Patents

Literature

36results about How to "Low protection level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

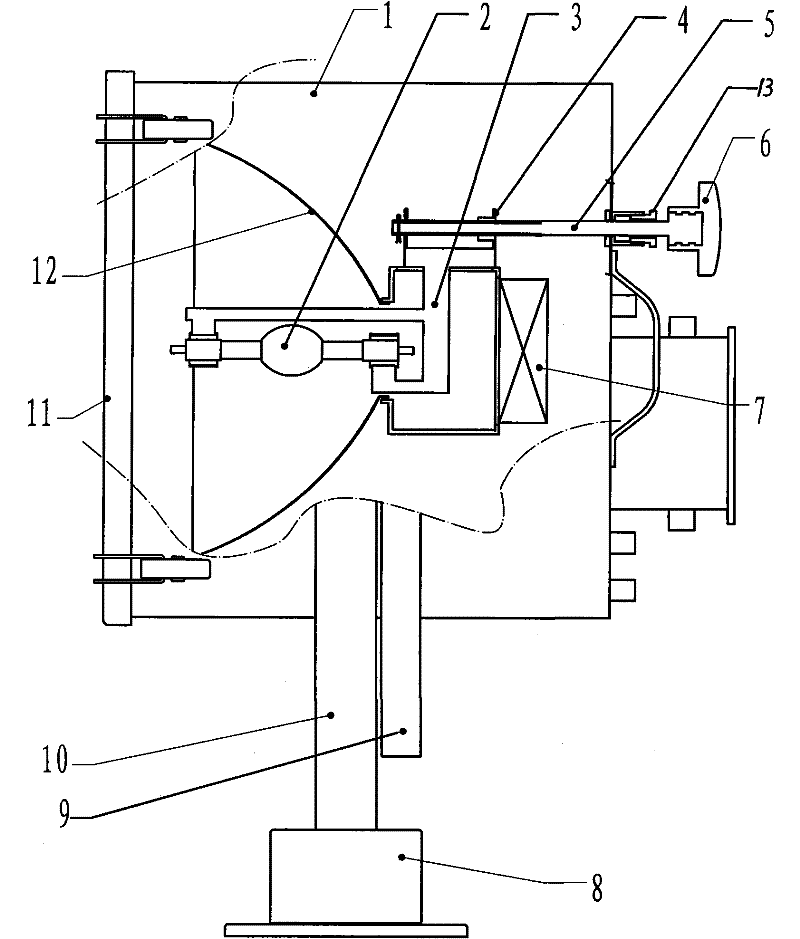

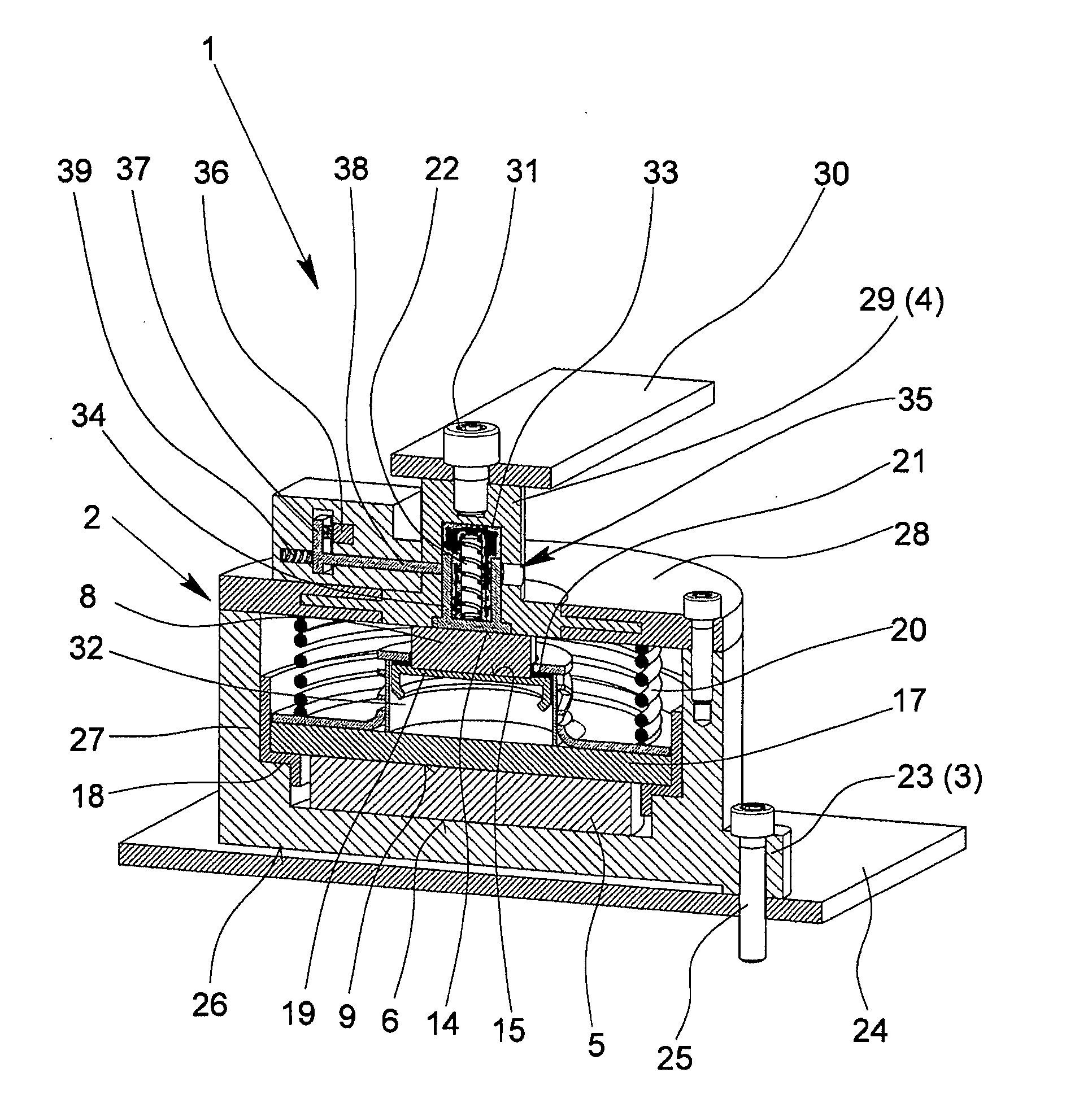

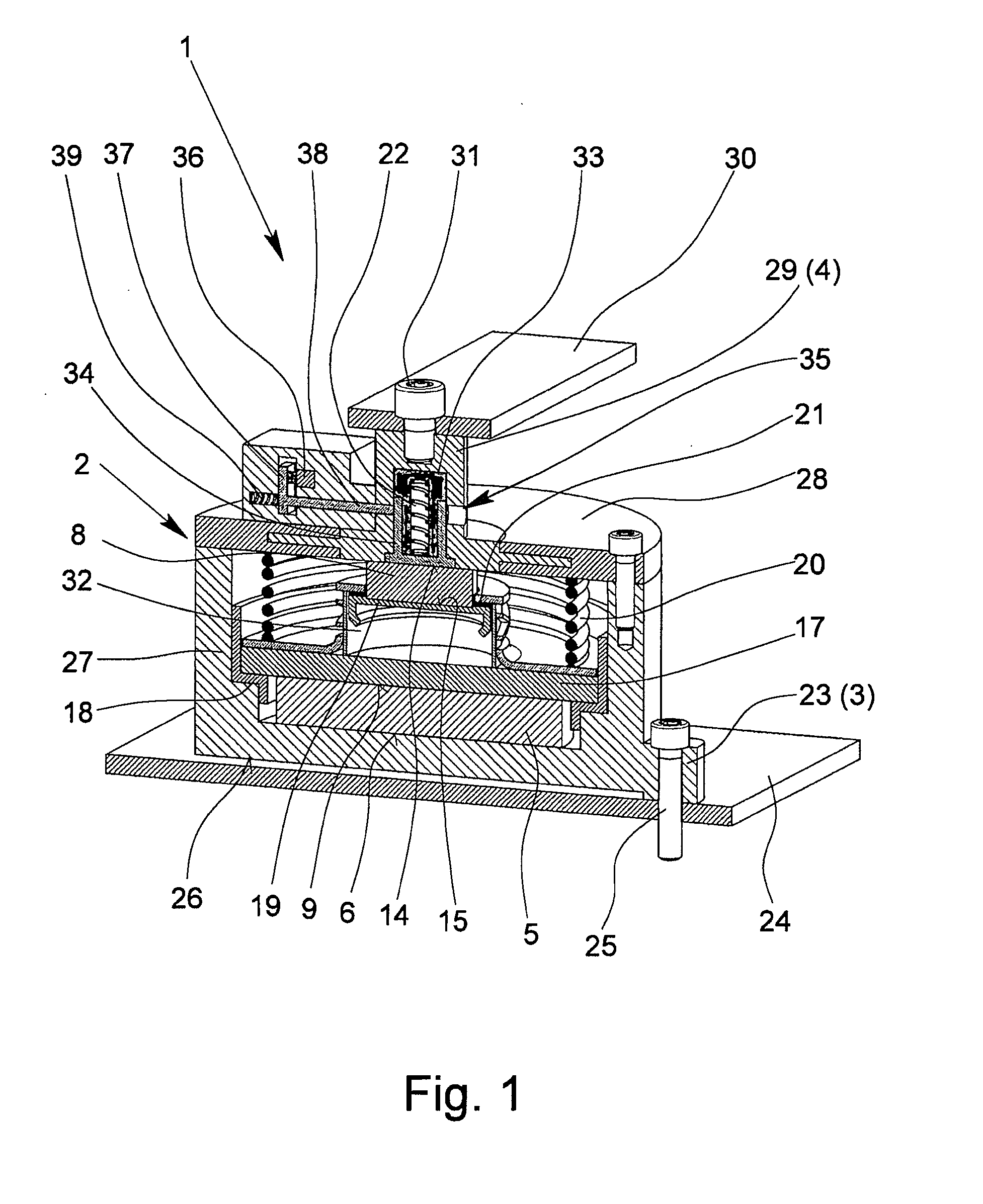

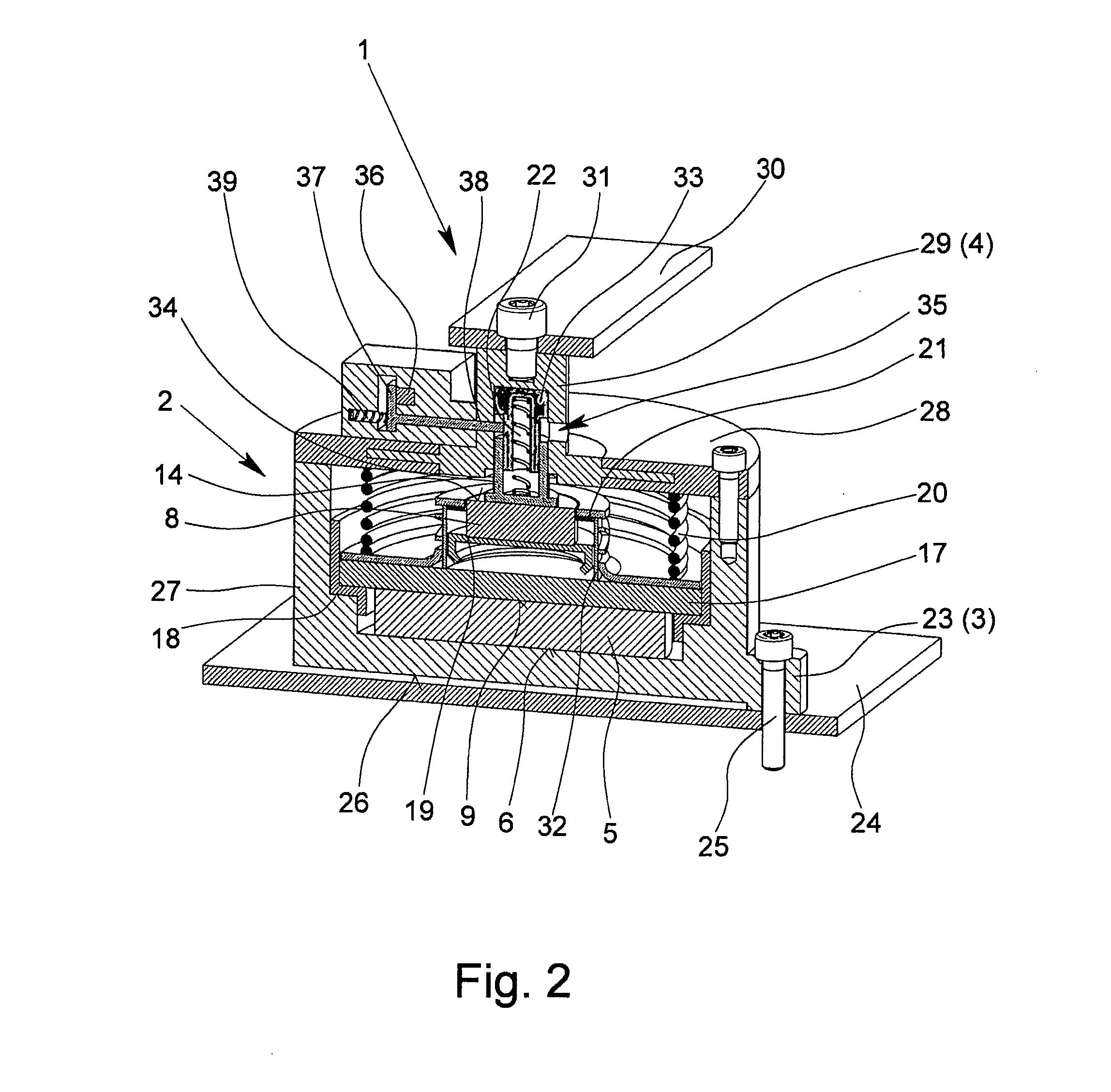

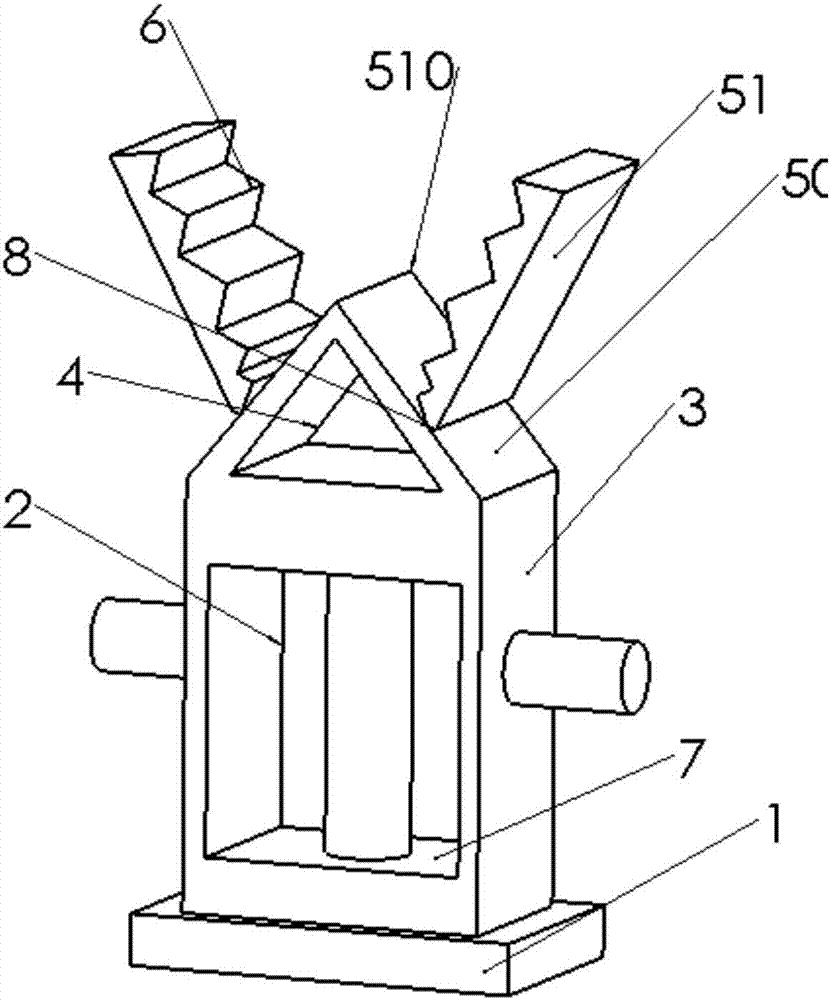

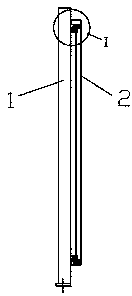

Adjustable search lamp

InactiveCN102162587AAchieve concentrationRealize regulationLighting heating/cooling arrangementsLight fasteningsEngineeringScrew thread

The invention relates to an adjustable search lamp, which comprises a lamp body, a lampshade, a lamp holder, a bulb, a reflector, a base, a bracket and an operating rod, wherein the bulb is fixedly arranged on the lamp holder; the lamp holder is arranged on a focal length adjusting device; the focal length adjusting device consists of an adjusting hand wheel, an adjusting screw and a lamp holder nut; one end of the adjusting screw is fixedly connected with the adjusting hand wheel, the middle part of the adjusting screw is arranged on the lamp body through a connecting nut, and the other end of the adjusting screw is connected with the lamp holder nut by screw threads; and the lamp holder nut is fixedly arranged on the lamp holder. The adjustable search lamp has the advantages of adjustable focal length of a light source, small volume, light weight, good protection performance and the like, and is suitable to be used as a large-area projecting illumination lamp in the places such as ships, docks, construction sites and the like.

Owner:HAIXING MARITIME ELECTRIC GROUP

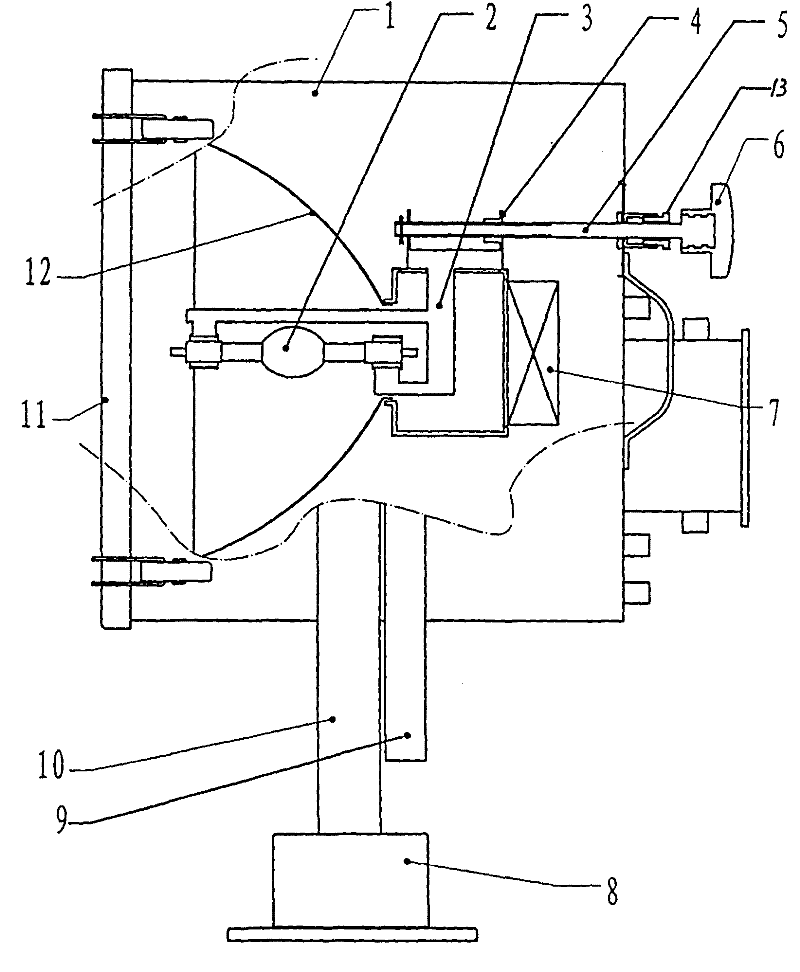

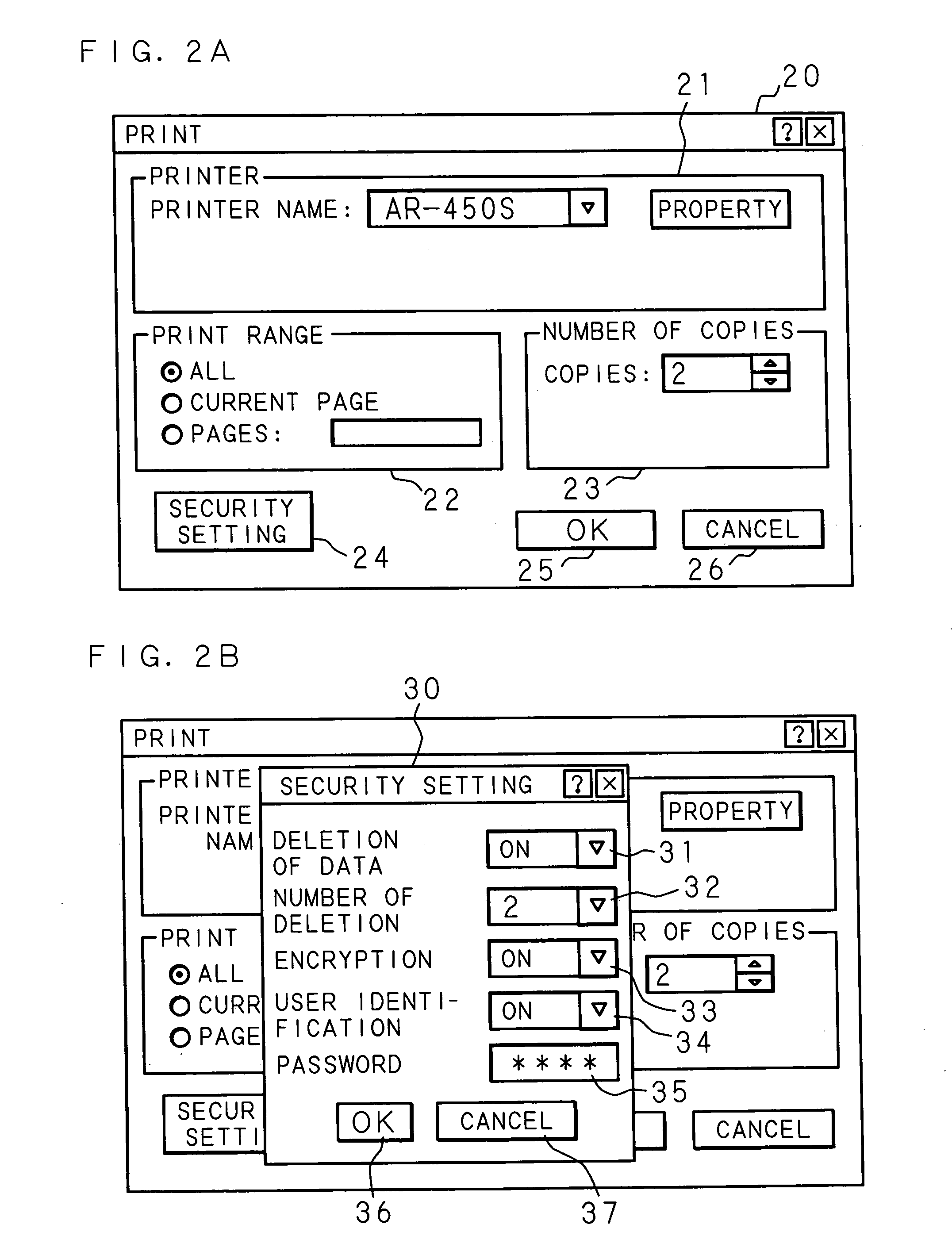

Image forming apparatus, image forming system and relaying apparatus

InactiveUS20060077420A1Low protection levelImprove protectionVisual presentationPictoral communicationConfidentialityImage formation

An image forming apparatus which accepts a job that includes image data and requires image formation on the basis of the image data, and which carries out image formation by carrying out a job that has been accepted is provided with: a means for determining whether or not the confidentiality of image data that is included in a job that has been accepted should be protected; a means for determining whether or not a process for protecting the confidentiality of the above described image data can be implemented, in the case where it has been determined that the confidentiality should be protected; and a means for reporting, in the case where it has been determined that the above described process cannot be implemented, to that effect.

Owner:SHARP KK

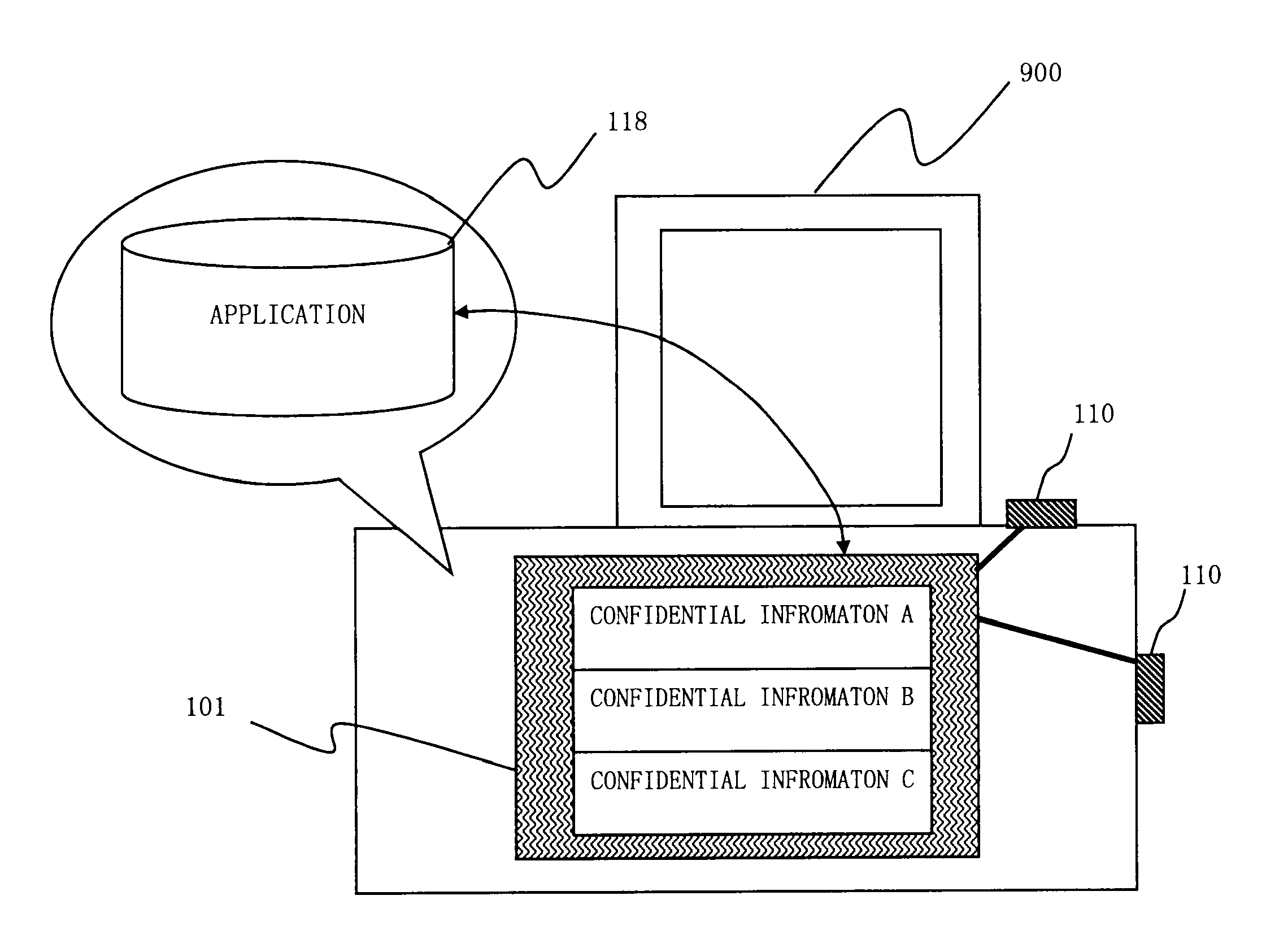

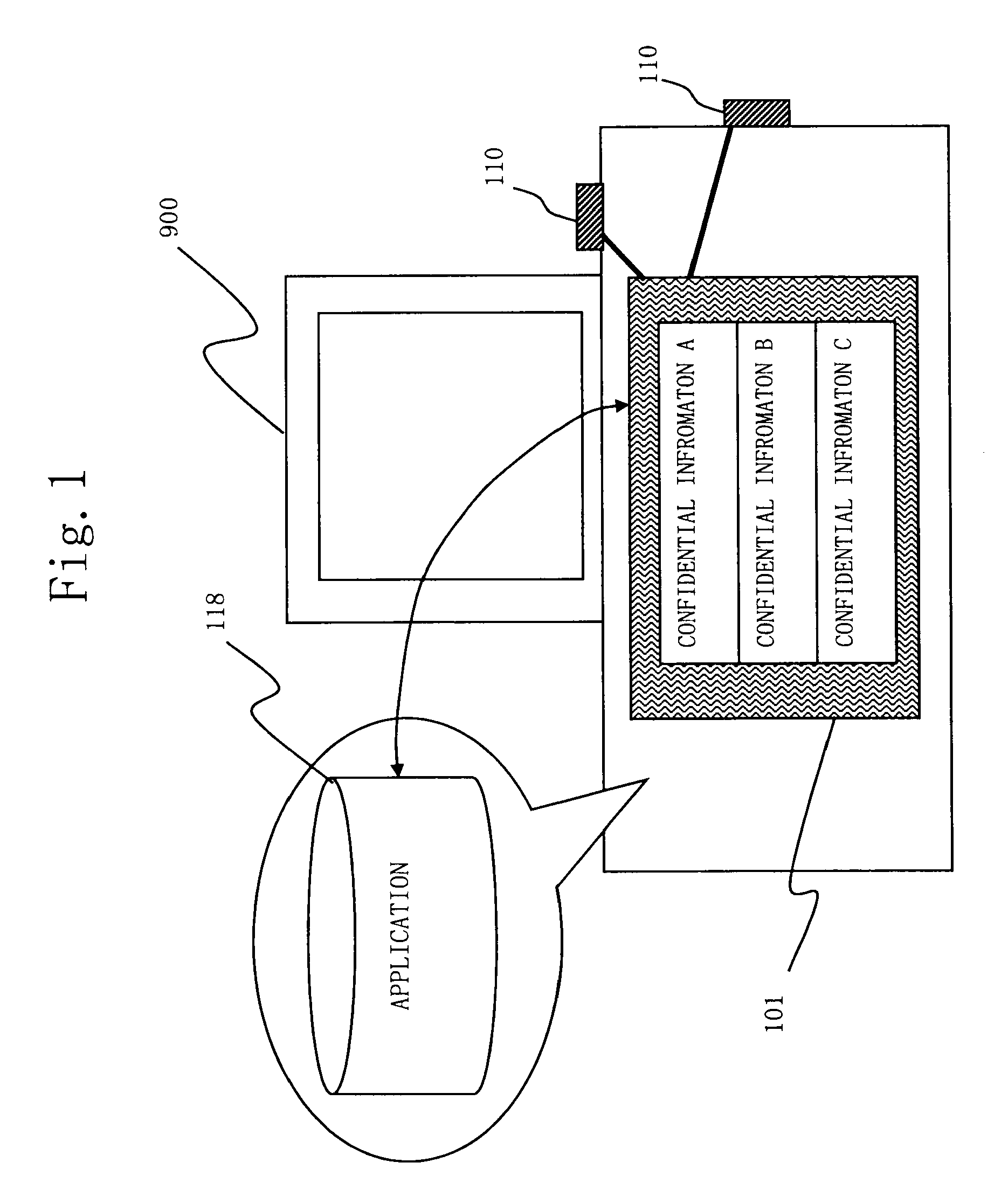

Confidential information memory apparatus, erasing method of confidential information, and erasing program of confidential information

InactiveUS8286005B2Low protection levelEasy to carryUnauthorized memory use protectionHardware monitoringInternet privacyInformation storage

A tamper resistant apparatus 101 is mounted inside of a PC 900 and stores confidential information A through C. The tamper resistant apparatus 101 receives data from an application 118 which operates on the PC 900, processes the data using the confidential information A through C, and returns processed data to the application 118. To the tamper resistant apparatus 101, plural external sensors 110 provided to the PC 900 are connected. The plural external sensors 110 detect opening / closing of a case of the PC 900 or movement of the body of the PC 900 and send a detection signal to the tamper resistant apparatus 101. On inputting the detection signal from the plural external sensors 110, the tamper resistant apparatus 101 selects and erases confidential information to be erased from the confidential information A through C according to the tamper resistant policy stored previously.

