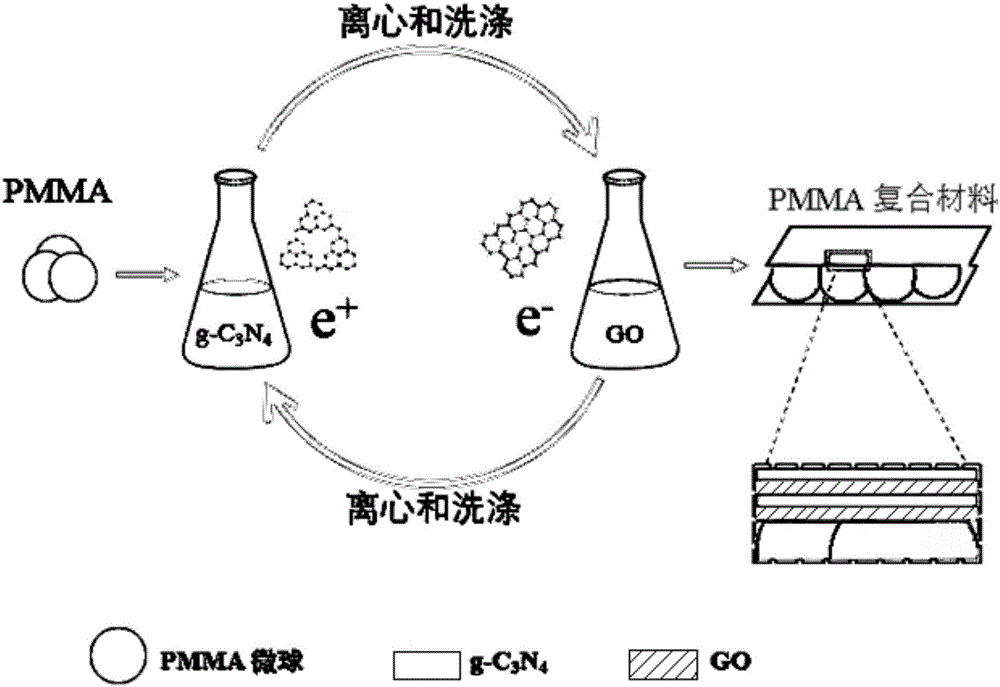

Flame-retardant modified PMMA (polymethylmethacrylate) microspheres and preparation method thereof

A technology of polymethyl methacrylate and microspheres, applied in coating and other directions, can solve the problem of low flame retardant level, and achieve the effect of improving flame retardant performance, realizing dispersibility, and requiring low operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

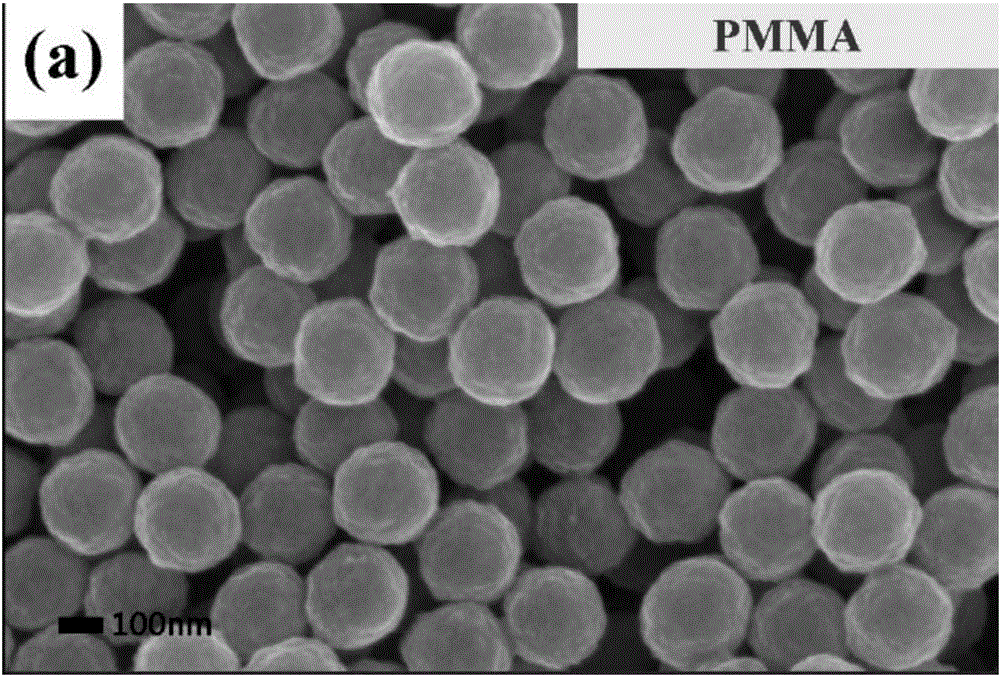

[0055] (1) Pretreatment of polymethyl methacrylate (PMMA) microspheres: Soak polymethyl methacrylate microspheres in isopropanol for 45 seconds, and then centrifuge at 8000 rpm for 12 minutes to obtain a precipitate. Processed PMMA microspheres, standby;

[0056] (2) Preparation of graphite phase carbon nitride suspension: 5g graphite phase carbon nitride (g-C 3 N 4 ) into 300mL of isopropanol, ultrasonicated for 4 hours to obtain a suspension, then sequentially added 4.5g of acetic acid and 0.70g of chitosan, ultrasonicated for 4 hours, and the upper suspension was taken to obtain a graphite phase carbon nitride suspension;

[0057] (3) Preparation of graphene oxide dispersion: put 0.5 g of graphene oxide (GO) into 500 mL of deionized water for 10 hours of ultrasonic dispersion, take the upper dispersion liquid, and obtain a 1 g / L graphene oxide dispersion liquid;

[0058] (4) Layer-by-layer self-assembly: Soak the pretreated PMMA microspheres in graphite-phase carbon nitri...

