A method of laser processing chip

A laser processing and chip technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of easy damage to the bottom readout circuit, damage to the bottom readout circuit, complicated corrosion process, etc., to eliminate position offset. Influence, high processing speed, small heat-affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

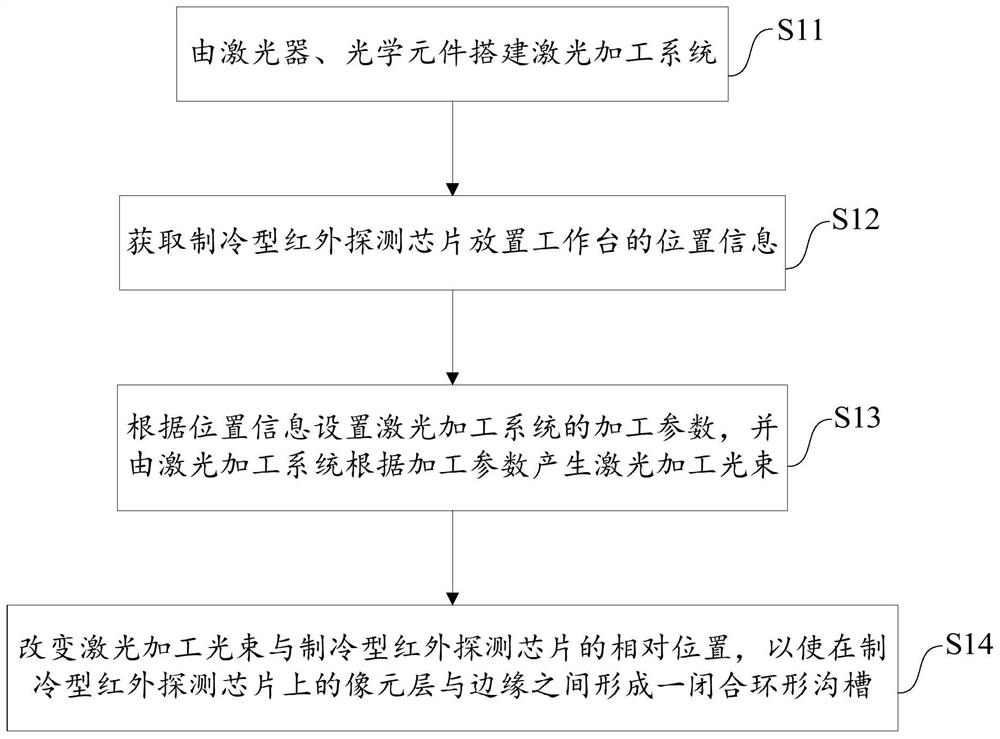

[0048] Embodiments of the present invention provide a method for laser processing chips, such as figure 1 As shown, the method includes:

[0049] S11. Build a laser processing system with lasers and optical components;

[0050] S12. Acquiring the position information of the workbench where the cooled infrared detection chip is placed;

[0051] S13. Set the processing parameters of the laser processing system according to the position information, and generate the laser processing beam according to the processing parameters by the laser processing system;

