Photo-stabilization type lubricating grease and preparation method thereof

A lubricating grease and light-stabilizing technology, applied in the field of lubricating grease, can solve the problems of reduced structural strength, complex production process formula, and reduced consistency, and achieve the effect of ensuring light stability, high cost performance, and obvious colloidal stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

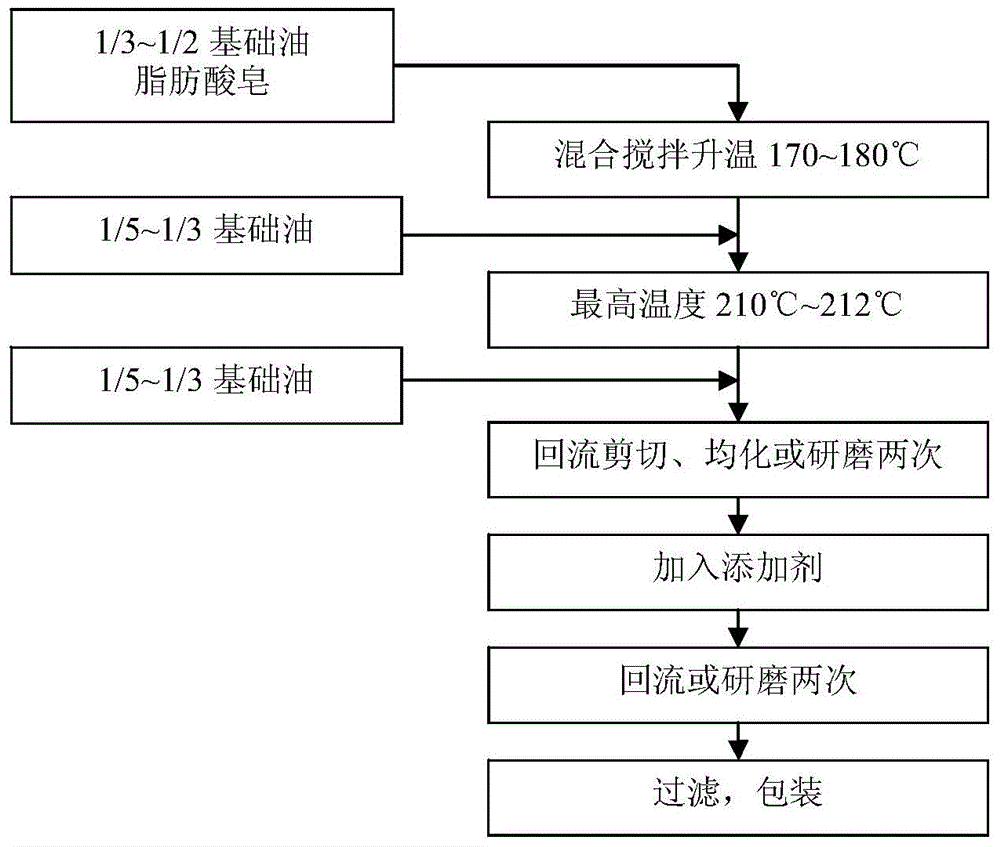

Method used

Image

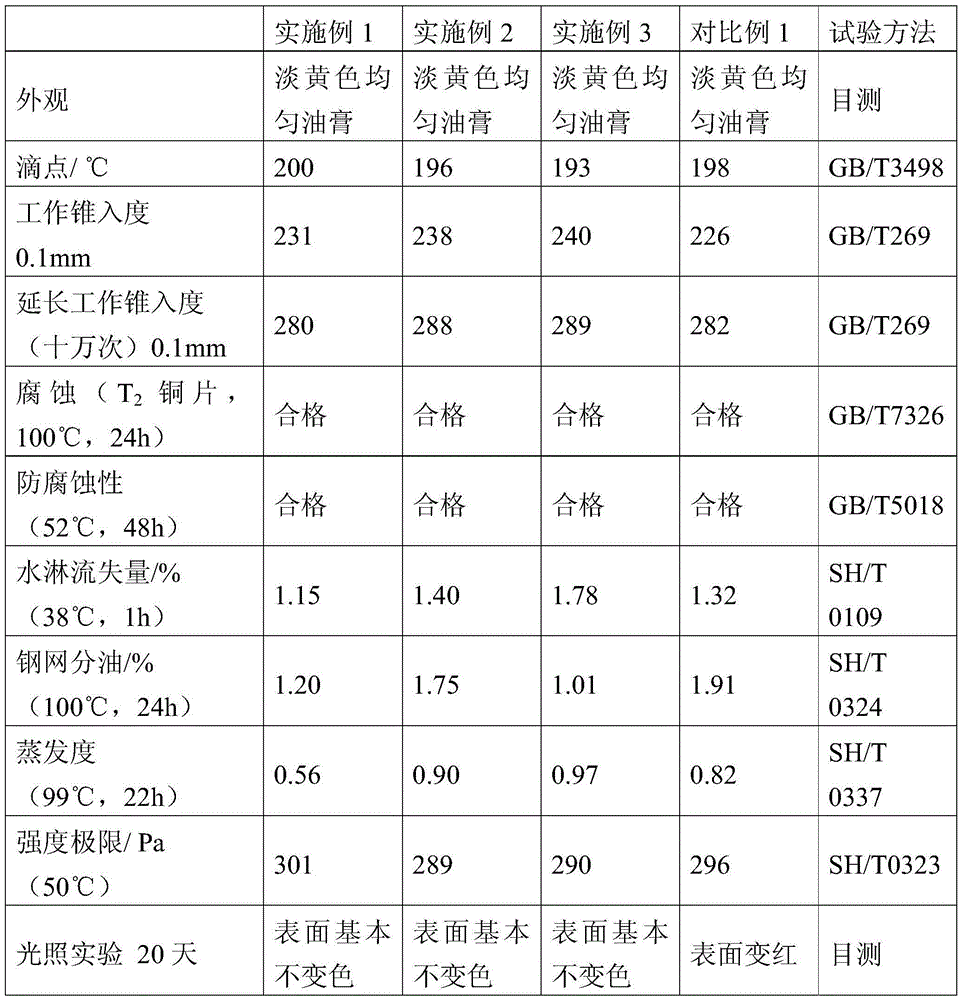

Examples

Embodiment 1

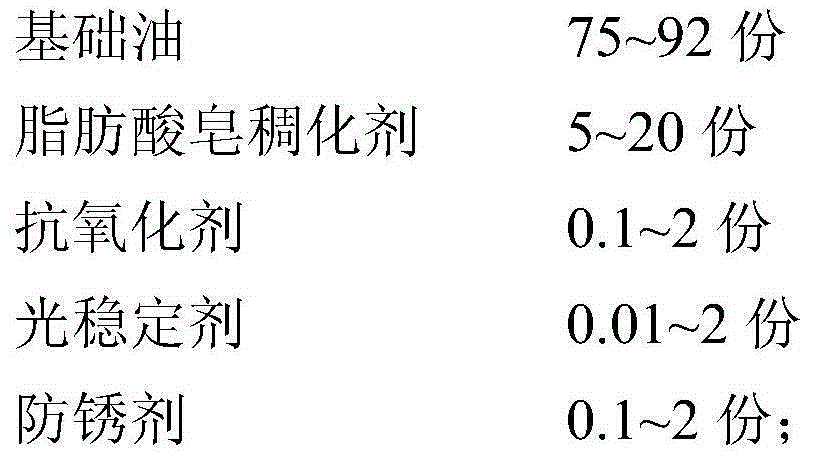

[0030] A light-stable lubricating grease is prepared according to the following steps:

[0031] (1) Put 35 parts of Class I mineral oil (kinematic viscosity of 120cst at 40°C) into the reactor, heat to 70°C and put in 18.2 parts of lithium lauryl stearate soap, stir and heat up to 170°C, add 25 parts of I Thickened with mineral oil (40℃ kinematic viscosity is 120cst);

[0032] (2) Heat up to the highest temperature of 210°C, add 20 parts of polyalphaolefin synthetic base oil (40°C kinematic viscosity is 100cst) after 2 minutes of heat preservation, keep heat at 180°C for 10 minutes, then transfer to the second reaction kettle, and cool to 135± Grind twice in a grinder at 5°C to obtain base grease;

[0033] (3) Cool the base grease obtained in step (2) to 80°C, add 0.5 parts of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole, 0.4 parts of benzotriazole , 0.3 parts of barium dinonylnaphthalene sulfonate, 0.6 parts of diphenylamine, after being ground twice by a grinder, filtered a...

Embodiment 2

[0035] A light-stable lubricating grease is prepared according to the following steps:

[0036] (1) Put 40 parts of type II mineral oil (kinematic viscosity of 110cst at 40°C) into the reaction kettle, heat to 60°C and put in 12 parts of lithium dodecyl hydroxystearate soap, stir and heat up to 180°C, add 30 Part II type mineral oil (40 ℃ kinematic viscosity is 110cst) for thickening;

[0037] (2) Heat up to the highest temperature of 212°C, add 15 parts of ester base oil (kinematic viscosity at 40°C is 80cst) after 2 minutes of heat preservation, heat at 182°C for 8 minutes, then transfer to the second reaction kettle, and cool to 135±5°C Reflow shearing to obtain base grease;

[0038] (3) Cool the base grease obtained in step (2) to 70°C, and add 0.01 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorinated benzene Triazole, 0.3 part of 2,6-di-tert-butyl-p-cresol, and 0.2 part of zinc naphthenate are refluxed and sheared by a reflux pump, filtered and packaged t...

Embodiment 3

[0040] A light-stable lubricating grease is prepared according to the following steps:

[0041] (1) Put 45 parts of type II mineral oil (40°C kinematic viscosity is 100cst) into the reactor, heat to 65°C and put in 5 parts of lithium lauryl stearate soap, 1 part of calcium lauryl stearate soap, Stir and heat up to 175°C, add 30 parts of type II mineral oil (40°C kinematic viscosity is 100cst) for thickening;

[0042] (2) Heat up to the highest temperature of 211°C, keep warm for 2 minutes, add 16 parts of type II mineral oil (40°C kinematic viscosity is 100cst), keep warm at 185°C for 5 minutes, cool to 135±5°C and grind twice with a grinder to obtain the foundation fat;

[0043] (3) Cool the base grease obtained in step (2) to 75°C, add 0.6 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.7 parts of 2, 4-dihydroxybenzophenone, 0.4 parts of alkenyl succinic acid, 1.3 parts of zinc dialkyl dithiophosphate, after being ground twice by a grinder, filtered and package...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com