Variable frequency control circuit and control method for electric hoist

A frequency conversion control and electric hoist technology, applied in the direction of AC motor control, control system, motor generator/starter, etc., can solve the problems of difficult installation, complex mechanical structure, high failure rate of equipment, etc., and achieve high reliability and reasonable control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

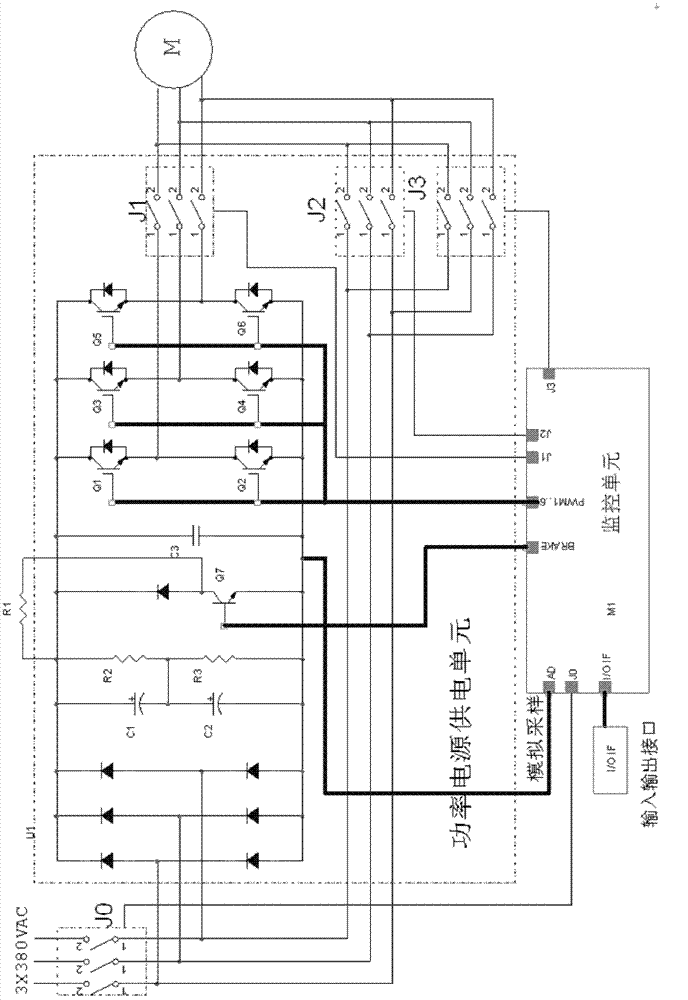

[0031] An electric hoist frequency conversion control circuit, such as figure 1 As shown, it consists of a power supply unit connected to a monitoring unit. The power supply unit, as a channel for transmitting electric power to the hoisting motor, includes a parallel low-frequency three-phase AC power supply branch and a high-frequency three-phase AC power supply branch. The motor provides 5Hz-10Hz low-frequency three-phase AC power supply to realize the slow running function of the hoisting motor; the three-phase AC power supply provides high-frequency three-phase AC power supply with a fixed frequency of 50Hz to the hoisting motor through the high-frequency three-phase AC power supply branch circuit, Realize the fast running function of the hoisting motor.

[0032] The monitoring unit is composed of a microprocessor and its peripheral circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com