Owner:MITSUBISHI ELECTRIC CORP

Overvoltage protection device

InactiveUS20150103462A1Durable and long-livedBuilt and mountable as simply and economicallyEmergency protective arrangement detailsOvervoltage protection resistorsOvervoltageElectrical conductor

A surge protection device having a housing, two connections for connection to a current path to be protected, and at least a first discharge conductor in the housing. In a normal state of the device, the first connection is electrically conductively connected to the first connection region of the discharge conductor, and the second connection is connected to the second connection region by at least one component. A metal safety element, which has two contact regions and a connecting region which connects the contact regions to one another, is arranged within the housing. The first contact region is electrically conductively connected to the second connection region and the second contact region is electrically conductively connected to the component in the normal state. The connecting region is a fuse by which brief pulse currents can be transmitted by the connecting region, whereas mains-frequency short-circuit currents overload the connecting region destroying it.

Owner:PHOENIX CONTACT GMBH & CO KG

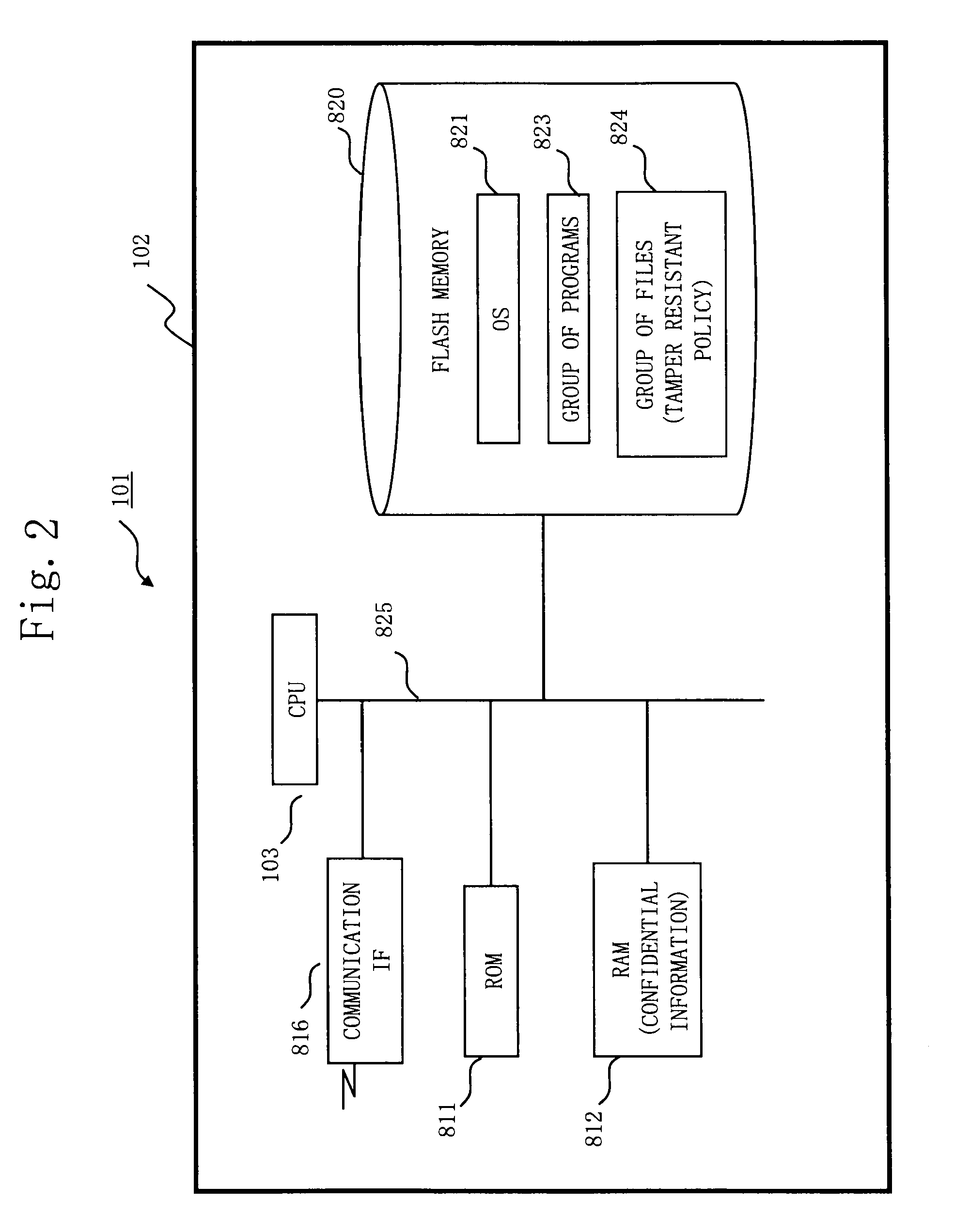

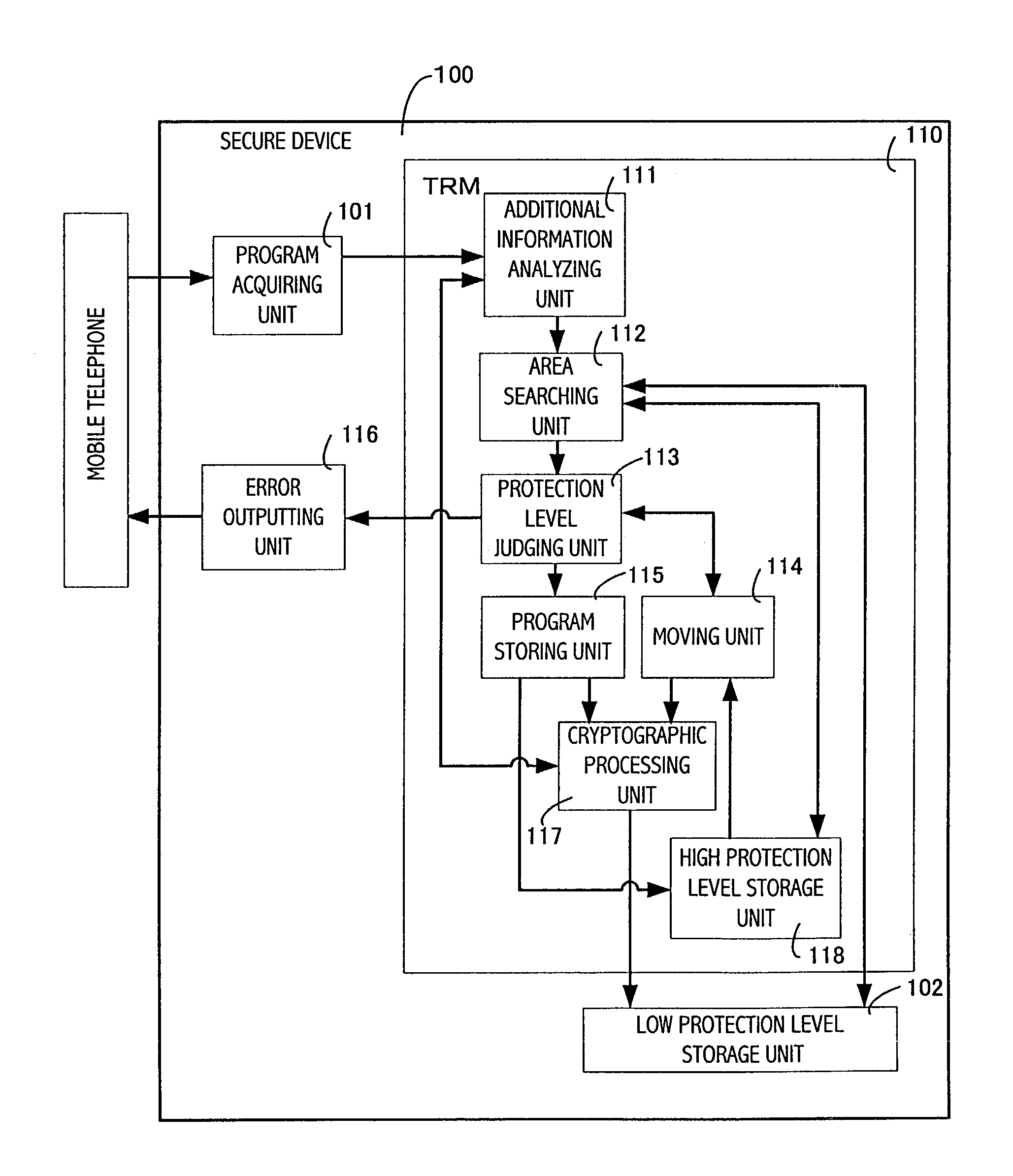

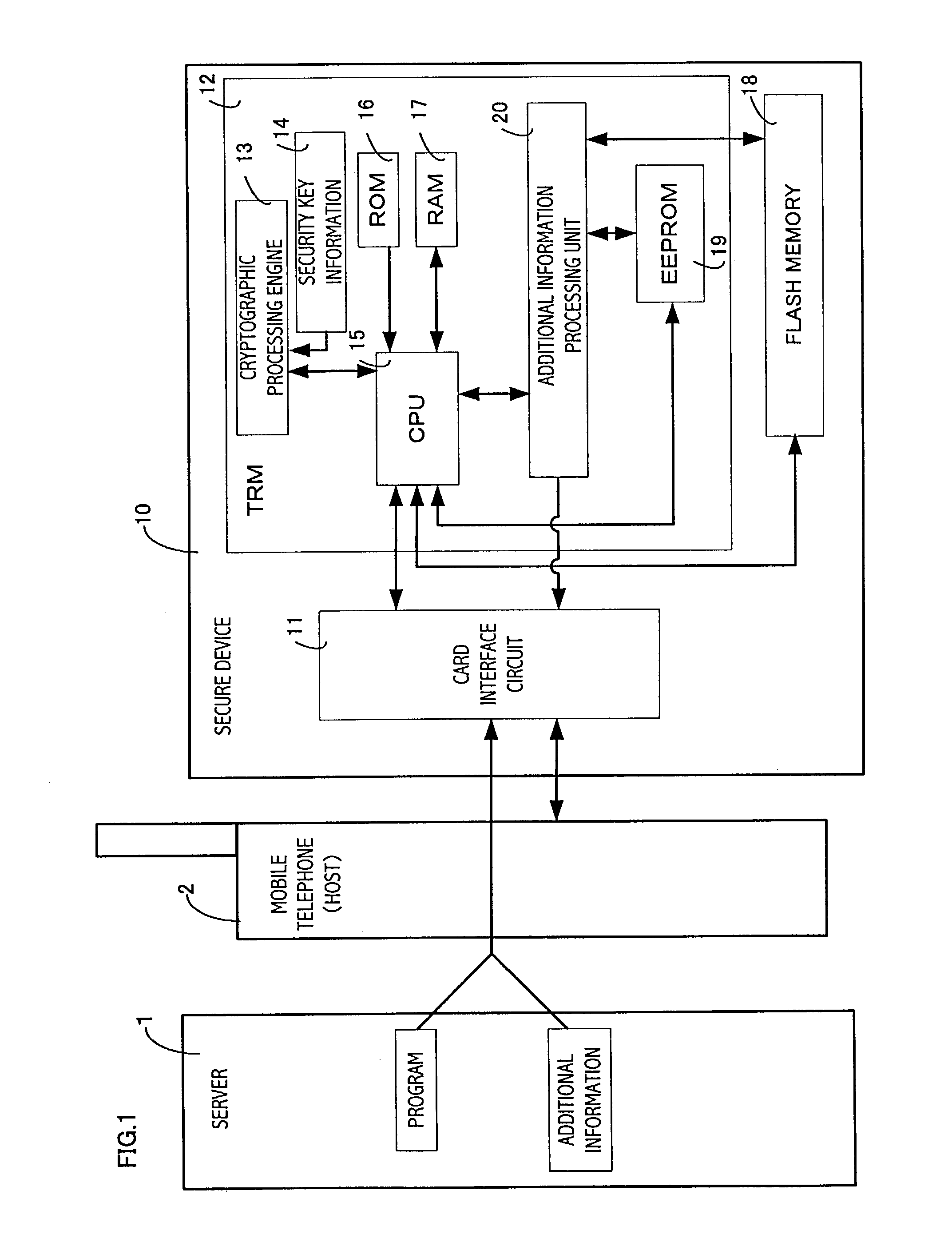

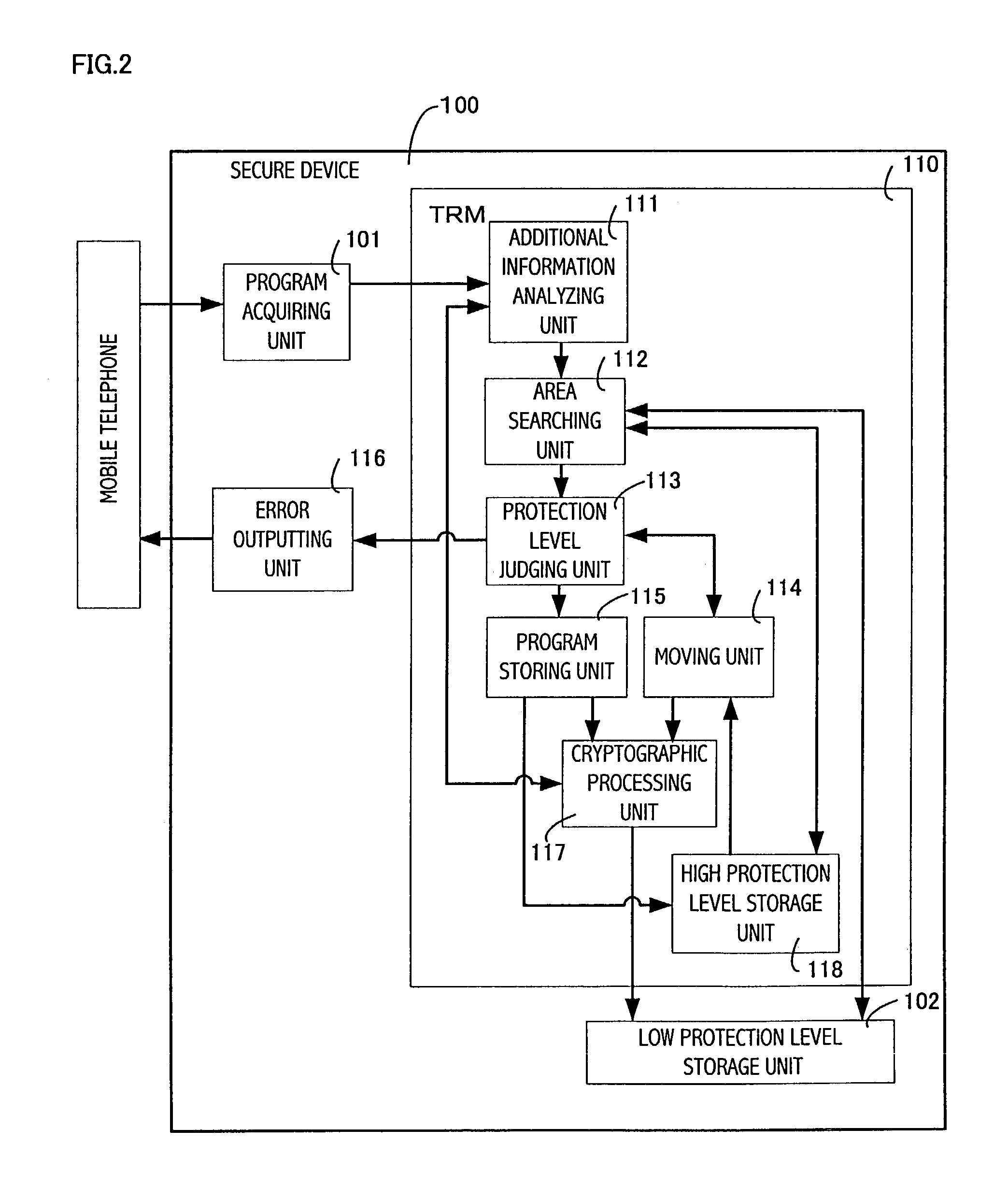

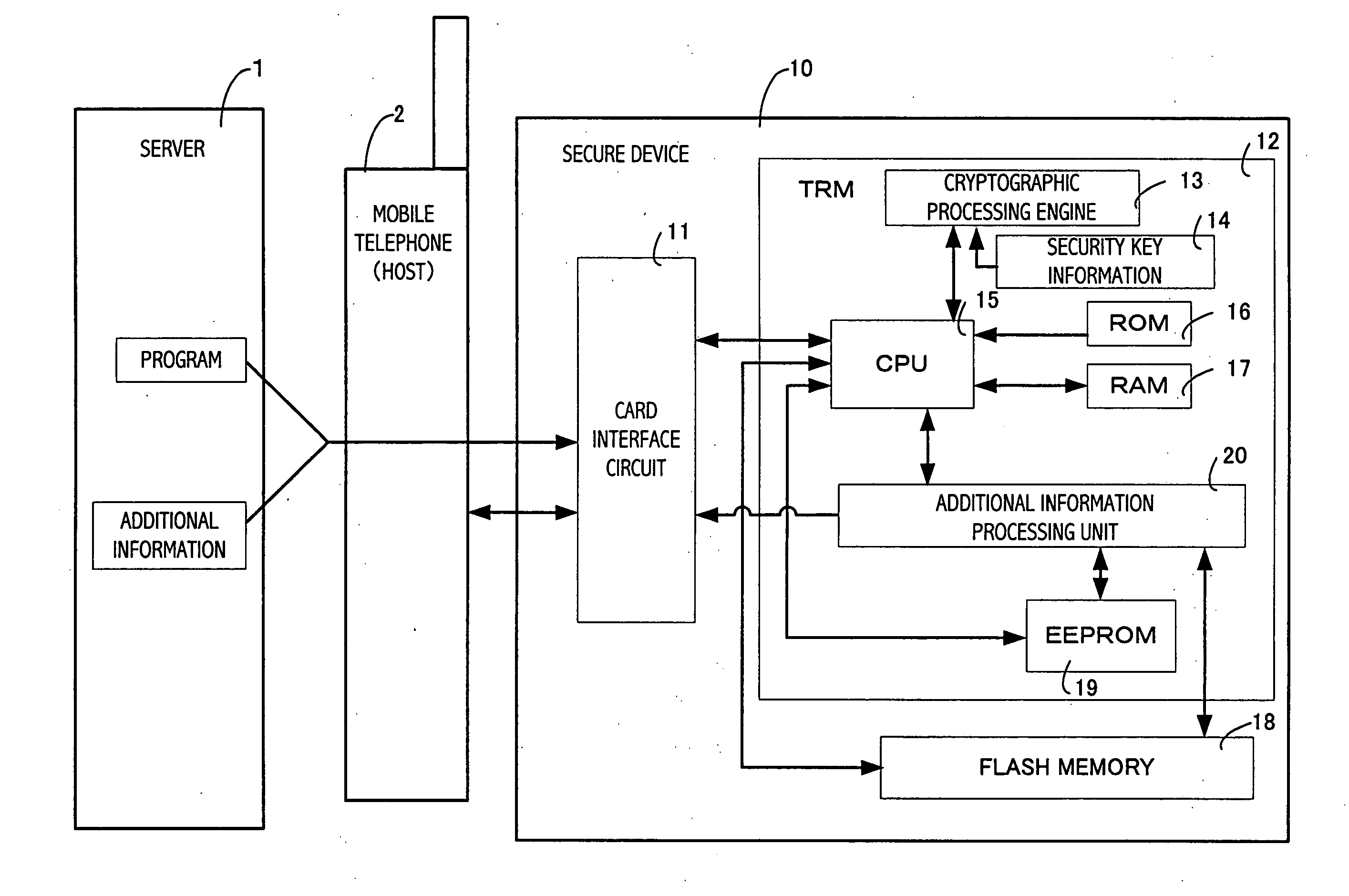

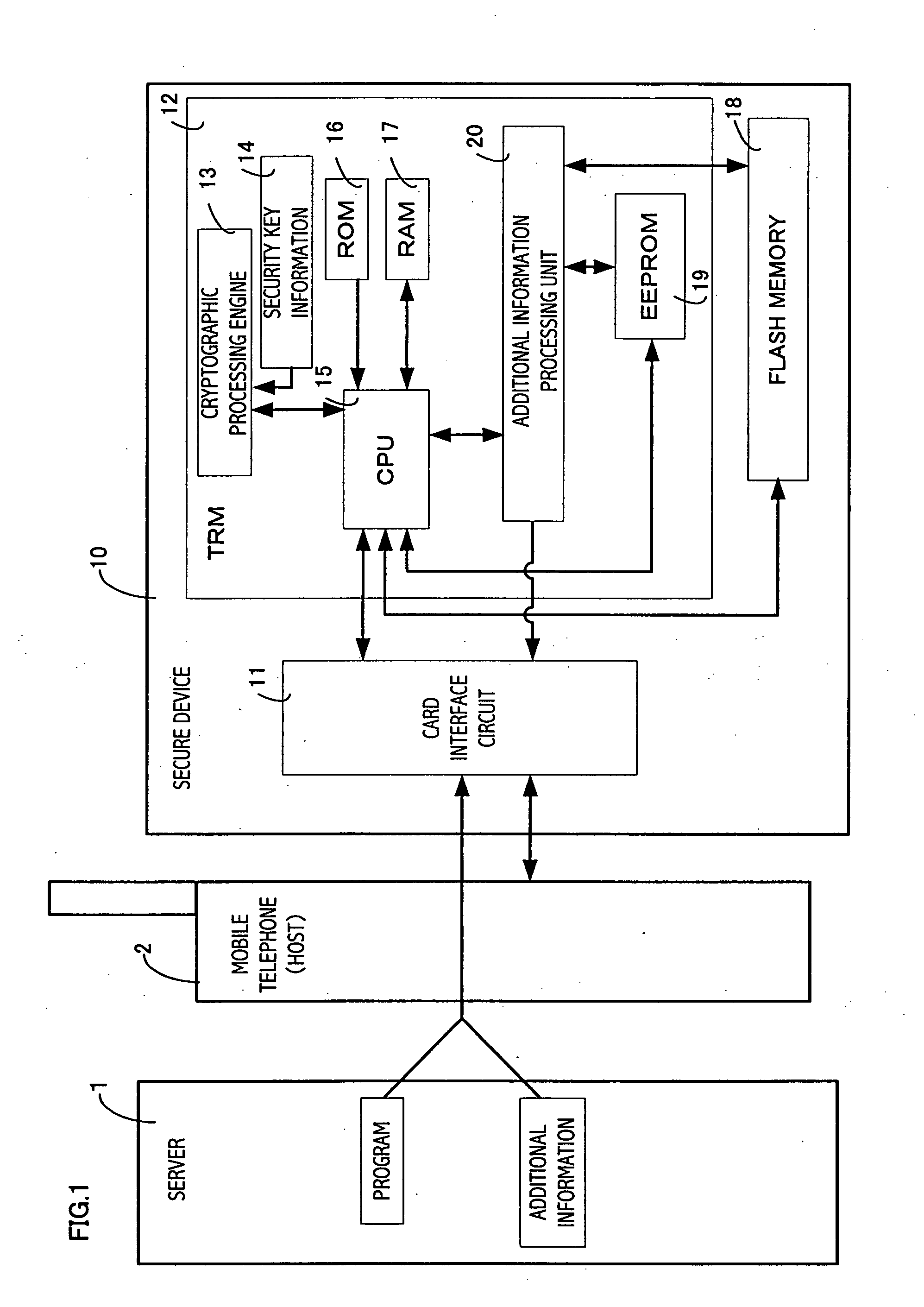

Secure device

InactiveUS7246247B2Improve securityData efficientRandom number generatorsUser identity/authority verificationComputer scienceOperating system

Owner:PANASONIC CORP

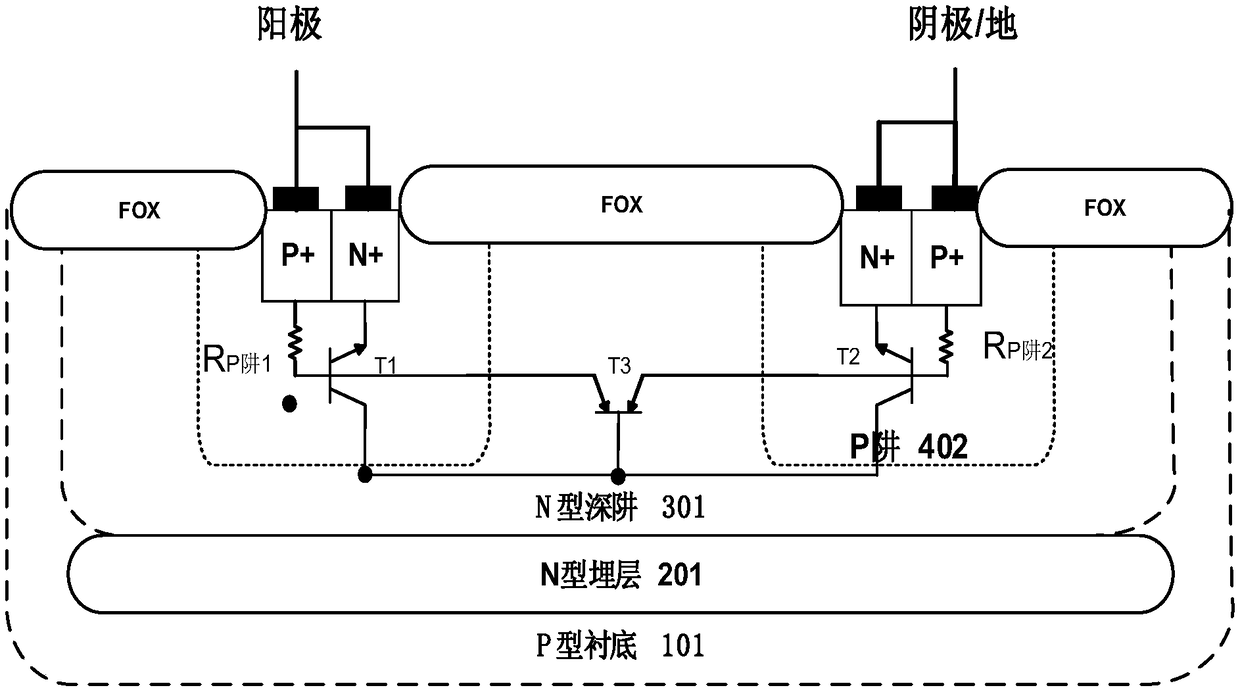

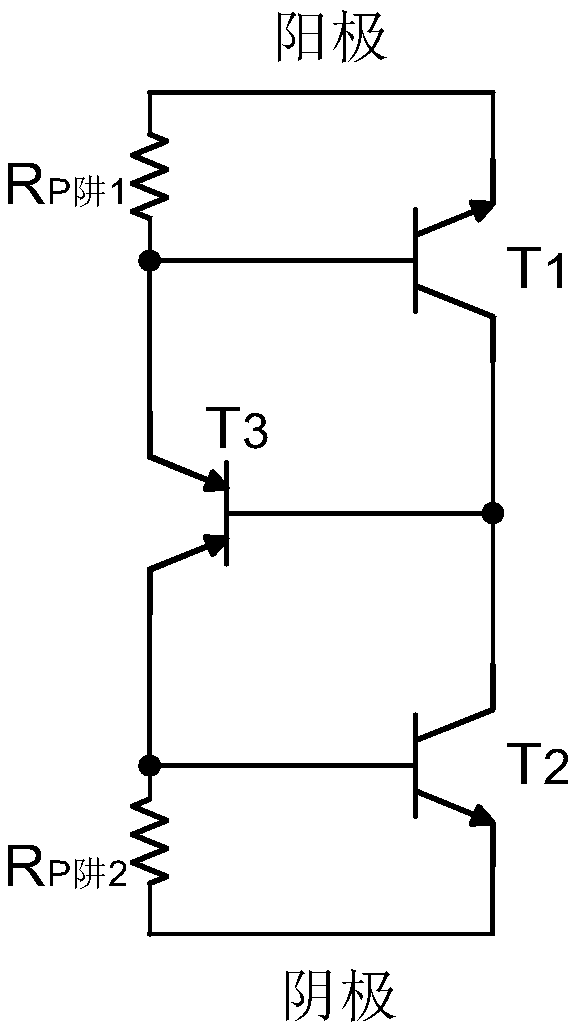

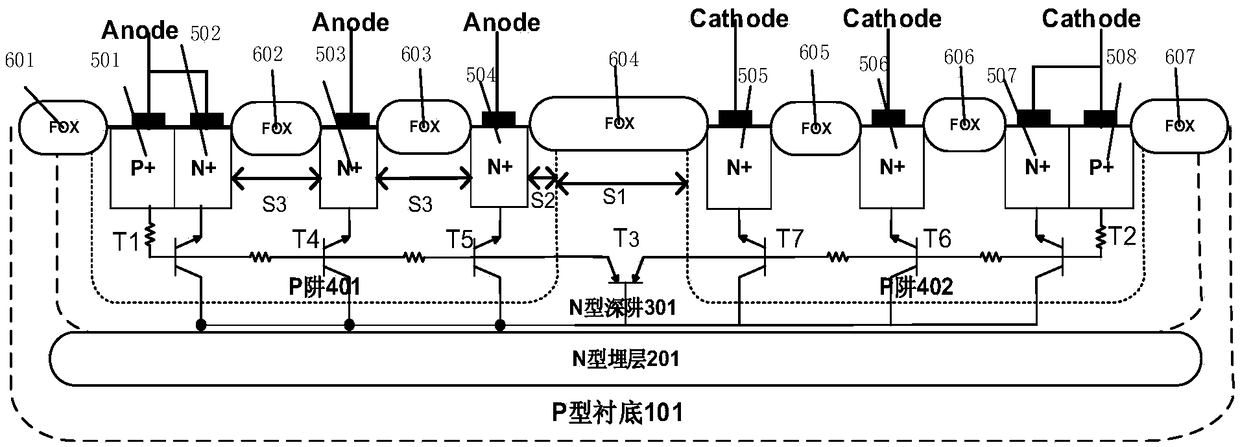

Bidirectional silicon-controlled electrostatic protection device with high protection level and fabrication method thereof

ActiveCN108807371AReduce in quantityImprove even distributionTransistorSolid-state devicesDIACCurrent distribution

The invention discloses a bidirectional silicon-controlled electrostatic protection device with high protection level. The bidirectional silicon-controlled electrostatic protection device comprises aP-type substrate, wherein an N-type buried layer is arranged in the substrate, an N-type deep well is arranged on the N-type buried layer, a first P well and a second P well are arranged in the N-typedeep well, a first P+ injection region and a plurality of N+ injection regions I are arranged in the first P well, a second P+ injection region and a plurality of N+ injection regions II are arrangedin the second P well, the first P+ injection region and all N+ injection regions I are connected and used as a positive electrode of the device, and the second P+ injection region and all N+ injection regions II are connected and used as a negative electrode of the device. The numbers of the N+ injection regions I and the N+ injection regions II can be increased or reduced according to differentprotection levels, the numbers of the N+ injection regions I and the N+ injection regions II are increased if the protection level is high, the uniform current distribution of the device is improved,and the robustness of the device is improved; and if the protection level is low, the numbers of the N+ injection regions I and the N+ injection regions II are reduced, and the layout area is reduced.

