Compound ion fluorinated alkyl sodium sulfate polymer degradation agent and preparation method and application thereof

A technology of fluorinated alkyl sodium sulfate and composite ions, which is applied in separation methods, chemical instruments and methods, drilling compositions, etc. The effect of reducing pollution, less corrosiveness and prolonging the working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

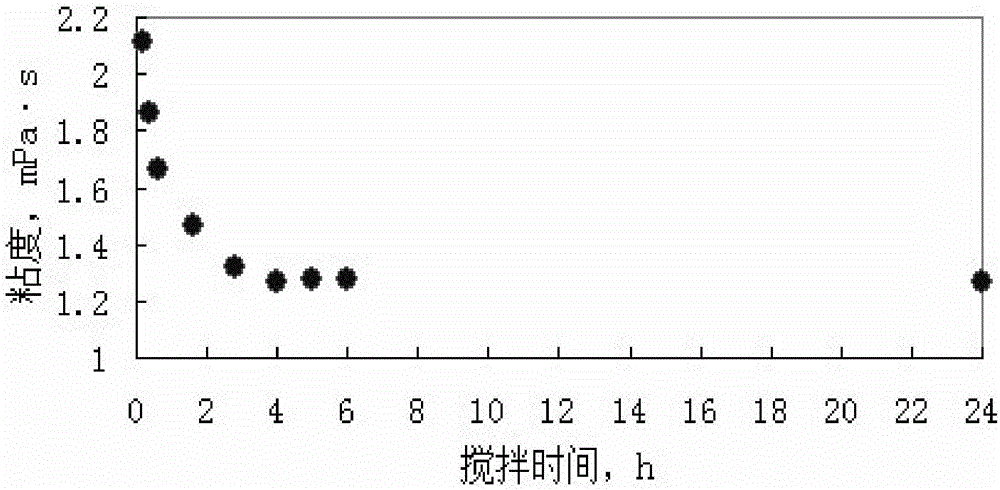

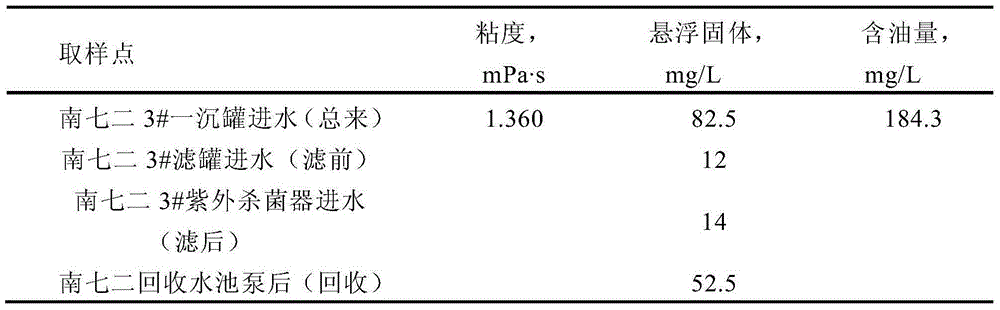

Image

Examples

Embodiment 1

[0031] Step 1, dilute 20% of citric acid and 10% of ferrous sulfate with distilled water and stir into a uniform liquid in a reactor;

[0032] Step 2, adding 5% ethylene glycol and 1% alkylbenzenesulfonic acid successively;

[0033] Step 3: Add 0.3% perfluorophosphate into the reaction kettle for fluorination. Under room temperature, the fluorination reaction takes 20-30 minutes to obtain a uniform liquid. The product is stable without delamination and deterioration after being placed for 12 months, and the viscosity-reducing rate of the polymer reaches 90%.

Embodiment 2

[0035] Step 1, dilute citric acid 22% and ferrous sulfate 12% with distilled water and stir into a uniform liquid in a reactor;

[0036] Step 2, adding 7% ethylene glycol and 1.2% alkylbenzenesulfonic acid successively;

[0037] Step 3: Add 0.4% perfluorophosphate into the reaction kettle for fluorination. Under room temperature, the fluorination reaction takes 20-30 minutes to obtain a uniform liquid. The product is stable without delamination and deterioration after being placed for 12 months, and the viscosity-reducing rate of the polymer reaches 93%.

Embodiment 3

[0039] Step 1, dilute 25% of citric acid and 15% of ferrous sulfate with distilled water and stir into a uniform liquid in a reactor;

[0040] Step 2, adding 10% ethylene glycol and 1.5% alkylbenzenesulfonic acid successively;

[0041] Step 3: Add 0.5% perfluorophosphate into the reaction kettle for fluorination. Under room temperature, the fluorination reaction takes 20-30 minutes to obtain a uniform liquid. No delamination and no deterioration after being placed for 12 months, the product is stable, and the viscosity-reducing rate of the polymer reaches 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com