Embodiment 2

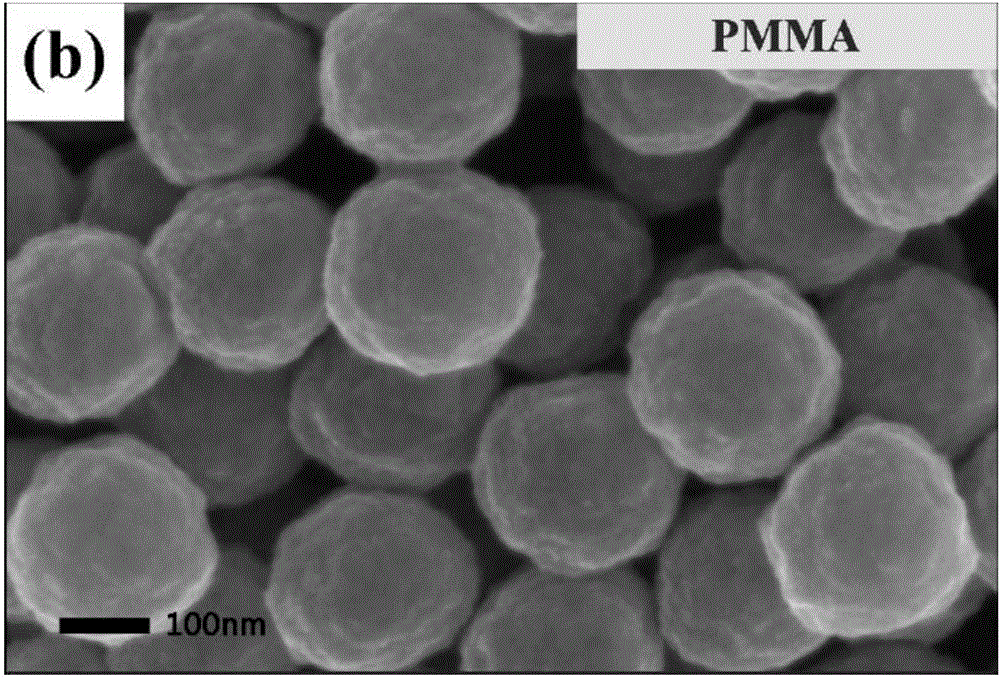

[0061] (1) Pretreatment of polymethyl methacrylate (PMMA) microspheres: Soak polymethyl methacrylate microspheres in isopropanol for 80 seconds, and then centrifuge at 6000 rpm for 15 minutes to obtain a precipitate. Processed PMMA microspheres, standby;

[0062] (2) Preparation of graphite phase carbon nitride suspension: 5g graphite phase carbon nitride (g-C 3 N 4 ) into 300mL of isopropanol, ultrasonicated for 3 hours to obtain a suspension, then sequentially added 2.4 g of acetic acid and 0.50 g of chitosan, ultrasonicated for 7 hours, and the upper suspension was taken to obtain a graphite phase carbon nitride suspension;

[0063] (3) Preparation of graphene oxide dispersion: put 0.25g graphene oxide (GO) into 500mL deionized water for 8 hours and ultrasonically disperse, take the upper dispersion to obtain 0.5 g / L graphene oxide dispersion;

[0064] (4) Layer-by-layer self-assembly: Soak the pretreated PMMA microspheres in graphite-phase carbon nitride suspension, soni...

Embodiment 3

[0067] (1) Pretreatment of polymethyl methacrylate (PMMA) microspheres: Soak the polymethyl methacrylate microspheres in isopropanol for 120 seconds, and then centrifuge them at 9000 rpm for 10 minutes to obtain a precipitate. Processed PMMA microspheres, standby;

[0068] (2) Preparation of graphite phase carbon nitride suspension: 5g graphite phase carbon nitride (g-C 3 N 4 ) into 300mL of isopropanol, ultrasonicated for 7 hours to obtain a suspension, then sequentially added 7.0 g of acetic acid and 1.25 g of chitosan, ultrasonicated for 3 hours, and the upper suspension was taken to obtain a graphite phase carbon nitride suspension;

[0069] (3) Preparation of graphene oxide dispersion: put 1 g of graphene oxide (GO) into 500 mL of deionized water for ultrasonic dispersion for 12 hours, take the upper dispersion to obtain a 2 g / L graphene oxide dispersion;

[0070] (4) Layer-by-layer self-assembly: Soak the pretreated PMMA microspheres in the graphite-phase carbon nitrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com