Owner:XIANGTAN UNIV

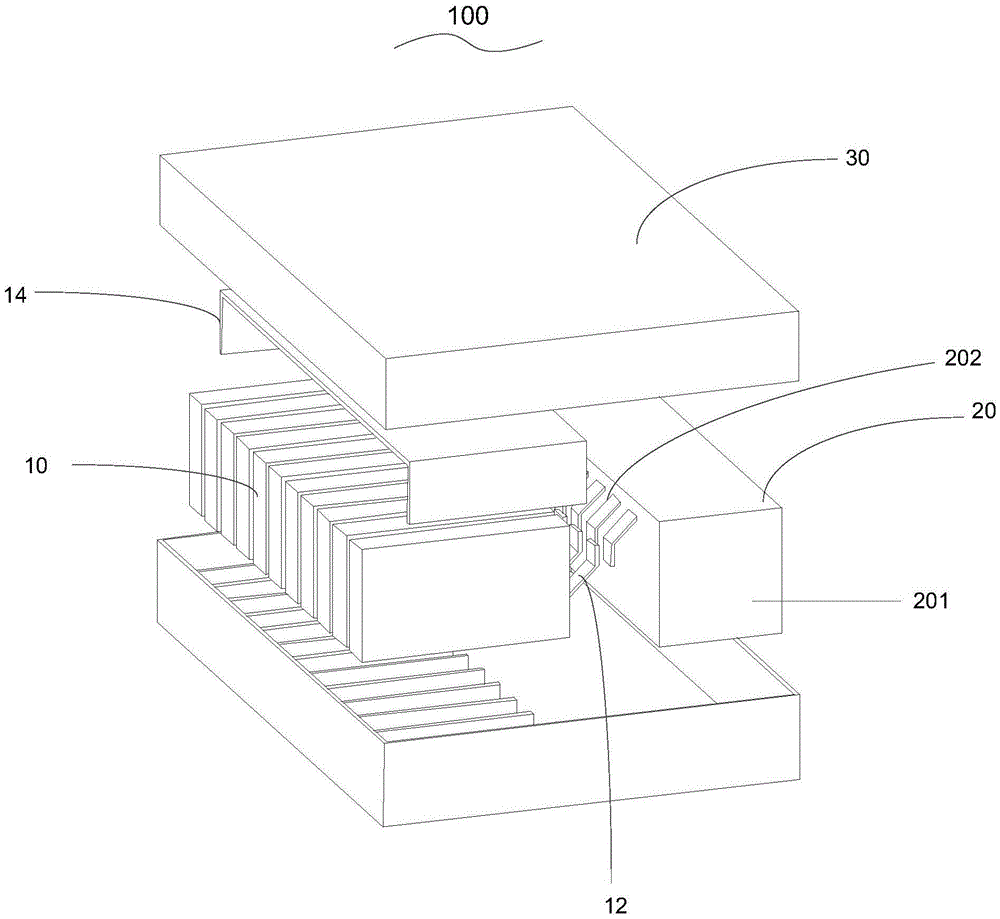

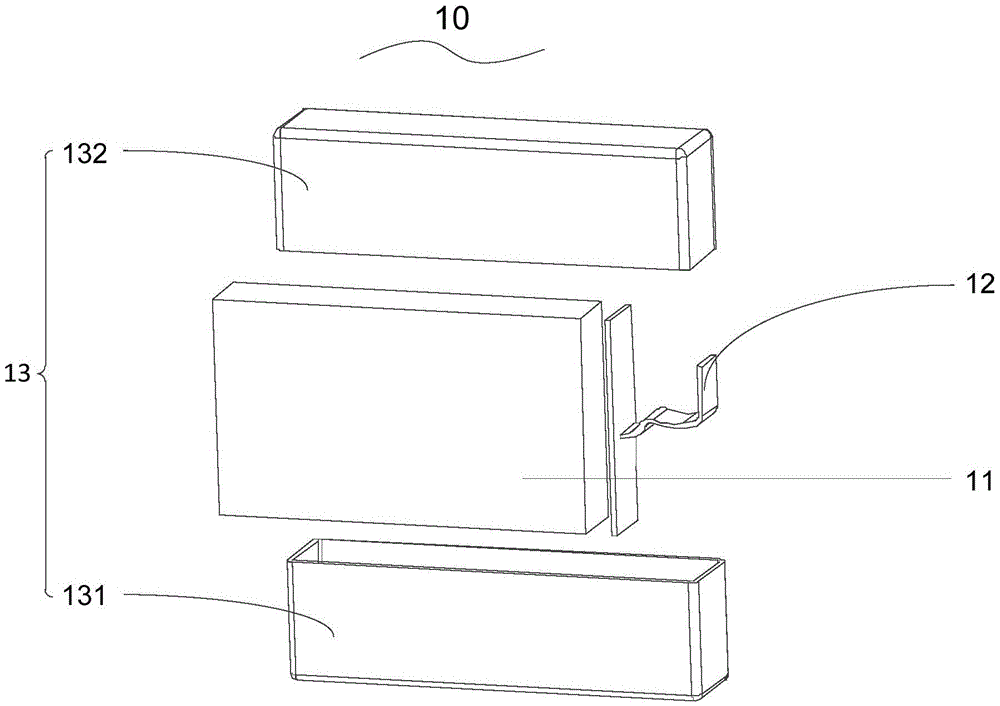

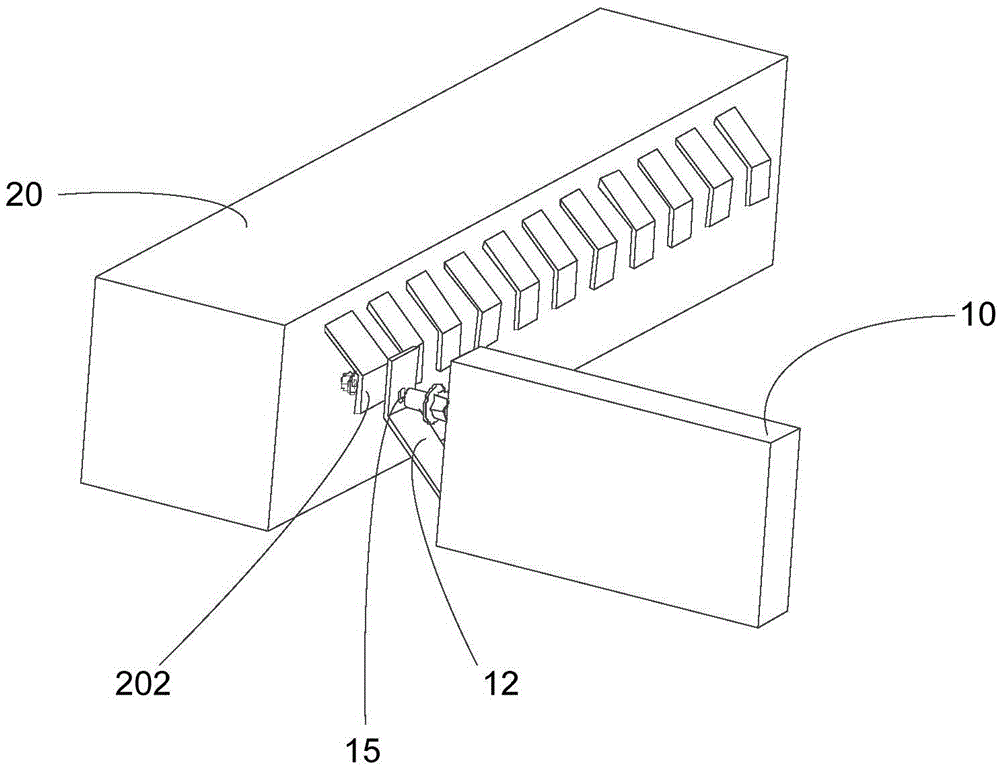

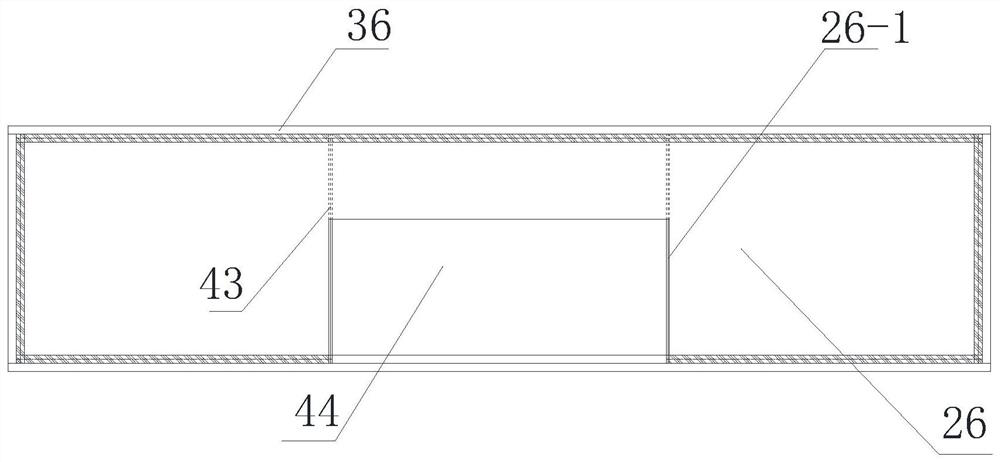

Battery pack

ActiveCN105529422ALow protection levelImprove cooling effectCell component detailsSecondary cells servicing/maintenanceEngineeringBattery cell

An embodiment of the invention provides a battery pack which comprises at least two battery cell units, a BMS (battery management system) control component and a shell. The battery cell units and the BMS control component are arranged in the shell, each battery cell unit is electrically connected with the BMS control component which comprises a protecting shell and an electroconductive structure extending out of the protecting shell, and an electronic element of the BMS control component is sealed in the protecting shell. The battery pack is easy in heat radiation, protecting grade of the shell of the battery pack can be lowered without lowering safety grade of the battery pack, assembling difficulty is lowered, production efficiency is improved, and convenience is brought to subsequent maintenance of the battery pack and replacement and repairing of the battery cell units.

Owner:CONTEMPORARY AMPEREX TECH CO

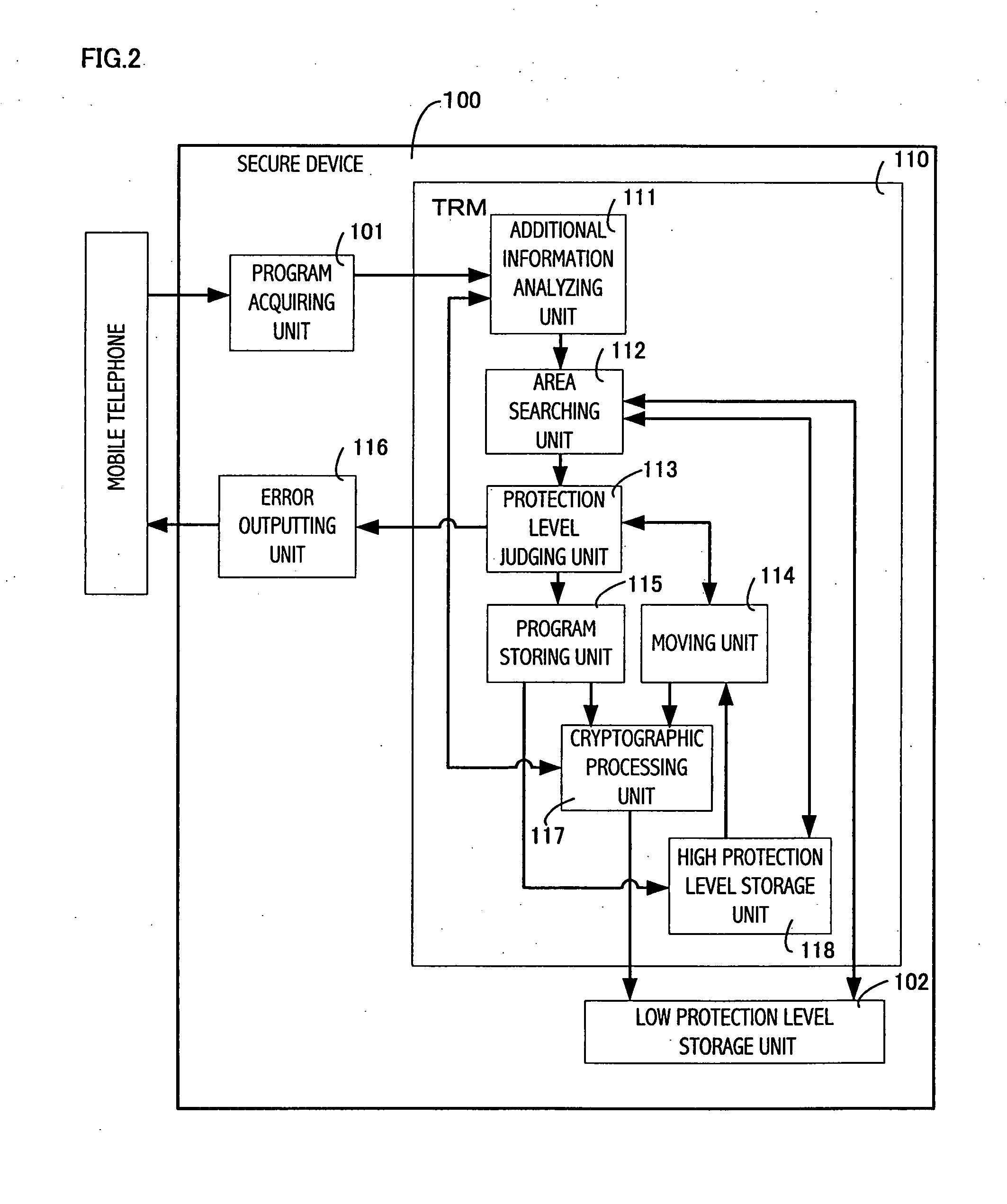

Secure device

InactiveUS20070234074A1Data efficientLow protection levelDigital data processing detailsDigital computer detailsSoftware engineeringOperating system

Owner:PANASONIC CORP

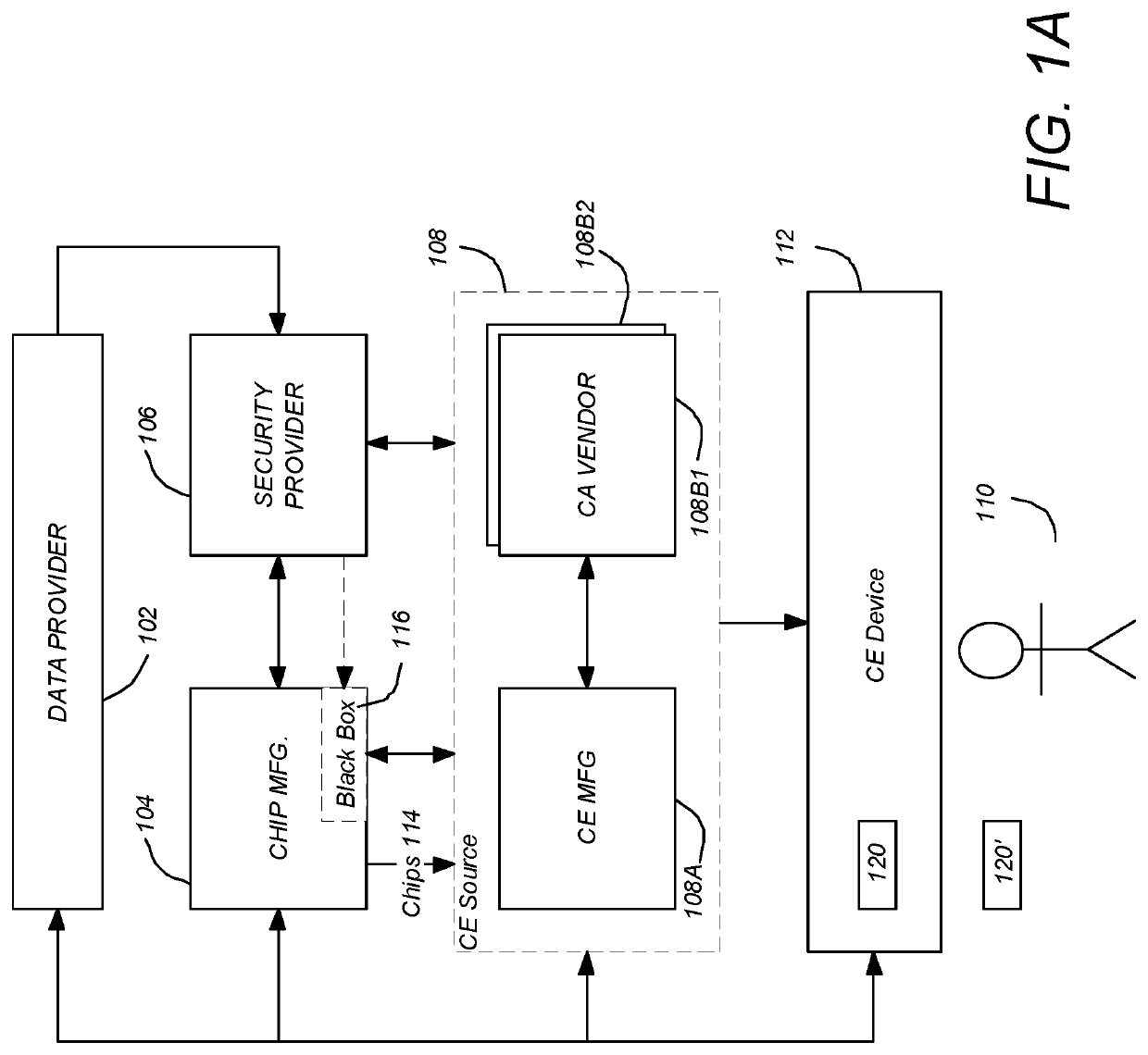

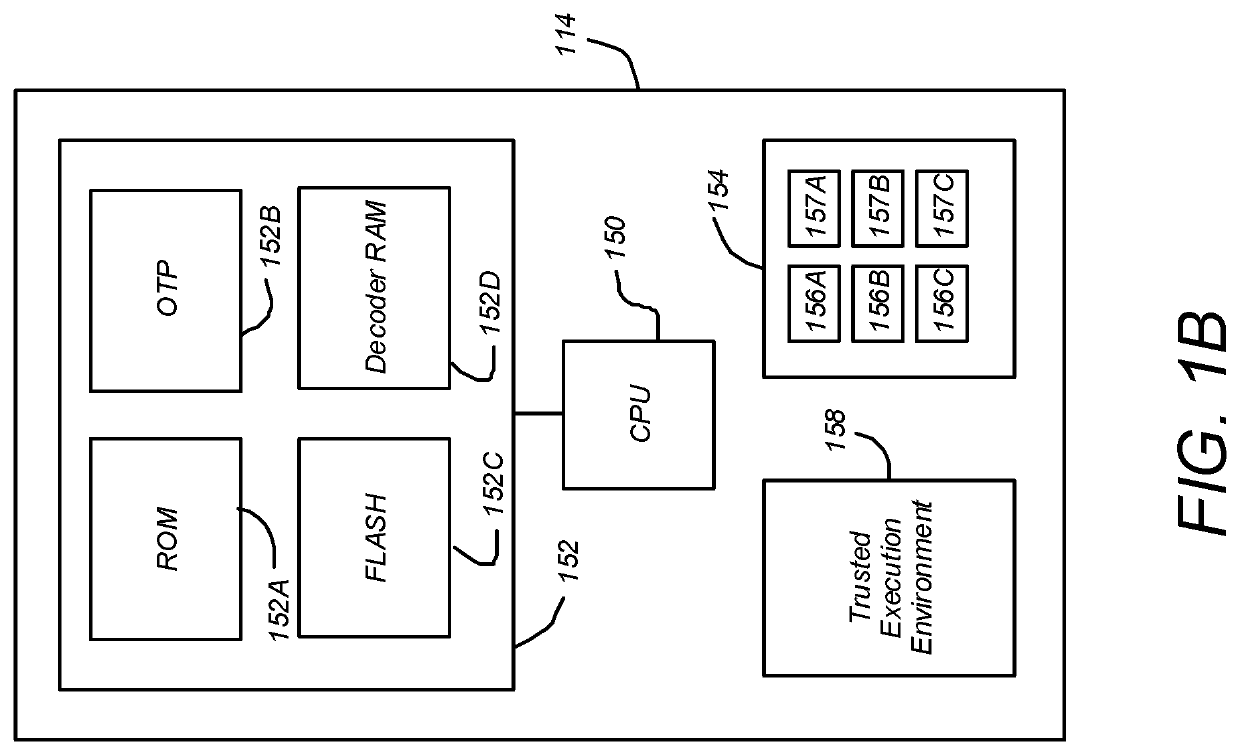

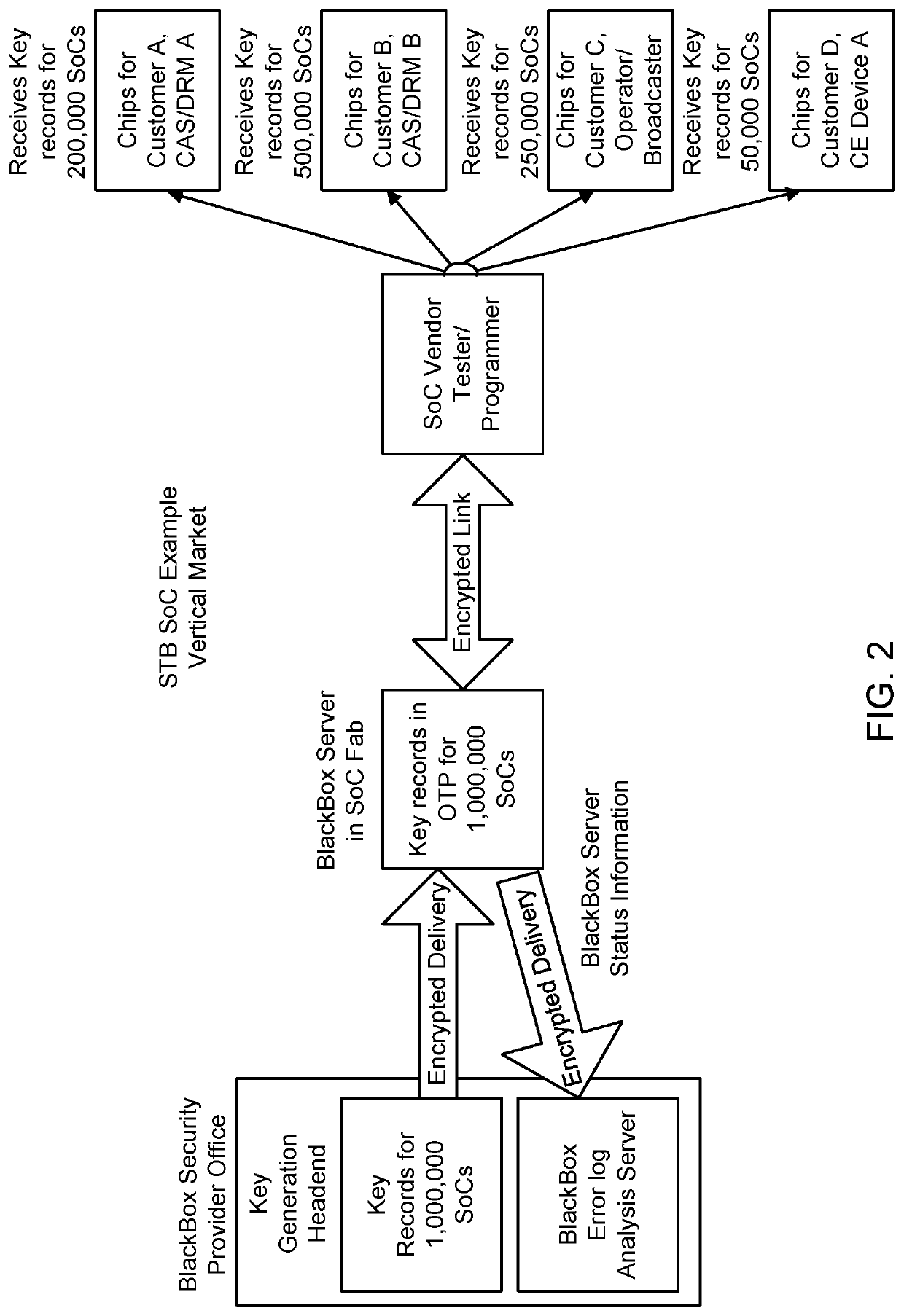

Method and apparatus for a blackbox programming system permitting downloadable applications and multiple security profiles providing hardware separation of services in hardware constrained devices

InactiveUS20200004933A1Low protection levelDigital data protectionInternal/peripheral component protectionComputer hardwareOperating system

A method, apparatus, article of manufacture, and a memory structure for providing a security infrastructure that permits the programming of limited hardware resources that can accept newly downloaded applications and securely support a very large number of services offered by content providers each have the potential to utilize their own independent CAS / DRM system. The CE device owner can consume content from a variety of sources and enable switching among different and existing CAS / DRM security profiles as required by the content provider applications loaded in CE devices.

