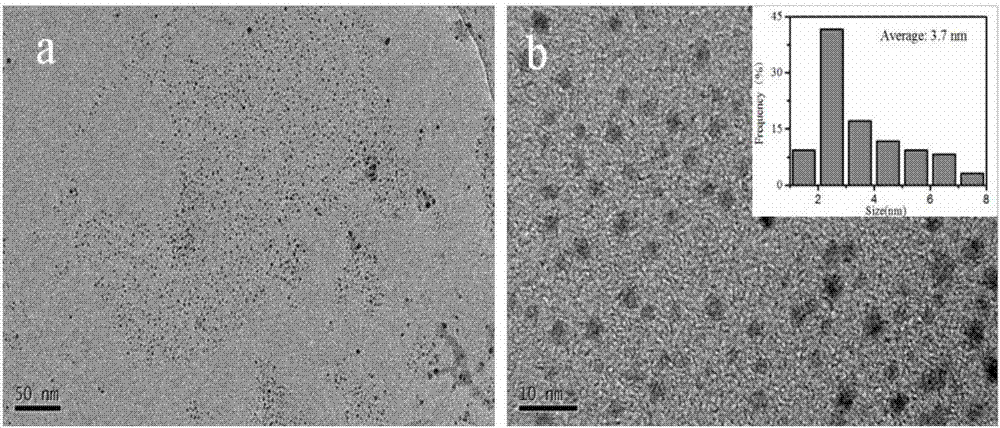

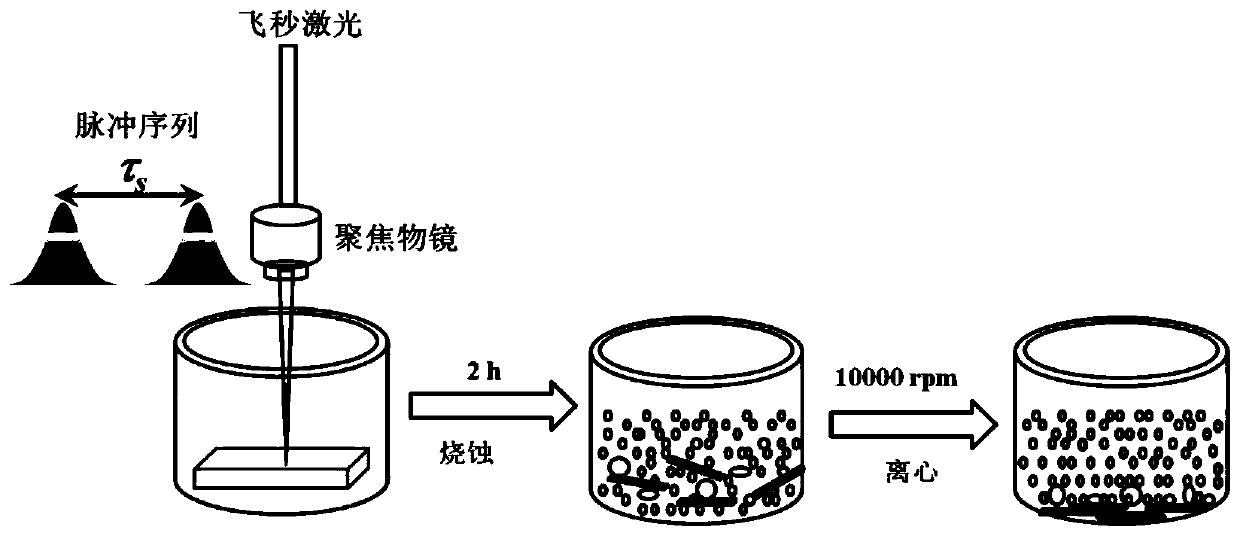

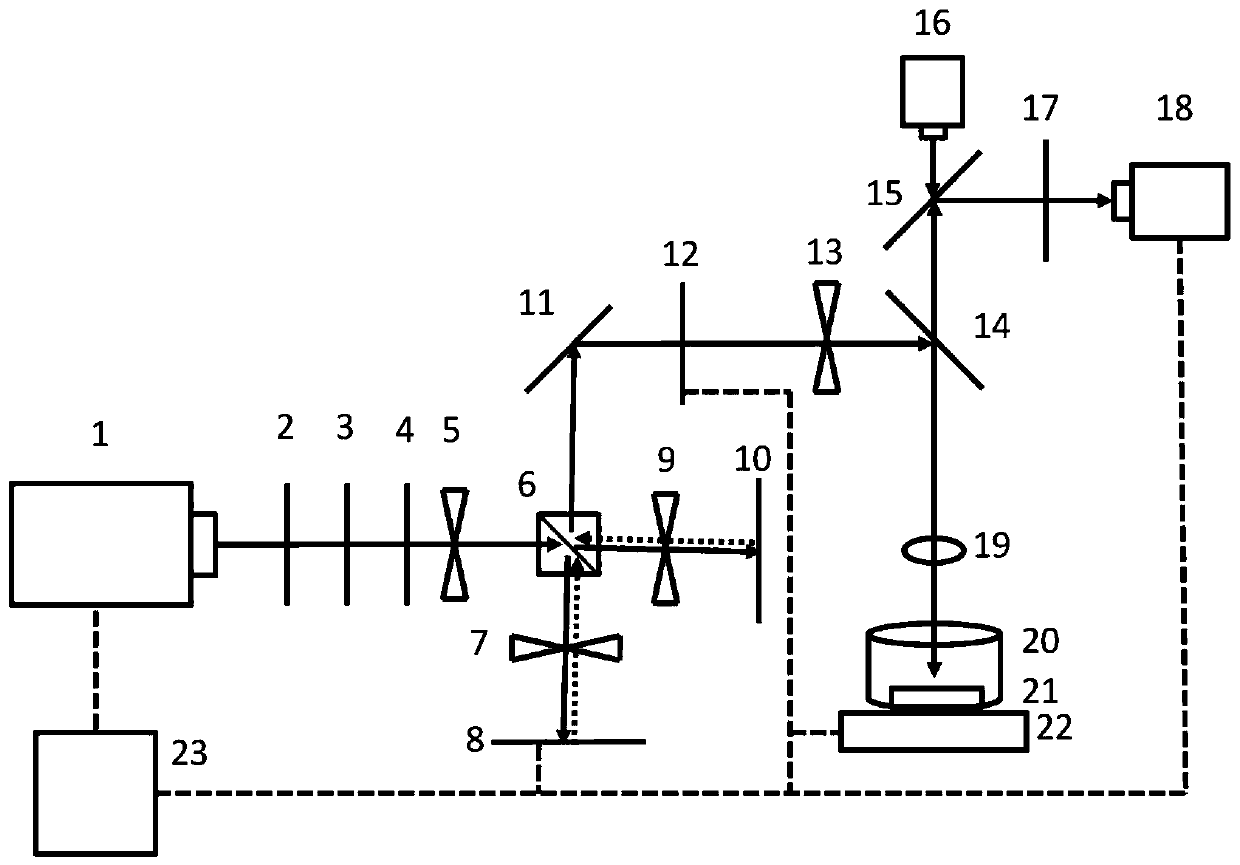

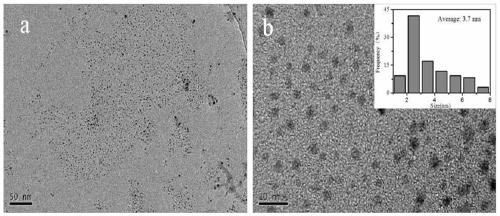

The invention relates to a method for preparing monolayer molybdenum disulfide quantum dots based on electronic dynamic regulation and control, in particular to a method for obtaining the monolayer molybdenum disulfide quantum dots with uniform particle sizes by obtaining molybdenum disulfide suspension and then centrifugally separating and belongs to the field of femtosecond laser application. The method disclosed by the invention comprises the following steps: aiming at the characteristics of a molybdenum disulfide material, carrying out pulse shaping on traditional femtosecond laser monopulse by using a Michelson interferometer to form a pulse sequence; adjusting energy of the pulse sequence, delay among sub pulses, laser scanning speed and scanning intervals; ablating blocky molybdenum disulfide in water and further regulating and controlling local transient electronic dynamics in the interaction process of laser and the material to form multistage photoablation monolayer molybdenum, and obtaining the monolayer molybdenum disulfide quantum dots with the uniform particle sizes; carrying out laser-induced water dissociation to enhance light absorption and improve the yield of the molybdenum disulfide quantum dots. The method disclosed by the invention has the advantages of no need of special chemical environment or chemical reagent, greenness, no pollution, and simple and flexible operation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

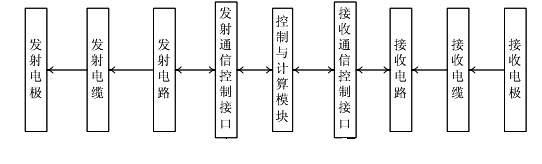

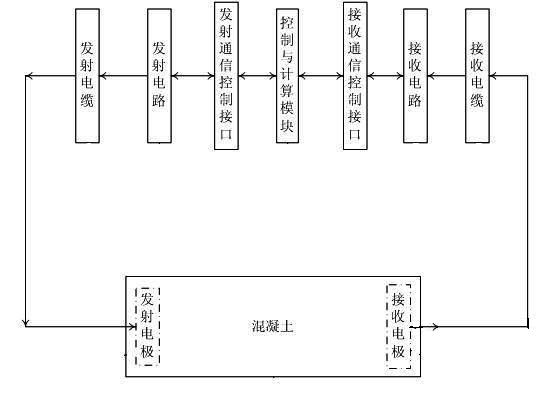

Concrete crack detector with reinforcing bar as electrode

InactiveCN102692431AReal-time forecastReal-time awarenessMaterial impedanceCommunication controlRebar

The invention discloses a concrete crack detector with a reinforcing bar as an electrode. A reinforcing bar emission electrode and a reinforcing bar receiving electrode are embedded in concrete, wherein the emission electrode is connected with an emission circuit through an emission cable; a signal transmitted by the emission circuit is sent out from the concrete through the emission electrode; the receiving electrode is connected with a receiving circuit through a receiving cable; and the receiving circuit is used for amplifying and filtering a signal received by the receiving electrode. An output signal of the emission circuit is connected to a control and computation module through an emission communication control interface, and two-way communication control is performed between the control and computation module and the emission circuit. An output signal of the receiving circuit is connected to the control and computation module through a receiving communication control interface, and two-way communication control is performed between the control and computation module and the receiving circuit. As the reinforcing bar is used as the electrode, the original construction features and stress features of the concrete do not change, a construction process and a construction method have no need to change, and the electrode and the concrete structure have the same service life. The concrete crack detector with the reinforcing bar as the electrode has the advantages of simplicity in design, convenience for construction, low cost and long service life.

Owner:SICHUAN UNIV

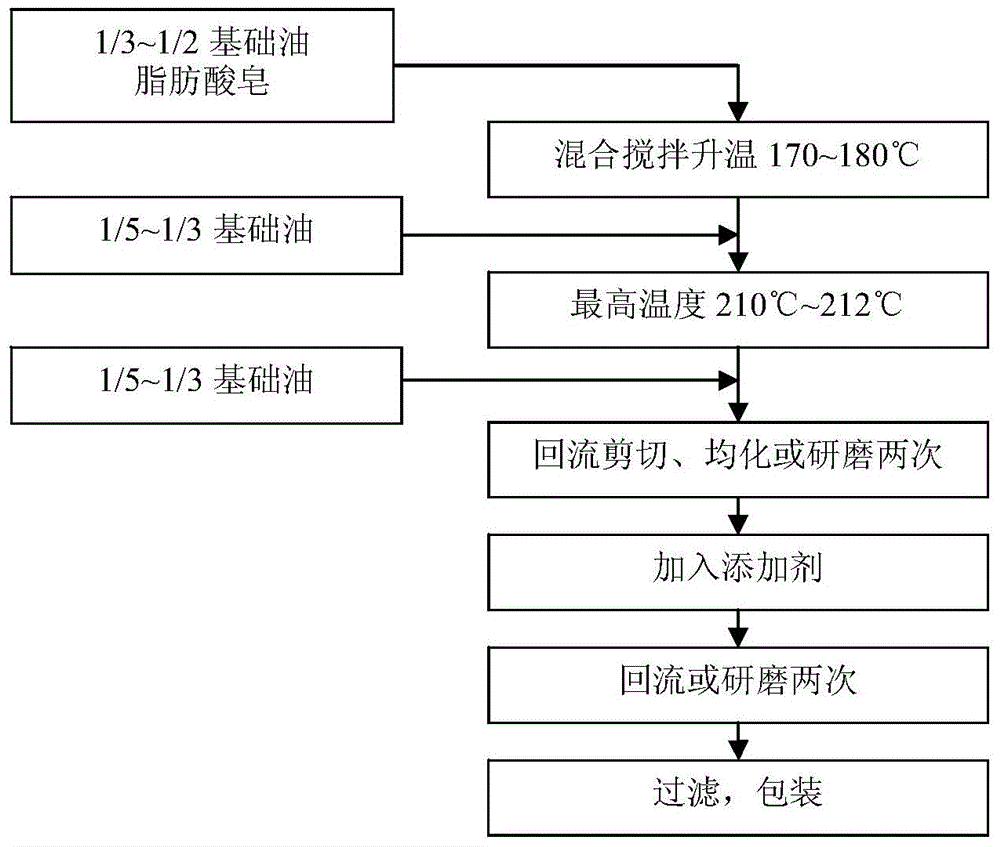

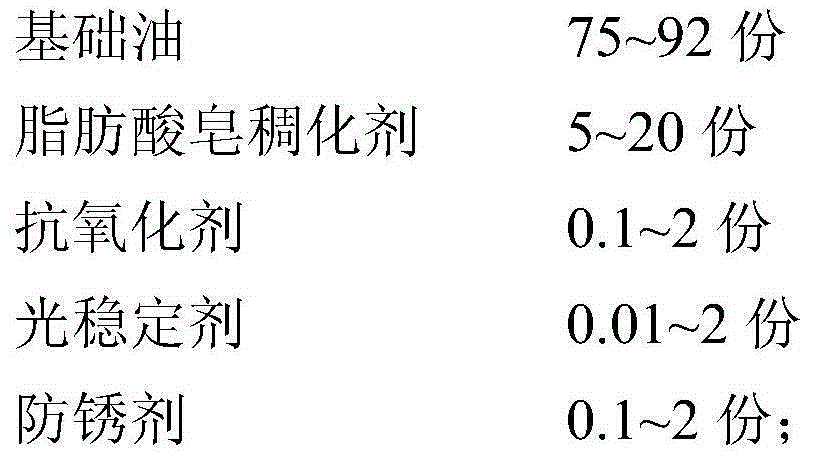

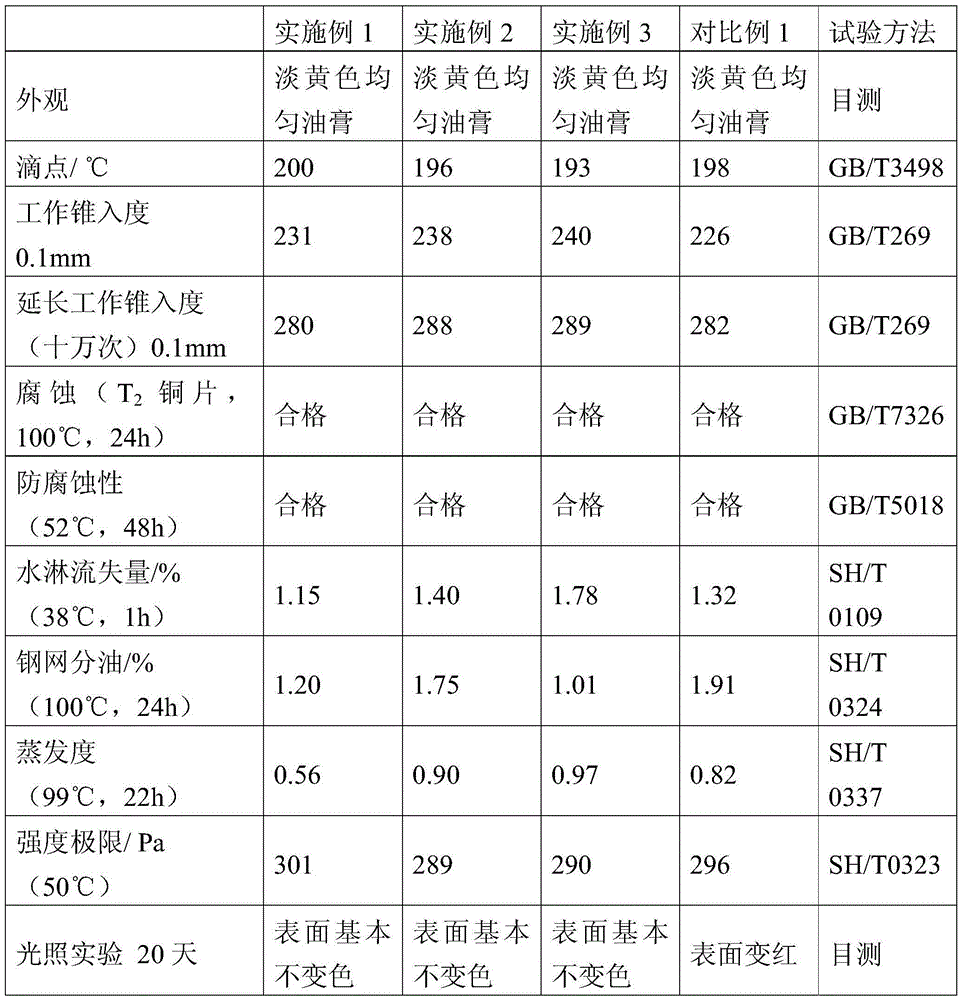

Photo-stabilization type lubricating grease and preparation method thereof

InactiveCN104403763AGuaranteed performanceGood value for moneyLubricant compositionPhoto stabilityBase oil

The present invention discloses a photo-stabilization type lubricating grease, which comprises, by weight, 75-92 parts of a base oil, 5-20 parts of a fatty acid soap thickener, 0.1-2 parts of an antioxidant, 0.01-2 parts of a light stabilizer, and 0.1-2 parts of an anti-rust agent, wherein the components are matched under a certain condition according to the ratio to obtain the photo-stabilization type lubricating grease. According to the present invention, the added functional additive does not affect the product structure, wherein the specific performance is that the consistency (cone penetration) and the strength limit of the product are not changed significantly; and with the addition of the light stabilizer, the photo-stabilization type lubricating grease of the present invention has the light stability, wherein the appearance of the lubricating grease is essentially the same before and after the illumination, and the product meets a variety of lubricating requirements.

Owner:无锡中石油润滑脂有限责任公司

Cellulose nanocrystalline/polylactic acid composite material as well as preparation method and application thereof

The invention provides a cellulose nanocrystalline / polylactic acid composite material as well as a preparation method and application thereof, and belongs to the technical field of polylactic acid composite materials. The preparation method comprises the following steps: mixing a cellulose nanocrystalline aqueous dispersion with a salt modifier, and carrying out electrostatic adsorption modification to obtain a modified cellulose nanocrystalline aqueous dispersion; dropwise adding the modified cellulose nanocrystalline aqueous dispersion into a polylactic acid solution, carrying out coprecipitation reaction, and drying a solid obtained by the coprecipitation reaction to obtain the cellulose nanocrystalline / polylactic acid composite material; wherein a solvent of the polylactic acid solution is a water-soluble organic solvent. According to the method, negatively charged groups on the surface of cellulose nanocrystal are effectively utilized, the modifier is adsorbed to the surface of the cellulose nanocrystal through a simple water-based method, modification is completed, the preparation process is simple, only one-time drying is needed, used water and the solvent can be recycled, and the method is a green and environment-friendly process.