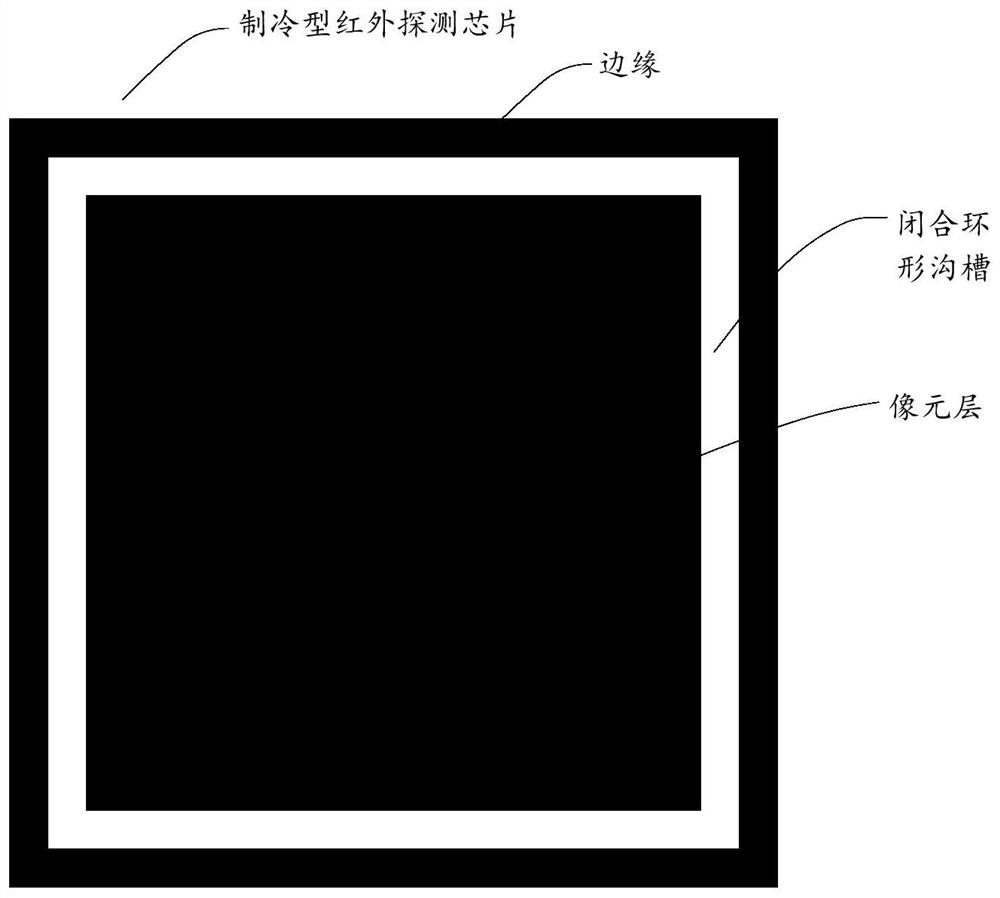

[0052] S14. Changing the relative position of the laser processing beam and the cooled infrared detection chip, so that a closed annular groove is formed between the pixel layer and the edge on the cooled infrared detection chip.

[0053] The laser processing chip method provided by the embodiment of the present invention mainly uses the laser processing system to generate a laser beam to prepare a closed annular groove on...

Embodiment 2

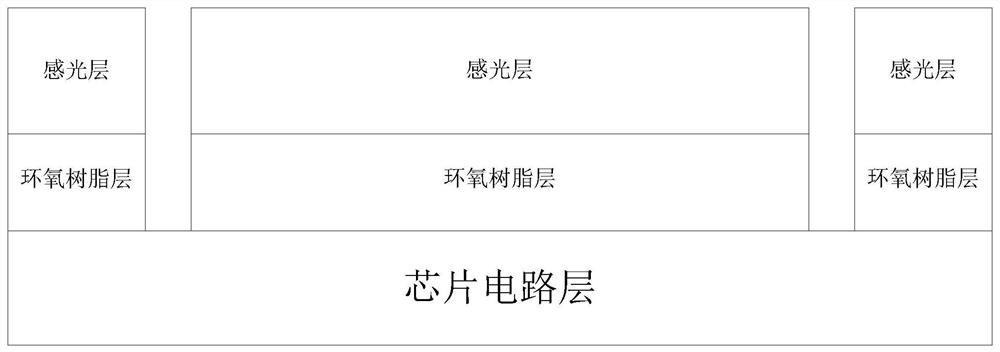

[0079] An embodiment of the present invention provides a device for laser processing chips, such as Figure 2 to Figure 4 As shown, the device includes:

[0080] Workbench, used to place the refrigerated infrared detection chip to be processed;

[0081] The control system is used to obtain the position information of the cooling type infrared detection chip placed on the workbench, and then set the processing parameters of the laser processing system according to the position information, and control the laser processing system to generate the laser processing beam according to the processing parameters;

[0082] The laser processing system is formed by a laser, a beam expander and collimator, and a galvanometer. It is used to expand and collimate the laser processing beam emitted by the laser through the beam expander and collimator, and then change the laser processing beam through the galvanometer. The relative position of the cooling type infrared detection chip is such t...

Embodiment 3

[0118] Since the cutting of infrared semiconductor materials by ultrashort pulse laser is mainly realized through the multiphoton absorption mechanism, the process of plasma recombination is often accompanied by the generation of dust and smoke. Inhaling a large amount of dust and the generated gas is not only harmful to the human body, but also has a bad impact on the mechanical and optical transmission, laser performance, etc. Therefore, these additional harmful substances are efficiently removed.

[0119] An embodiment of the present invention provides a device for laser processing chips, such as Image 6 As shown, the device includes:

[0120] Workbench, used to place the refrigerated infrared detection chip to be processed;

[0121] The dust removal device is arranged between the laser processing system and the workbench and establishes a processing chamber on the workbench, which is used to feed auxiliary gas into the processing chamber so that the processing chamber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com