Owner:RAMBUS INC

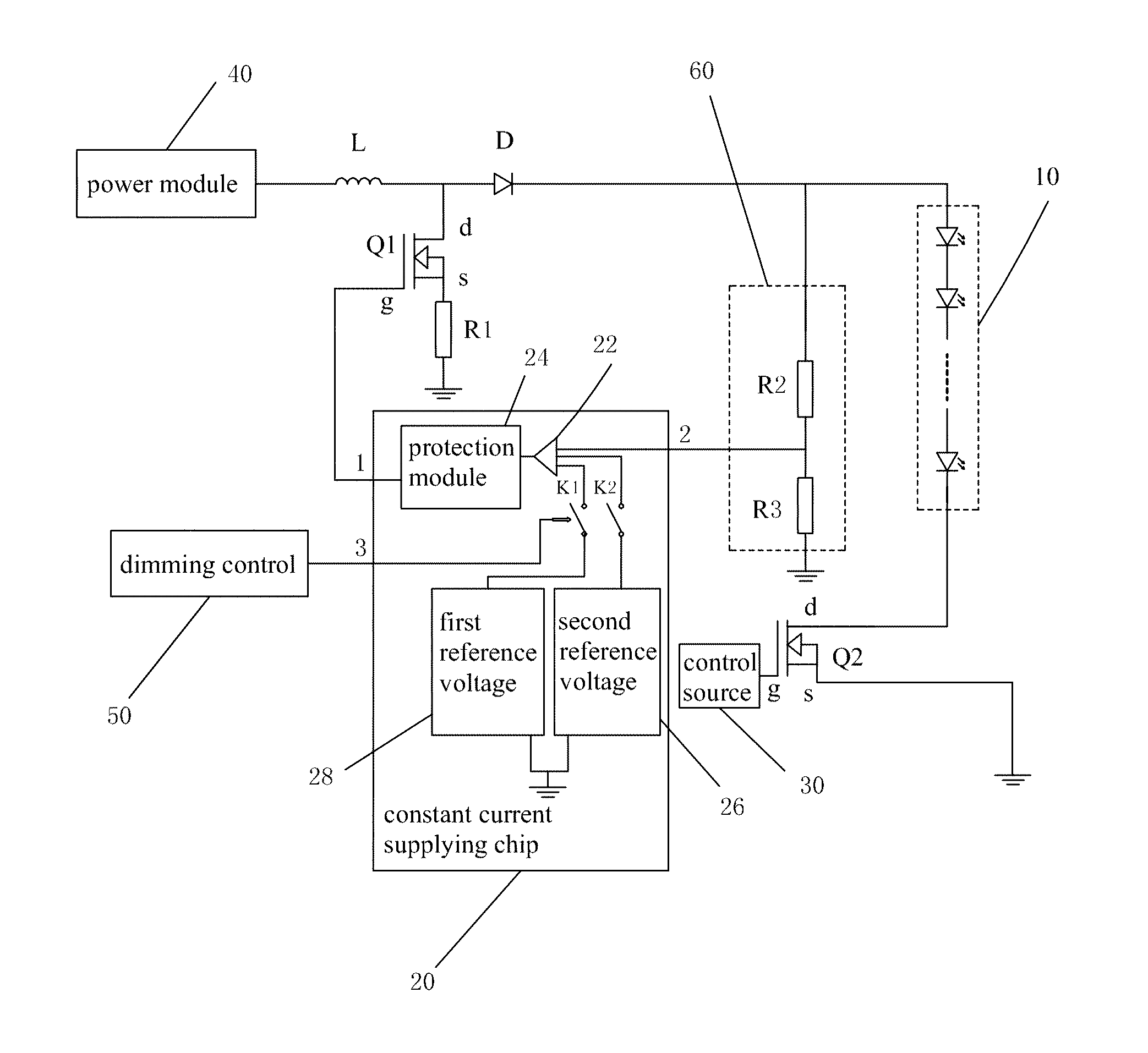

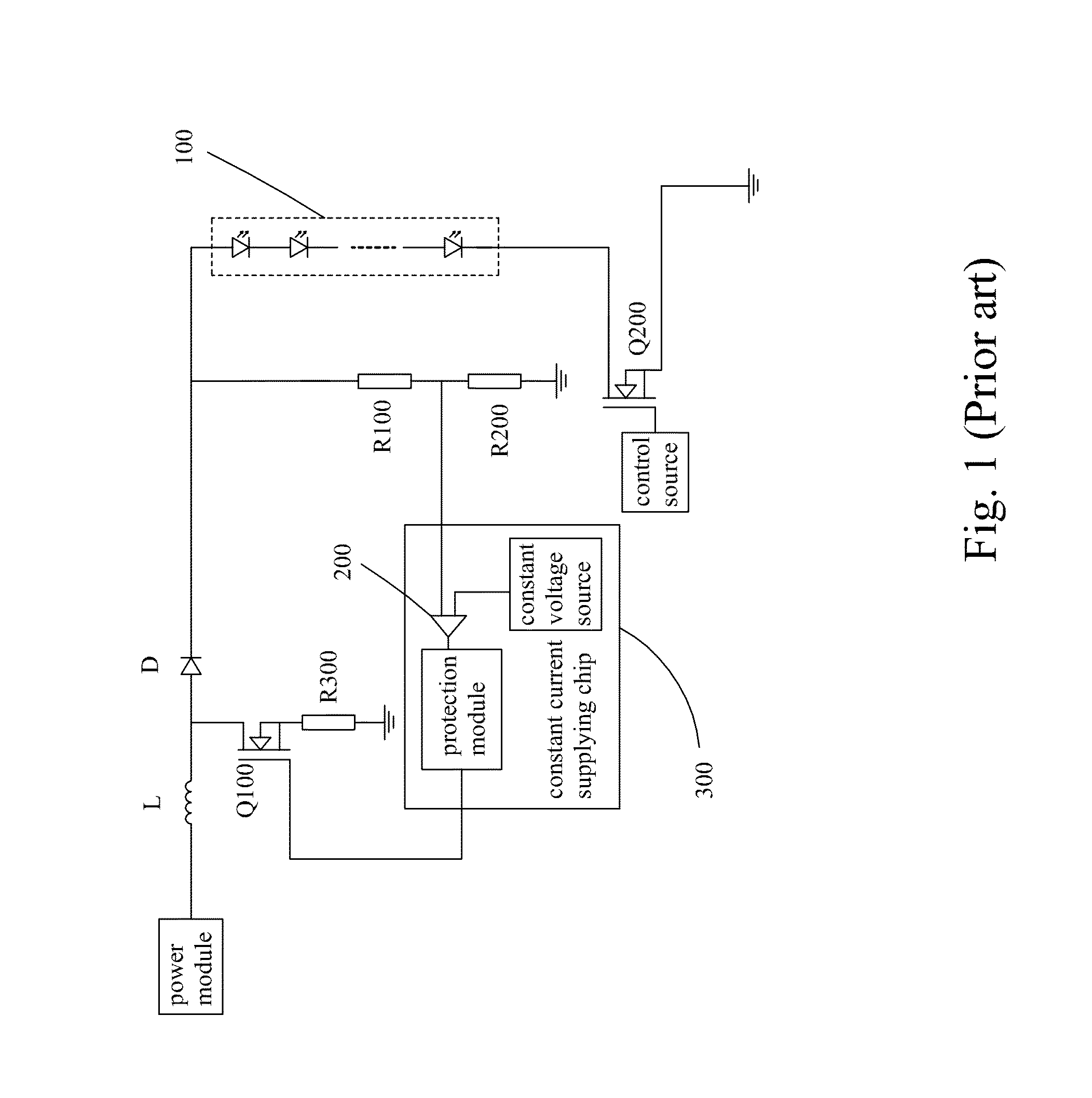

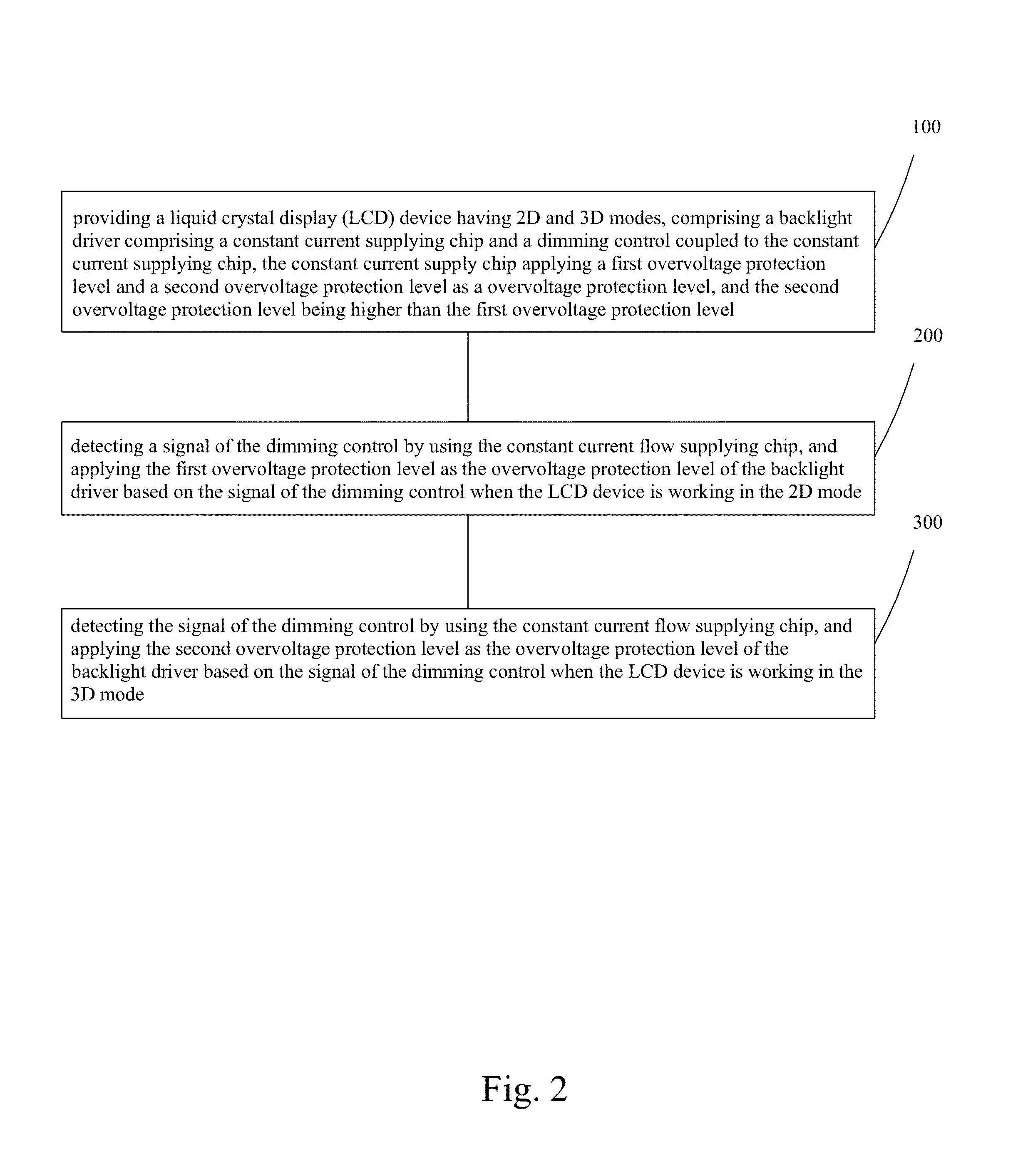

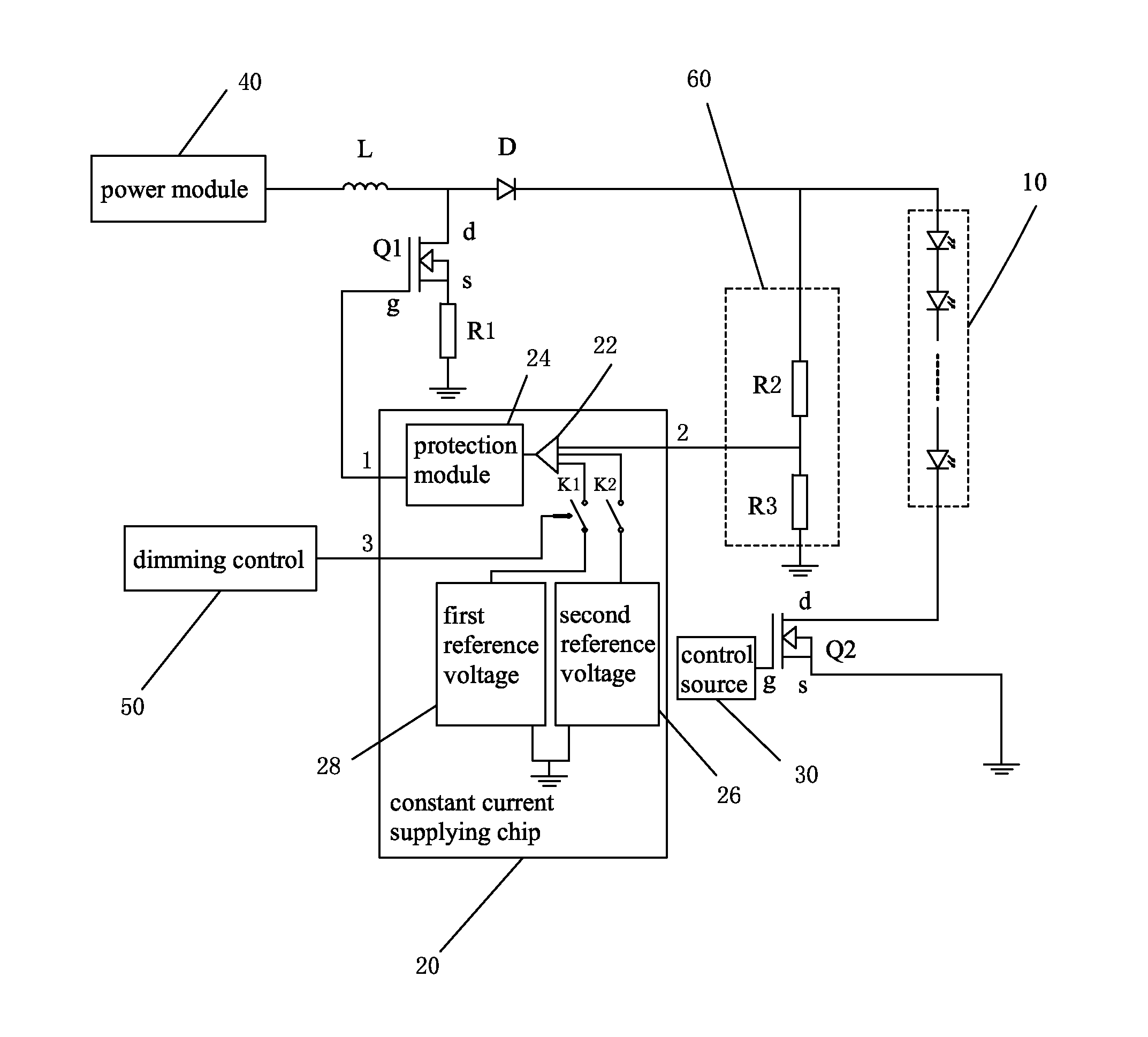

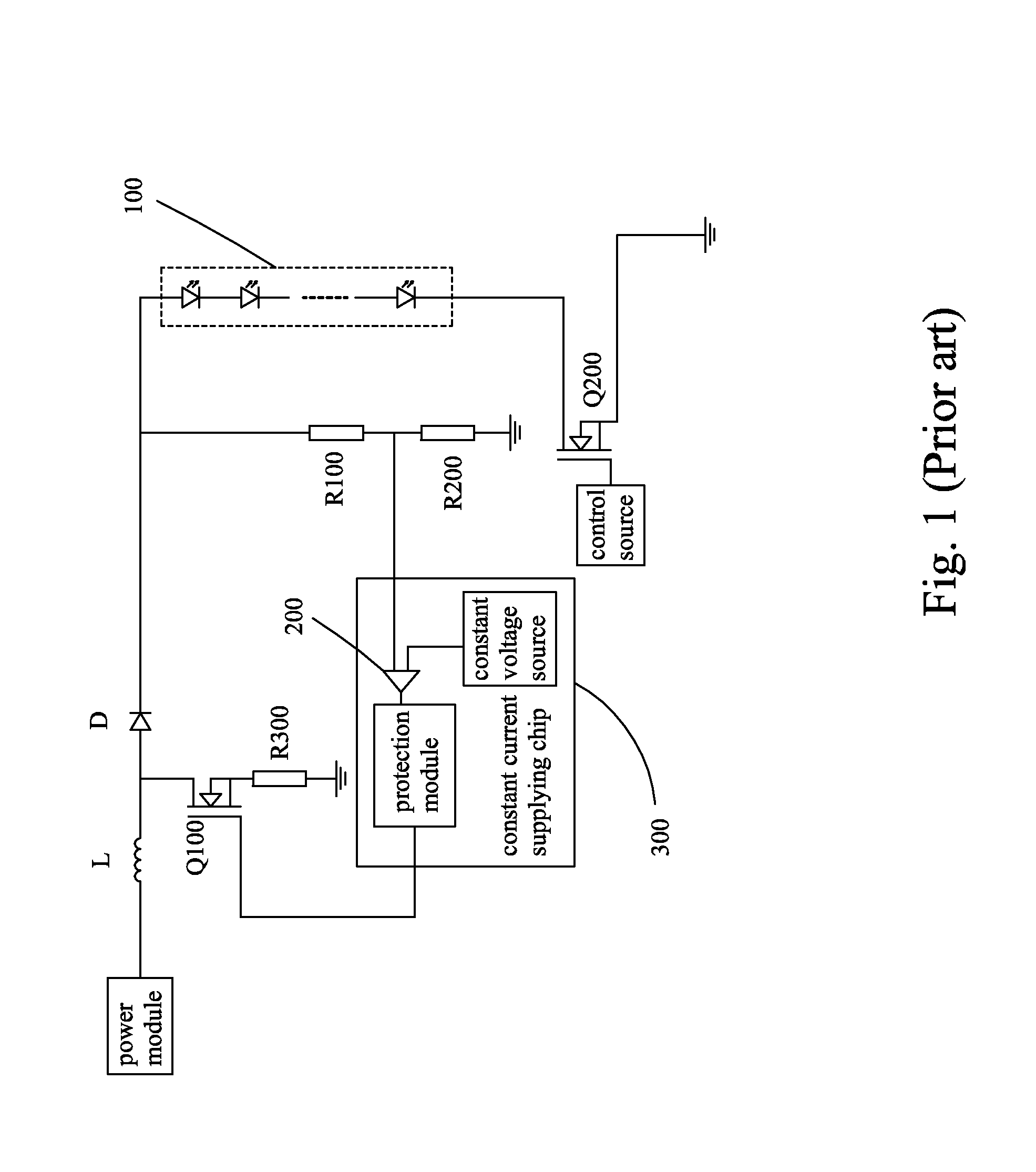

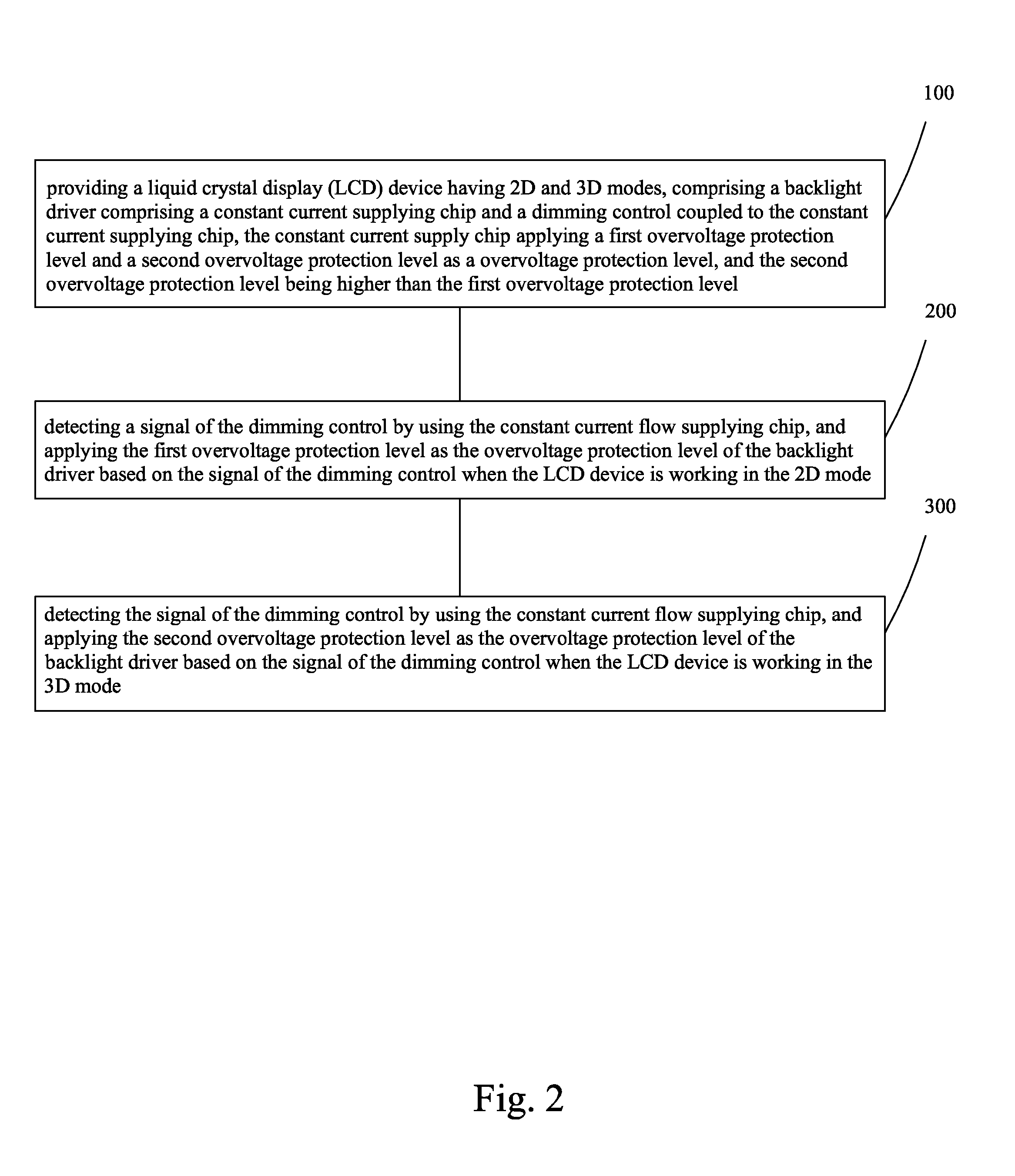

Overvoltage protection method for backlight driver

InactiveUS8982521B2Prevent abrupt power augmentExtended service lifeSemiconductor lamp usageCathode-ray tube indicatorsOvervoltageConstant current

An overvoltage protection method for backlight driver includes: providing an LCD device having 2D and 3D modes, comprising a backlight driver comprising a constant current supplying chip and a dimming control coupled to the constant current supplying chip, the constant current supply chip applying a first overvoltage protection level and a second overvoltage protection level as a overvoltage protection level; detecting a signal of the dimming control by using the constant current flow supplying chip, and applying the first overvoltage protection level as the overvoltage protection level based on the signal of the dimming control when the LCD device is in the 2D mode; and detecting the signal of the dimming control by using the constant current flow supplying chip, and applying the second overvoltage protection level as the overvoltage protection level based on the signal of the dimming control when the LCD device is in the 3D mode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

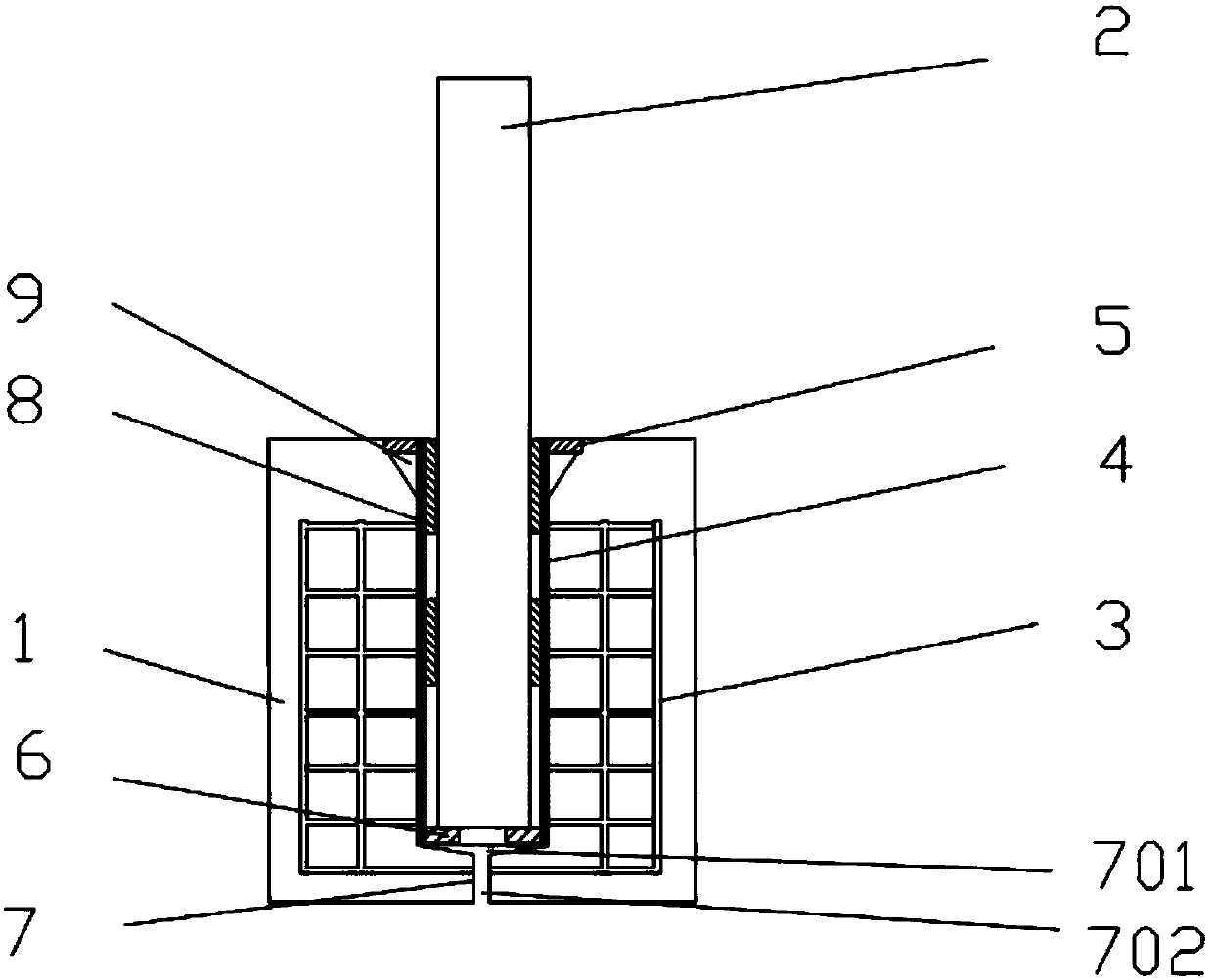

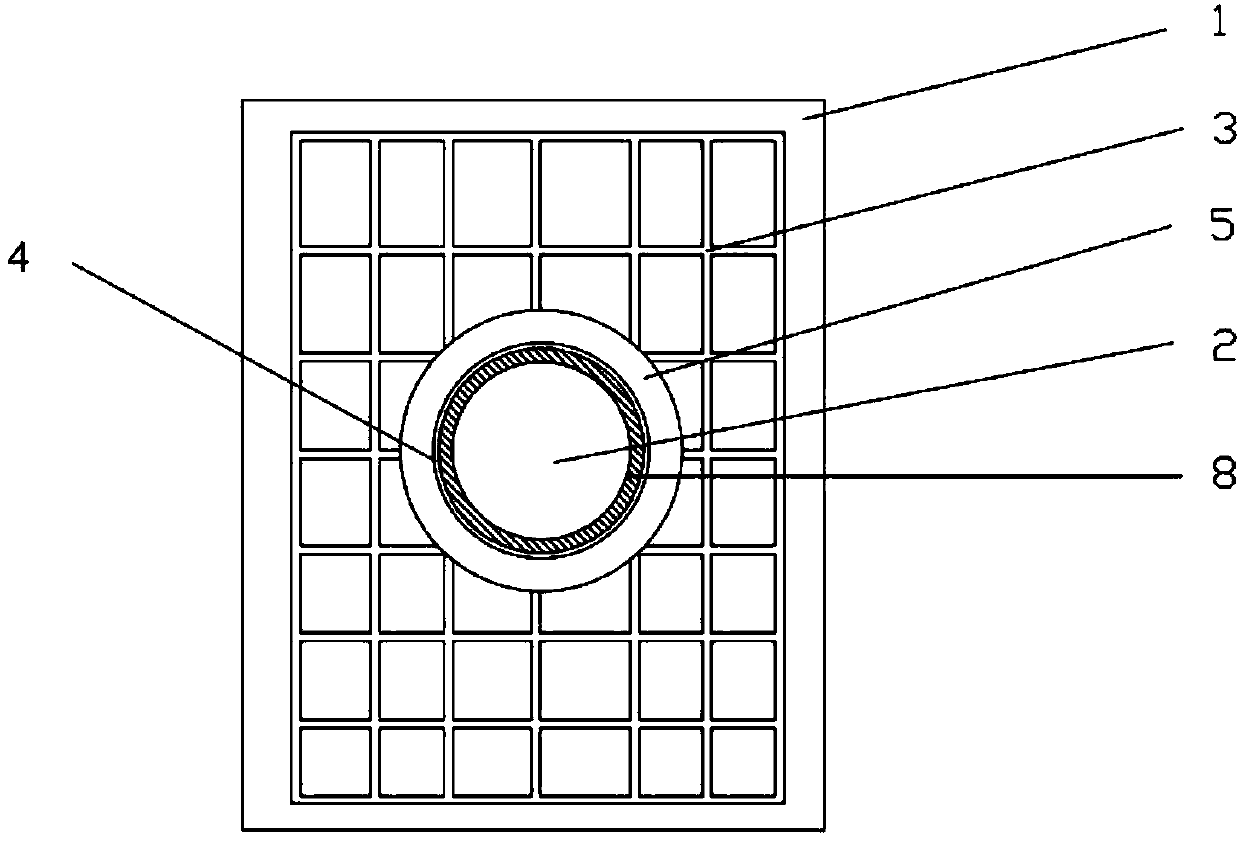

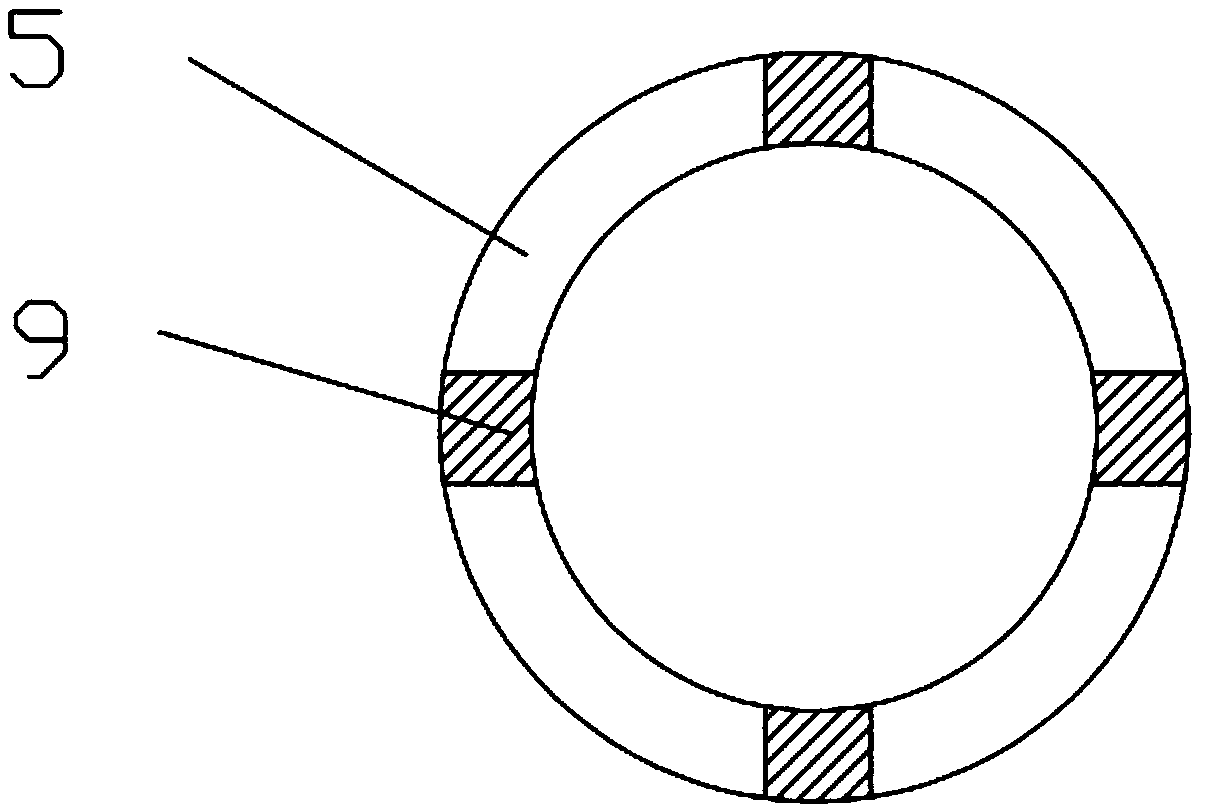

Novel concrete base safety guard device

The invention discloses a novel concrete base safety guard device, comprising a base and a vertical post arranged in the base; the base is made of cast-in-place concrete or pre-made in a factory; thebase is integrated to a subgrade; a reinforcing cage is embedded in the base; a post cavity is arranged in the base; a post sleeve is pre-arranged on the inner periphery of the post cavity and is fixedly connected with the reinforcing cage; the upper peripheral rig of the post sleeve is fixedly connected with a reinforcing disc, the lower peripheral edge of the post sleeve is provided with a drainpassage, a plurality of limiting blocks are fixed to the inner wall of the post sleeve, and a plurality of damping seal rings are arranged between the inner wall of the post sleeve and the vertical post from top to bottom. The novel concrete base safety guard device has the advantages that the damaged vertical post is quick to change so that operating time is effectively shortened for construction staff; the novel concrete base safety guard device is well compatible with current standard facilities and is highly applicable; materials selected herein are common, the novel concrete base safetyguard device is simple to manufacture and widely applicable, and the vertical post in a vertical tube can be protected from damage so that reusing is achieved; the novel concrete base safety guard device is solid, durable, economical and reliable, and low in cost.