Owner:NORTHEAST FORESTRY UNIVERSITY

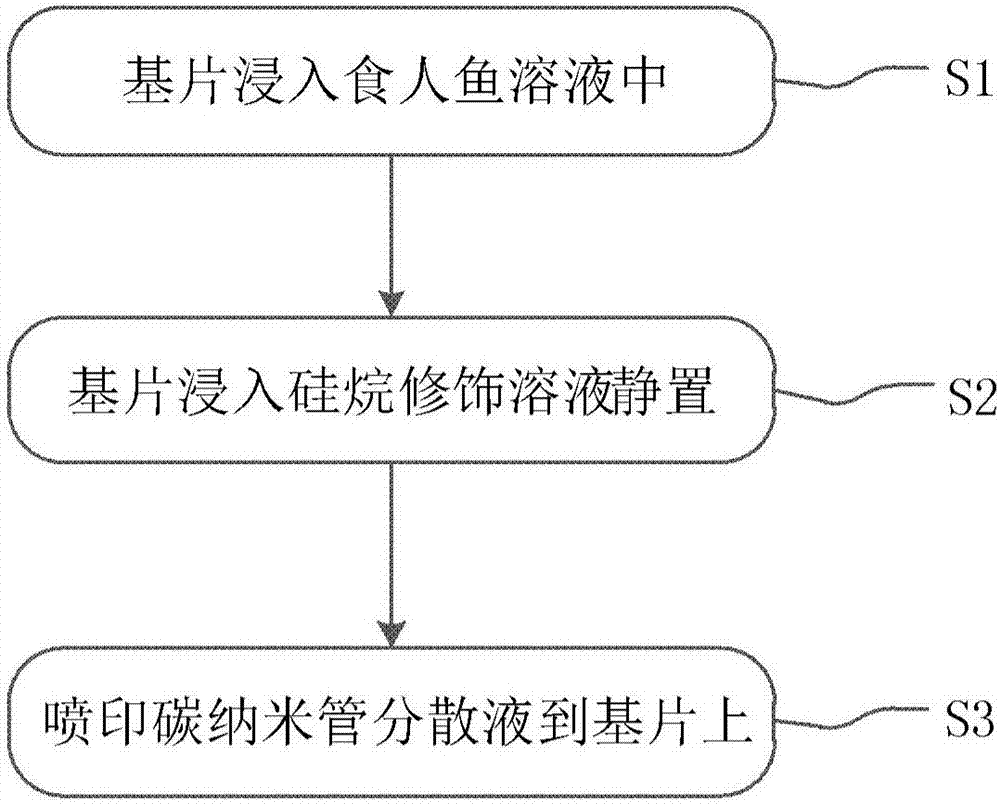

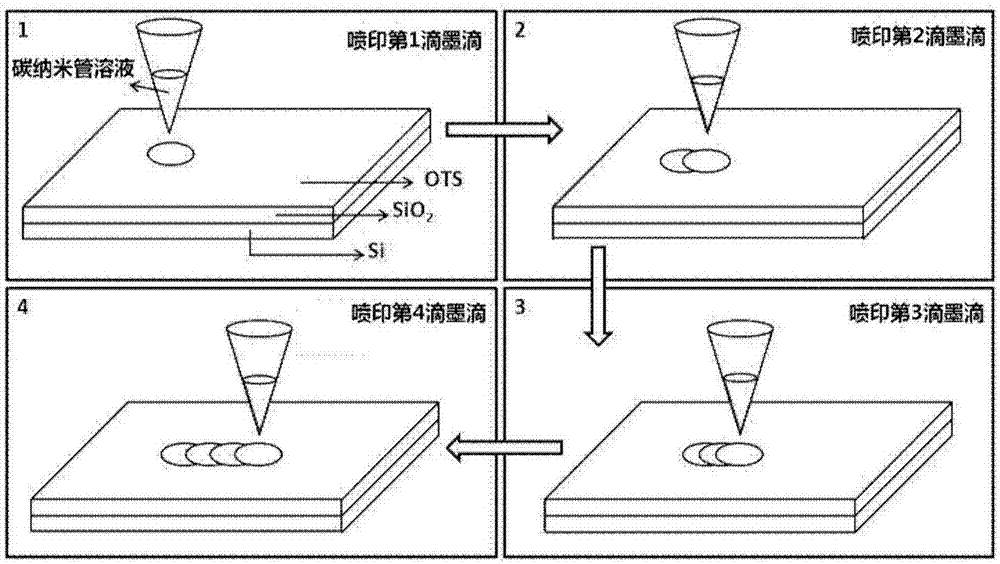

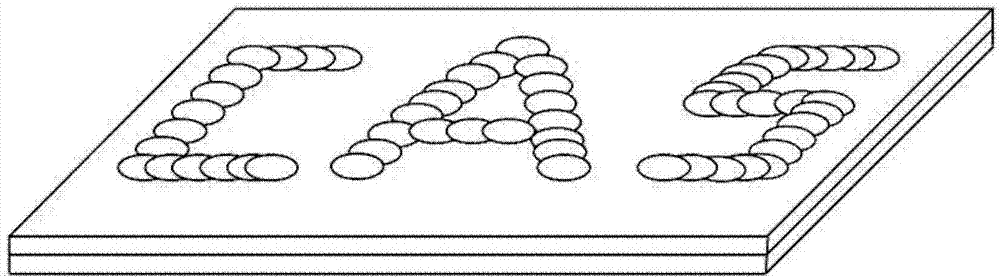

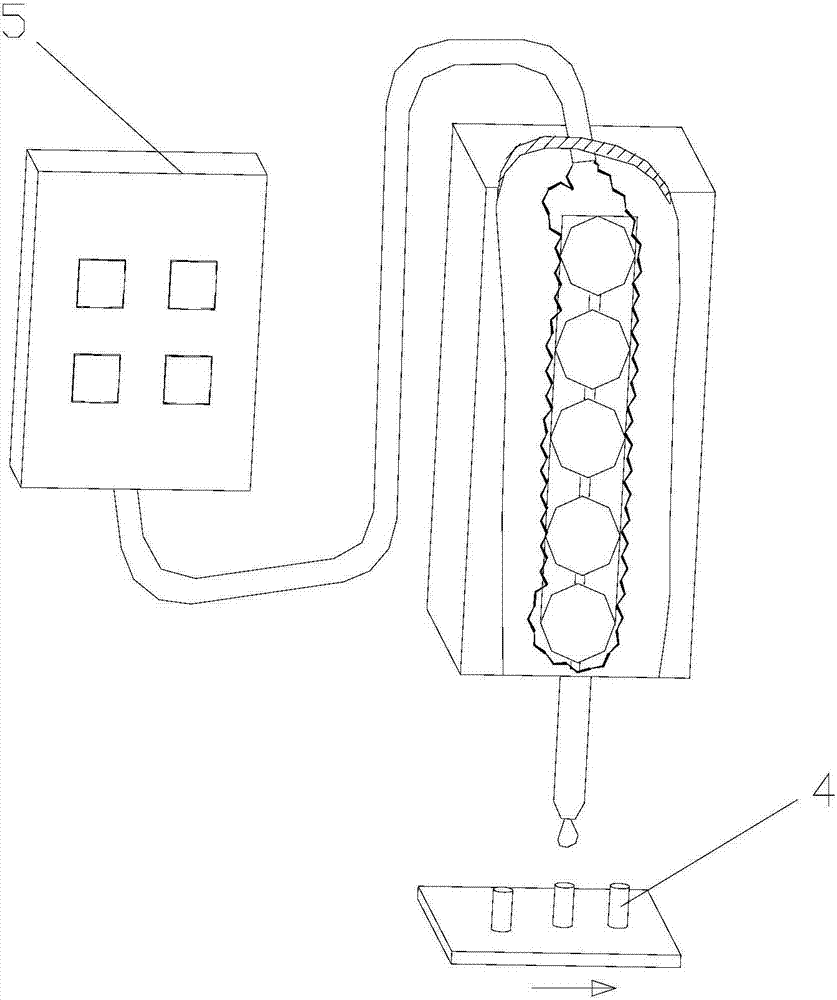

Single aligned carbon nano tube jet-printing arrangement method

ActiveCN107963610ASimple processAchieve patterningMaterial nanotechnologyNanostructure manipulationOctadecyltrichlorosilaneNano-device

The invention provides a single aligned carbon nano tube jet-printing arrangement method. The method comprises the steps that a substrate is modified with octadecyltrichlorosilane (OTS), so that the surface of the substrate has a hydrophobic property; precise control over the thin film position, the aligned density and patterning of aligned carbon nano tubes is achieved on the functional hydrophobic substrate through ink-jet printing, and a carbon nano tube thin film which is uniform in density and consistent in orientation and has different patterns is arranged. By means of the method, the carbon nano tube arrangement area of the size from several micrometers to the wafer level can be effectively controlled; the problems can be solved that in all existing arrangement methods, the arrangement position, the arrangement orientation, the arrangement density and the thin film array patterning of one-dimensional nano materials on the substrate cannot be efficiently and precisely controlled;the method can be widely used for preparing various high-performance photoelectric devices, logic circuits and functional thin films based on the carbon nano tubes, and the method also has a wide application prospect in the field of flexible wearable nano devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

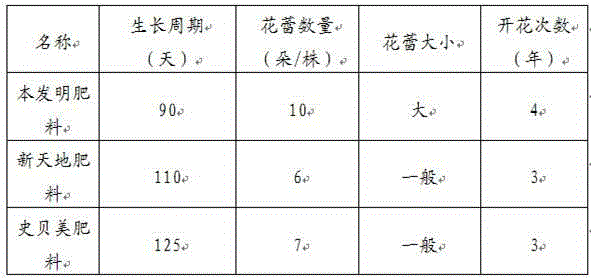

Organic compound fertilizer suitable for flower planting

InactiveCN104803796AImprove yield and qualityShorten the growth cycleFertilizer mixturesWater contentChemistry

The invention relates to an organic compound fertilizer suitable for flower planting. The organic compound fertilizer comprises the following constituents in percentages by weight: 20-25% of plant straws, 10-15% of cow dungs, 20-30% of shell powder, 8-12% of powdered rock phosphate, 20-30% of plant shells, 3-6% of humic acid and 3-5% of biological bacteria, wherein the sum of the constituents is 100%. The organic compound fertilizer prepared according to the formula is prepared by the following specific steps: mixing the plant raw materials according to the corresponding proportion, adding humic acid and the biological bacterial strains into the mixed raw materials according to the corresponding proportion, uniformly stirring, retaining the moisture to be 50-55%, performing stacking fermentation for 10 days, then turning over the stacks, feeding the fermented materials into a flap type fermentation tower to be fermented for 12 days, fermenting by an aerobic fermentation method, keeping the water content of the mixed and fermented plant raw materials to be 20%, when the fermented materials are free of stink obviously, discharging the fermented materials from the fermenting tower, uniformly and fully mixing the fermented materials with the powdered rock phosphate, performing over crushing, screening and qualification inspecting, and at last pelletizing or grinding into powder, so as to obtain the finished product of the dedicated fertilizer for the flower.

Owner:ZUNYI LIMANFENG FERTILIZER IND

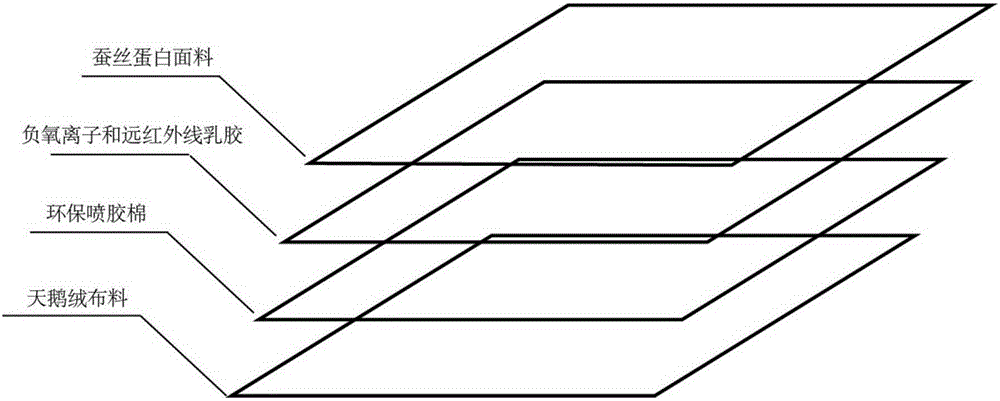

Latex sheet material, preparation method and latex mattress prepared from same

InactiveCN105237827ADoes not change propertiesGood synergyStuffed mattressesSpring mattressesProduction lineOxygen ions

A provided latex sheet material is mainly prepared from the following compositions in parts by weight: a latex solution, a negative oxygen ion powder and nanometer silver, the negative oxygen ion powder accounts for 3%-6% by mass of the latex solution, and nanometer silver accounts for 0.3%-0.5% by mass of the latex solution. The invention also provides a preparation method for the latex sheet material. The method can help to add the negative oxygen ion powder and nanometersilver into the latex mattress without an extra processing step and without changing a conventional latex mattress production line, thereby substantially reducing production cost, and the method possesses wide application prospect. Also, the invention provides the latex mattress prepared by employing the above latex sheet material. When a person lies flat on the mattress, the person can contact with far infrared ray and negative oxygen ion in a large area, and the provided mattress gives play to health-care effect without adding any equipment and without consuming extra time.

Owner:深圳智卫宾生物科技有限公司

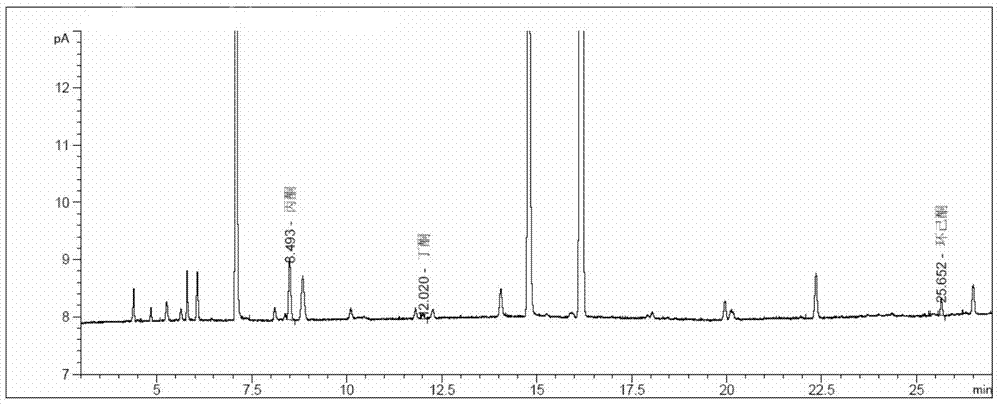

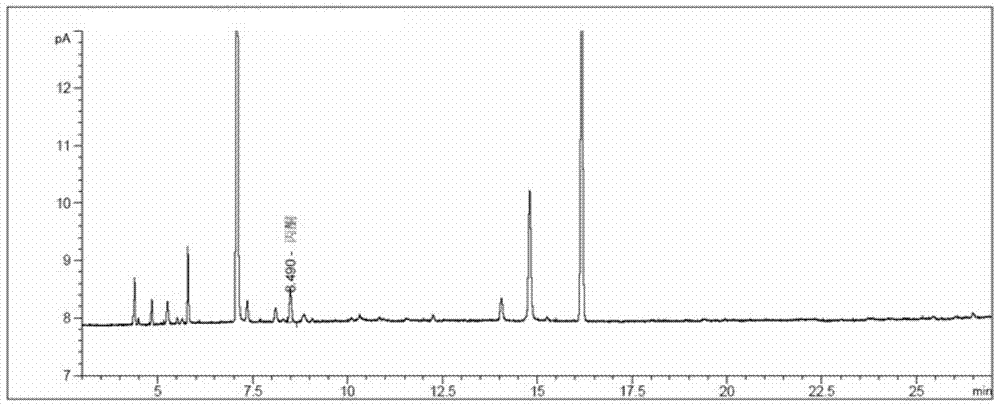

Ketone-removing additive for removing ketone substances from packaging card paper and application of additive

ActiveCN103882766AEasy to removeExcellent selective elimination effectDefoamers additionNon-macromolecular organic additionPropanoic acidPtru catalyst

The invention discloses a ketone-removing additive for removing ketone substances from packaging card paper, and application of the additive. The ketone-removing additive comprises organic amine and a catalyst, wherein the organic amine is one or more of ethanediamine, propane diamine, butanediamine, ethanolamine, guanidine and dimethyl biguanide; the catalyst is one or more of acetic acid, propionic acid, citric acid and malic acid; the mass ratio of the organic amine to the catalyst is 1.5: 1 to 2.5: 1. The ketone-removing additive is added into a water dispersible coating solution containing acrylic resin at room temperature to obtain a water-based coating solution, wherein the mass percent of the ketone-removing additive in the coating solution is 0.5%-5.0%. The water-based coating solution is used for removing the ketone substances from the packaging card paper. An experiment shows that the water-based coating solution can be used for effectively removing the ketone substances from the packaging card paper. The water-based coating solution is low in production cost, cannot change the structure and the characteristics of the paper in a ketone removing process, and cannot influence the subsequent processing process of the packaging card paper.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

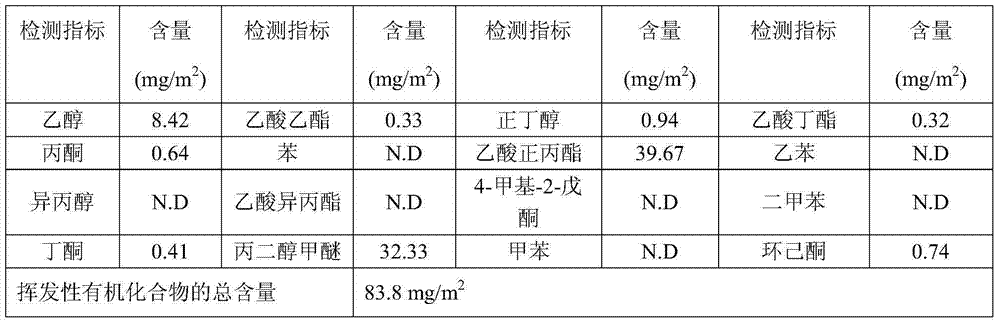

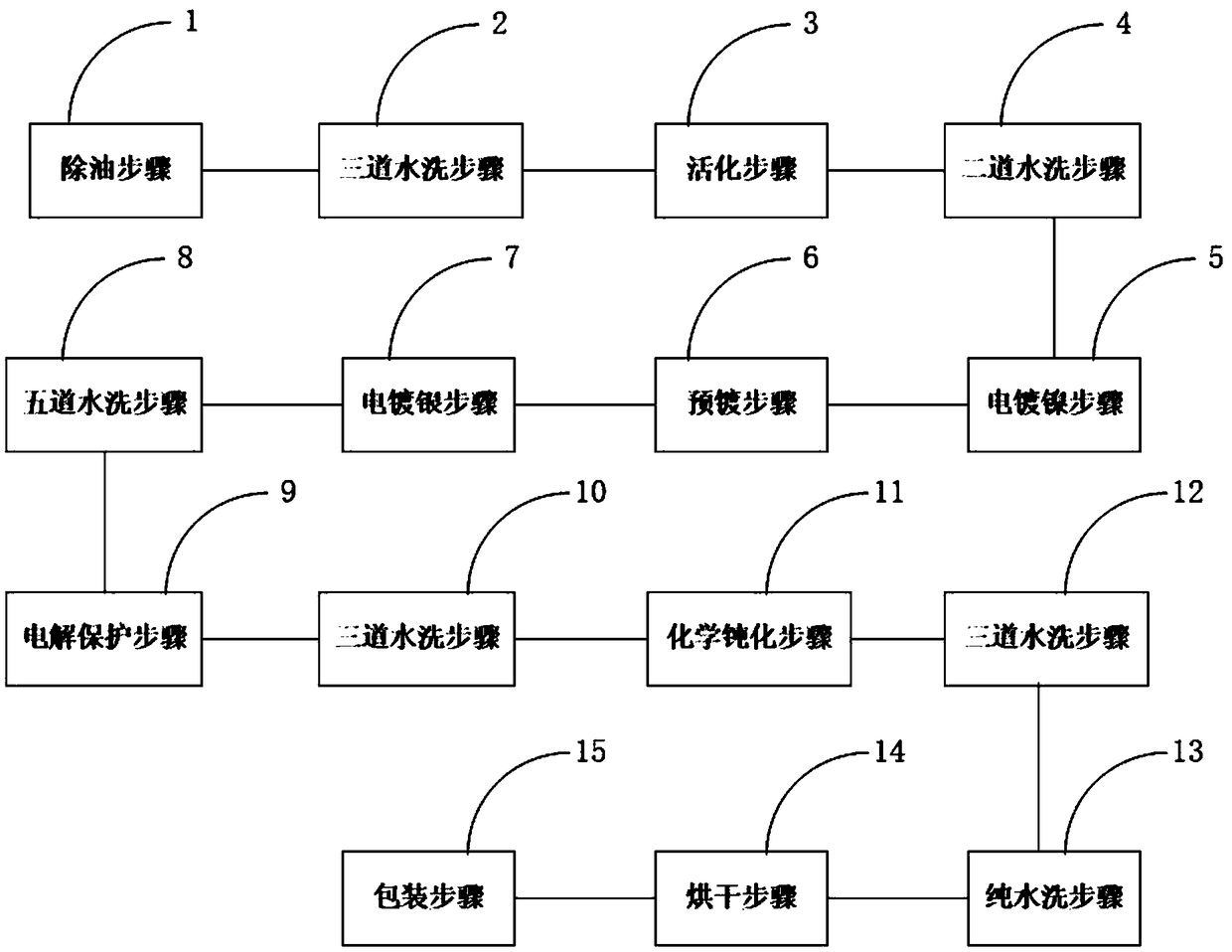

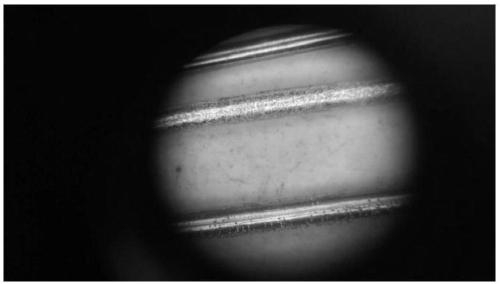

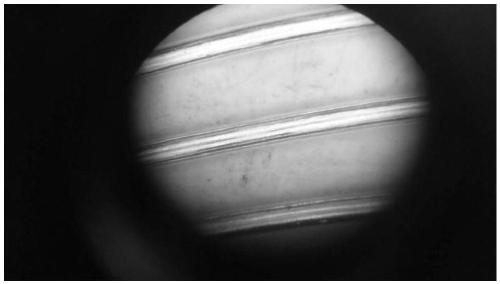

Electroplating post-processing process for silver-plate copper wire

ActiveCN109295445AImprove anti-corrosion performanceDoes not change propertiesProcess efficiency improvementSuperimposed coating processSilver plateElectrolysis

