Absorbent for cutting ceramics by aid of fiber laser

A fiber laser and absorber technology, which is applied in laser welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of inability to cut ceramics at one time and cut light, etc., and achieve the effect of easy cleaning and good light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

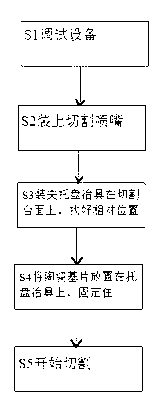

[0017] Embodiment 1, a kind of method for optical fiber laser cutting ceramics, see attached Figure 1-4 , including the following steps:

[0018] S1. Debug the equipment, set the laser frequency, pulse width, speed and focus height and other parameters. The laser frequency is 10kHz, the pulse width is 28ms, the speed is 50mm / s, and the focus height is 20000step, where step is the laser cutting equipment Standard units in the parameter database when adjusting focus height;

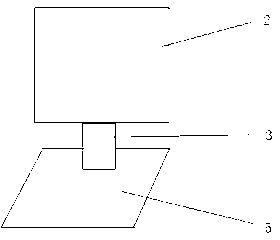

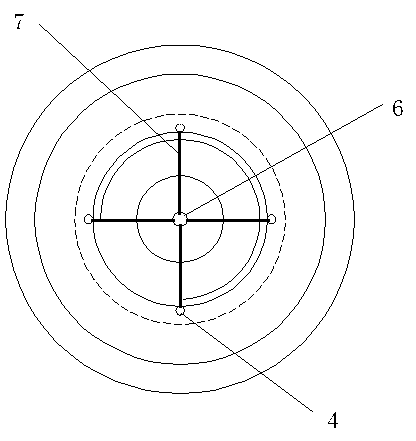

[0019] S2, install the cutting nozzle, the nozzle and the cutting head 2 of the laser equipment are connected by threads, this nozzle is different from the traditional nozzle, it is redesigned, the nozzle is made of copper material, including the nozzle body 3, the air flow channel 1 and the jet hole 6, the nozzle, the jet hole 6 and the air guide hole 4 are all circular, and there are 4 air guide holes 4 and cross grooves 7 on the contact surface 8 of the nozzle, the diameter of the jet hole 6 is 0.8mm, ...

Embodiment 2

[0024] Embodiment 2: It differs from Embodiment 1 in that,

[0025] In step S1, the frequency of the laser is 5 kHz, the pulse width is 10 ms, the speed is 8 mm / s, and the focus height is 18000 steps;

[0026] In step S2, the diameter of the jet hole 6 is 0.7 mm, and the diameter of the air guide hole 4 is 0.5 mm;

[0027] In step S4, the volume ratio of the oily material to acetone is 1:500, the pigment accounts for 10% by mass of the oily material, the pigment auxiliary agent accounts for 10% by mass of the oily material, and the stabilizer accounts for 10% by mass of the oily material 30%, the mass percentage of the resist in the oily material is 30%, the mass percentage of the wetting agent in the oily material is 10%, and the mass percentage of the preservative in the oily material is 10%.

[0028]

Embodiment 3

[0029] Embodiment 3: It differs from Embodiment 1 in that,

[0030] In step S1, the frequency of the laser is 15kHz, the pulse width is 50ms, the speed is 80mm / s, and the focus height is 18000step;

[0031] In step S2, the diameter of the jet hole 6 is 1 mm, and the diameter of the air guide hole 4 is 0.8 mm;

[0032] In step S4, the volume ratio of the oily material to acetone is 1:550, the pigment accounts for 30% by mass of the oily material, the pigment auxiliary agent accounts for 30% by mass of the oily material, and the stabilizer accounts for 30% by mass of the oily material is 10%, the mass percentage of the resist is 10% of the oily material, the wetting agent is 10% of the mass of the oily material, and the preservative is 10% of the mass of the oily material.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com