Owner:张玉建

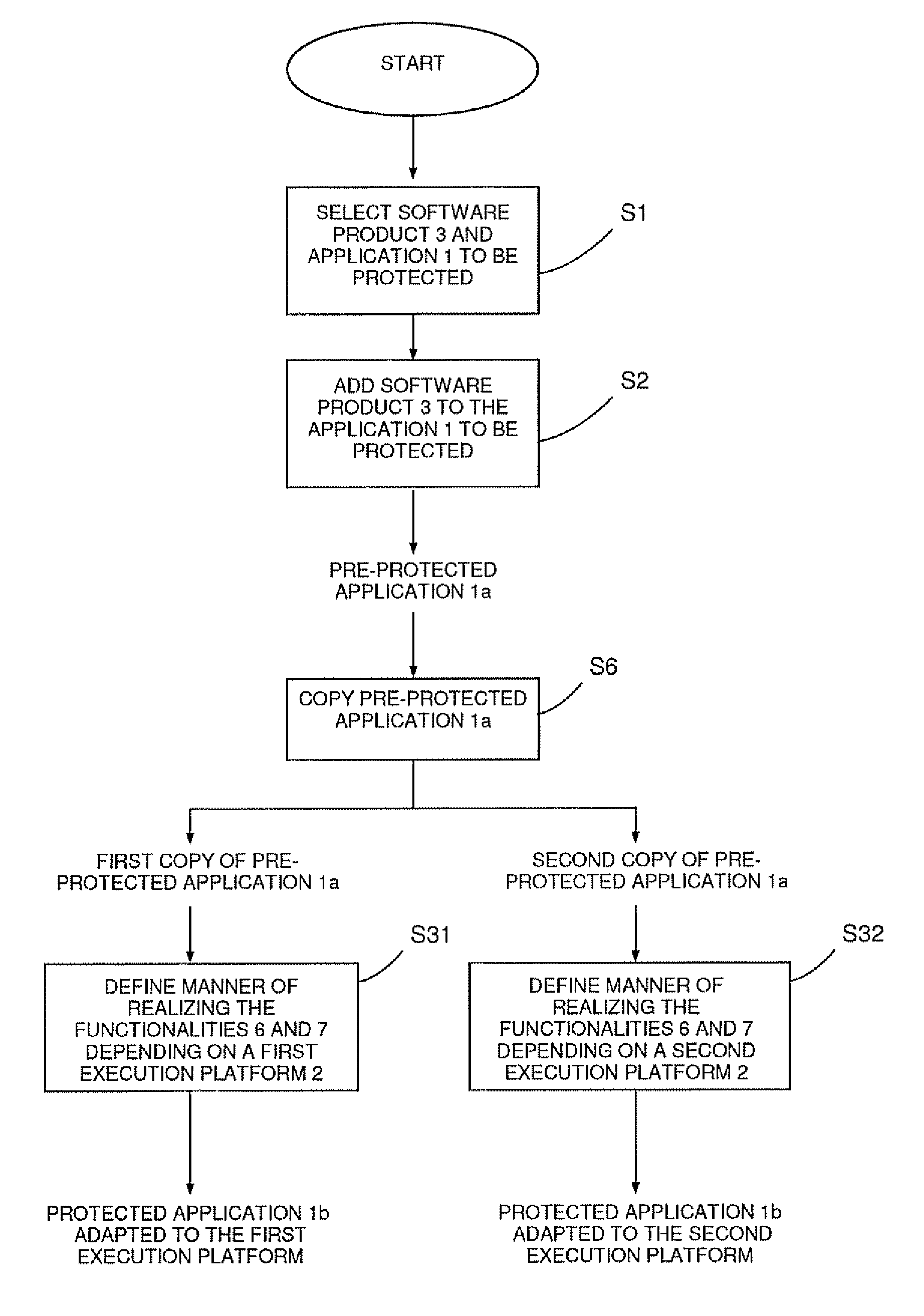

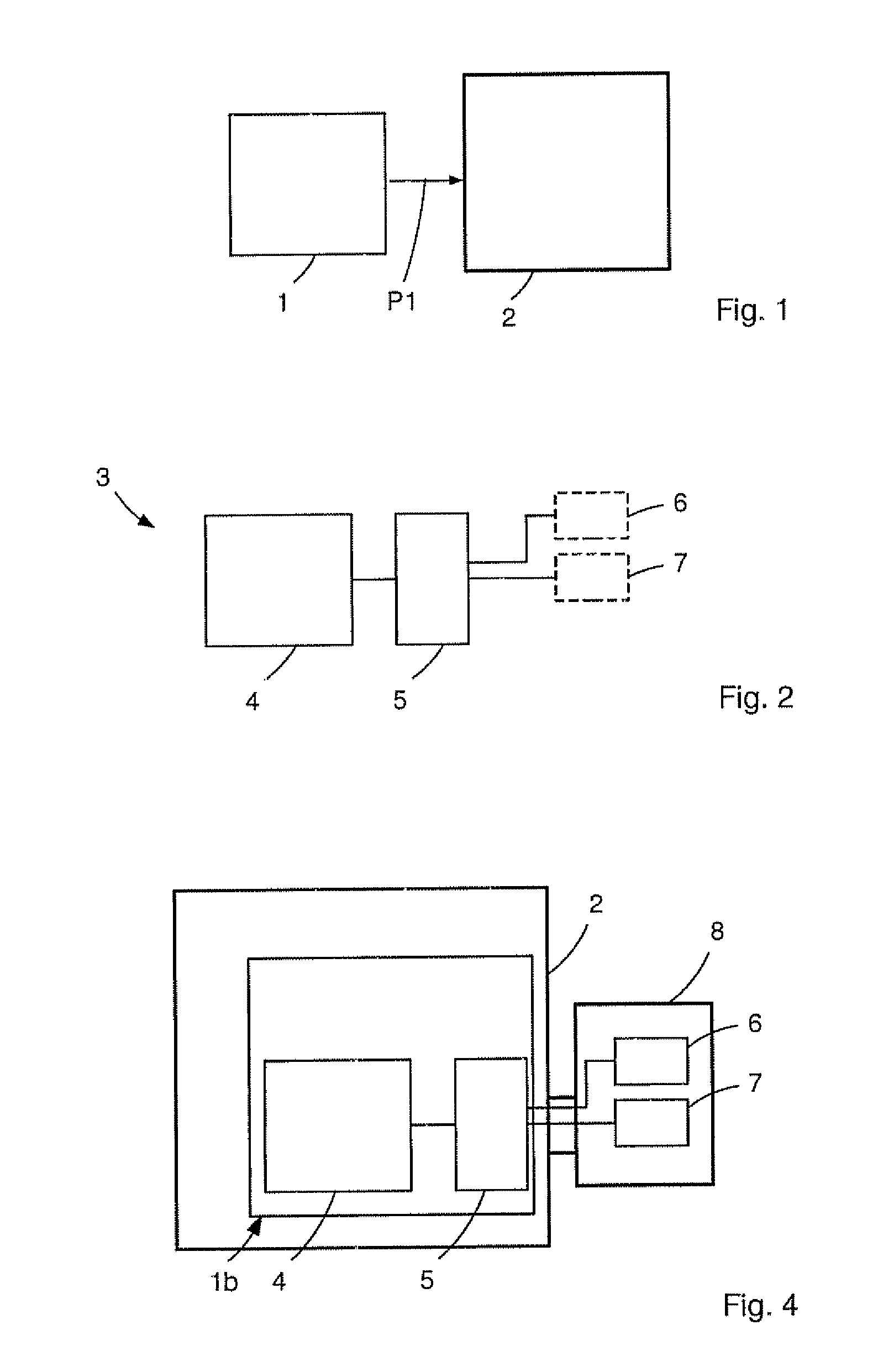

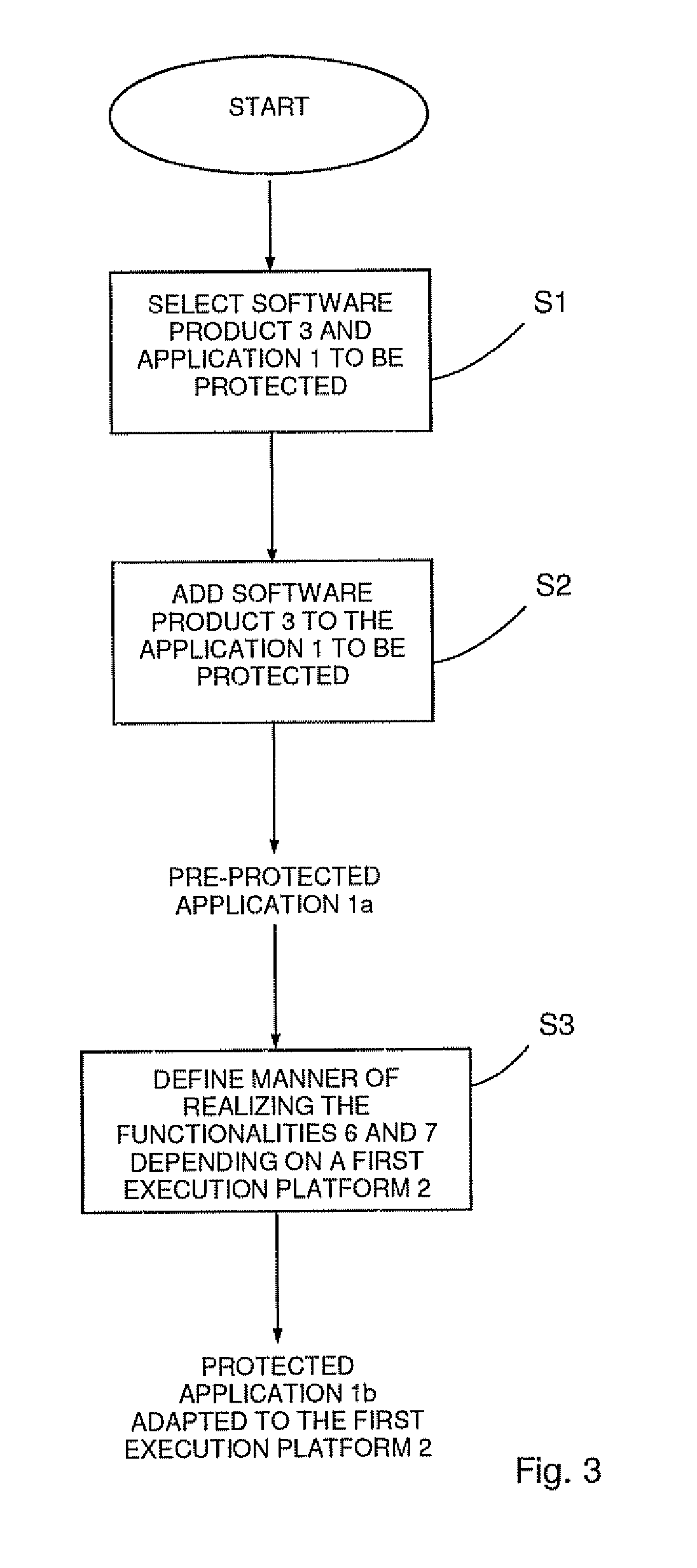

Method and apparatus for obtaining a protected application protected against unauthorized use by implementing a predetermined licensing model

InactiveUS20080228649A1High protection levelUse in some applicationProgram/content distribution protectionCommerceApplication softwareSoftware engineering

There is provided a method for obtaining a protected application protected against unauthorized use by implementing a predetermined licensing model, said method comprising the steps of: adding a software product to said application, said software product providing the possibility of defining one of several different manners of realizing a functionality to be used for implementing the predetermined licensing model, and defining one of the several manners of realizing the functionality and an apparatus for obtaining a protected application protected against unauthorized use by implementing a predetermined licensing model, which apparatus adds a software product to said application, said software product providing the possibility of defining one of several different manners of realizing a functionality to be used for implementing the predetermined licensing model, and defines one of the several manners of realizing the functionality. Further, there is provided a software product, which is to be added to an application in order to obtain a protected application protected against unauthorized use by implementing a predetermined licensing model, said software product providing the possibility of defining one of several different manners of realizing a functionality to be used for implementing the predetermined licensing model and a method of distributing a software application, said method comprising the steps of: protecting the software application to be distributed by adding a software product to said software application, said software product providing the possibility of defining one of several different manners of realizing a functionality to be used for implementing a predetermined licensing model, and defining one of the several manners of realizing the functionality, sending the protected software application to the user.

Owner:SFNT GERMANY

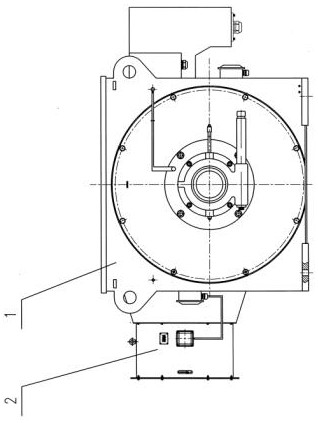

Hydraulic manipulator

InactiveCN107877530AMoment of activity is largeLow protection levelGripping headsElectric driveGrippers

The invention provides a hydraulic manipulator. The front end of the hydraulic manipulator is rotatable. The hydraulic manipulator comprises a rack, a rotating oil cylinder, a manipulator oil cylinderexternal cavity, a manipulator oil cylinder piston rod and a manipulator part device. The rack is fixed to the left end of a shell of the rotating oil cylinder through screws. A rotating shaft of therotating oil cylinder and the manipulator oil cylinder external cavity are integrated. The manipulator part device is fixed to the right end of the manipulator oil cylinder external cavity and composed of a manipulator fixing seat and a manipulator part. The fixing seat is movably connected with the middle of the manipulator part. The left end of the manipulator part is connected with the manipulator oil cylinder piston rod. The manipulator part is provided with at least one antiskid device. The hydraulic manipulator adopts pure hydraulic driving, grasping and releasing of a finger gripper are achieved, movement is flexible and diverse, the structure is compact, the weight is low, the efficiency is high, the hydraulic manipulator can be used in a harsh industrial environment, the protection level requirement is low, the working force of the hydraulic manipulator is much higher than that of an electric driven manipulator with the same level, and the cost of the hydraulic manipulator ismuch lower.

Owner:周士忠

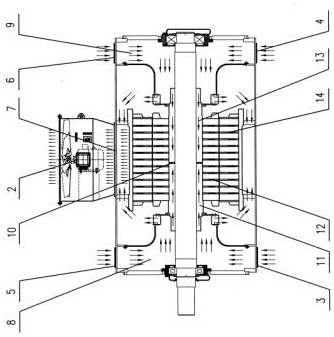

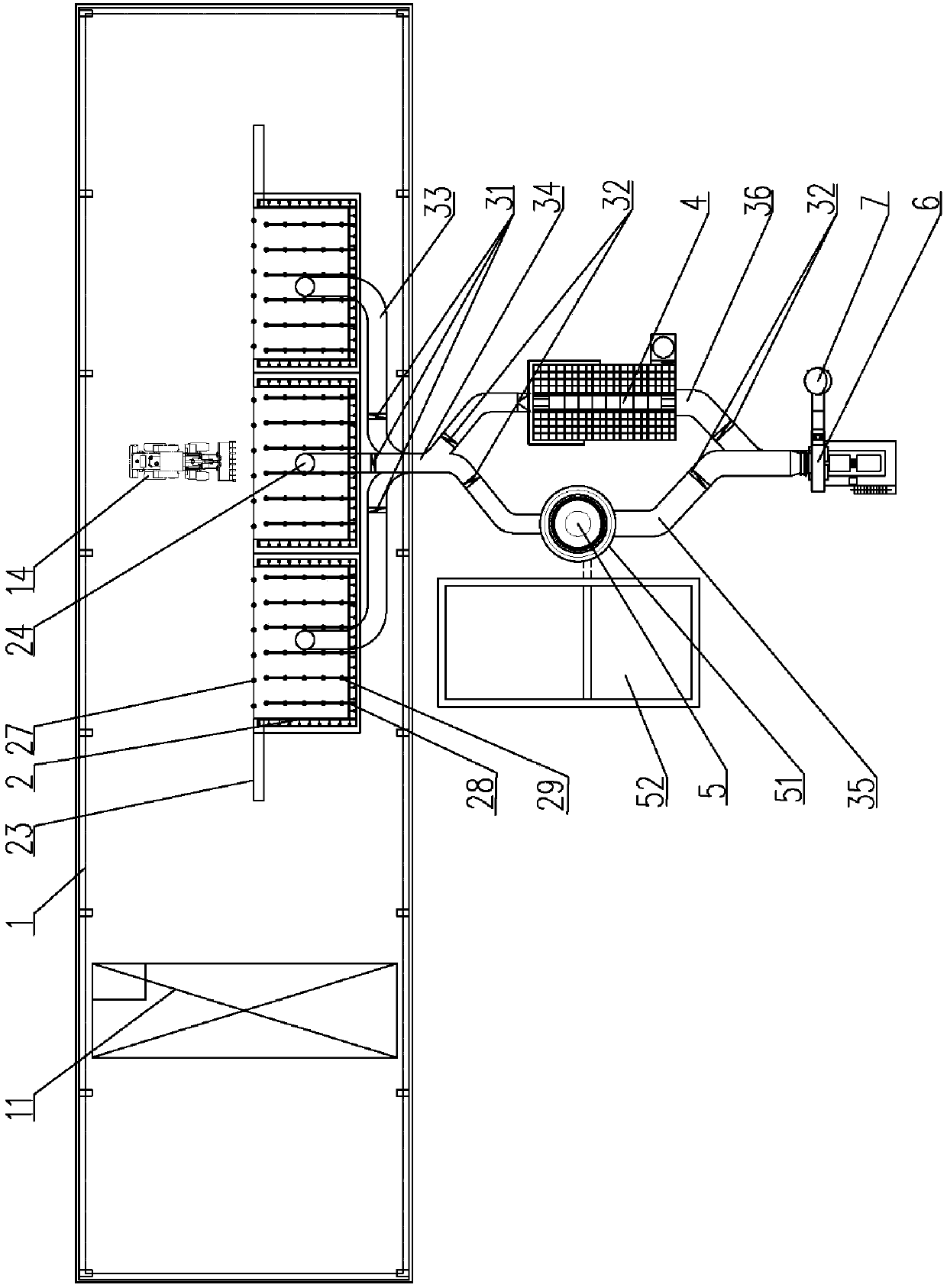

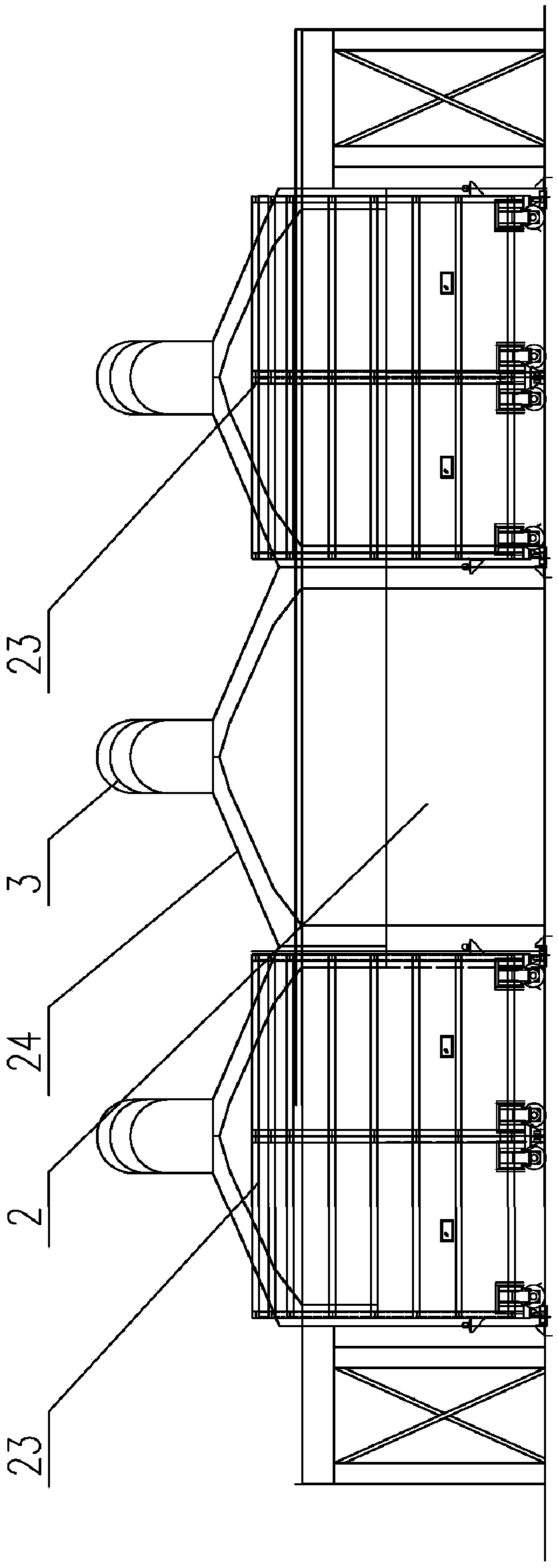

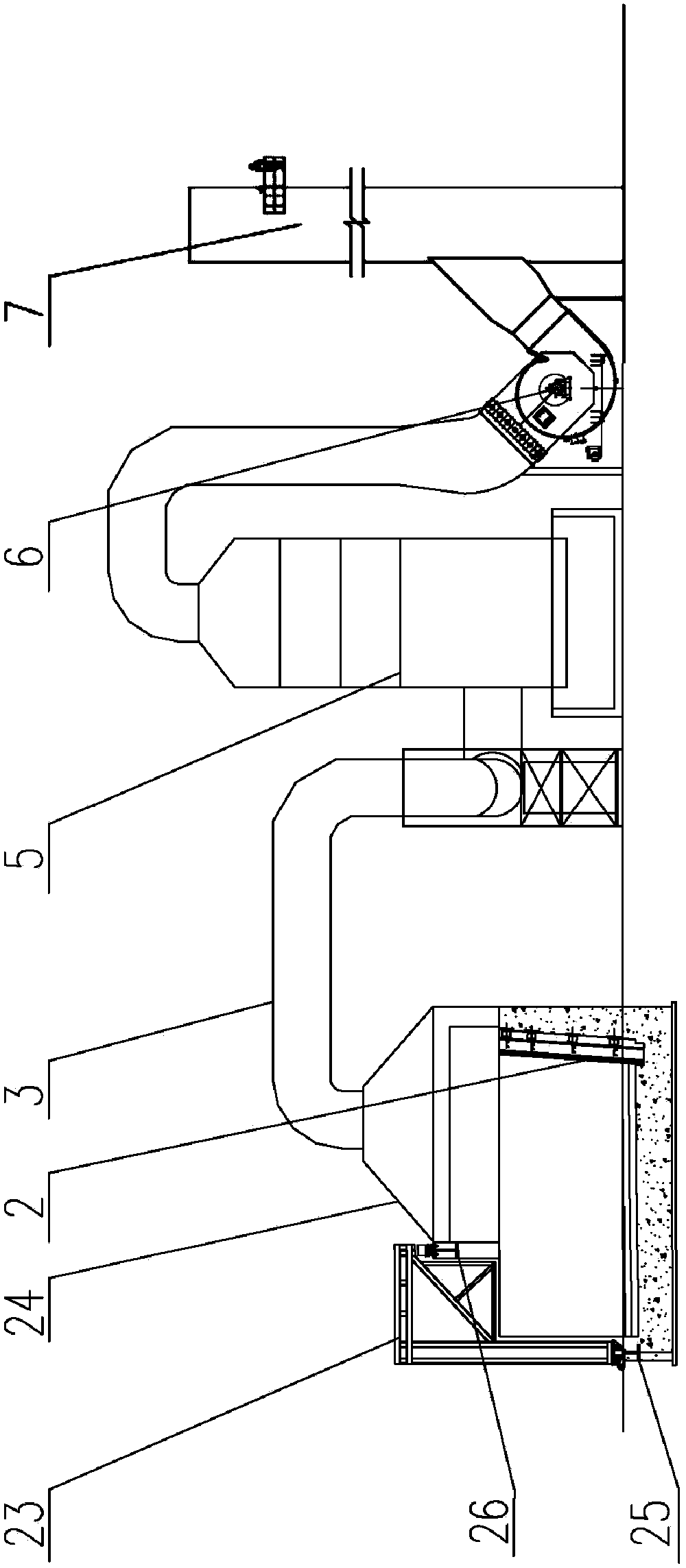

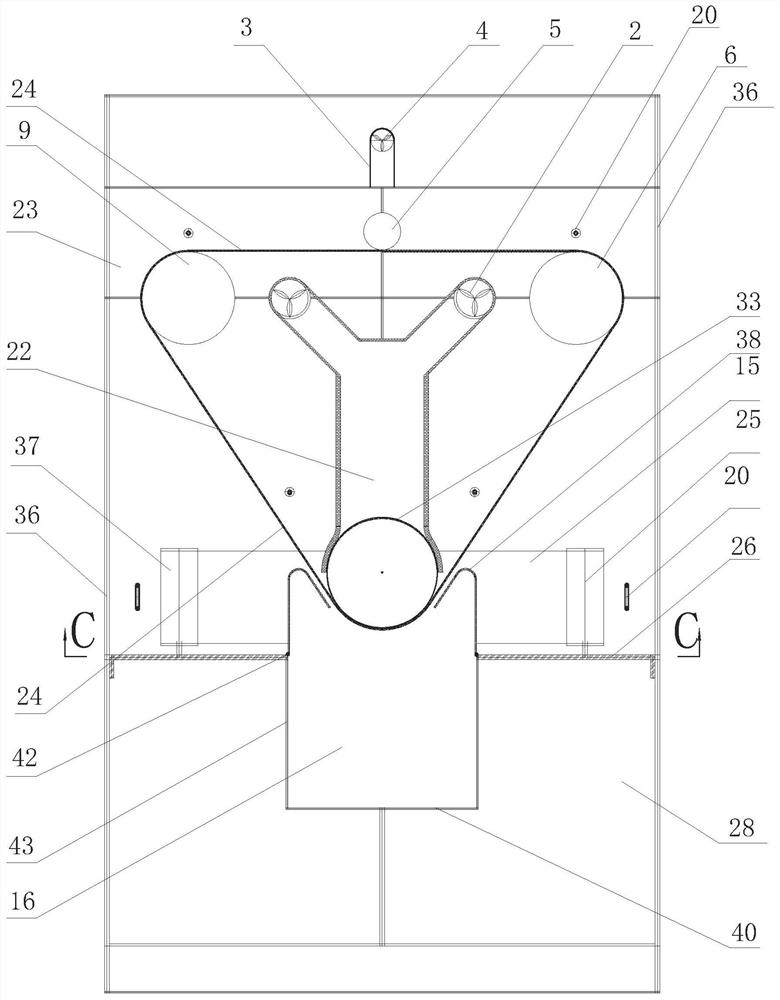

Strong air cooling structure of broadband variable-frequency motor

PendingCN114069940AMeet the requirements of indoor working environmentSimple structureMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

The invention discloses a strong wind cooling structure of a broadband variable-frequency motor, and solves the problems of how to meet the heat dissipation requirement of a high-power and wide-frequency-conversion variable-frequency motor and how to greatly reduce the occupied space of the whole equipment. A double-air-path cooling structure is adopted in the motor, the traditional mode that an air-air heat exchange cooler is arranged at the top end of the motor is changed, the air-air heat exchange cooler is omitted, and a centrifugal fan on a rotating shaft of the motor is omitted; a driving end and a non-driving end on the front side of a motor shell are respectively provided with a front air inlet, a driving end and a non-driving end on the rear side of the motor shell are respectively provided with a rear air inlet, an air outlet is formed in the middle of the rear side of the motor shell, a cooling fan is connected to the air outlet, and a double-loop strong air cooling air path is formed in the motor through the cooling fan; therefore, the strong wind cooling of the motor is realized, and the occupied space of the whole equipment is saved.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

Overvoltage Protection Method for Backlight Driver

InactiveUS20140204492A1Lower overvoltage protection levelExtended service lifeSemiconductor lamp usageEmergency protective arrangements for limiting excess voltage/currentOvervoltageConstant current

An overvoltage protection method for backlight driver includes: providing an LCD device having 2D and 3D modes, comprising a backlight driver comprising a constant current supplying chip and a dimming control coupled to the constant current supplying chip, the constant current supply chip applying a first overvoltage protection level and a second overvoltage protection level as a overvoltage protection level; detecting a signal of the dimming control by using the constant current flow supplying chip, and applying the first overvoltage protection level as the overvoltage protection level based on the signal of the dimming control when the LCD device is in the 2D mode; and detecting the signal of the dimming control by using the constant current flow supplying chip, and applying the second overvoltage protection level as the overvoltage protection level based on the signal of the dimming control when the LCD device is in the 3D mode.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

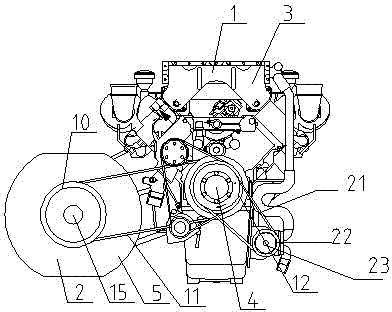

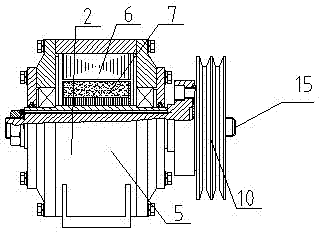

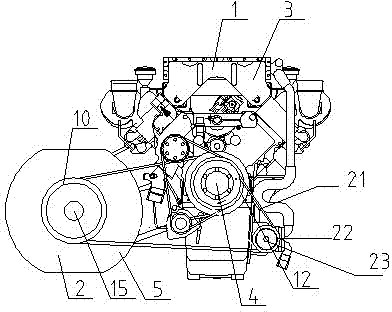

Generator assembly for car

The invention relates to the field of car power and particularly relates to a generator assembly for a car. The assembly comprises a generator stator, a generator rotor and a generator casing and is characterized in that a generator and a water pump are respectively located on two sides of a car engine, a crank of the car engine is connected with a drive shaft of the rotor and a drive shaft of the water pump through a belt respectively, the crank of the car engine drives the drive shaft of the rotor and the drive shaft of the water pump to rotate, and the generator is an integral machine of a generator and a starter. Compared with the prior art, the assembly has the advantages of being capable of saving materials, utilizing space reasonably, improving safety, saving space and utilizing power sources effectively.