The invention belongs to the technical field of electroplating, and provides an electroplating post-processing process for a silver-plate copper wire. The electroplating post-processing process for the silver-plate copper wire comprises the step of passivating a plating piece electroplated with silver. The passivation treatment step comprises an electrolysis protection step and a chemical passivation step carried out sequentially; according to the electrolysis protection step, electrolysis protection powder is adopted for carrying out electrolysis protection treatment and is dissolved in an electrolysis protection tank filled with pure water; and according to the chemical passivation step, kangli tablets are adopted for carrying out chemical passivation treatment, and the plating piece isfed into a chemical passivation groove containing the kangli tablets and pure water. According to the electroplating post-processing process for the silver-plate copper wire provided by the invention,the electrolysis protection powder is firstly adopted for carrying out electrolysis protection treatment on the silver-plate copper wire, the kangli tablets are adopted for carrying out chemical passivation treatment on the silver-plate copper wire, and a transparent anti-oxidation film is formed on the surface of a silver coating through the double passivation treatment on the silver-plate copper wire, so that the generation of sulfide can be prevented, the corrosion prevention of the surface of the silver coating can be improved, and meanwhile, the characteristics of the surface of the silver coating cannot be changed.

Owner:YANGZHOU HY TECH DEV

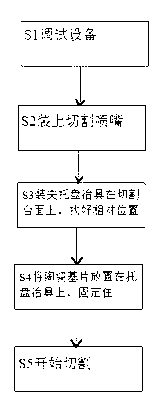

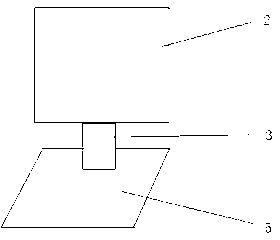

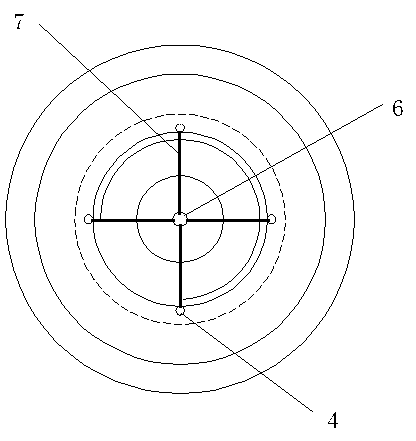

Absorbent for cutting ceramics by aid of fiber laser

ActiveCN103192199AEasy to cleanEnhance light absorptionSpray nozzlesWelding/cutting media/materialsResistPreservative

Disclosed is an absorbent for cutting ceramics by the aid of fiber laser. The absorbent is coated on the surface of a ceramic in a technological process for cutting the ceramic by the aid of the fiber laser. The absorbent is characterized in that an oily material and acetone are proportioned to manufacture the absorbent, and colorants, colorant assistants, stabilizers, resists, wetting agents and preservatives are proportioned to manufacture the oily material. The absorbent has the advantages that a light absorption effect of the ceramic is excellent after the absorbent is used for the ceramic, a phenomenon of light interruption is prevented, the ceramic can be cut by the aid of the laser at one step, the absorbent is environment-friendly, can be easily coated on the surface of the ceramic and is easy to clean, the ceramic can be cleaned in alcohol after being cut, intrinsic characteristics of the ceramic cannot be changed, corrosion is prevented, the appearance of the ceramic is identical to that of a ceramic which is not coated with the absorbent, and the like.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

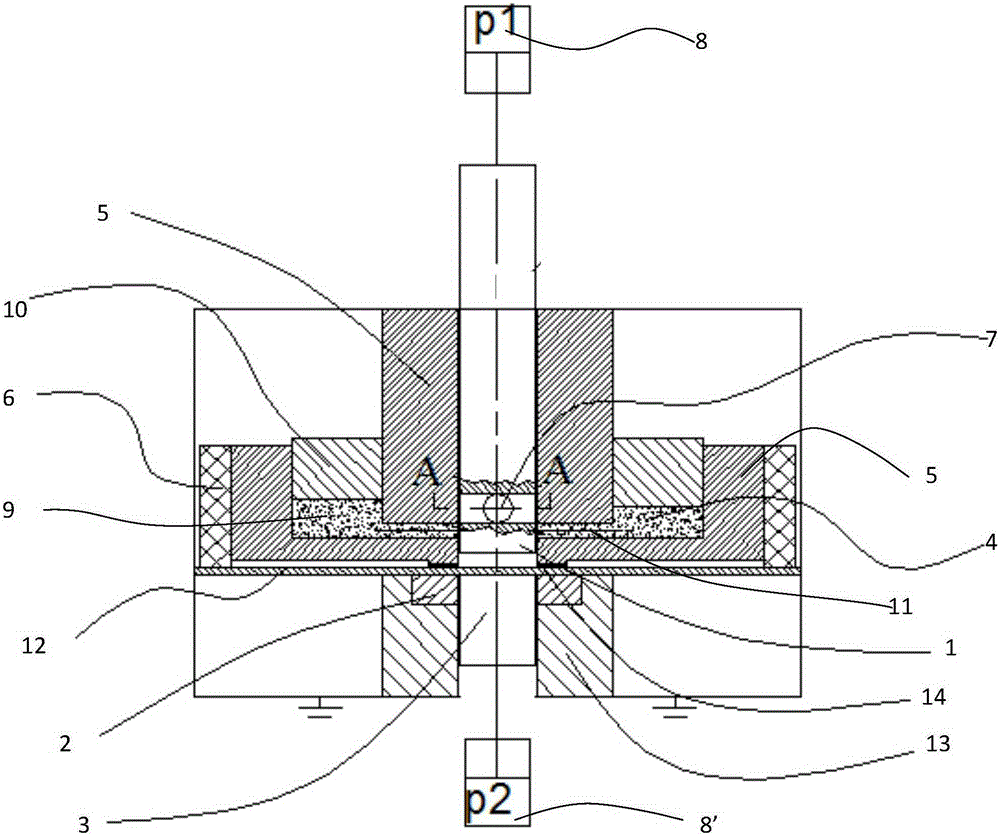

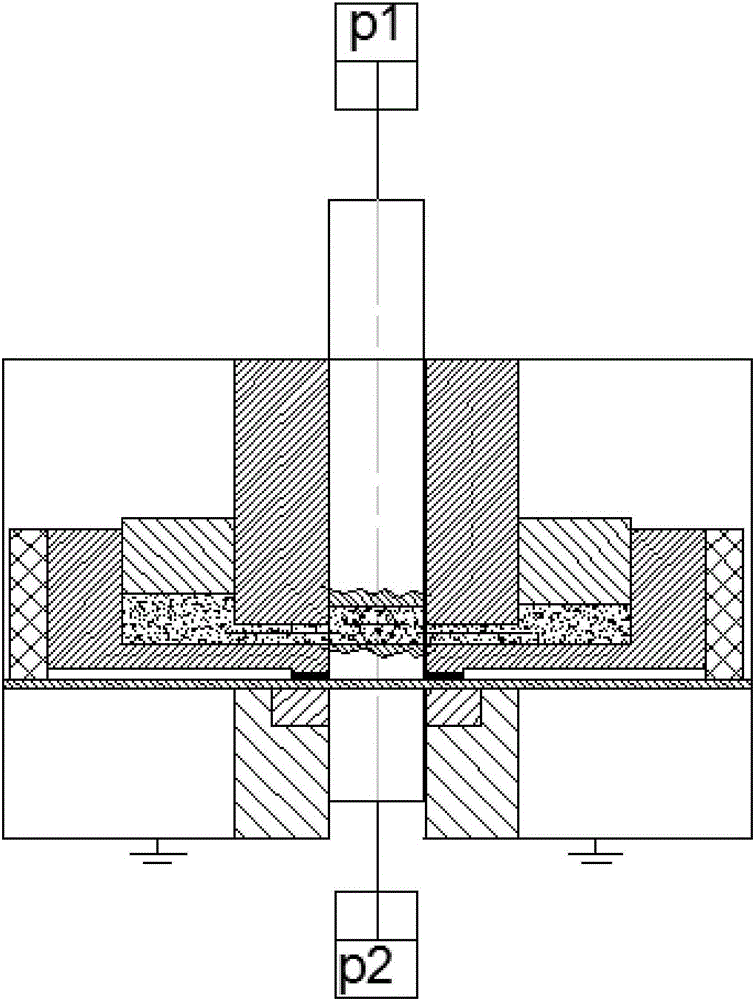

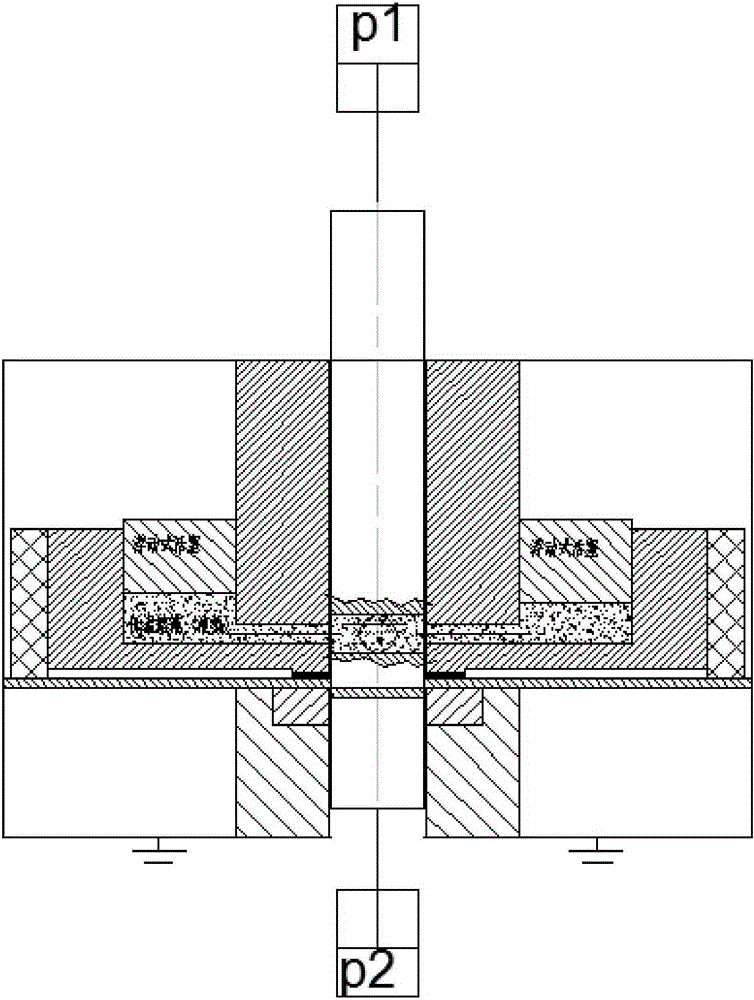

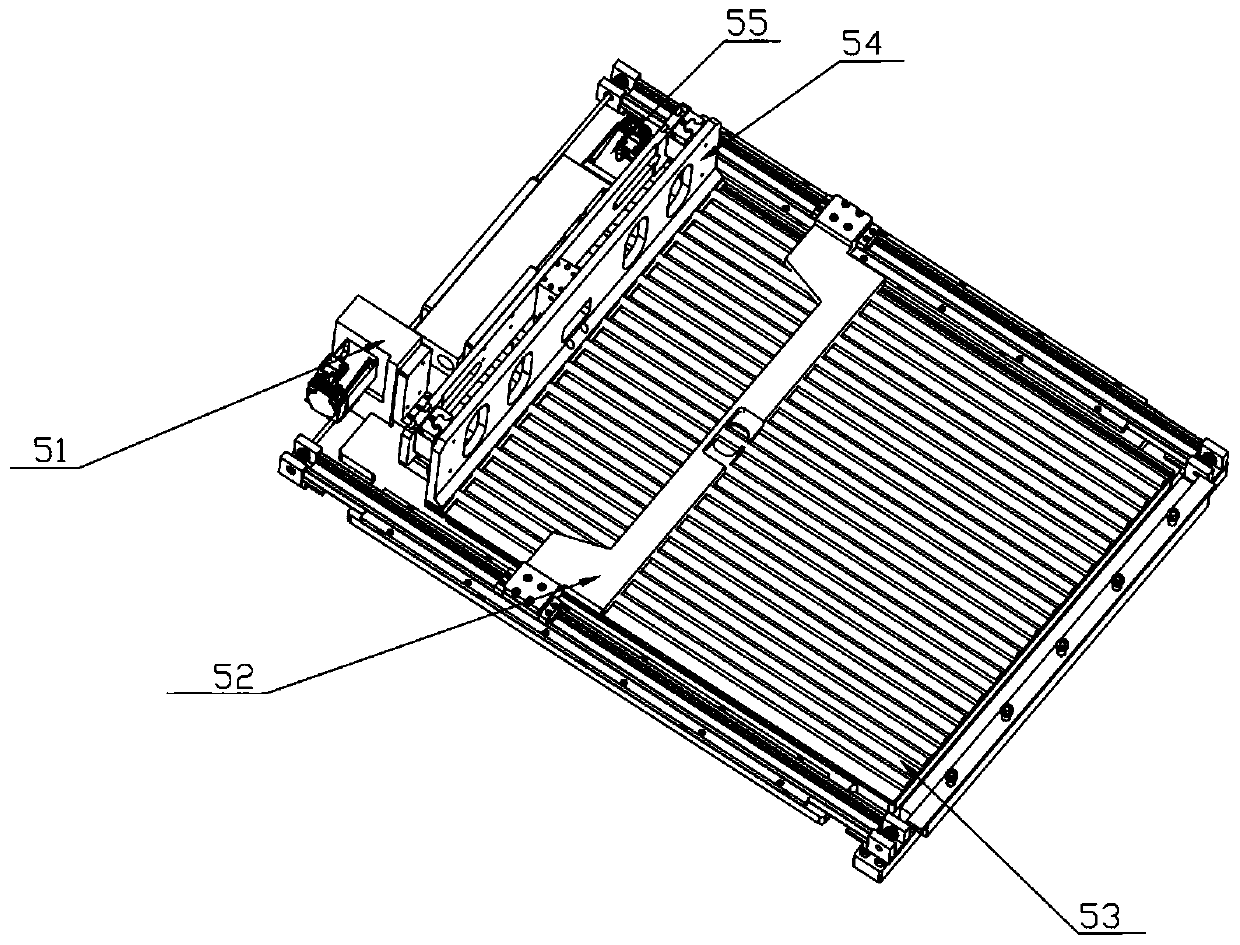

Cryogenic stamping, shearing and forming device with terrace die for micro workpieces and forming method using cryogenic stamping, shearing and forming device

InactiveCN105328003APrevent downward flowAchieve precision machiningShaping toolsHydraulic cylinderPiston

The invention relates to a cryogenic stamping, shearing and forming device with a terrace die for micro workpieces and a forming method using the cryogenic stamping, shearing and forming device, and belongs to the field of mechanical engineering. The cryogenic stamping, shearing and forming device comprises the terrace die, a hollowing block, an ejector rod, a low-temperature solution, a blank holder, a heat insulating material and a terrace die supporting base, wherein the side wall of the terrace die is locally provided with a through hole; a hydraulic cylinder drives the terrace die to move in the blank holder; the hollowing block is fixed in a hollowing block supporting base; the hydraulic cylinder drives the ejector rod to move in the hollowing block; a storage slot capable of accommodating the low-temperature solution is formed in the blank holder; the top of the storage slot is provided with a floating type piston; and the inner side wall of the blank holder is provided with a side wall hole capable of allowing the low-temperature solution to flow. The forming method based on the device comprises the five steps of clamping plates, cooling, stamping and shearing, drawing the plates out of the die and carrying out shape inspection. According to the cryogenic stamping, shearing and forming device with the terrace die for micro workpieces and the forming method using the cryogenic stamping, shearing and forming device, the advantages are that precision processing for micro workpieces is realized, deckle edges and burrs are reduced in a facilitated mode, section is flattened, section forming precision and forming precision for forming the workpieces are improved, and batched production is realized.