Owner:HUNAN VAQOUNG ELECTRIC +1

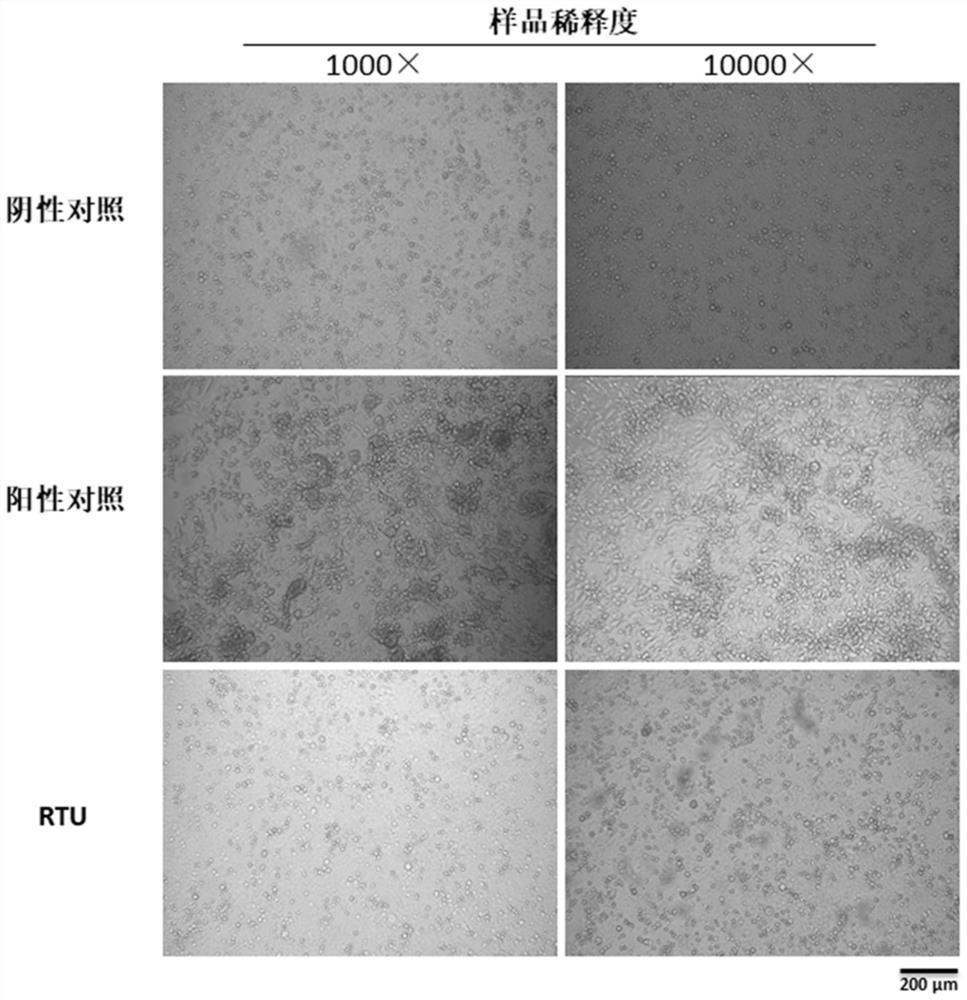

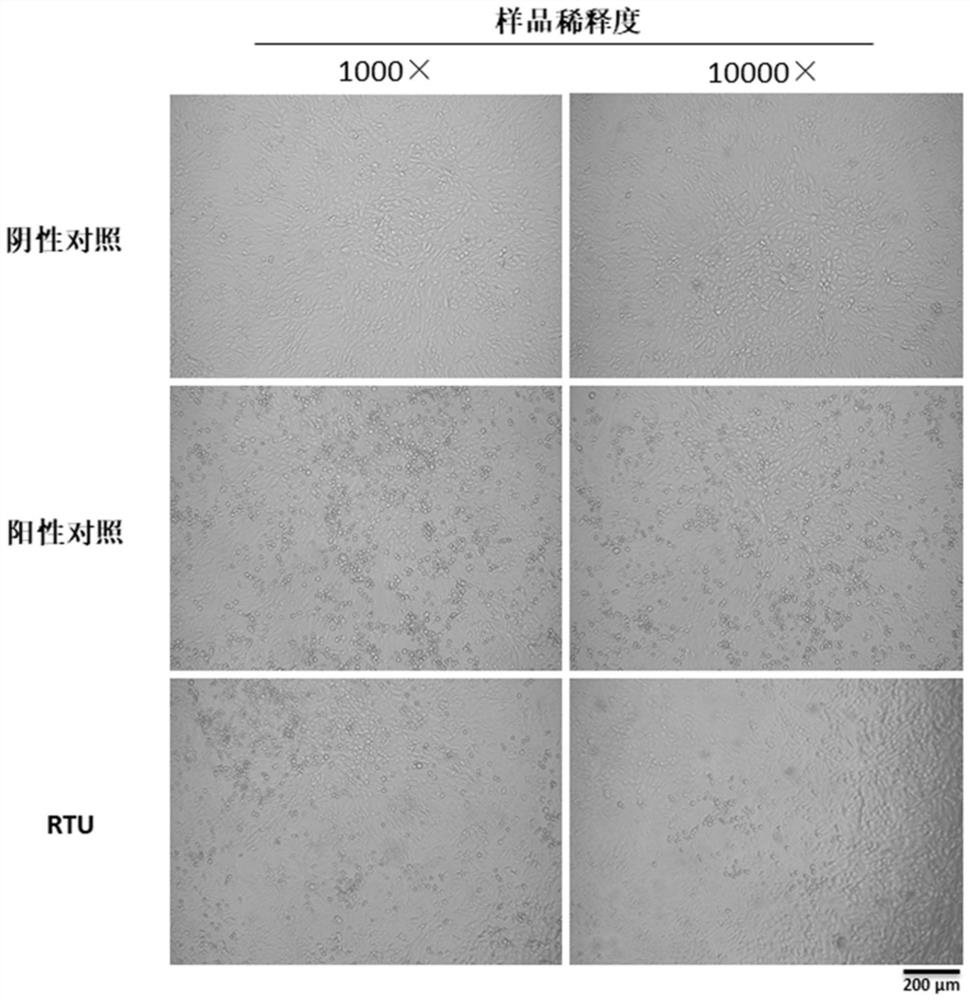

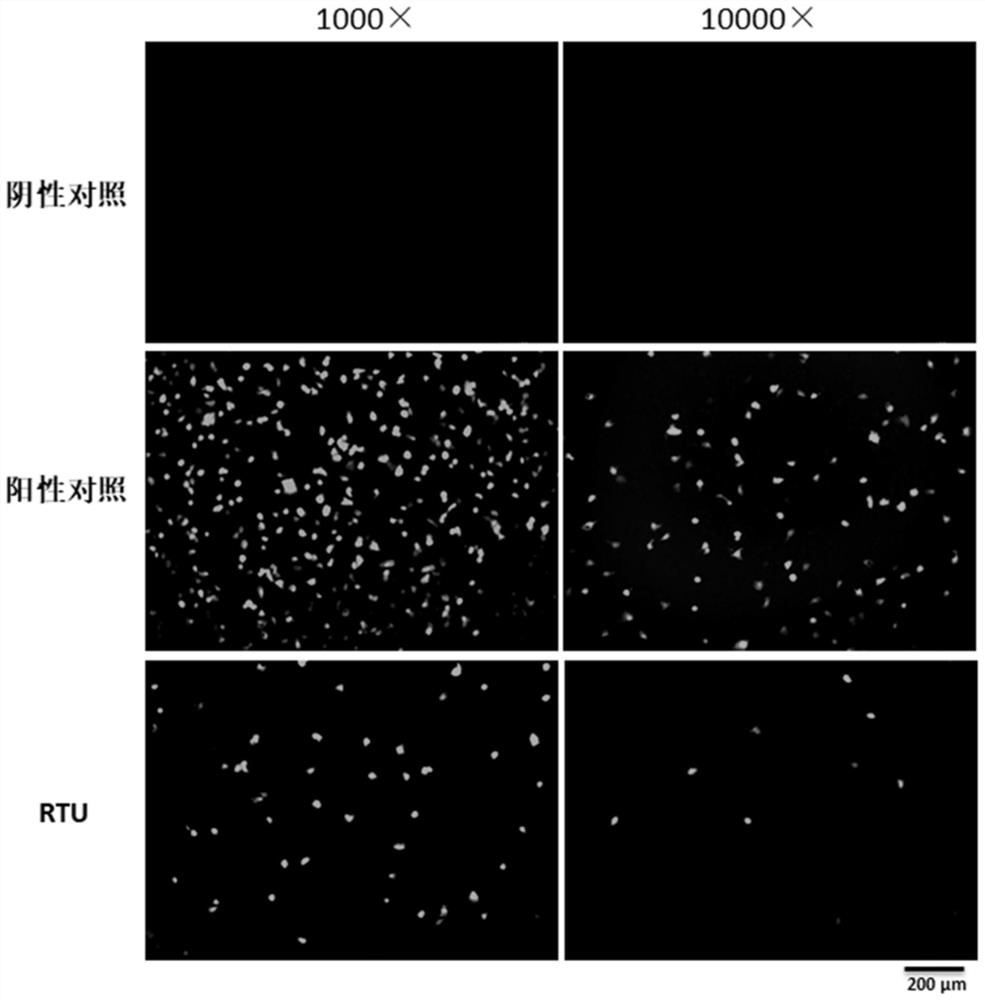

Reagent for Respiratory Virus Treatment and Its Application

ActiveCN111621481BReduce the risk of infectionConducive to preservationSsRNA viruses negative-senseSsRNA viruses positive-senseActive componentRespiratory virus

The invention relates to the field of virus detection, in particular to a respiratory virus treatment reagent and its application. The respiratory virus treatment reagent is a solution comprising the following main active components: TWEEN20, Nonidet P40 and dithiothreitol. The respiratory virus treatment reagent provided by the present invention can greatly improve the screening efficiency, reduce the risk of personnel infection in the process of sample transfer and detection operation, reduce the protection level of the detection laboratory operation process, save the cost of transfer and storage, and prevent respiratory virus epidemics such as The prevention and control of COVID‑19 is of great significance.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT) +1

Preparation method of high-nickel lithium ion battery positive electrode material

ActiveCN113072100AImprove responseLow protection levelSecondary cellsPositive electrodesLithium carbonatePhysical chemistry

The invention provides a preparation method of a high-nickel lithium ion battery positive electrode material, and aims to overcome the defect that lithium carbonate cannot be applied to preparation of a high-nickel ternary material by a method for reducing melting and thermal decomposition temperatures of lithium carbonate and improving reaction activity in a manner of developing an organic additive. According to the method, the process difficulty of the high-nickel lithium carbonate is greatly reduced under the condition of high nickel (Ni mol% is more than or equal to 60% and less than or equal to 98%), and meanwhile, the cost is greatly reduced.

Owner:TIANJIN ENERGIES

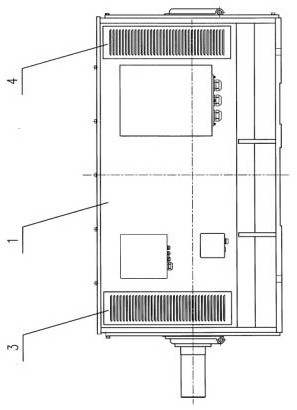

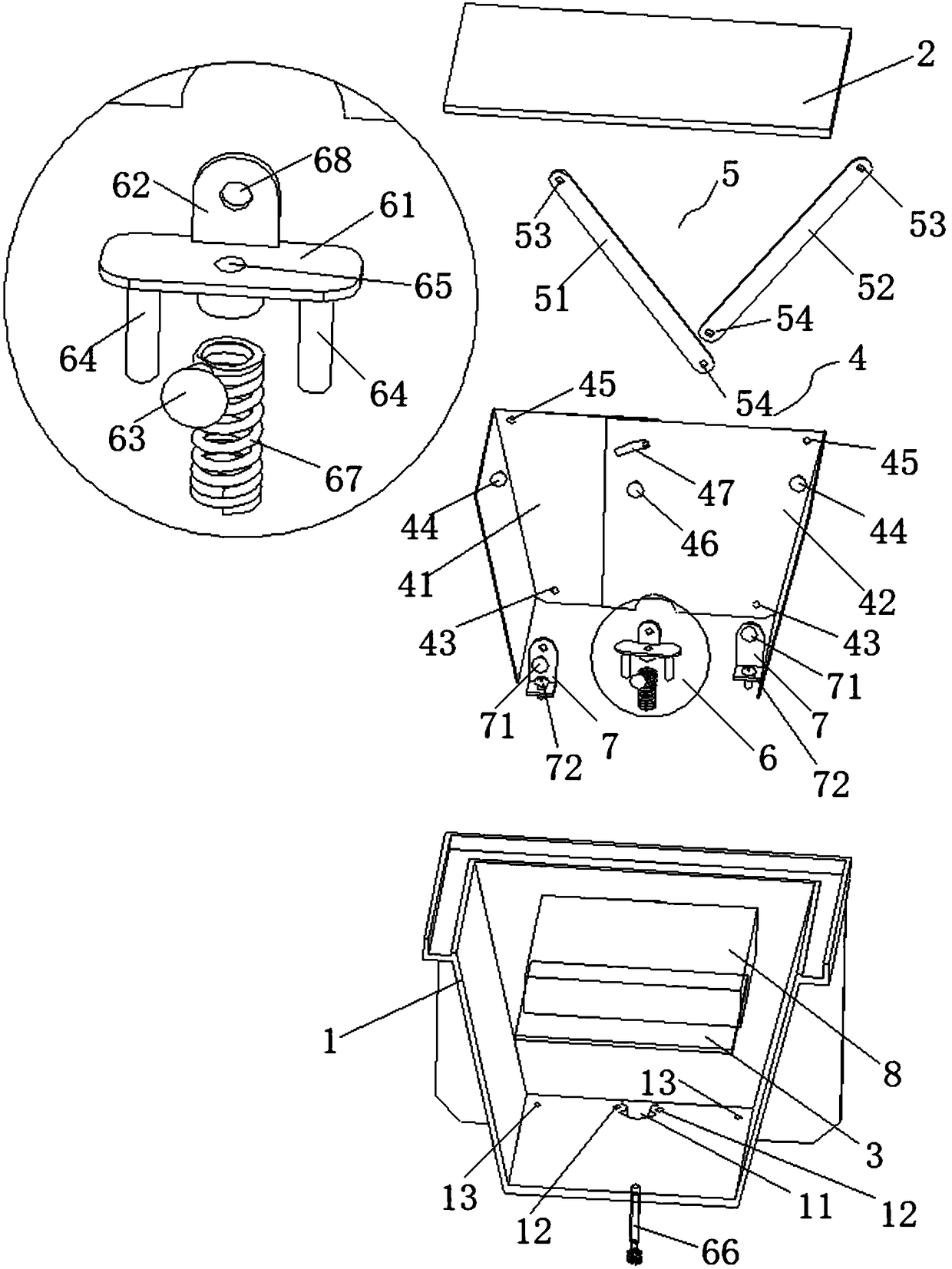

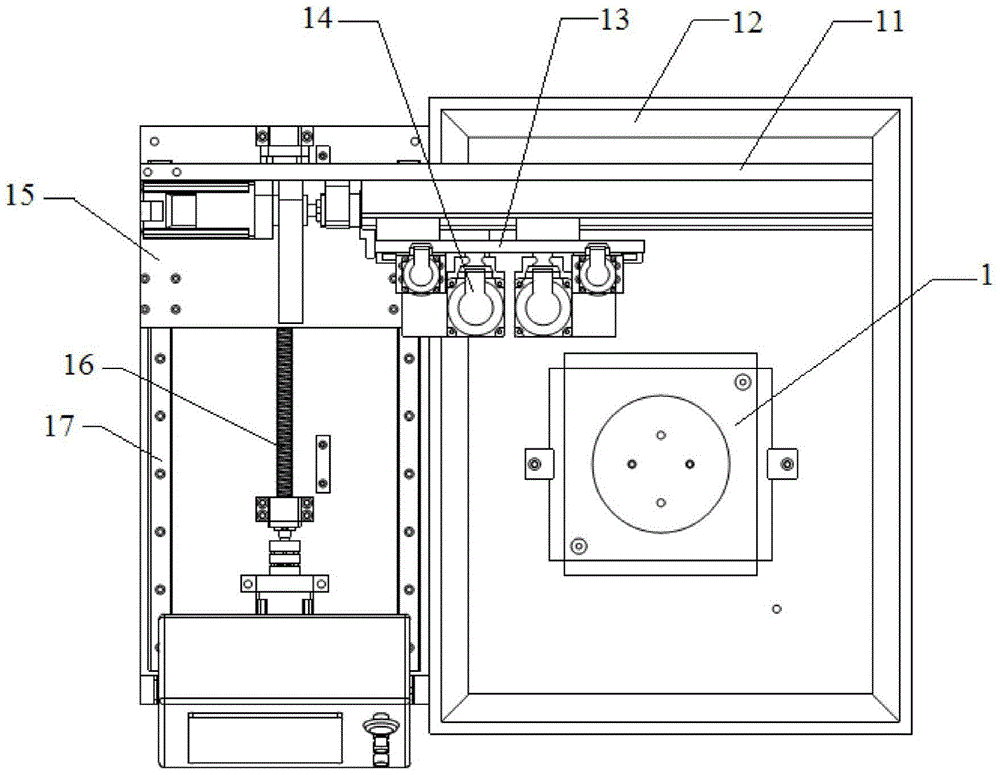

Lamp capable of adjusting light spot size

ActiveCN108799854ALow protection levelLow light efficiencyProtective devices for lightingLight fasteningsLight spotPulp and paper industry

The invention relates to a lamp capable of adjusting the light spot size. A reflection cover of the lamp comprises a left half reflection cover and a right half reflection cover which are rotationallyconnected with a shell of the lamp, the lamp comprises adjusting plates and a center adjusting part, the adjusting plates comprise the left adjusting plate and the right adjusting plate, the center adjusting part comprises an adjusting part main body, a guide column, a thread hole vertically formed in the adjusting part main body and an adjusting screw, one ends of the left and right adjusting plates are rotationally connected with the adjusting part main body, the other ends of the left and right adjusting plates are rotationally connected with the left and right half reflection covers, theguide column is arranged at the bottom of the shell in a sliding penetrating mode, the adjusting screw and the bottom of the shell are axially and rotationally connected, the bottom end is used as theadjusting end and exposed out of the bottom of the shell, and the upper end penetrates through an adjusting hole in the bottom of the shell to be in thread fit with the thread hole. According to thelamp, the light spot size is adjusted, and since the reflection cover is adjusted inside the lamp, the whole protection level and light effect of the whole lamp are not reduced.

Owner:SHANGHAI YAMING LIGHTING +1

Device for transferring overvoltage and use thereof

ActiveCN114287090ADoes not change propertiesLow protection levelSpark gaps with auxillary triggeringCurrent/voltage measurementOvervoltageEngineering

Owner:EPCOS AG

Environmental protection slag pouring device for hot pouring steel slag

ActiveCN106222338BImprove cooling effectImprove recycling efficiencyCombination devicesRecycling and recovery technologiesSlagFlue gas

The invention provides an environment-friendly slag-splashing device for hot-splashing steel slag, which comprises: a plurality of slag-splashing tanks, a smoke collection cover is provided on the top surface of each of the slag-splashing tanks, and a A water pipe network, the water pipe network is located below the flue gas collection cover, and the water pipe network is provided with a plurality of sprinklers; a fan is located on one side of the plurality of slag dumping tanks, and the fan is connected to the plurality of A washing tower and a bag filter are arranged in parallel between the slag-removing pipes, one end of the dust-removing pipe is connected to the suction port of the fan, and the other end of the dust-removing pipe is connected to a plurality of the slag-removing pipes. connected to the fume collection hood. The invention can process various steel slags, has the advantages of energy saving, environmental protection, zero discharge, low operation cost and wide application range.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Isolation window for preventing and controlling cross infection of pharyngeal/nasal test sample

PendingCN113827347AAvoid cross infectionReduce displacementSurgeryVaccination/ovulation diagnosticsMedicineNose

The invention provides an isolation window for preventing and controlling cross infection of pharynx / nose test sample. The isolation window comprises a disinfection cavity, an induction window, an annular belt-shaped filter membrane, isolation cloth and an air suction pipe with an inlet covered by the filter membrane, the filter membrane longitudinally surrounds the air suction pipe and is supported and driven by a roller to circularly rotate and disinfect in the disinfection cavity, a detection channel is arranged under an inlet of the air suction pipe, the induction window is arranged above the front end of the detection channel, the induction window is located right in front of the inlet section of the air suction pipe, the isolation cloth covers the induction window, extends into the disinfection cavity, circularly rotates in a disinfection cabinet under supporting and driving of the roller and performs disinfection, and surrounds the inlet section of the air suction pipe in the horizontal direction, a disinfection cavity exhaust fan is arranged at the upper part of the disinfection cavity, and suction is used through a fan to keep the micro-negative pressure at a gap where the filter membrane and the isolation cloth enter the disinfection cavity. According to the isolation window, a head of an examinee can be accurately positioned, the sampling efficiency is high, gas exhaled by the examinee can be sucked out, filtered and disinfected in a short distance, disinfection is thorough, safety and reliability are achieved, and the isolation window is compact in structure.

Owner:WUHAN UNIV OF SCI & TECH +1

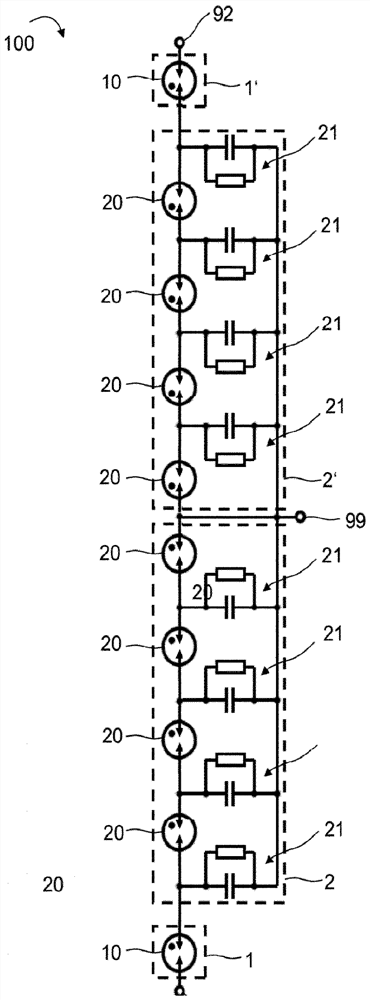

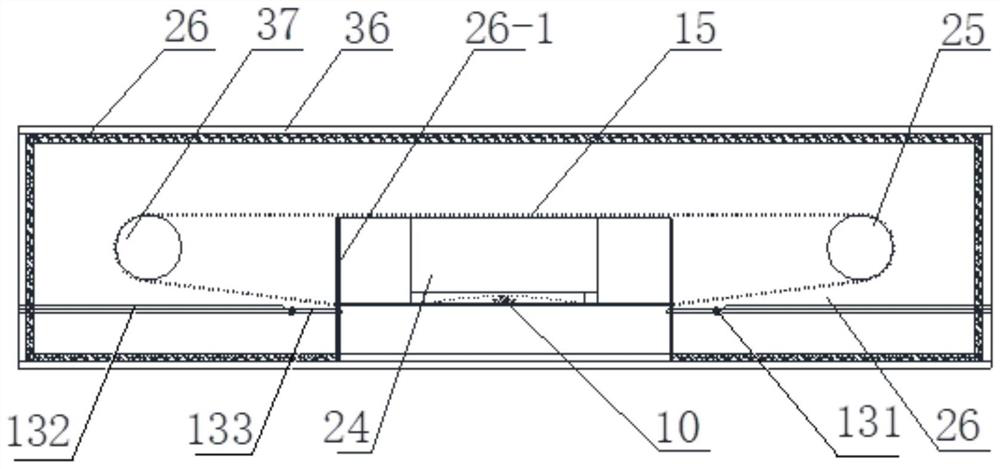

Voltage dividing device of ring network cabinet type high-voltage electronic equipment

PendingCN110416988ALow protection levelReduce large measurement errorsEmergency protective arrangements for limiting excess voltage/currentObservational errorEngineering

The invention discloses a voltage dividing device of ring network cabinet type high-voltage electronic equipment, which comprises cable T joints and conductive wires, wherein the number of the cable Tjoints is three, each cable T joint is provided with a voltage divider below, each voltage divider is provided with a tail cover below, and the voltage dividers below the three cable T joints are mutually connected through the conductive wires. According to the voltage dividing device of the ring network cabinet type high-voltage electronic equipment, a measuring and monitoring circuit of split phases is arranged on the high voltage side, so that the voltage at the primary side of a current transformer is enabled to be 0, the parasitic current generated by high voltage is thoroughly removed,and the problem of great measurement errors brought about by current waveform deformation due to great voltage difference between the primary and secondary sides of the transformer is reduced; and thethree phases of voltage dividers adopt a star connection method, the common point is not grounded, and high voltage resistance and insulation are achieved. The lightning protection only needs to be carried out between phases, and the protection between the phases and the ground is not considered. The protection level of lightning protection can be reduced.

Owner:武汉德能电网技术有限公司

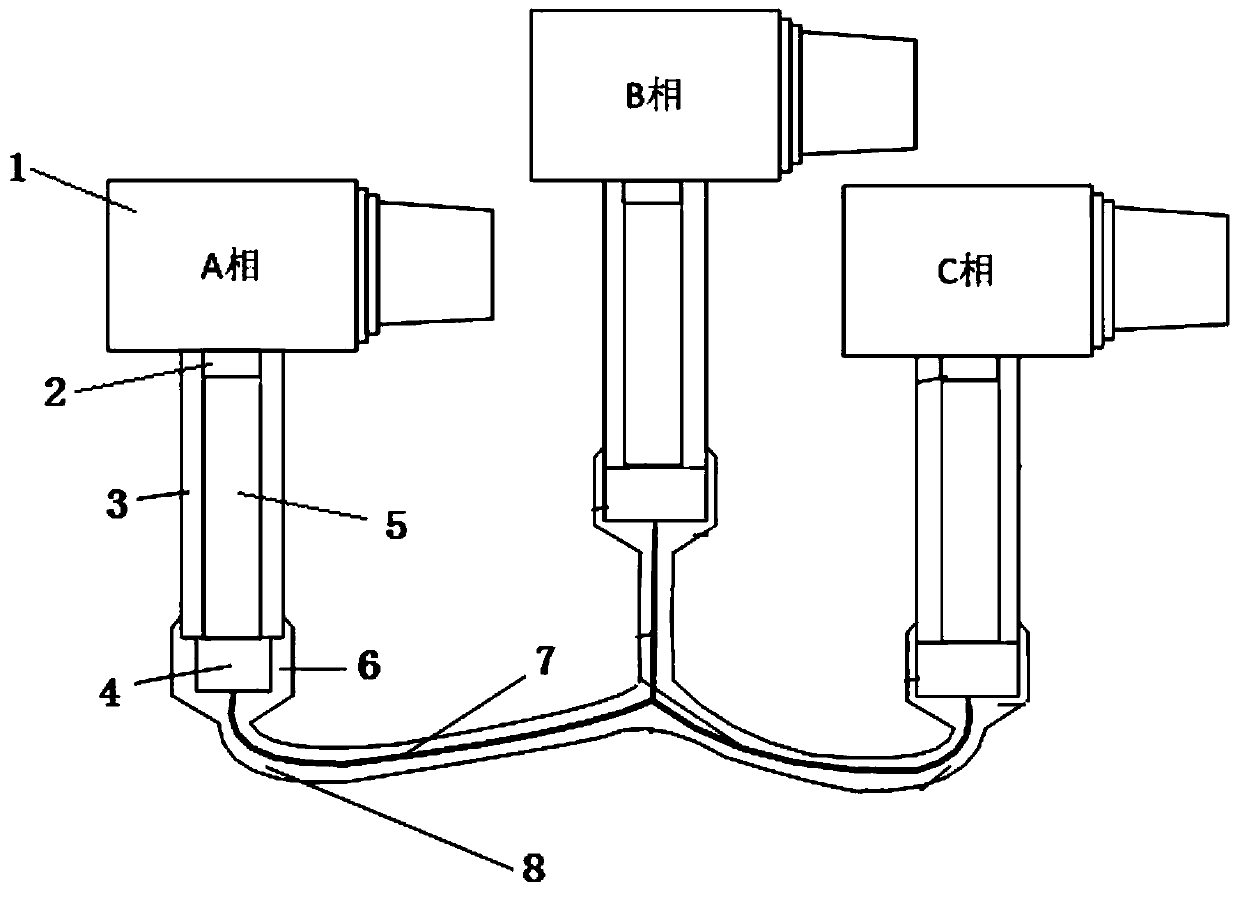

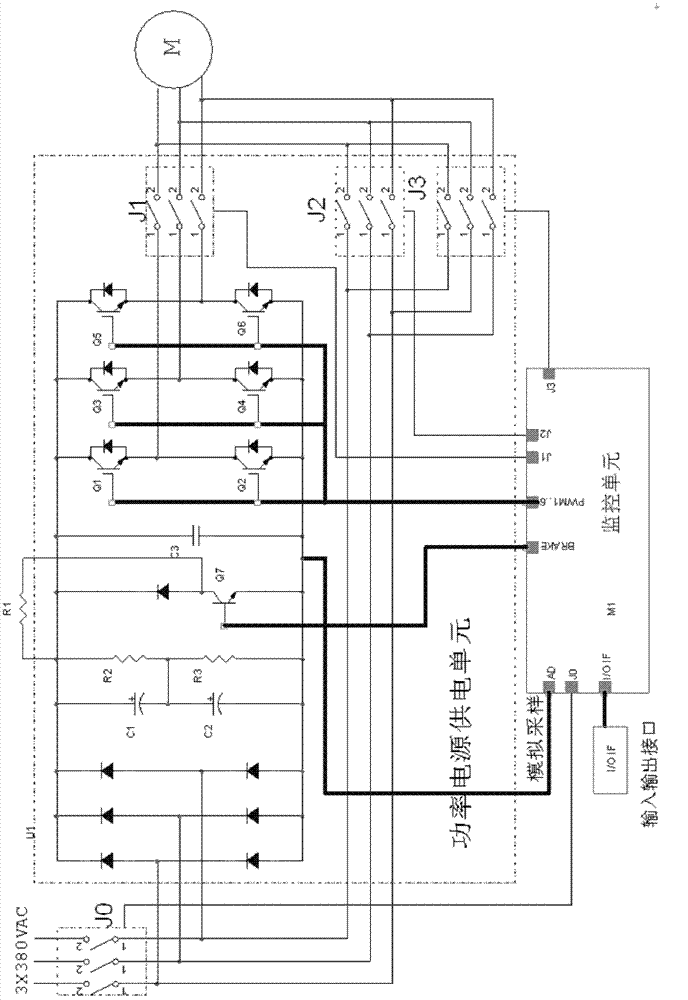

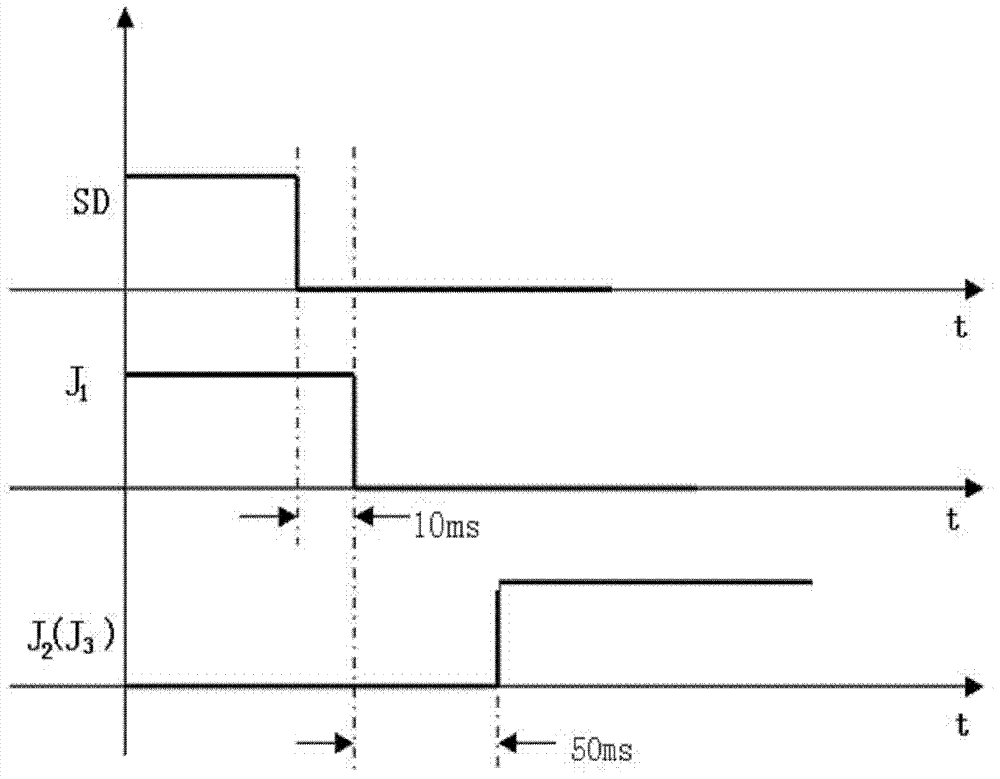

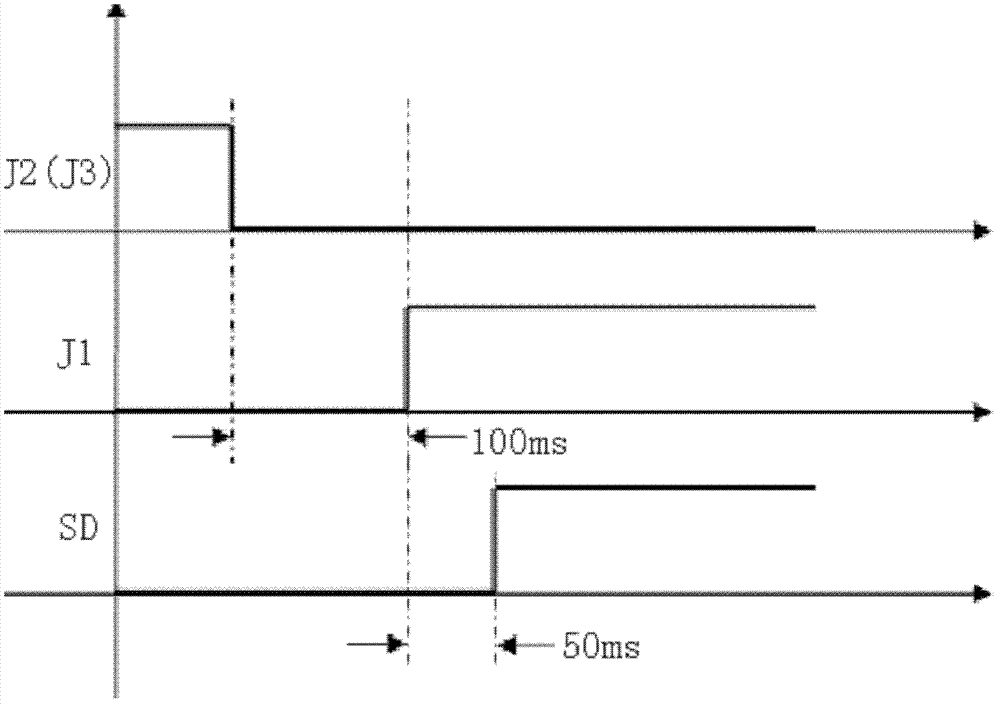

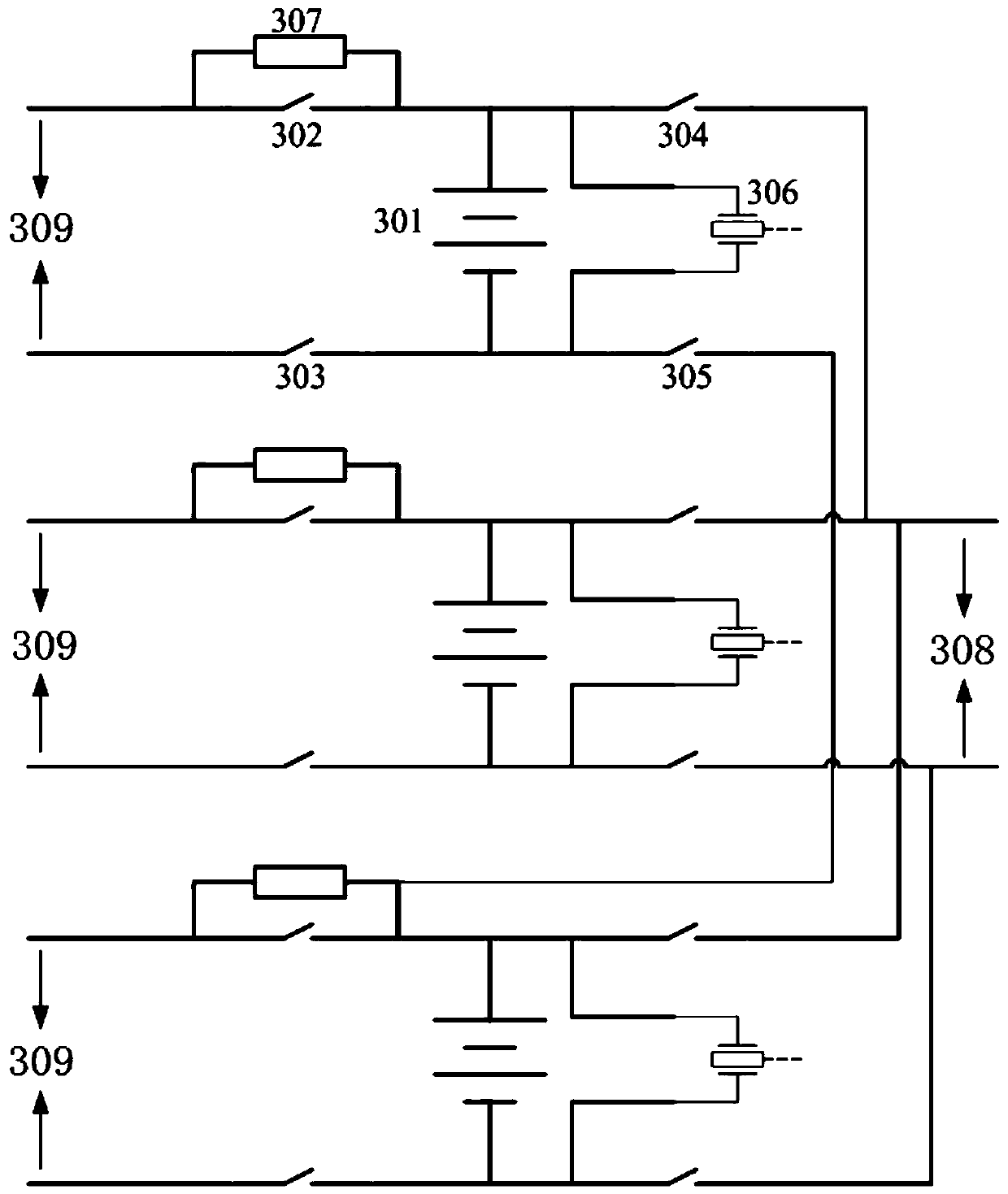

Variable frequency control circuit and control method for electric hoist

InactiveCN102545776BReasonable controlEffective controlAC motor controlPolyphase induction motor starterLow speedElectric machine

The invention relates to a variable frequency control circuit and a variable frequency control method for an electric hoist. The control circuit consists of a power supply unit and a monitoring unit, which are connected. A three-phase alternating current power supply supplies low-frequency three-phase alternating current power to a hoisting motor through a low-frequency three-phase alternating current power supply branch to realize the low-speed running function of the hoisting motor, and supplies high-frequency three-phase alternating current power to the hoisting motor through a high-frequency three-phase alternating current power supply branch to realize the high-speed running function of the hoisting motor. The control method comprises a switching control method for the low-speed running to high-speed running of the hoisting motor and a switching control method for the high-speed running to low-speed running of the hoisting motor. The circuit and the method have the characteristics of rational design, low cost, high reliability and the like, and can be widely applied in the field of motor driving and control for hoisting machinery; and the requirements of the electric hoist on speed control and safe running are met.

Owner:TIANJIN TIANAN CRANE ELECTRIC EQUIP

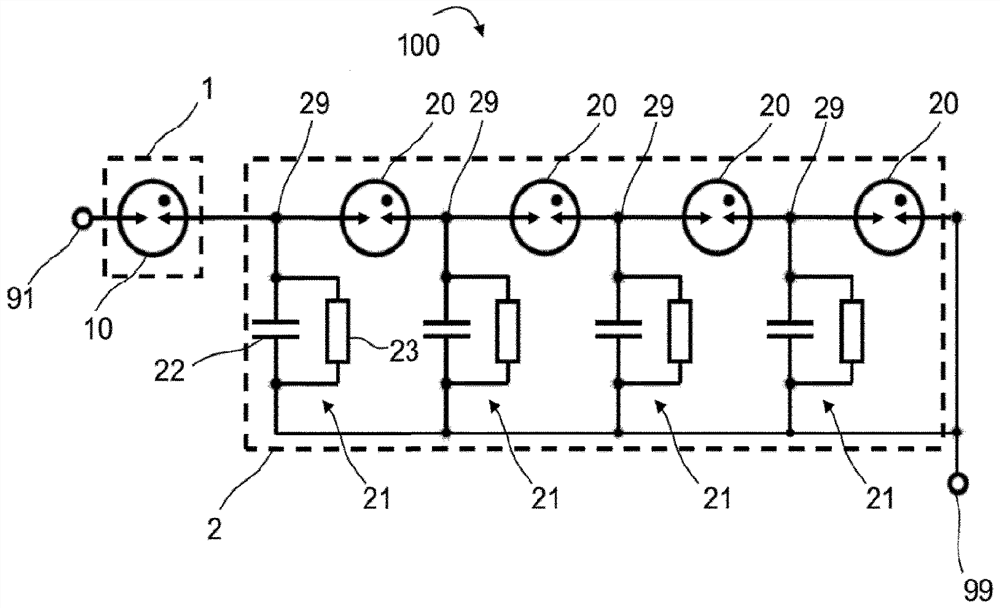

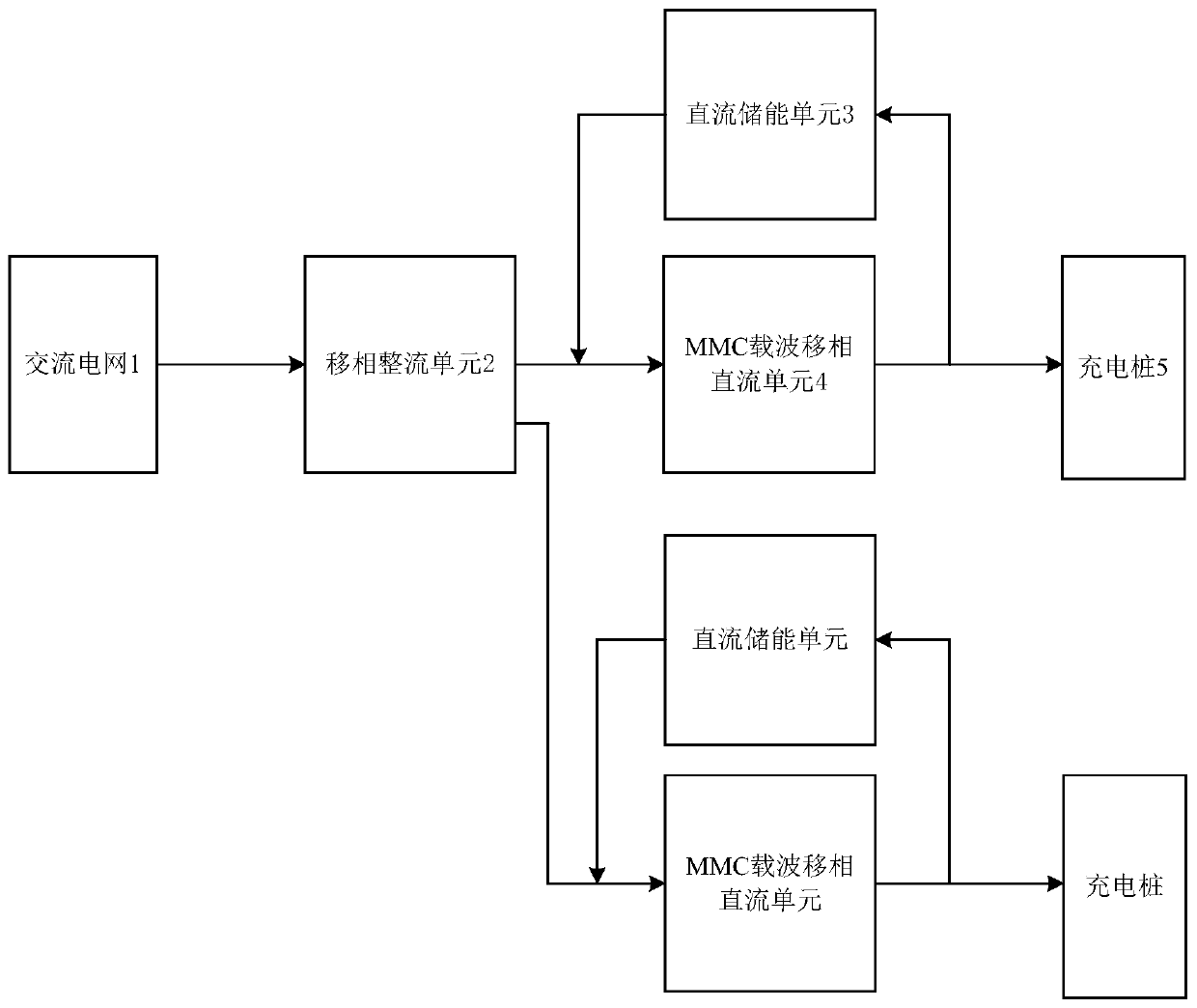

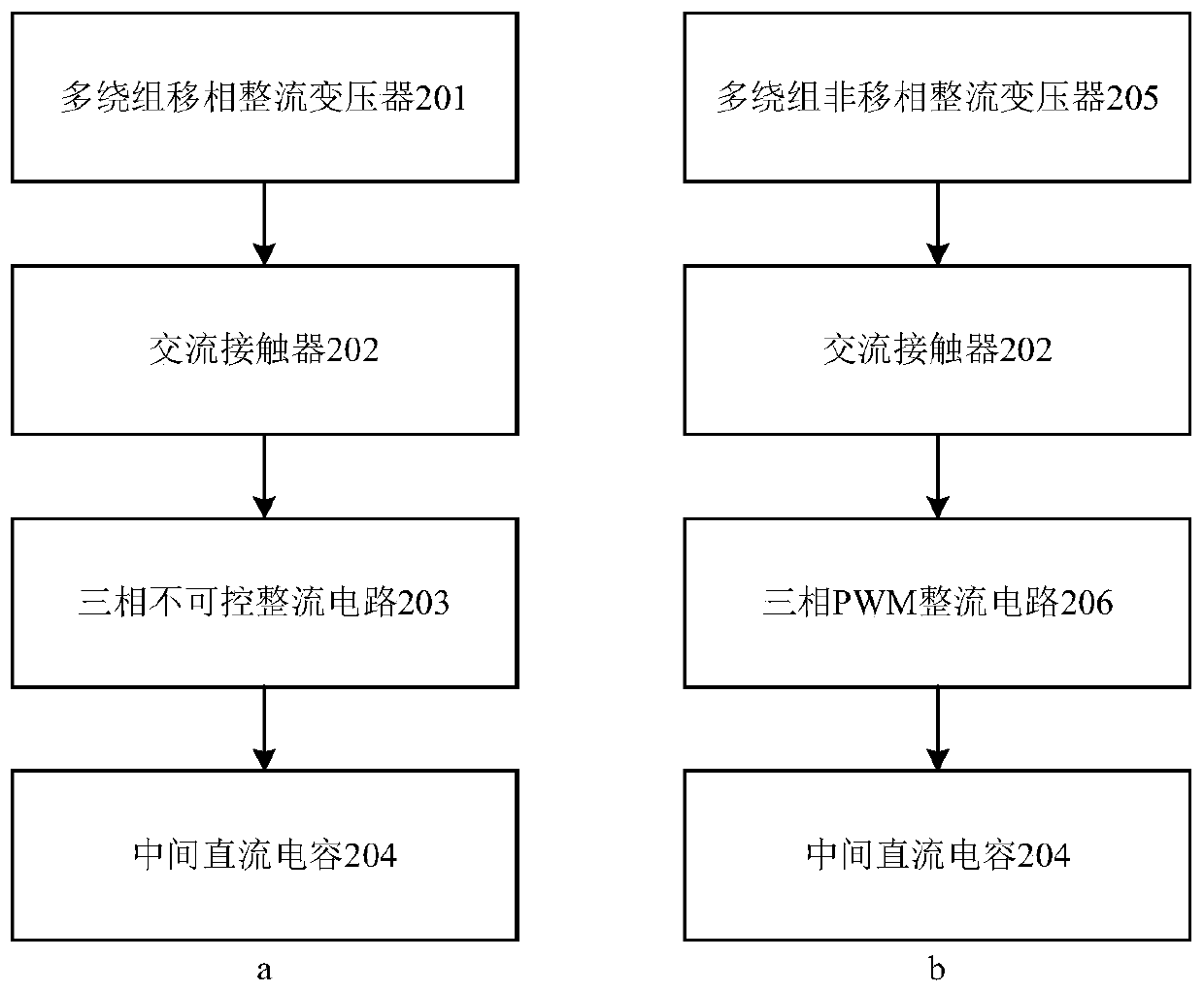

A flexible intelligent charging station and charging method

ActiveCN106972599BLow protection levelReduce maintenance costsCharging stationsMobile unit charging stationsPhase shiftedEngineering

The invention discloses a novel flexible and intelligent charging station. The charging station comprises charging piles, a phase shift rectification unit, direct current energy storage units and MMC carrier phase shift direct current units. The invention also discloses a novel flexible and intelligent charging method. According to the invention, under the condition that charging requirements of all charging piles are larger than the stipulated required power, the number of the charging piles is limited through flexible control, so in case of certain input power, charging requirements of electric vehicles can be met to the greatest degree.