Owner:JILIN UNIV

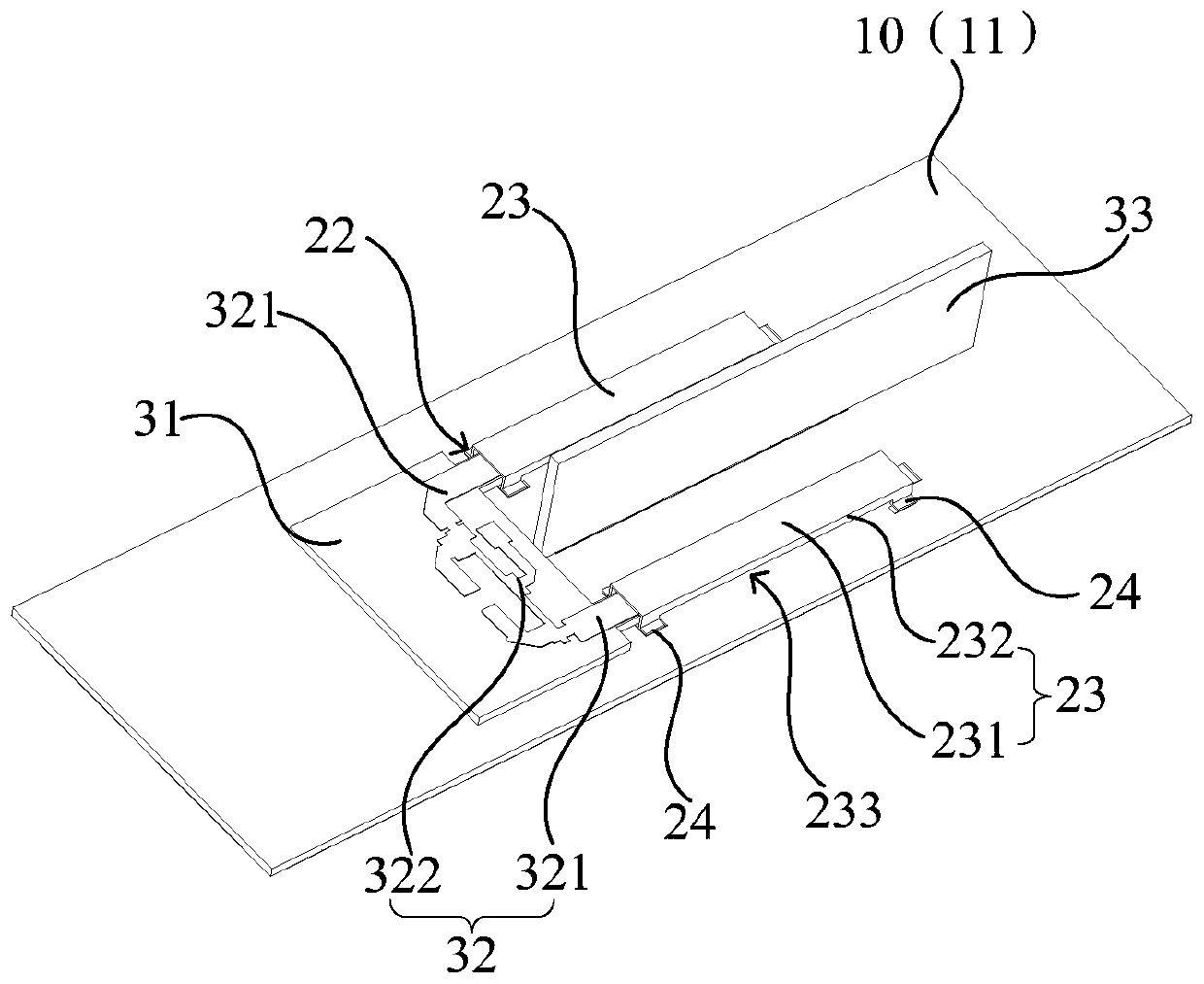

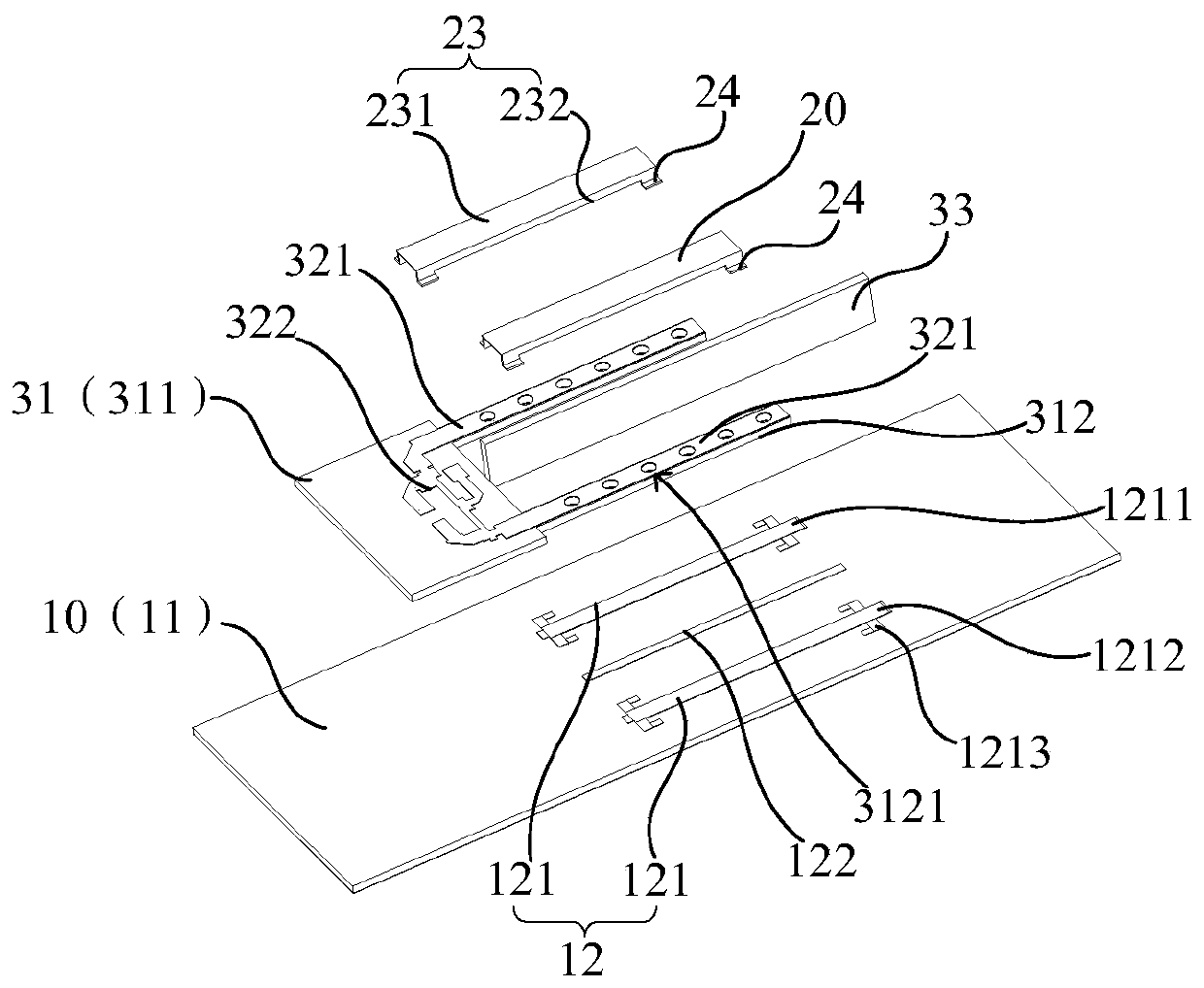

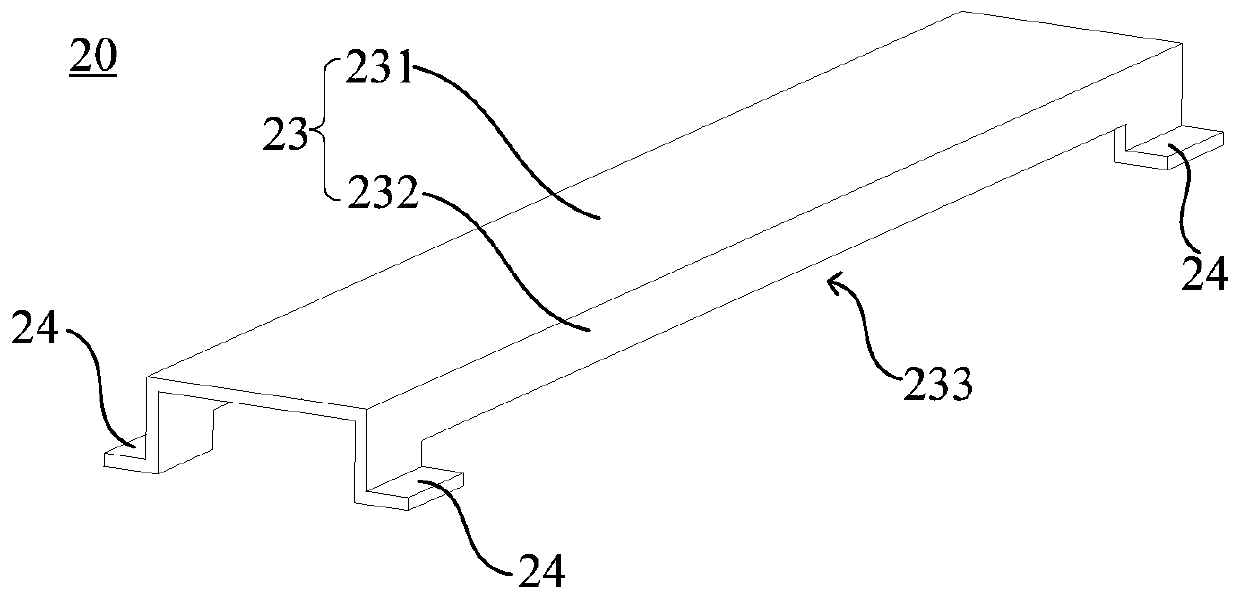

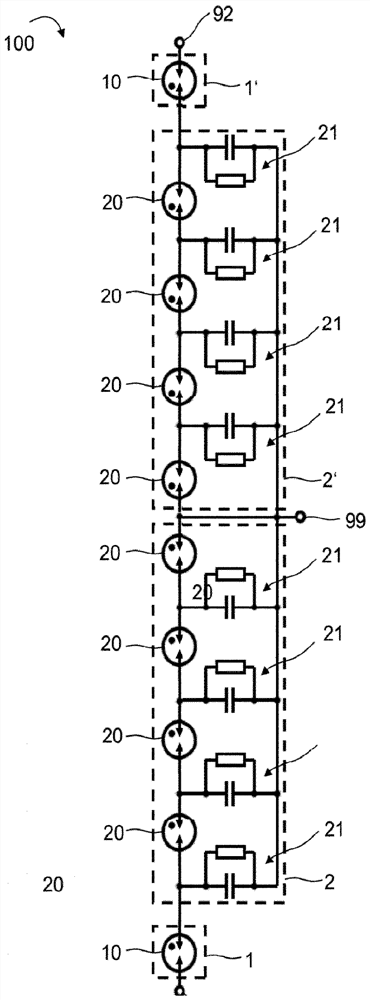

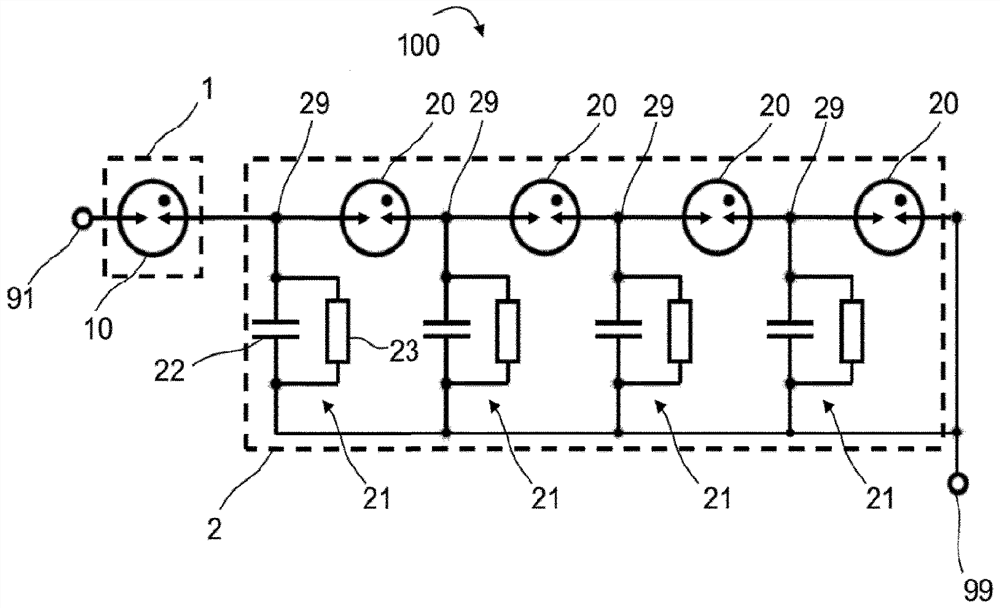

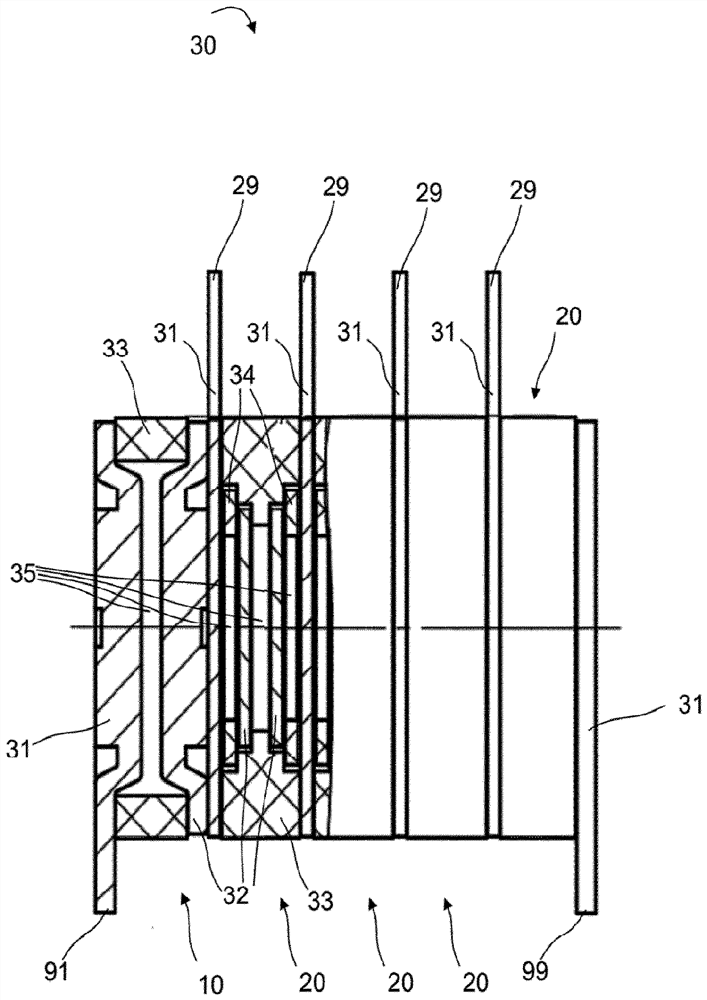

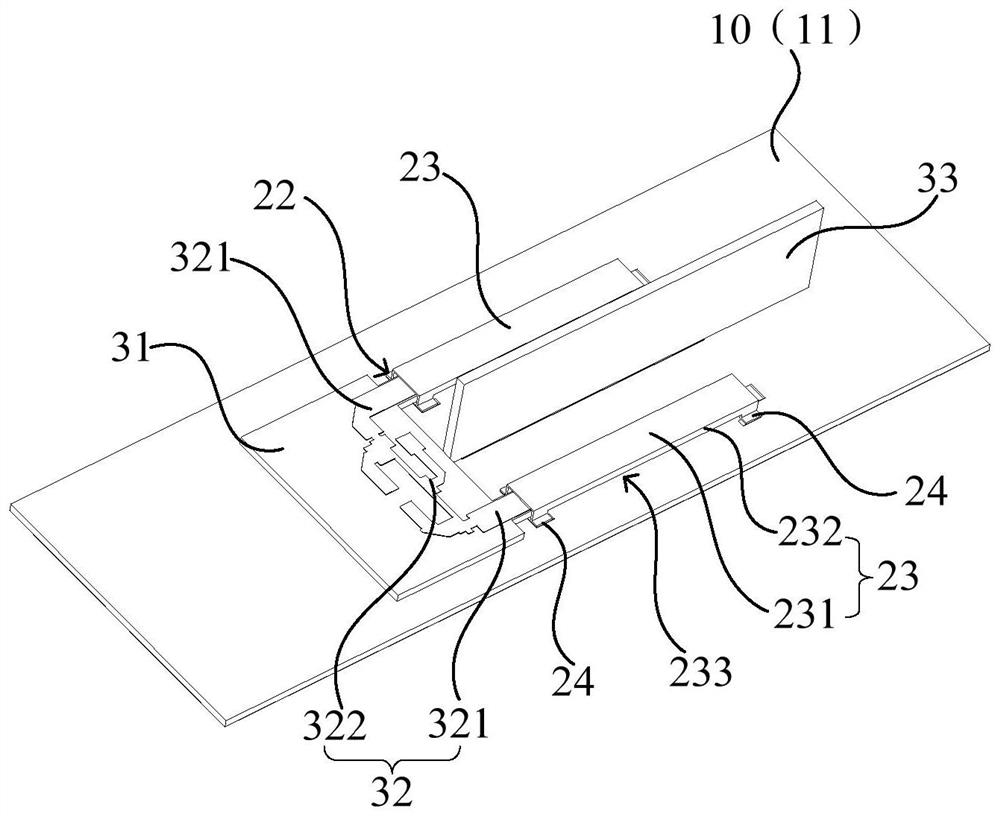

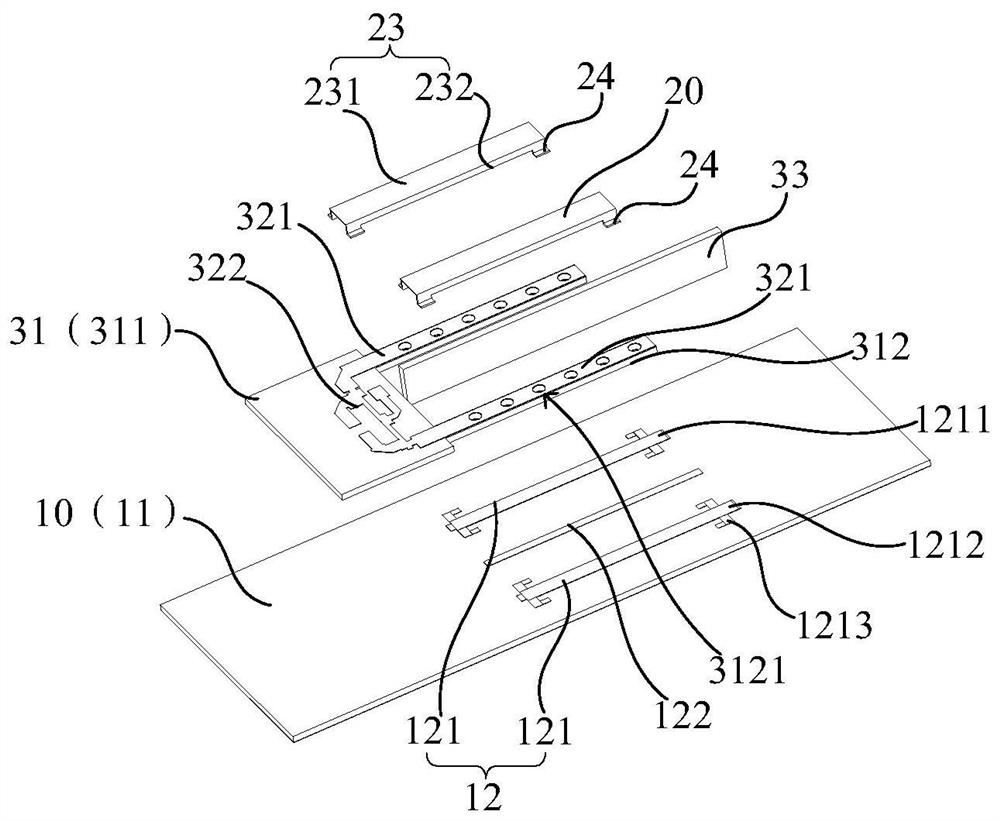

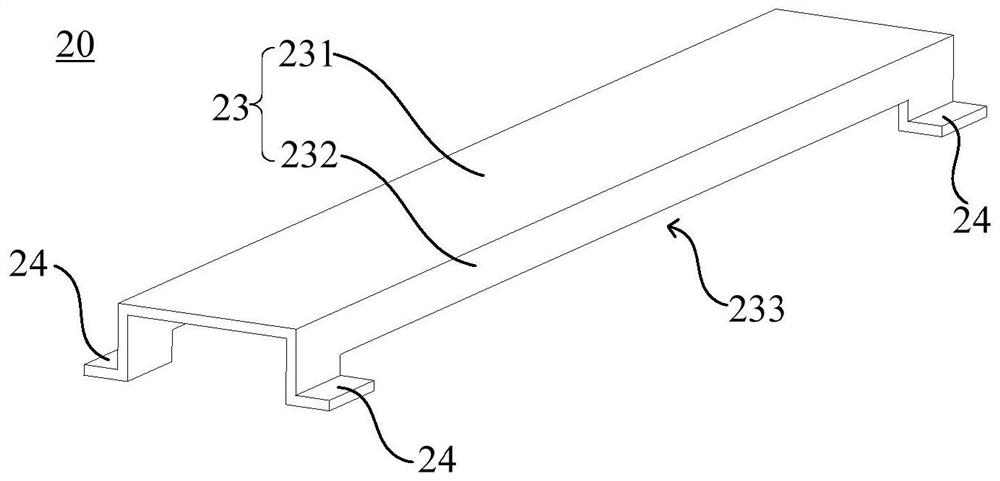

Filtering phase shifter and antenna

ActiveCN111342174ALarge power capacityOverall small sizeWaveguide type devicesElectrical conductorHemt circuits