Owner:WUHAN ZHONGYUAN ELECTRONICS GRP

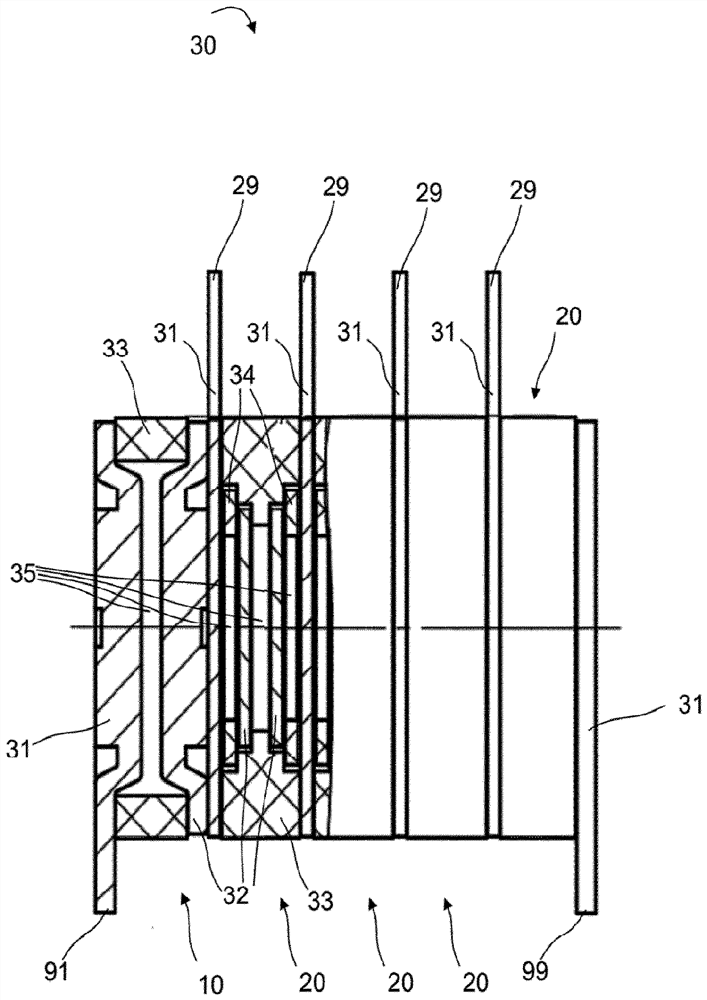

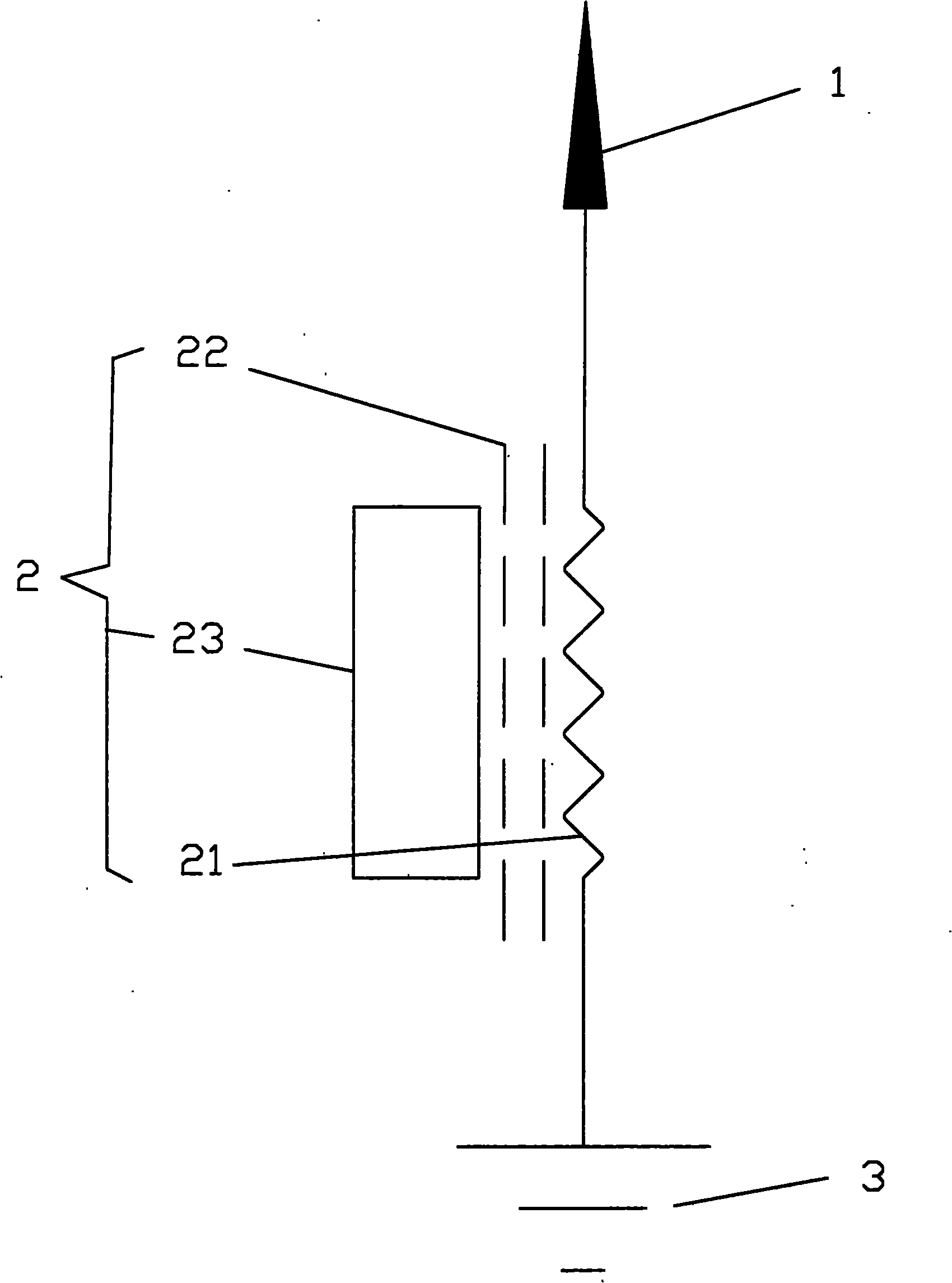

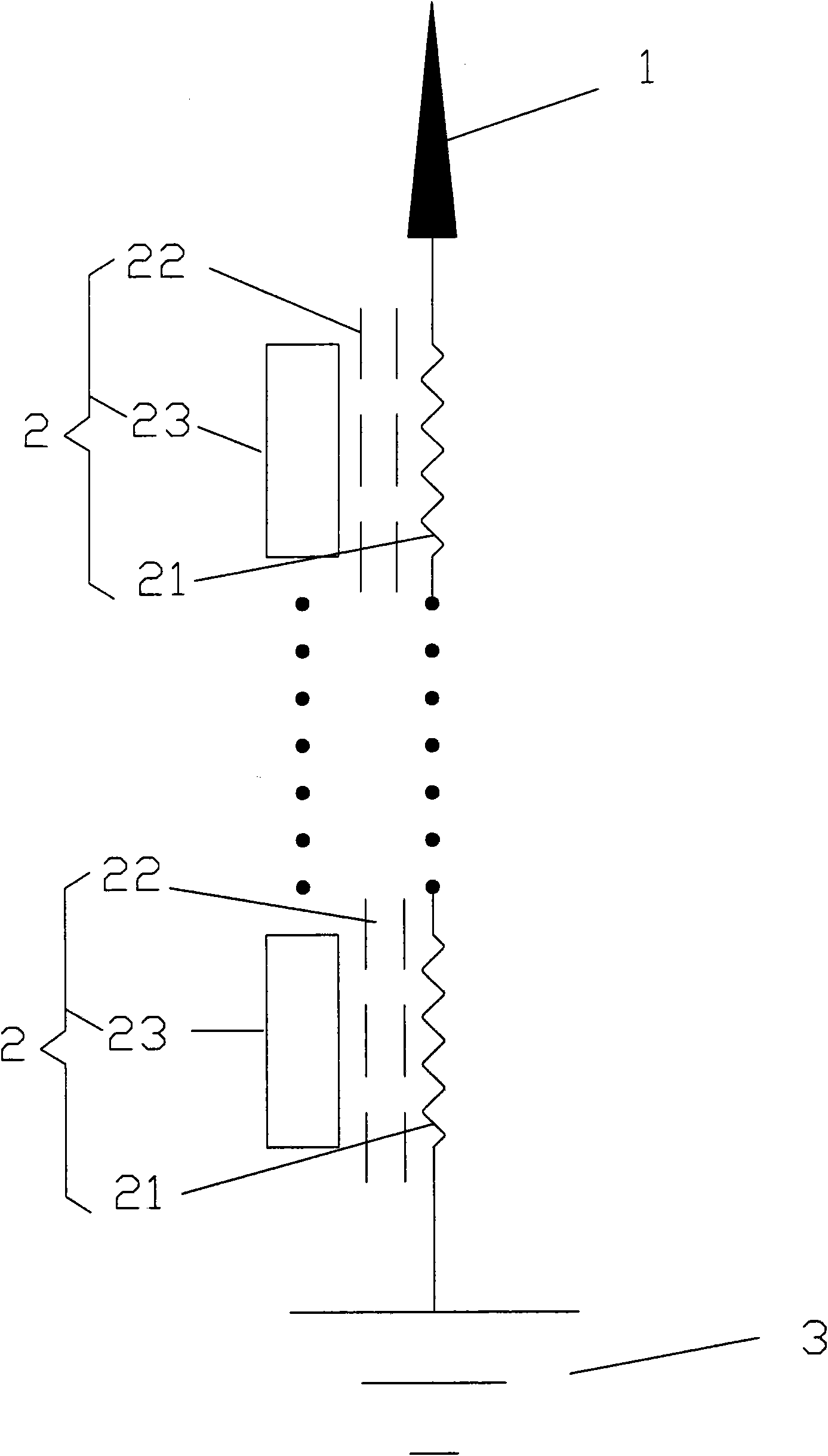

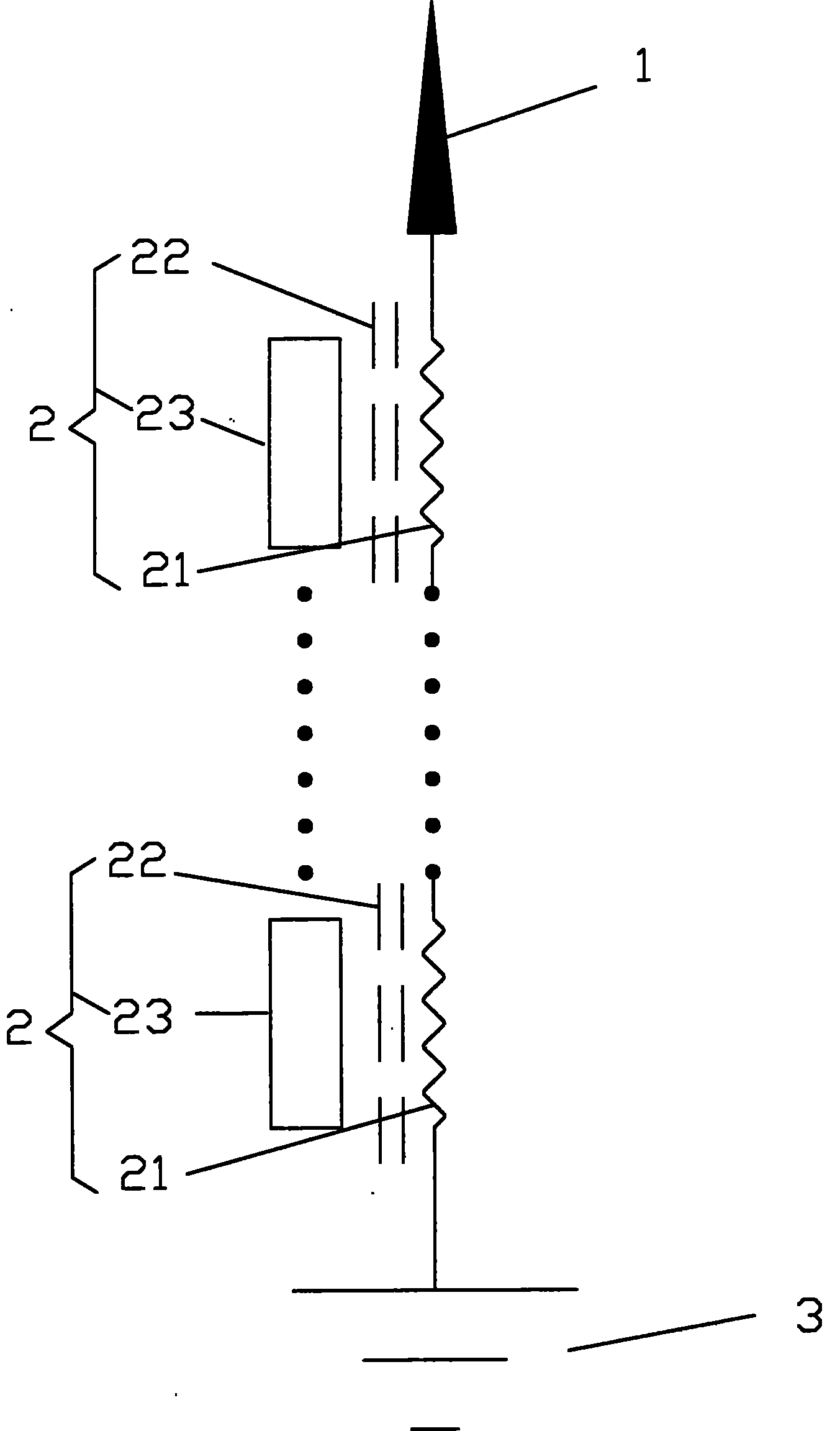

Lightning arresting method and device with function of inhibiting lightning stroke current intensity

InactiveCN102255246ALimit sizeReduce the intensity of surge overvoltageCorona dischargeElectromagnetic couplingLightning strokes

The invention provides a lightning arresting method and device with function of inhibiting lightning stroke current intensity and relates to a lightning arresting method and device with function of inhibiting lightning stroke current intensity which are applied to direct lightning flash protection of buildings. The device comprises a lightning arrester, at least one high-frequency impulse transformer and a grounded device, wherein the high-frequency impulse transformer comprises a primary coil, a magnetic core and a secondary short circuit coil; the primary coil and the secondary short circuit coil form electromagnetic coupling through the magnetic core; a loop is formed by the secondary short circuit coil; and when more than two high-frequency impulse transformers are arranged, the primary coils of the high-frequency impulse transformers are connected in series with a loop formed by the lightning arrester and the grounded device. When lightning stroke current passes through the lightning arrester, the primary coils of the high-frequency impulse transformers and a lightning stroke release loop, energy in the primary coils is coupled to the secondary short circuit coils through the magnetic cores of the high-frequency impulse transformers and is consumed by internal resistors of the secondary short circuit coils, and thus the size of the lightning stroke current in the lightning stroke release loop is limited and the purpose of inhibiting the lightning stroke current is achieved.

Owner:曾献昌

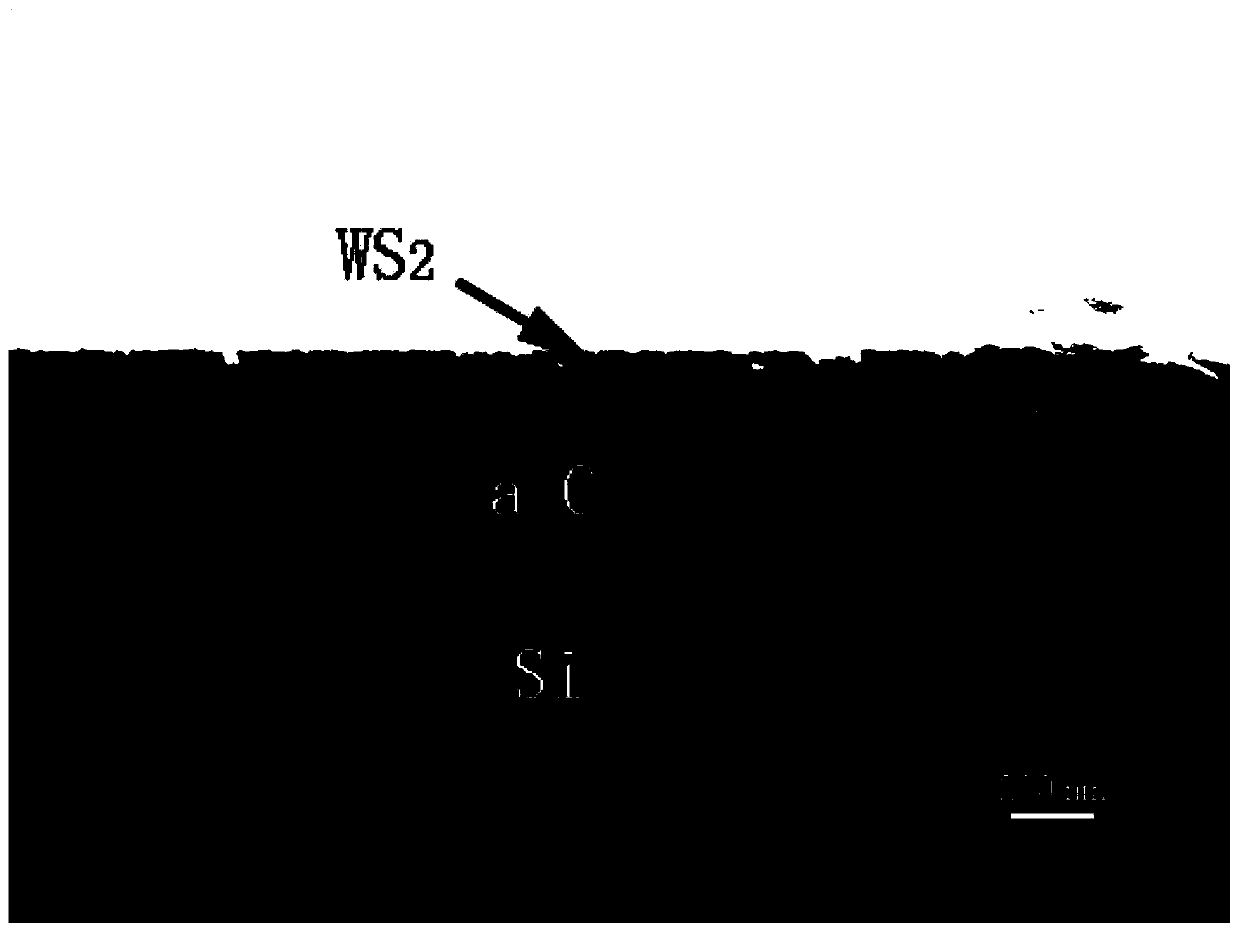

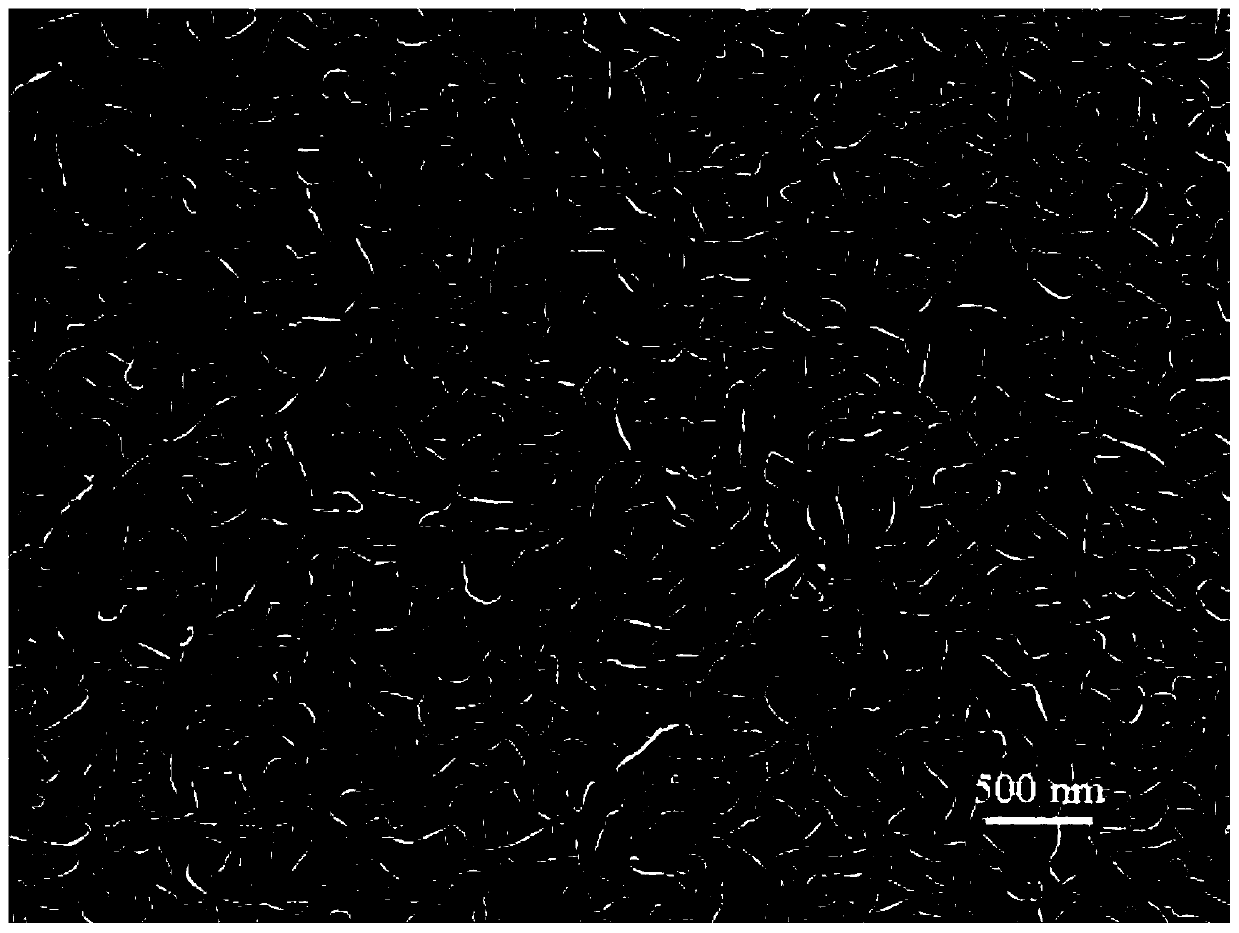

A kind of preparation method of wear-resistant tungsten disulfide film

ActiveCN107058949BChange in growth characteristicsImprove mechanical propertiesVacuum evaporation coatingSputtering coatingCarbon filmWear resistant

A preparation method of wear-proof tungsten disulfide film comprises the following steps that (1) pretreatment is conducted on a monocrystalline silicon piece, the surface of the monocrystalline silicon piece is made clean, the roughness of the surface of the monocrystalline silicon piece is made not higher than Ra 0.1, a graphite target, a WS2 target and the pretreated monocrystalline silicon piece are fed in a multi-target magnetron sputtering deposition chamber, after the air pressure in the deposition chamber is made to be 1.0*10<-3> Pa, through pumping, the target-substrate distance is adjusted to be appropriate, and pulse direct-current negative bias voltage is applied to a base material; (2) high-purity argon is fed to be used as work gas, and amorphous-state carbon film with the deposition thickness being 20-400 nm is deposited on the surface of the monocrystalline silicon piece with the graphite target as a sputtering target material; (3) the temperature of the amorphous-state carbon film obtained in the step (2) is adjusted to 200 DEG C, WS2 film is deposited on the amorphous-state carbon film with the deposit thickness being 140-740 nm with the WS2 target as a sputtering target material, and then the tungsten disulfide film is obtained. The preparation method is simple in technology, good in economical efficiency, capable of greatly improving the mechanical performance of the tungsten disulfide film and the wear-proof performance of the tungsten disulfide film in vacuum or in a humid environment.

Owner:ZHEJIANG UNIV OF TECH

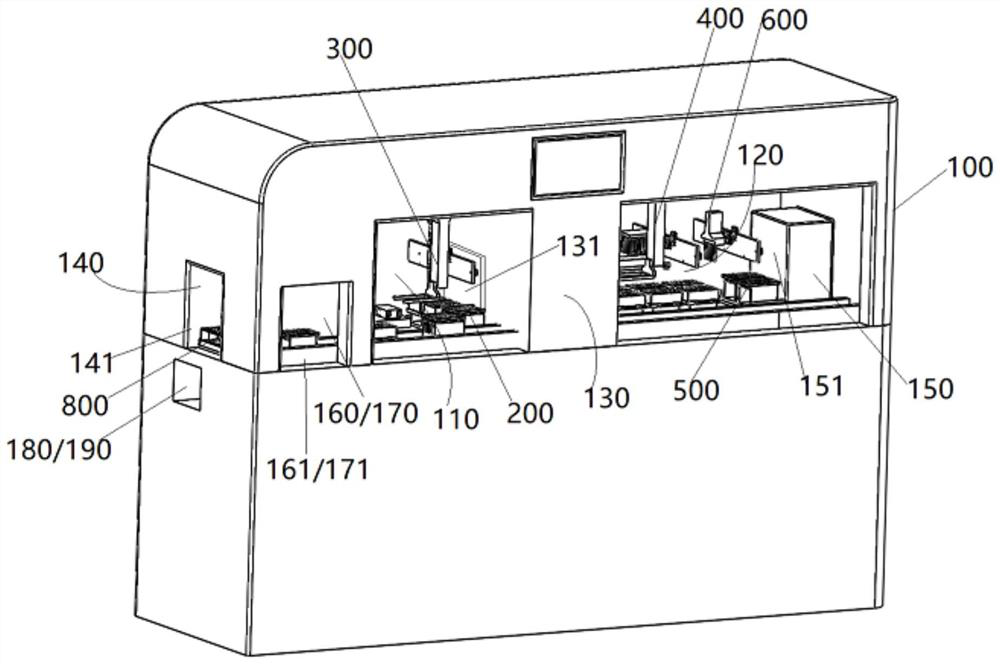

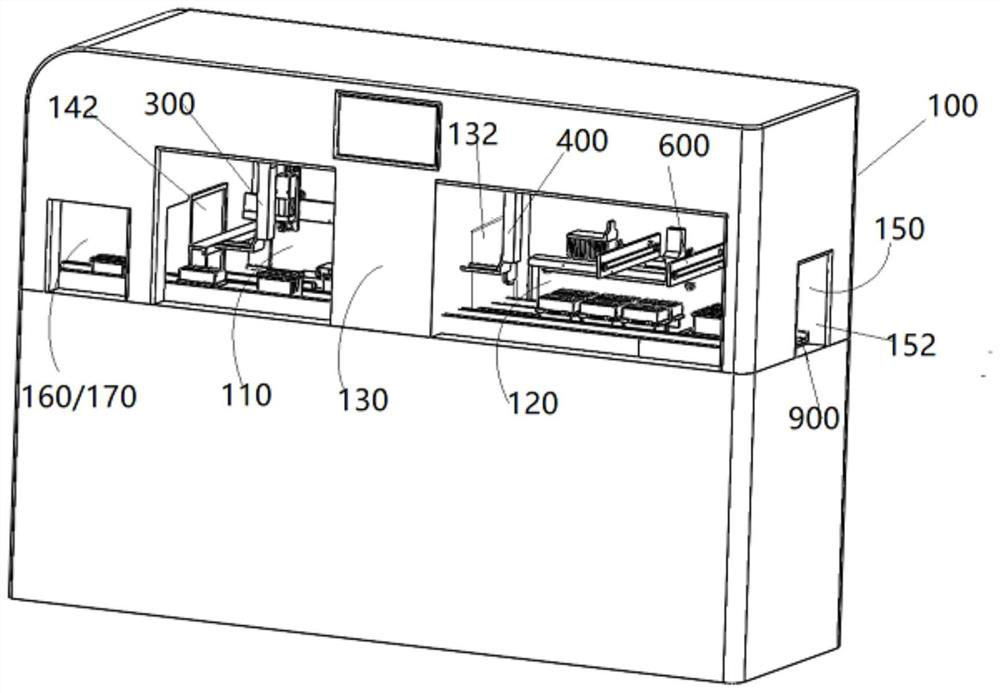

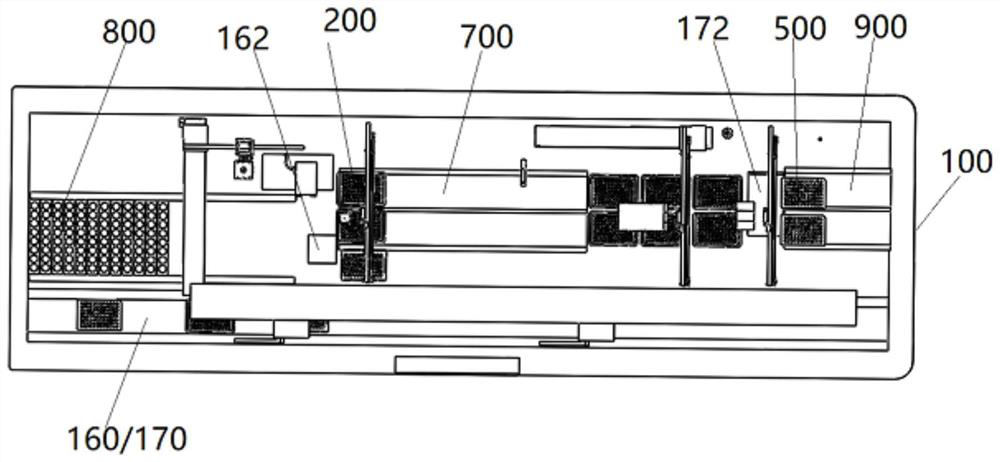

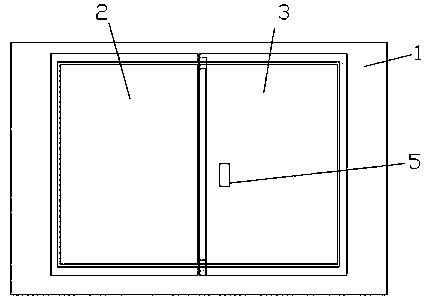

Nucleic acid detection pretreatment device

ActiveCN113801770AReduce pollution levelLow protection levelBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyNucleic acid detection

The invention provides a nucleic acid detection pretreatment device. The nucleic acid detection pretreatment device comprises a sterile isolation box body, an extraction plate, a cup separation treatment mechanism and a nucleic acid extraction mechanism; the extraction plate is arranged in the sterile isolation box body; the cup separation treatment mechanism is arranged in the sterile isolation box body and is used for separating the samples conveyed into the sterile isolation box body to the extraction plate in a cup separation manner; and the nucleic acid extraction mechanism is arranged in the sterile isolation box body and is used for performing nucleic acid extraction on the samples on the extraction plate. According to the device, the infection risk and the protection grade requirement on detection personnel can be reduced, and the processing efficiency is improved.

Owner:谢央达

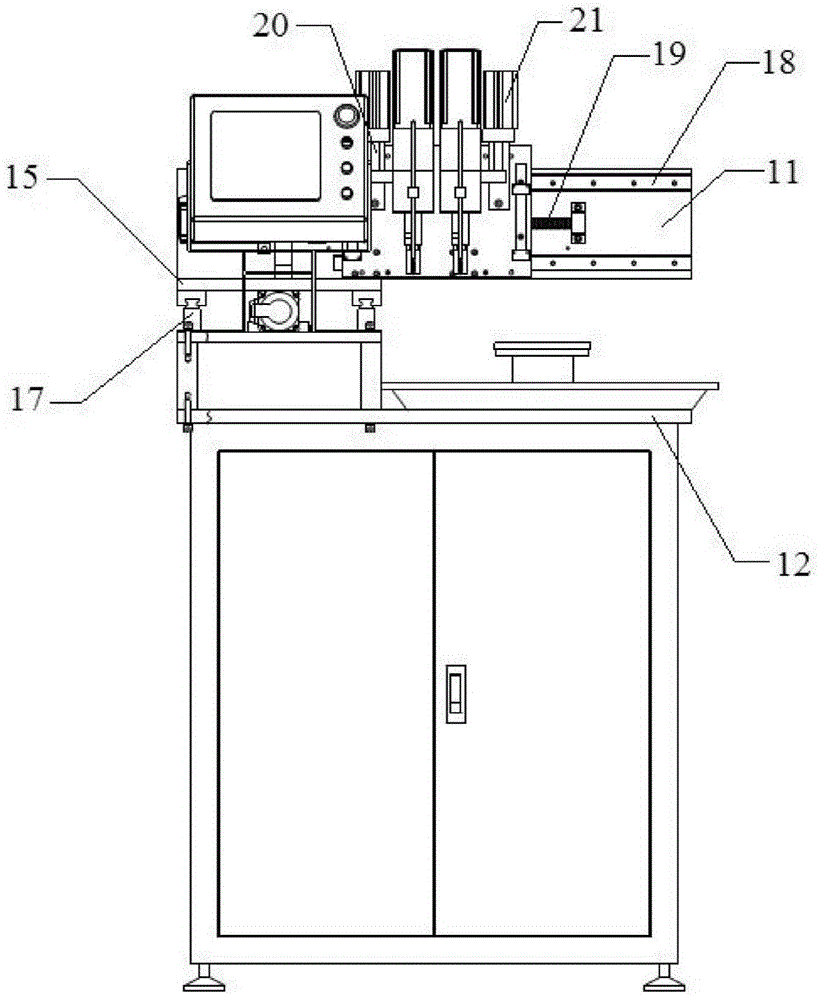

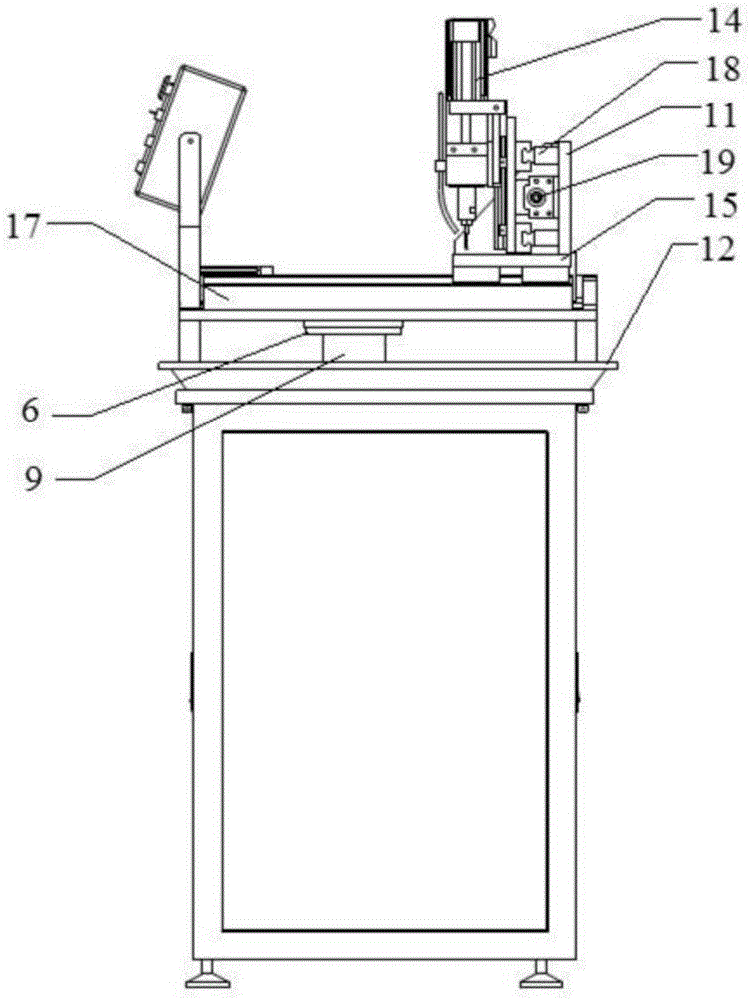

A double-head drilling and tapping machine tool

ActiveCN104339232BEasy clampingLow protection level requirementsThread cutting machinesFeeding apparatusEngineeringMachine tool

The invention relates to a double-head drilling and tapping machining tool. The double-head drilling and tapping machining tool comprises an operating platform, a floating positioning tool and two drill bits, wherein the floating positioning tool is arranged on the operating platform and is transversely and elastically connected with the operating platform; a workpiece to be drilled is fixed on the floating positioning tool; pits are arranged at a hole to be drilled of the workpiece to be drilled; two drill bits are arranged above the floating positioning tool in parallel and are supported by virtue of the operating platform; the operating platform supports the two drill bits to move along the three directions of front-back direction Y, left-right direction X and vertical direction Z by virtue of a servo positioning device. According to the double-head drilling and tapping machining tool, the accurate automatic positioning of machining holes of the workpiece to be drilled can be realized, and the motion of the drill bits on the operating platform along the three directions of front-back direction Y, left-right direction x and vertical direction z is realized; moreover, a mechanical structure is simplified, the drilling or tapping can be realized well based on the reduction of protection levels of an X-axis servo transmission mechanism and a Y-axis servo transmission mechanism, therefore, the production cost can be reduced.

Owner:北京奥博汽车电子电器有限公司

Box-type substation structure with high protection level

PendingCN110265206ALeave no gapsGuaranteed pressingTransformers/inductances casingsSealing arrangementsEngineering

Owner:ZHENJIANG TIANLI TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com