The invention relates to a filtering phase shifter and an antenna. The filtering phase shifter comprises a fixed circuit, an auxiliary conductor transmission section and a movable circuit. The movablecircuit moves relative to a first carrier plate to enable a second transmission line to move in or out of a containing cavity, the coupling amount between a movable line layer and a fixed line layerand the coupling amount between the movable line layer and the auxiliary transmission conductor section can be changed, and therefore the electrical length of signal transmission in the filtering phase shifter is changed, and phase adjustment of the output port is achieved. In addition, a filtering stub is additionally arranged in a movable circuit of a U-shaped transmission line type phase shifter, so that the integrated design of a filter and a phase shifter is realized. In addition, input signals are subjected to filtering and phase shifting at the same time, the space utilization rate is increased, and the size is effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

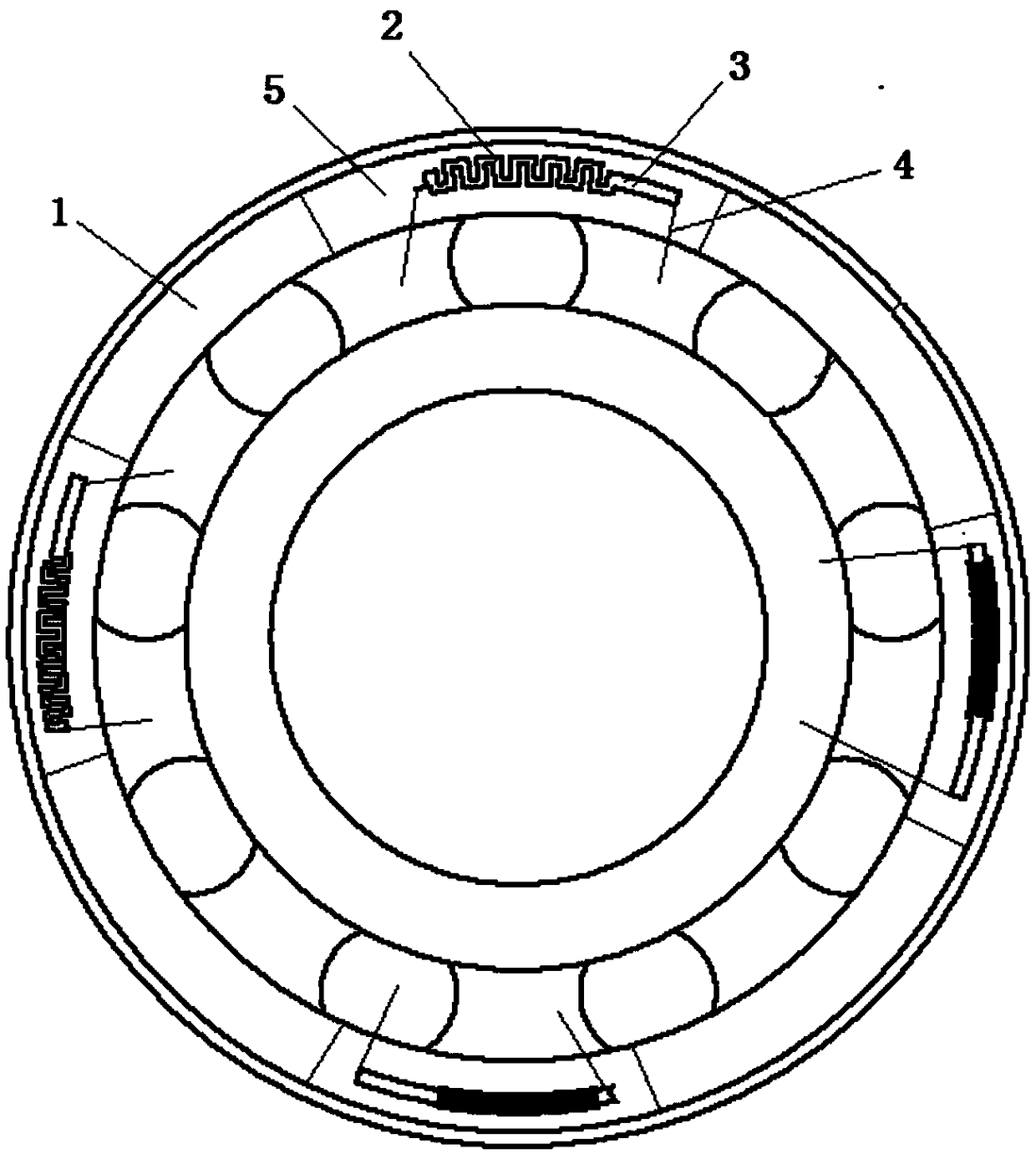

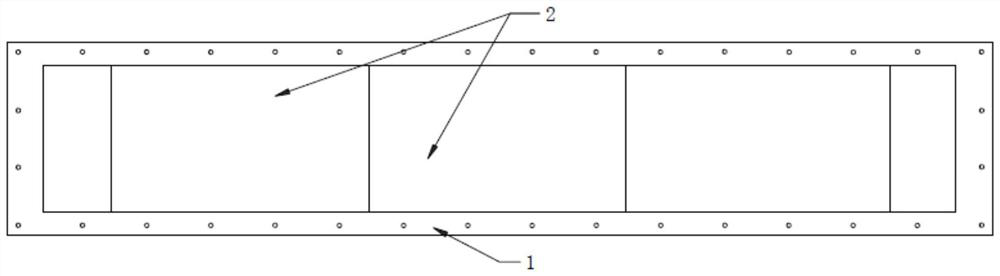

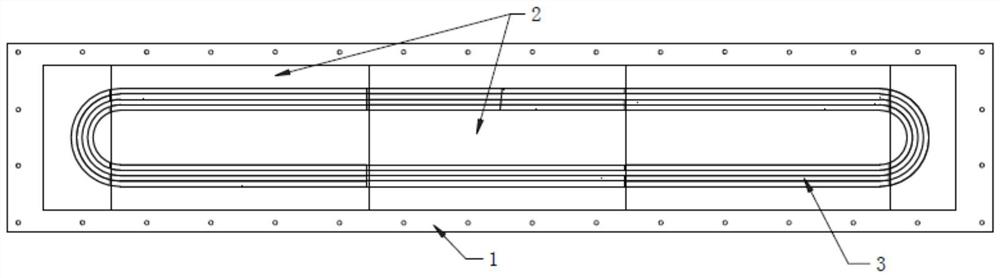

Sensor for monitoring temperature/strain signals of bearings

ActiveCN109341777ARealize the ability to output a variety of signalsSimple structureMachine bearings testingThin film sensorMonitoring temperature

The invention relates to a sensor for monitoring temperature / strain signals of bearings. The sensor is formed by preparing a strain sensitive layer (2) and a temperature sensitive layer (3) on an outer-ring end face (1) of a bearing. One end of the strain sensitive layer (2) and one end of the temperature sensitive layer (3) are overlapped with each other. The strain sensitive layer (2), the temperature sensitive layer (3) and the overlap surface of the strain sensitive layer (2) and the temperature sensitive layer (3) are insulated from the outer-ring end face (1) of the bearing. The resistance value of the strain sensitive layer (2) can change with strain so as to form a strain sensor. The voltage value of the overlap surface of the strain sensitive layer (2) and the temperature sensitive layer (3) can change with temperature so as to form a thermocouple temperature sensor. Signals are led out by leads (4) at the other end of the strain sensitive layer (2) and at the other end of thetemperature sensitive layer (3). A thin film sensor of a composite structure is realized, which can simultaneously detect the temperature and strain parameters of bearings.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

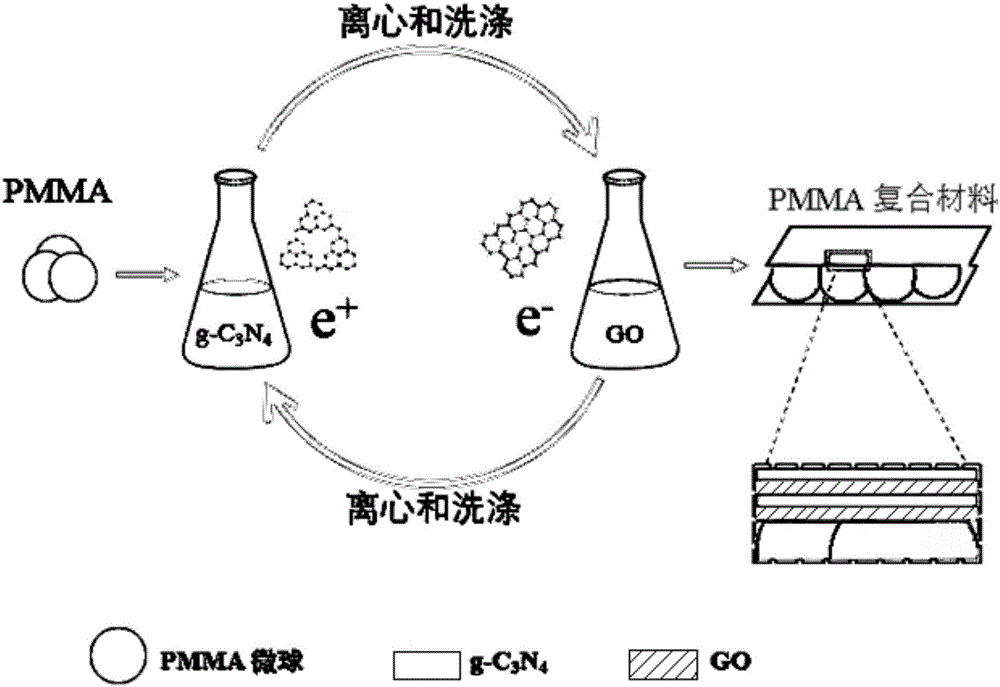

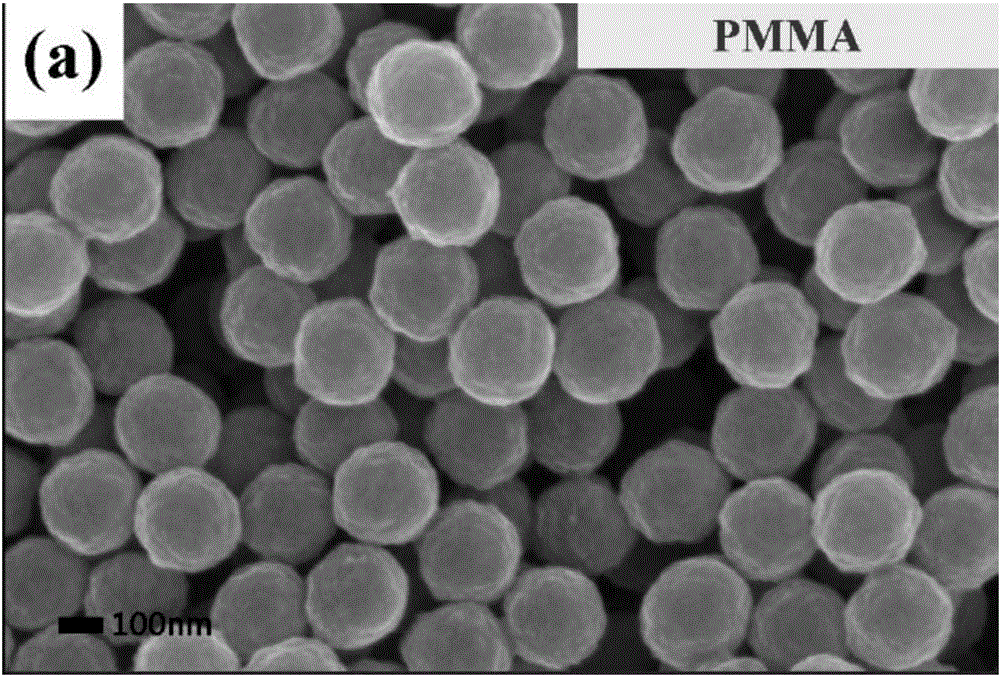

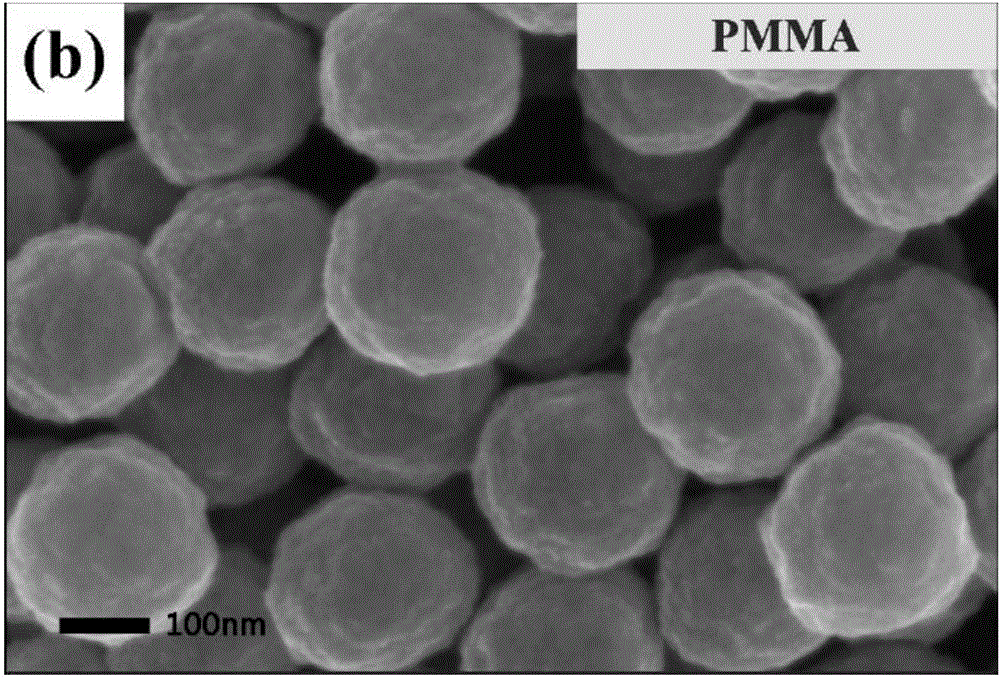

Flame-retardant modified PMMA (polymethylmethacrylate) microspheres and preparation method thereof

The invention discloses flame-retardant modified PMMA (polymethylmethacrylate) microspheres and a preparation method thereof. The flame-retardant modified PMMA microspheres are of a nanometer core-shell structure, an inner core is PMMA microspheres, and an outer shell is an electrolyte layer formed by alternately depositing of different two-dimensional nanosheet layers. The preparation method comprises the steps as follows: soaking the PMMA microspheres pretreated by isopropanol in a graphite phase carbon nitride suspension liquid and a graphene oxide dispersion liquid sequentially for layer-by-layer self-assembly to obtain the flame-retardant modified methyl methacrylate microspheres. According to the flame-retardant modified PMMA microspheres, the hindering effect on oxygen and volatile gas transfer and the barrier effect on heat flow are realized mainly based on the physical barrier function of the two-dimensional nanometer sheet layers, and accordingly, excellent flame retardant performance and self-extinguishing performance are obtained. The preparation method is simple and flexible to operate, good in stability, lower in cost, low in operation condition requirement, and beneficial to large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Method for repairing ship cylinder end through TIG welding

InactiveCN108723556AImprove welding pass rateEasy to operateArc welding apparatusEngineeringCleansing Agents

The invention discloses a method for repairing a ship cylinder end through TIG welding. The method comprises the following steps that (1) a welding material is manufactured according to one of following methods, specifically, a body piston ring corresponding to a welded workpiece is selected and cut into small pieces as required to be used as the welding material after being degreased through a metal cleaning agent, or a casting iron welding rod CHC408 is selected, a coating is removed, and a flux core is used as the welding material; (2) the surface of the welded workpiece is treated, specifically, a to-be-repaired welded workpiece is detected, a welding repair position is determined, the welded workpiece is subjected to ultrasonic cleaning, the to-be-welded position is cleaned through grinding, new parent metal is exposed, and welding repair is instantly conducted after drying; and (3) welding repair is conducted, specifically, a TIG direct current welding method is selected, argon shielded welding parallel welding is adopted, and leftward welding is conducted. Through the method, welding is easy, the welding yield is high, fusion degree is high, the reuse rate of the cylinder end can be increased, and capital and time for recast are reduced.

Owner:广州文冲船舶修造有限公司

Water-based fluorinated acrylate copolymer and hybrid membrane, and preparation methods and application thereof

The invention discloses a water-based fluorinated acrylate copolymer and a hybrid membrane, and preparation methods and application thereof. According to the water-based fluorinated acrylate copolymerdisclosed by the invention, an alkyl acrylate monomer is polymerized to form a core; an alkyl acrylate monomer, a fluorinated acrylate monomer and a hydroxyethyl acrylate monomer are copolymerized toform a shell; the mass of the alkyl acrylate monomer accounts for 78.13%-92.70% of the mass of the total monomers; the mass of the fluorinated acrylate monomer accounts for 6.21-20.94% of the mass ofthe total monomers; the mass of the hydroxyethyl acrylate monomer accounts for 0.91-1.09% of the mass of the total monomers; and the number of fluorocarbon atoms is less than or equal to 6. The hybrid membrane prepared from the water-based fluorinated acrylate copolymer emulsion has good effects in water repellency, dirt repellency, uniform membrane formation and corrosion resistance, can be usedfor oil-water separation, uses water as a solvent, is friendly to environment, low in cost, simple and efficient, and has good market application prospects.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

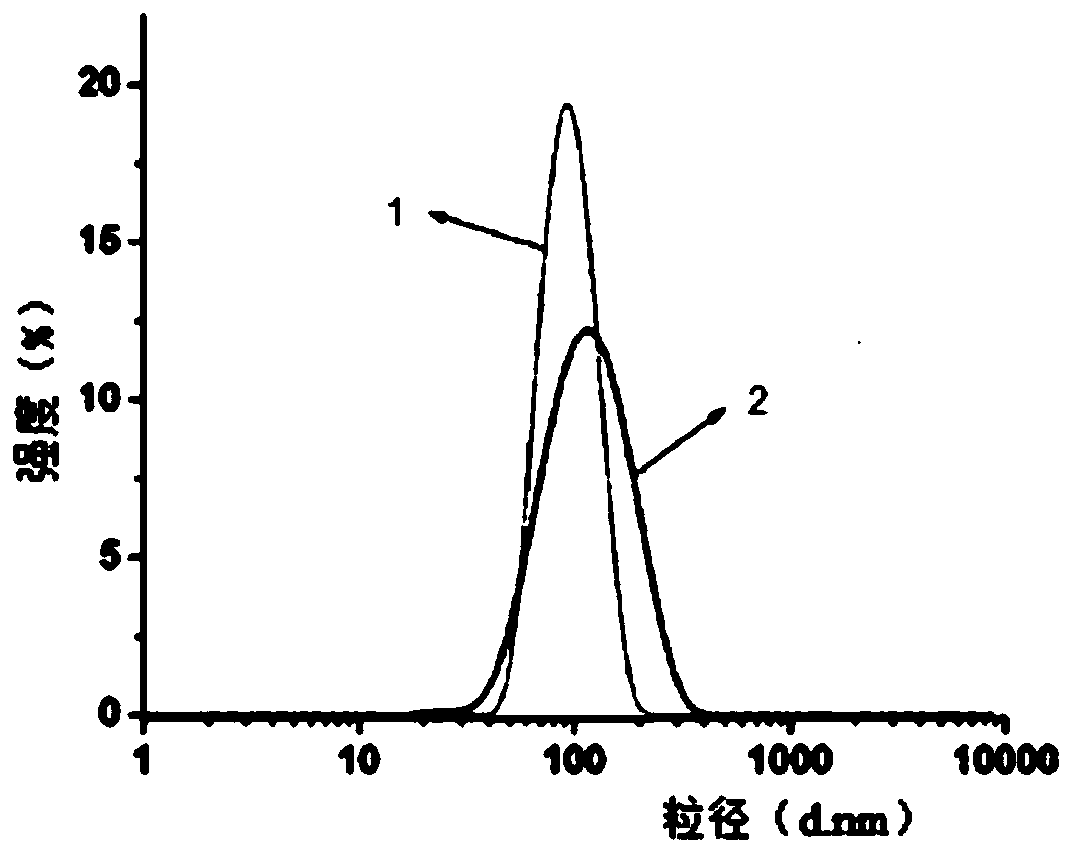

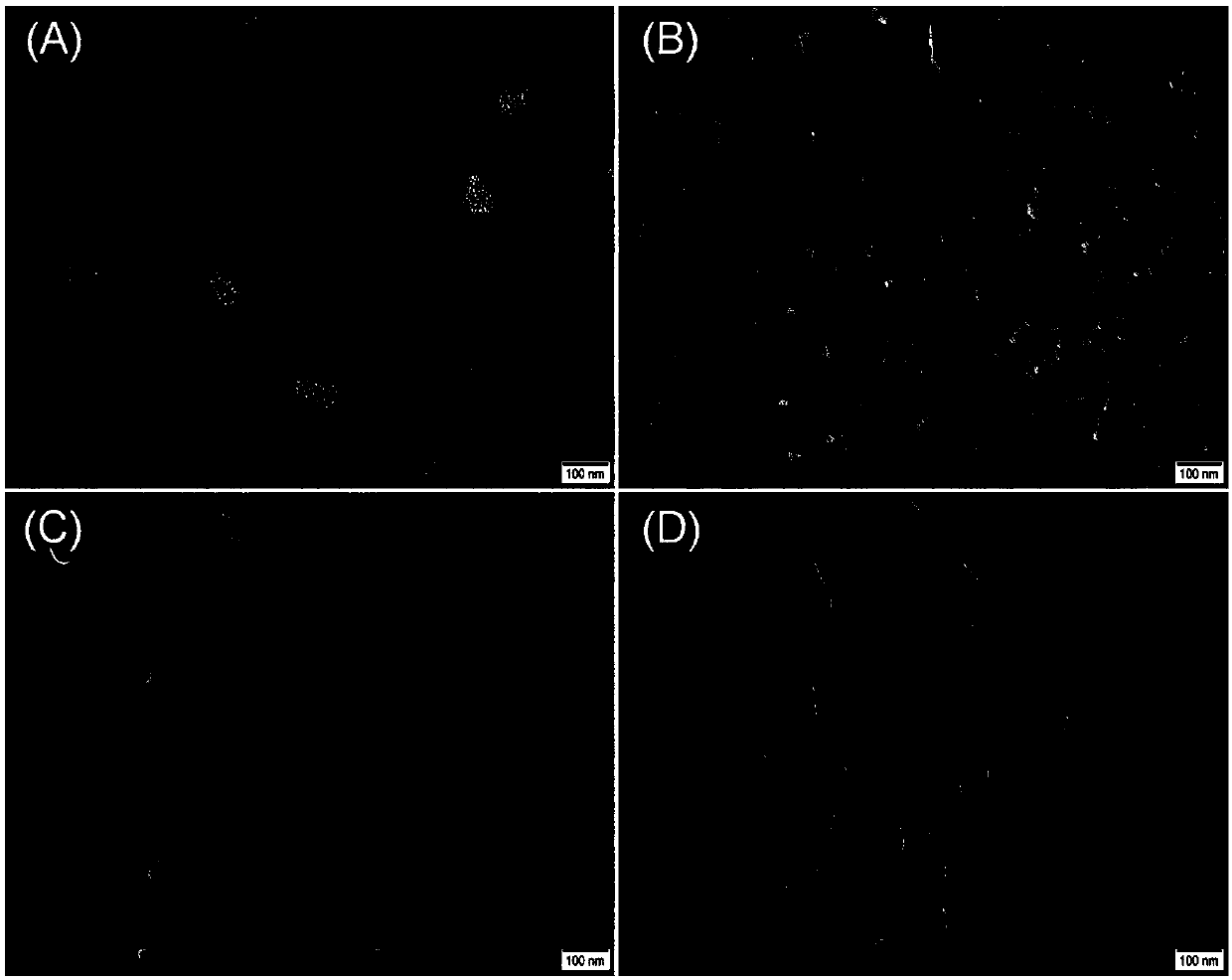

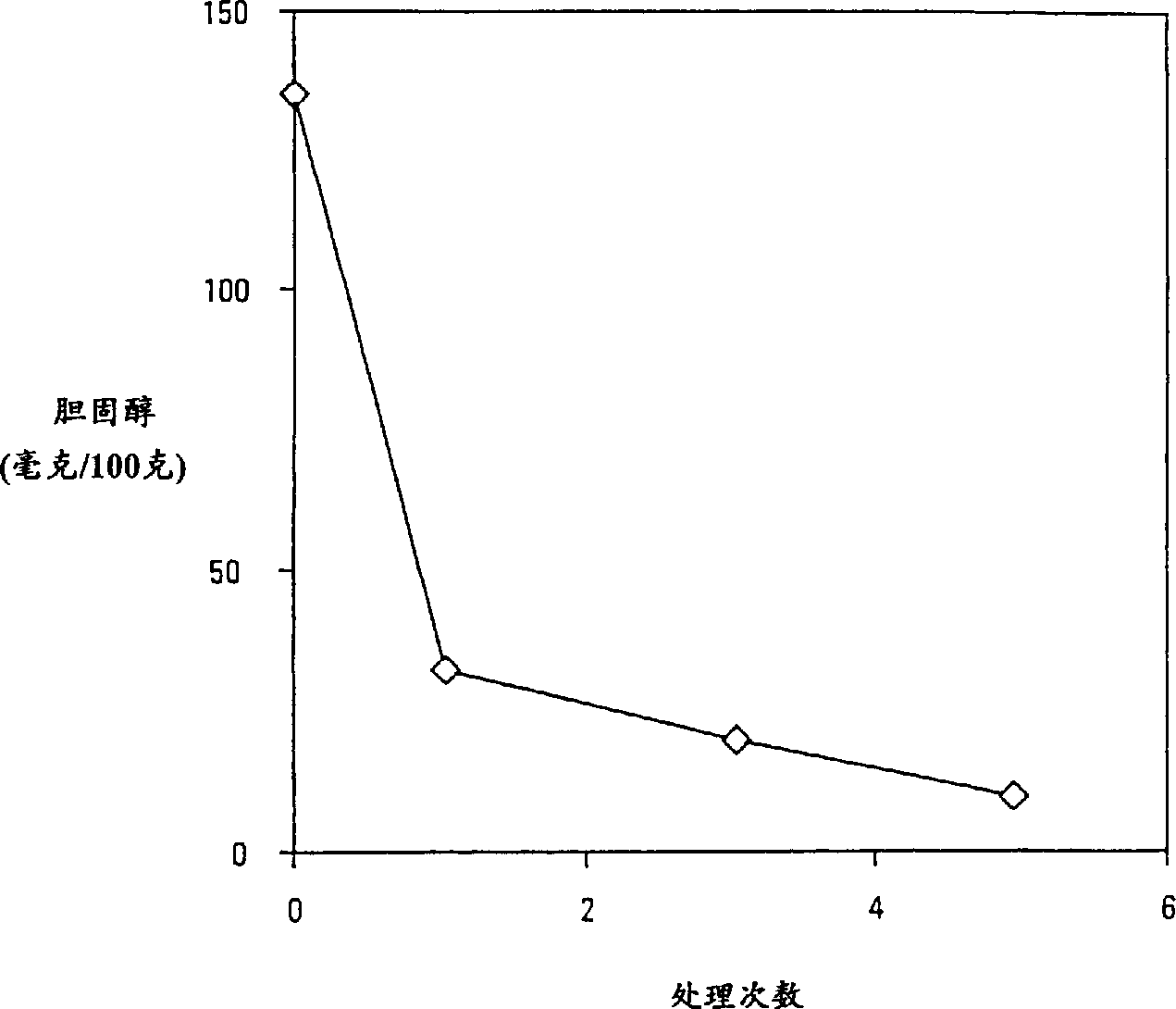

Phospholipid-based removal method of sterols from fats and oil

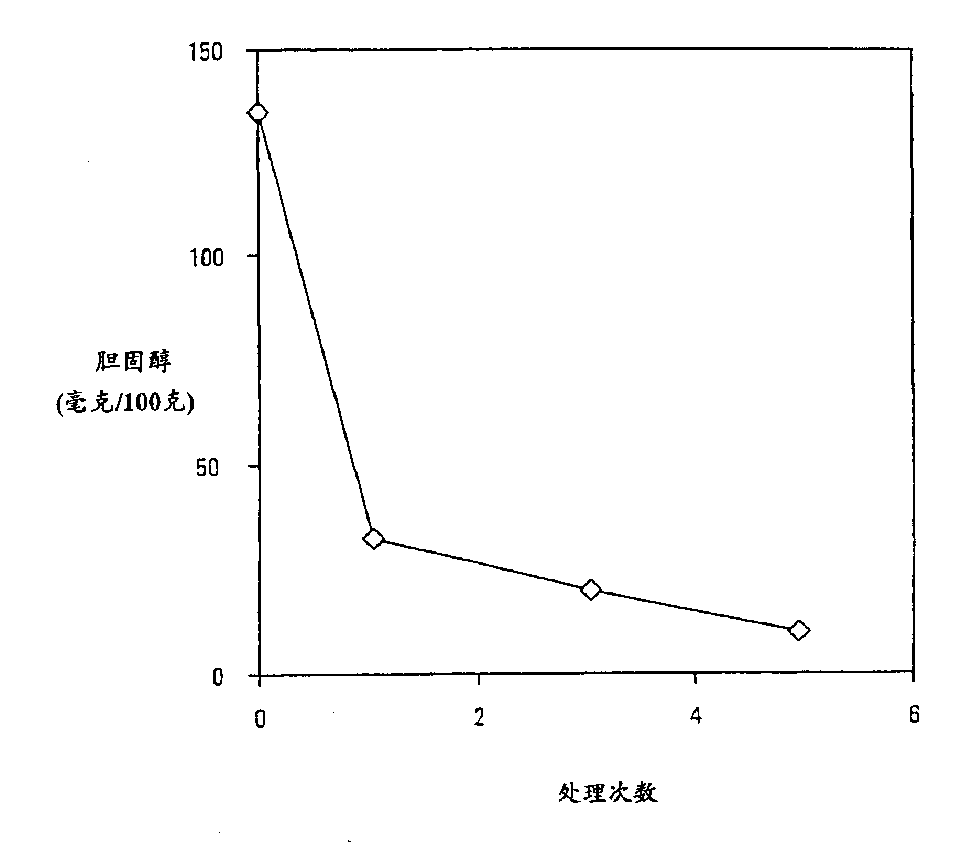

InactiveCN1244890AReduced potential for thermal deteriorationReduce thermal degradationBiocideFatty-oils/fats refiningSterolPhospholipid

Disclosed is a method for reducing the sterol, for example cholesterol, content of sterol-containing substances such as fats and oils. The method provides an efficient and cost effective process based on the phospholipid bilayers. Phospholipid aggregates are contacted with, for example, a sterol-containing fat or oil in an aqueous environment and then mixed. Following adequate mixing, the sterol-reduced fat or oil is separated from the aqueous separation mixture as shown in the figure. Alternatively, the corresponding sterol-enriched phospholipid also may be isolated from the aqueous separation mixture.

Owner:CARGILL INC

Space environment damage prevention protective coating as well as preparation method and application thereof

InactiveCN104830230AHigh resistance to atomic oxygen attackAluminum content can be adjustedAnti-corrosive paintsSilazaneSpace environment

The invention provides a method for preparing a space environment damage prevention protective coating. The method comprises the following steps: preparing polysilazane from organochlorosilane and an ammonia gas through reaction, enabling polysilazane and aluminum isopropoxide to react to prepare a polyaluminum chloride silazane polymer, coating the polyaluminum chloride silazane polymer on the surface of a space material, and curing, thereby obtaining the coating resistant to elemental oxygen corrosion. The protective coating prepared by using the method is applicable to an external material which is sensitive to near-earth orbit elemental oxygen corrosion on space aircrafts. By adopting the method for preparing the space environment damage prevention protective coating, the corrosion resistance of the protective coating to the near-earth orbit elemental oxygen corrosion is improved, and meanwhile the tendency that an organic silicon coating has cracks in the ceramic conversion process can be inhibited.

Owner:JIANGXI SCI & TECH NORMAL UNIV +1

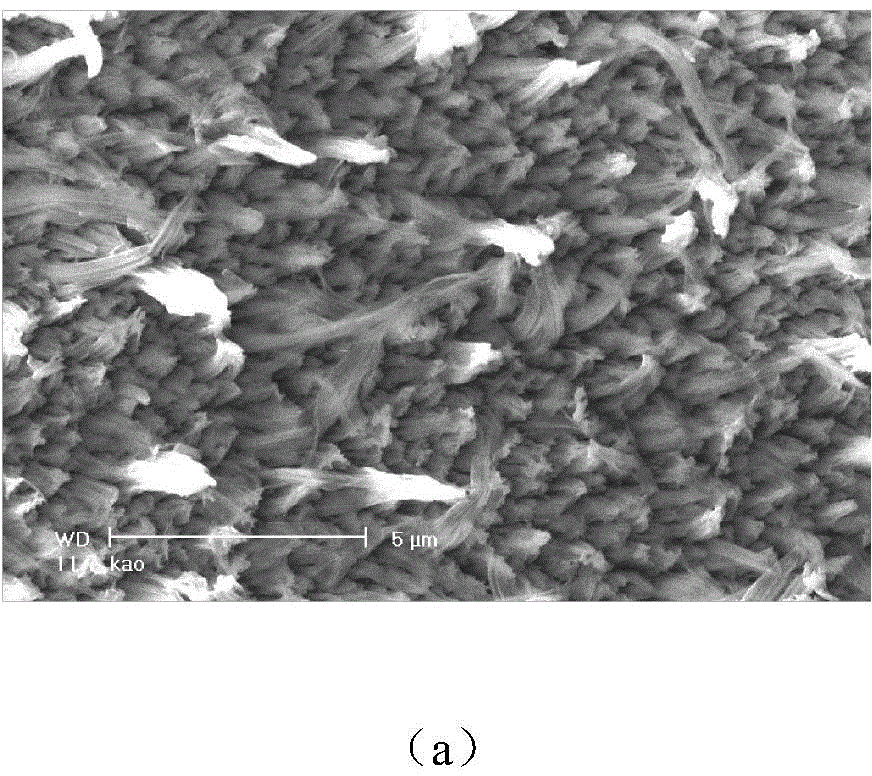

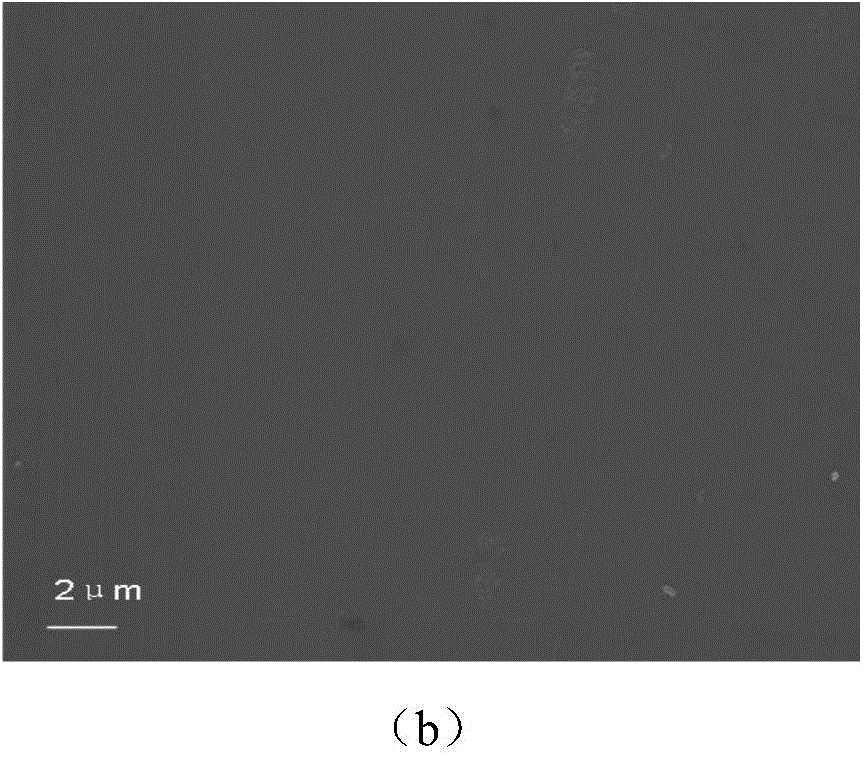

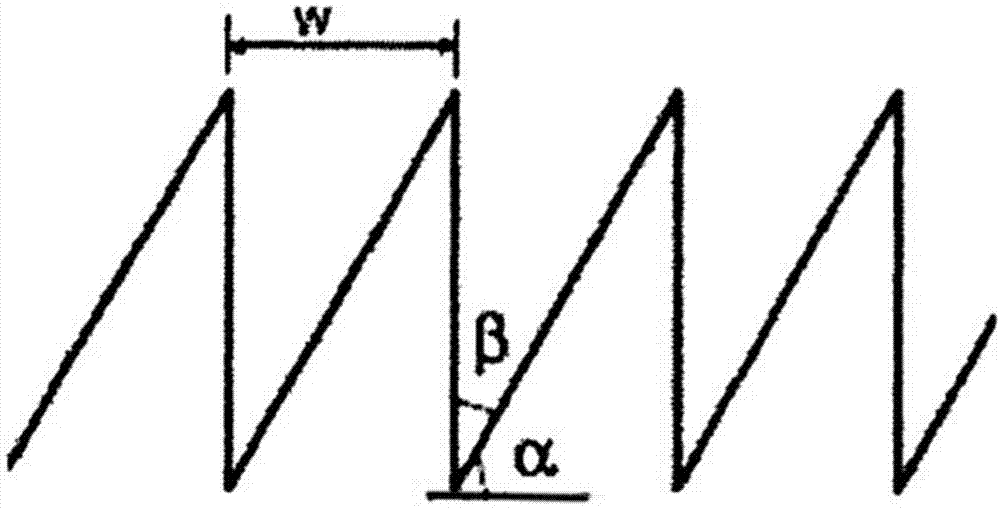

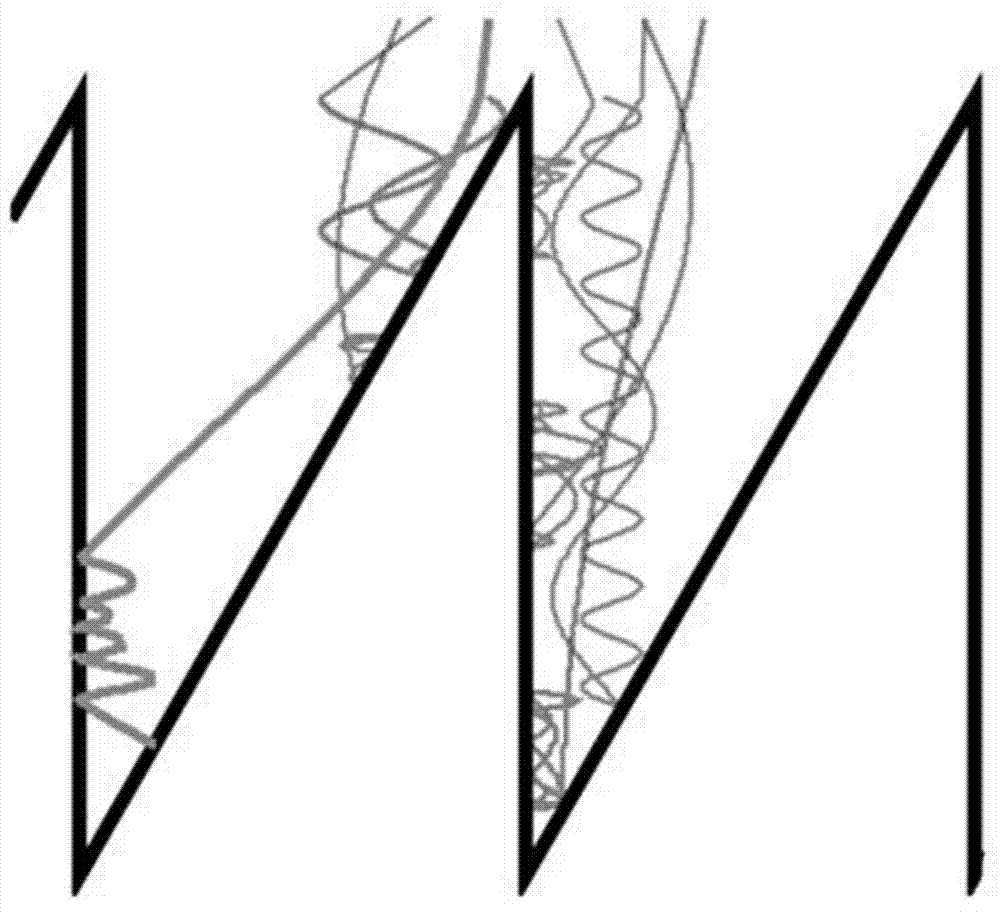

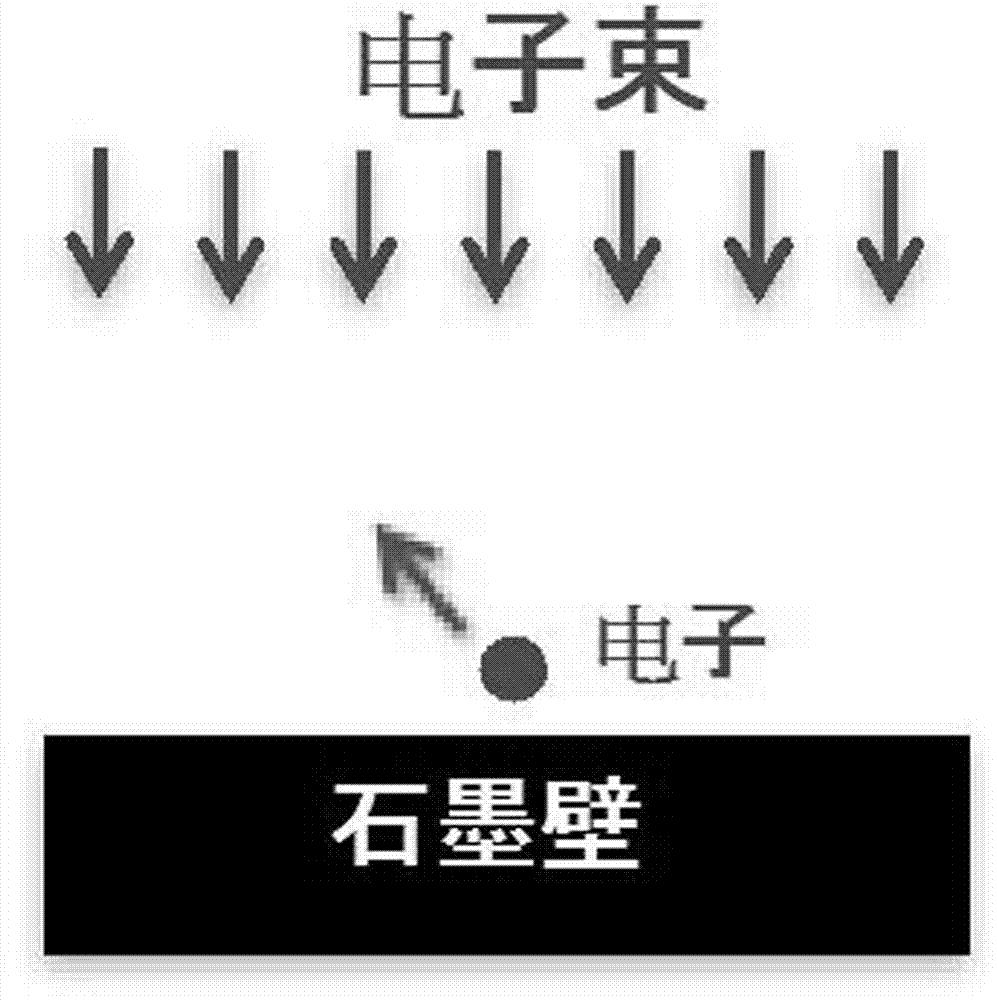

Material for suppressing secondary electron emission

ActiveCN104241061ADoes not change propertiesDoes not change plasma propertiesDischarge tube solid thermionic cathodesMaterials science

The invention relates to material for suppressing secondary electron emission. The material comprises a graphite wall and carbon fibers. The carbon fibers are vertically and evenly distributed on the surface of the graphite wall. Electrons are applied to bombard the graphite wall to generate secondary electrons, the secondary electrons are emitted at different angles from the surface of the graphite wall, very few of the secondary electrons return to vacuum after multiple emission and absorption of the carbon fibers, emission coefficient of the secondary electrons is less than 1 and close to zero, secondary electron emission is suppressed, wall potential is significantly increased since the secondary electron emission is decreased, heat flux of the electrons from plasma to the graphite wall is decreased, wall heating, wall evaporation and plasma cooling are suppressed, and features of the graphite wall and properties of the plasma are unchanged.

Owner:SUZHOU UNIV

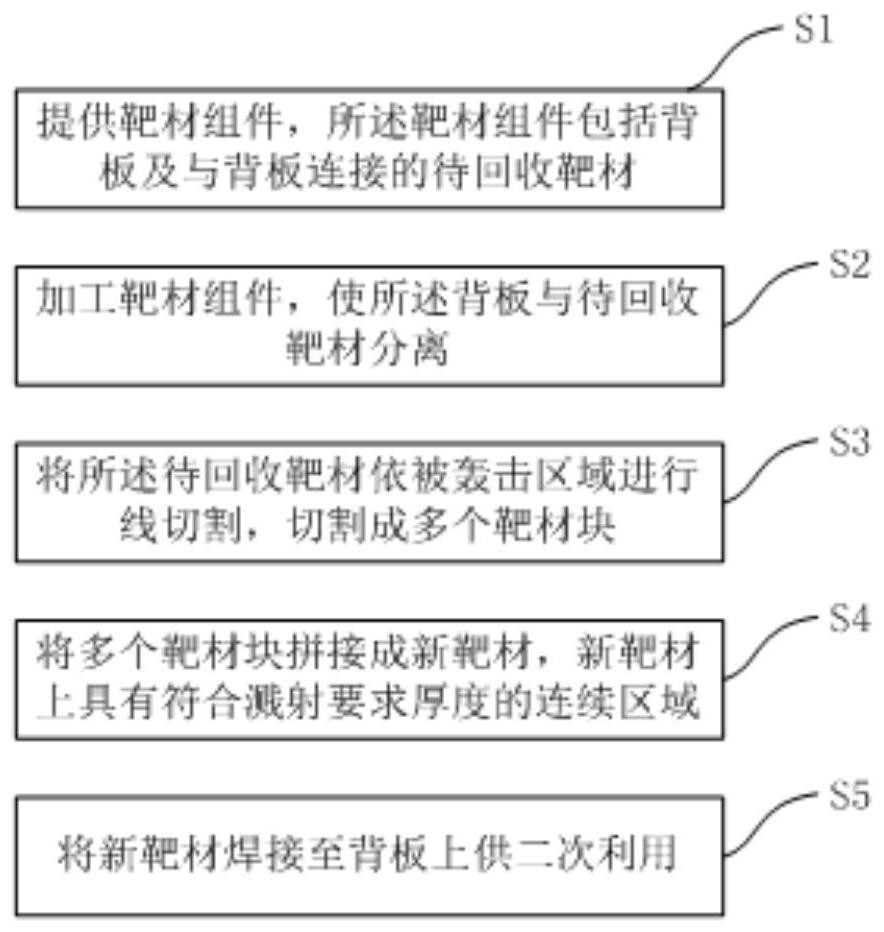

Target material secondary utilization method

InactiveCN111690903ADoes not change propertiesEasy to operateVacuum evaporation coatingSputtering coatingSputteringNuclear engineering

The invention discloses a target material secondary utilization method. The target material secondary utilization method comprises the following steps that a target material assembly is provided, wherein the target material assembly comprises a back plate and a to-be-recovered target material connected with the back plate, the to-be-recovered target material is provided with a bombarded area, andthe thickness of the bombarded area is smaller than that of other areas; the target material assembly is machined to make the back plate be separated from the to-be-recovered target material; the to-be-recovered target material is linearly cut according to the bombarded area to be cut into multiple target material blocks; the multiple target material blocks are spliced into a new target material,and the new target material is provided with a continuous area with the thickness meeting the sputtering requirement; and the new target material is welded to the back plate for secondary utilization.According to the method, the utilization rate of the target material after vacuum sputtering can be further improved, moreover, the operation is simplified, and the cost is reduced.

Owner:江西兴泰科技股份有限公司

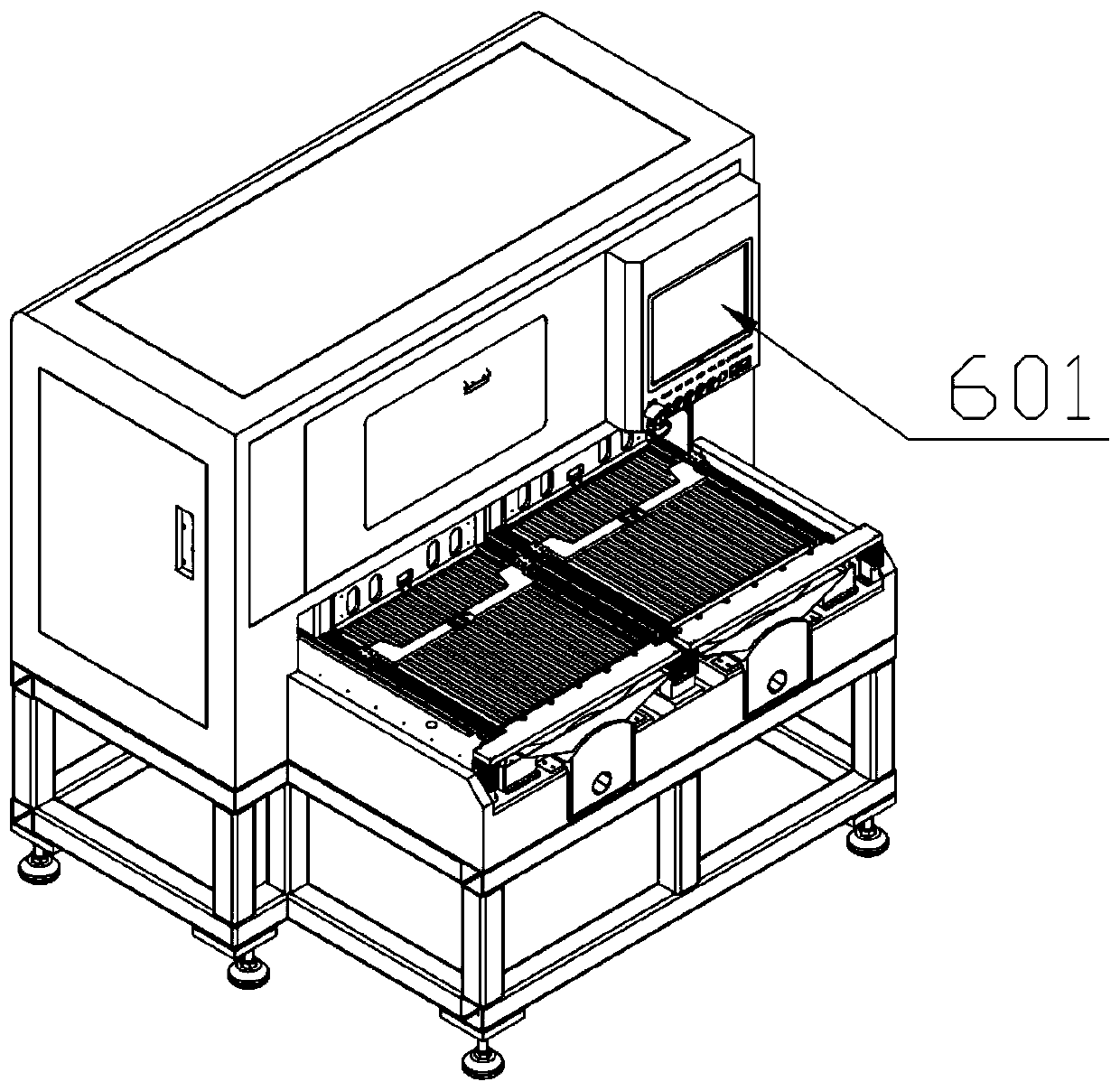

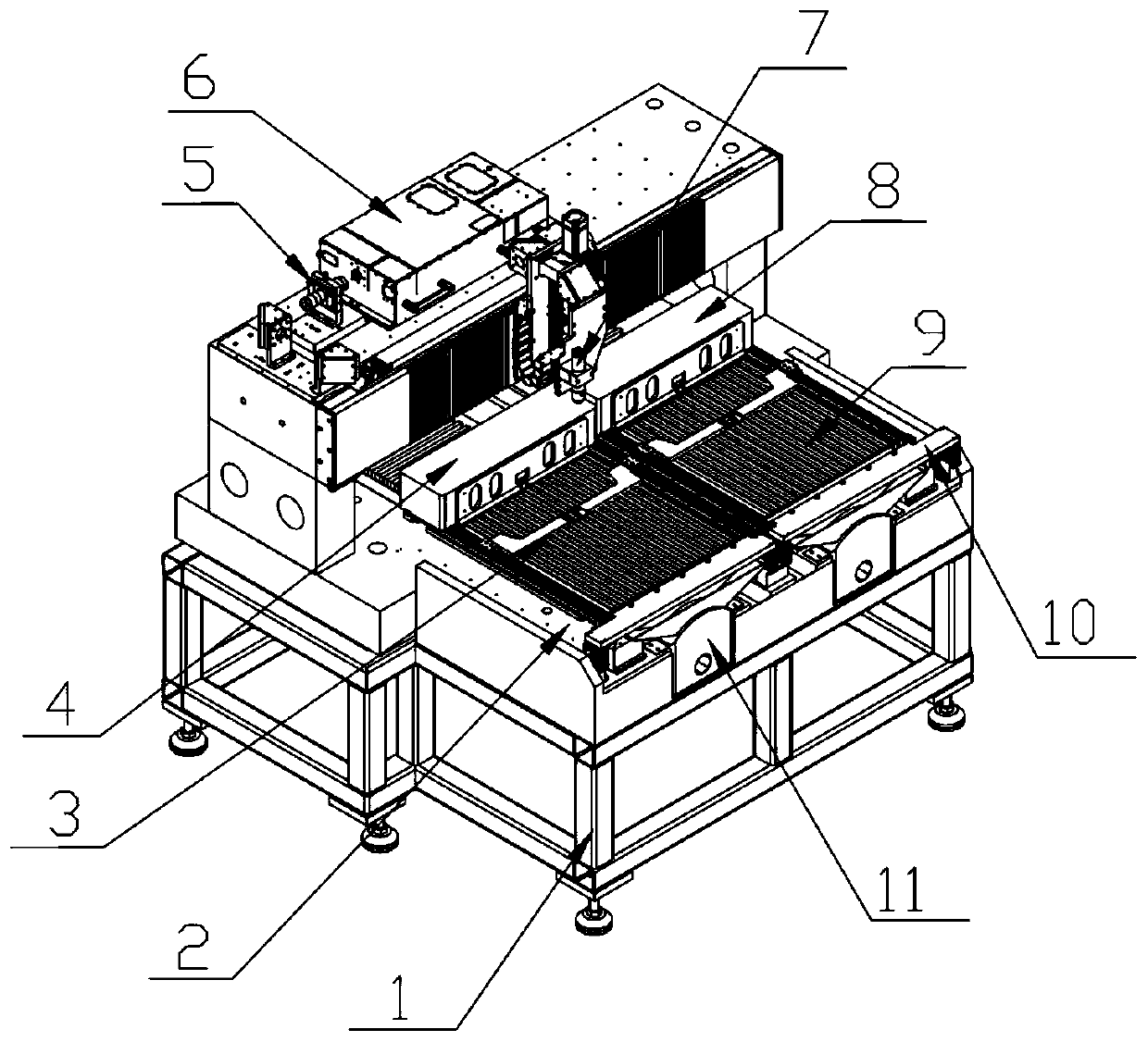

Automatic glass tube laser cutting and separating device

PendingCN110746102ADoes not change propertiesImprove efficiencyGlass severing apparatusPicosecond laserFemto second laser

The invention relates to the technical field of glass cutting, and particularly discloses an automatic glass tube laser cutting and separating device. The automatic glass tube laser cutting and separating device comprises a main rack, a marble platform is fixedly mounted on the upper side of the main rack, a feeding system is arranged on the upper side of the marble platform, a glass tube positioning and rotating system is fixedly mounted on the feeding system, the feeding system is used for placing and transporting multiple glass tubes, cyclic cutting can be realized, the cutting production efficiency is high, the labor cost is low, the precision is high, the yield rate is high, the environment-friendly and pollution-free effect is achieved, a glass tube separation system and a material collection system are arranged, a head material of the glass tube can be broken and collected, so that the waste can be recovered and reused, a picosecond laser device or a femtosecond laser device isadopted by a laser device, a laser generated by the laser device is utilized by a laser cutting head to generate a laser plasma to be acted on the glass tubes, almost no heat is generated during cutting, and the characteristics of the glass are not changed.

Owner:上海致凯捷激光科技有限公司

Flame retardant high polymer material

InactiveCN107778511AImprove flame retardant performanceLower requirementFireproof paintsWax coatingsPolymer scienceAluminium hydroxide

The invention discloses a flame retardant high polymer material which comprises a high polymer material matrix and a compound flame retardant coating, wherein the compound flame retardant coating coats the surface of the high polymer material matrix, and the compound flame retardant coating is a mixture of chlorinated paraffin-70 and aluminium hydroxide. The invention provides the flame retardanthigh polymer material, a player of compound flame retardate coating coats the surface of the high polymer material matrix, and the flame retardance of the high polymer material matrix is improved by the flame retardance of the compound flame retardant coating, so that the high polymer material with high flame retardance can be obtained. The invention further provides a preparation method of the flame retardant high polymer material. The method is simple in steps, low in requirements on materials and devices, and suitable for process and preparation of low cost and large scope.

Owner:GUILIN QUANZHOU LIAOYUAN SCI & TECH

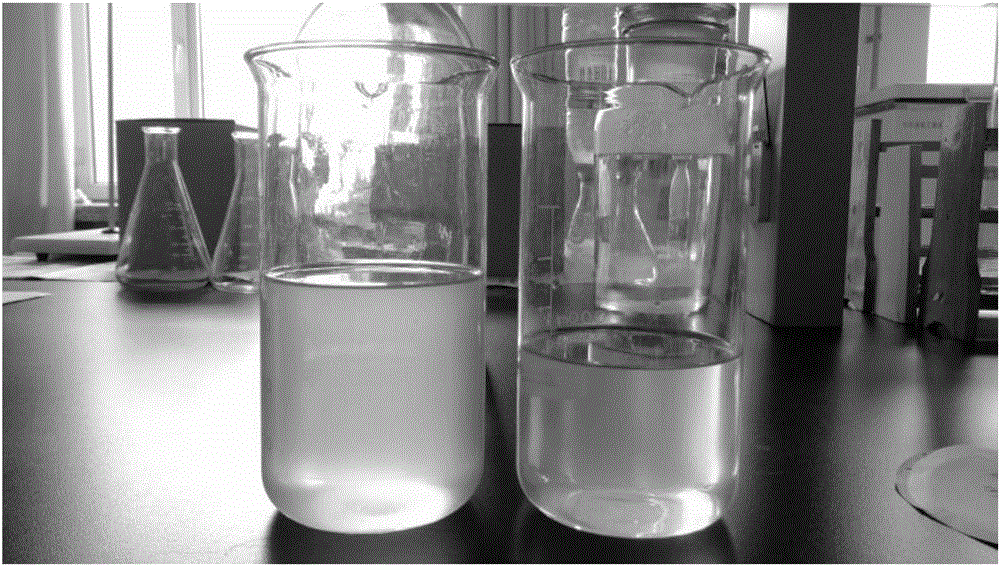

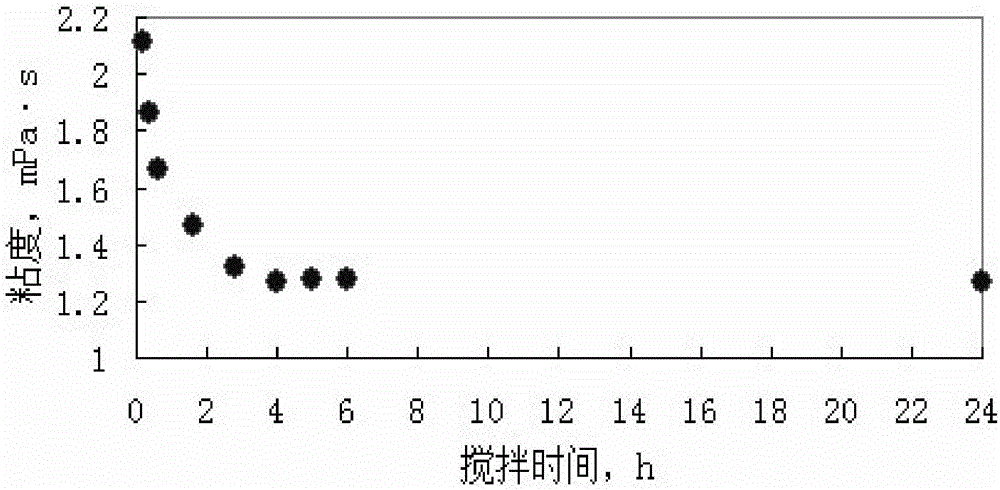

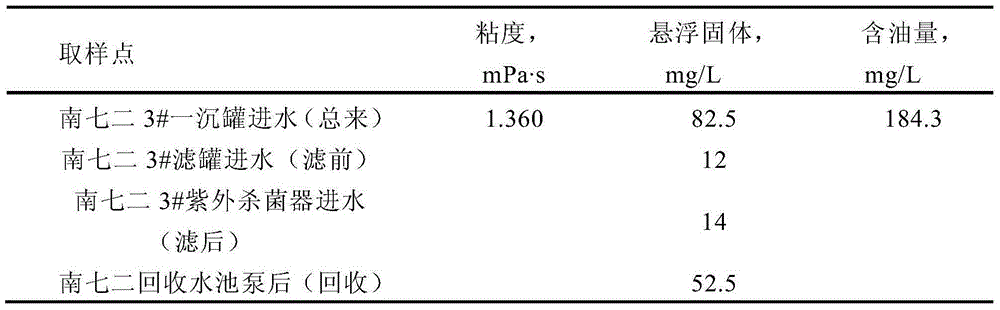

Compound ion fluorinated alkyl sodium sulfate polymer degradation agent and preparation method and application thereof

InactiveCN105062449AGood adaptabilityExtend the operating cycleDrilling compositionFiltration separationIonBenzene

The invention relates to a compound ion fluorinated alkyl sodium sulfate polymer degradation agent and a preparation method and application. The compound ion fluorinated alkyl sodium sulfate polymer degradation agent comprises the following components in percentage by weight: 0.3-0.5% of perfluorophosphate, 1-1.5% of alkyl benzene sulfonic acid, 20-25% of critic acid, 5-10% of ethylene glycol, 15-20% of ferrous sulfate and the balance of water. The compound ion fluorinated alkyl sodium sulfate polymer degradation agent provided by the invention is suitable for reducing viscosity and assisting filtration of a polymer-containing produced liquid in oil field production, and is wide in applicable temperature range, and the crude oil and the polymer-containing produced liquid are successfully separated at a temperature over the freezing point of the crude oil of the produced liquid. Through multiple experiences, the oil content in filtered water is less than 0.02% which reaches the national standard, and the compound ion fluorinated alkyl sodium sulfate polymer degradation agent is energy-saving and environmental-friendly, the pollution is reduced, and the ecological environment is extremely improved.

Owner:李佳芯 +1

Device for transferring overvoltage and use thereof

ActiveCN114287090ADoes not change propertiesLow protection levelSpark gaps with auxillary triggeringCurrent/voltage measurementOvervoltageEngineering

Owner:EPCOS AG

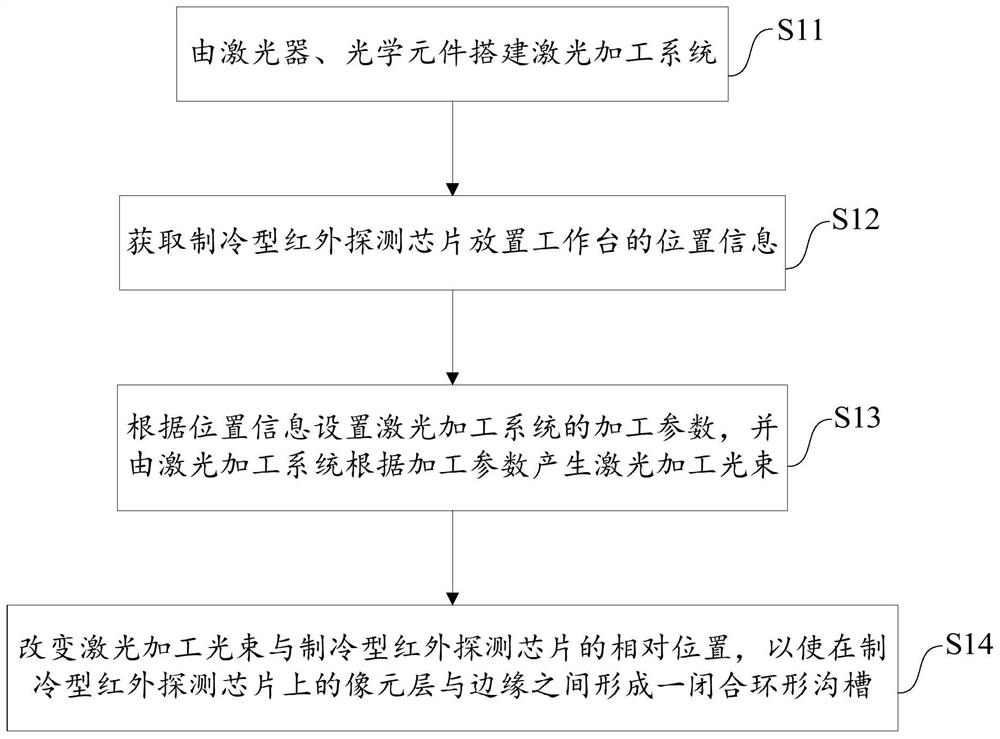

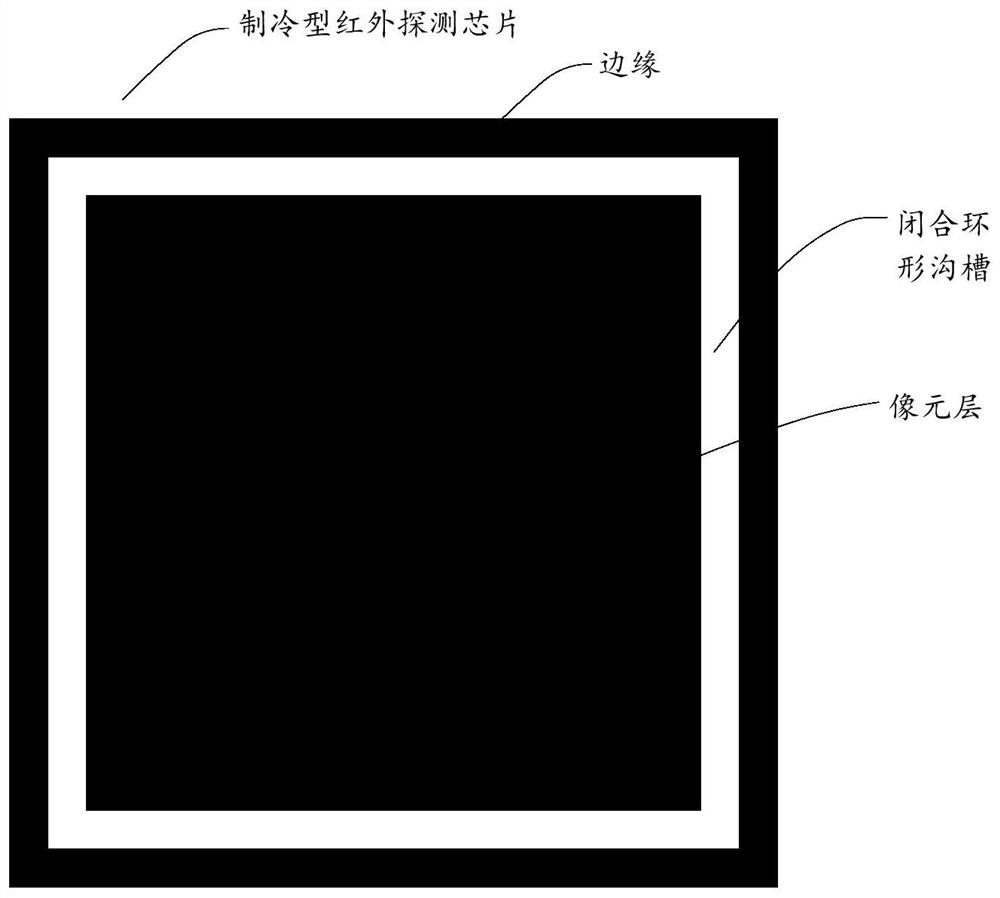

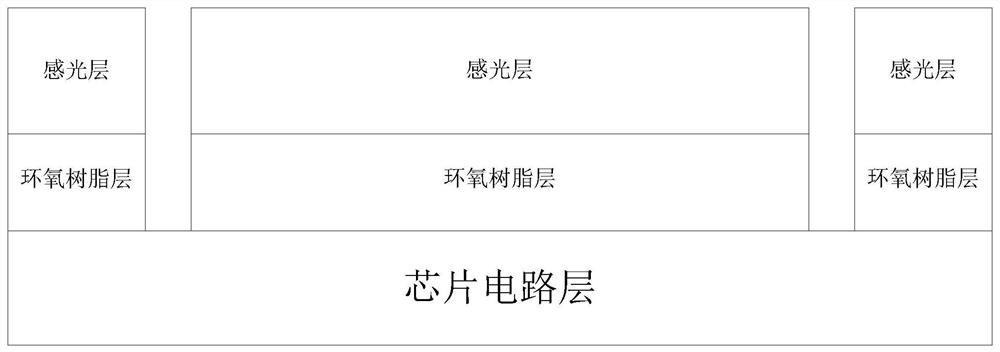

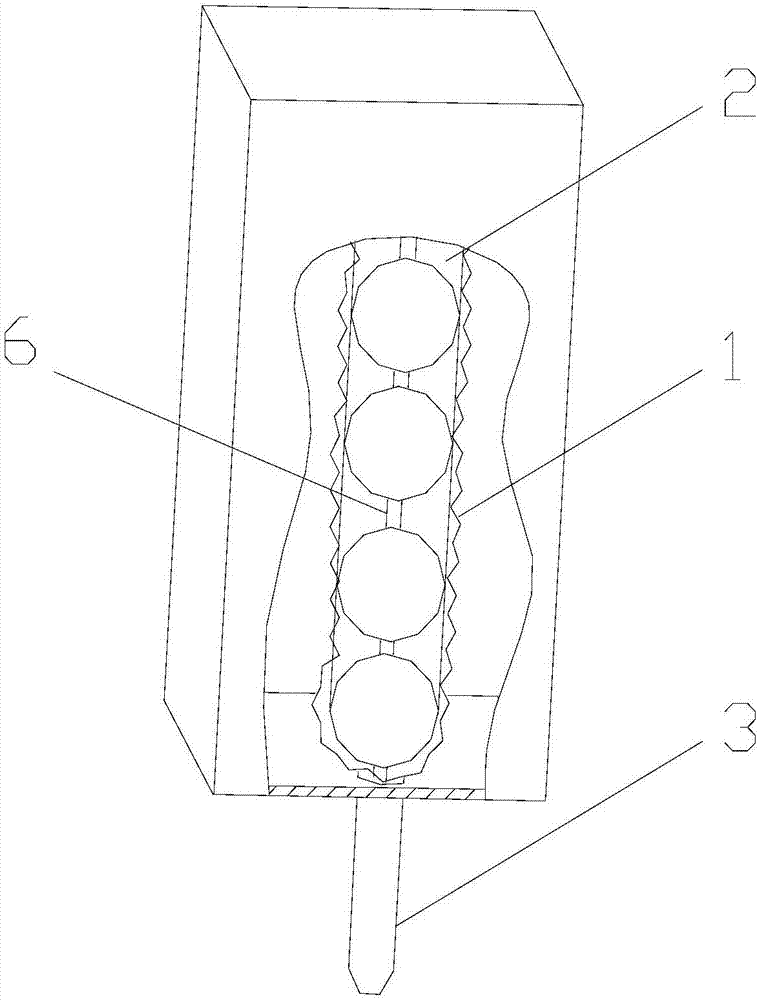

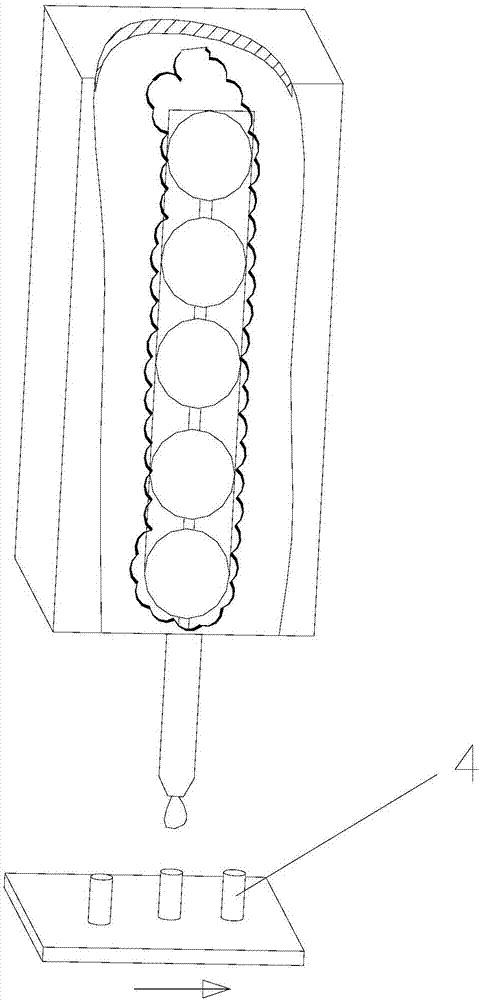

A method of laser processing chip

ActiveCN109530930BDoes not change propertiesHigh degree of automationLaser beam welding apparatusEpoxyLaser processing

The invention provides a method for laser processing chips, comprising: building a laser processing system with lasers and optical elements; obtaining the position information of the cooling type infrared detection chip placed on the workbench; setting the processing parameters of the laser processing system according to the position information, and using the laser The processing system generates a laser processing beam according to the processing parameters; changing the relative position of the laser processing beam and the cooled infrared detection chip, so that a closed annular groove is formed between the pixel layer and the edge on the cooled infrared detection chip. The invention can evenly reduce the pulling of the overflowing filling glue around the pixel layer on the cooling type infrared detection chip when the temperature cycle passes, and then can efficiently and uniformly eliminate the thermal stress on the photosensitive layer and epoxy resin of the cooling type infrared detection chip Position offset effects between layers.

Owner:北京中科镭特电子有限公司

Production method of stainless steel wire rod material

The invention relates to the technical field of metal smelting, in particular to a production method of a stainless steel wire rod material. The production method comprises the following steps: raw material selection and pretreatment; welding into a long strip; hole pattern extrusion; flying shear treatment; and taking up the wire. The production method does not involve steel smelting and steel rolling procedures, and is low in energy consumption, small in pollutant discharge amount and environmentally friendly; the used raw material is stainless steel waste, the raw material cost is low, and good economic benefits are achieved.

Owner:淄博淄翼金属材料有限公司

A tube and use of said tube

InactiveCN101321896BDoes not change propertiesAvoid it happening againThermal non-catalytic crackingVacuum evaporation coatingEmissivityMetal alloy

A metallic tube for heating a medium or subject outside thereof or inside it by transfer of heat energy through walls of the tube, in which heat is absorbed or emitted at least to a substantial degree by radiation on one or both of the inner and outer surfaces of the tube, is of a material forming a layer of essentially AI2O3 on the surfaces thereof when heated to at least approximately 750 C. Atleast one of the external and the internal surface of the tube is coated by one of a metal, metal alloy and metal compound, which after oxidation forms a layer having an emissivity coefficient exceeding 0.7, or by a layer essentially consisting of a metal oxide which has an emissivity coefficient exceeding 0.7.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Glass forming bead dripping stove and glass forming system

ActiveCN106904818ADoes not change propertiesWill not pollutePot furnacesHalogen/halogen-acidsAdhesiveCrucible

The invention discloses a glass forming bead dripping stove and a glass forming system and relates to the technical field of glass forming devices. The glass forming bead dripping stove comprises a heating device, a crucible device and a discharge nozzle device. The heating device is used for heating the crucible device; the crucible device is used for containing and melting glass powder; the discharge nozzle device is vertically connected to the bottom of the crucible device and communicated with an inner cavity of the crucible device. According to the glass forming bead dripping stove, the glass powder is heated in the crucible device, melted into liquid, and enters the discharge nozzle device, the glass liquid drips at the bottom of the discharge nozzle device in a droplet form because of the effects of the weight and surface tension of the glass liquid, and then is cooled to be formed, no adhesives are needed in the forming process, no pollution is caused to the environment, the formed glass is harmless to the human body, the original characteristic of the glass cannot be changed, the problem that the glass is formed by means of the adhesives and accordingly pollution is caused to the environment is solved, and the glass forming bead dripping stove and the glass forming system have application and popularization values.

Owner:南京广兆测控技术有限公司

Filter Phase Shifter and Antenna

ActiveCN111342174BLarge power capacityOverall small sizeWaveguide type devicesElectrical conductorHemt circuits

The invention relates to a filtering phase shifter and an antenna. The filtering phase shifter comprises a fixed circuit, an auxiliary conductor transmission section and a movable circuit. The movablecircuit moves relative to a first carrier plate to enable a second transmission line to move in or out of a containing cavity, the coupling amount between a movable line layer and a fixed line layerand the coupling amount between the movable line layer and the auxiliary transmission conductor section can be changed, and therefore the electrical length of signal transmission in the filtering phase shifter is changed, and phase adjustment of the output port is achieved. In addition, a filtering stub is additionally arranged in a movable circuit of a U-shaped transmission line type phase shifter, so that the integrated design of a filter and a phase shifter is realized. In addition, input signals are subjected to filtering and phase shifting at the same time, the space utilization rate is increased, and the size is effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

A method for preparing single-layer molybdenum disulfide quantum dots based on electronic dynamic regulation

ActiveCN106905966BHigh yieldPromote absorptionCatalyst activation/preparationNanotechnologyPhotoablationFemto second laser

The invention relates to a method for preparing monolayer molybdenum disulfide quantum dots based on electronic dynamic regulation and control, in particular to a method for obtaining the monolayer molybdenum disulfide quantum dots with uniform particle sizes by obtaining molybdenum disulfide suspension and then centrifugally separating and belongs to the field of femtosecond laser application. The method disclosed by the invention comprises the following steps: aiming at the characteristics of a molybdenum disulfide material, carrying out pulse shaping on traditional femtosecond laser monopulse by using a Michelson interferometer to form a pulse sequence; adjusting energy of the pulse sequence, delay among sub pulses, laser scanning speed and scanning intervals; ablating blocky molybdenum disulfide in water and further regulating and controlling local transient electronic dynamics in the interaction process of laser and the material to form multistage photoablation monolayer molybdenum, and obtaining the monolayer molybdenum disulfide quantum dots with the uniform particle sizes; carrying out laser-induced water dissociation to enhance light absorption and improve the yield of the molybdenum disulfide quantum dots. The method disclosed by the invention has the advantages of no need of special chemical environment or chemical reagent, greenness, no pollution, and simple and flexible operation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com