Sensor for monitoring temperature/strain signals of bearings

A strain sensor and signal monitoring technology, applied in mechanical bearing testing, instruments, measuring devices, etc., can solve the problems of poor bearing working conditions, narrow space, and inability to monitor the working state of the aircraft in real time, so as to increase the overall weight, volume, and structure The effect of simplicity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

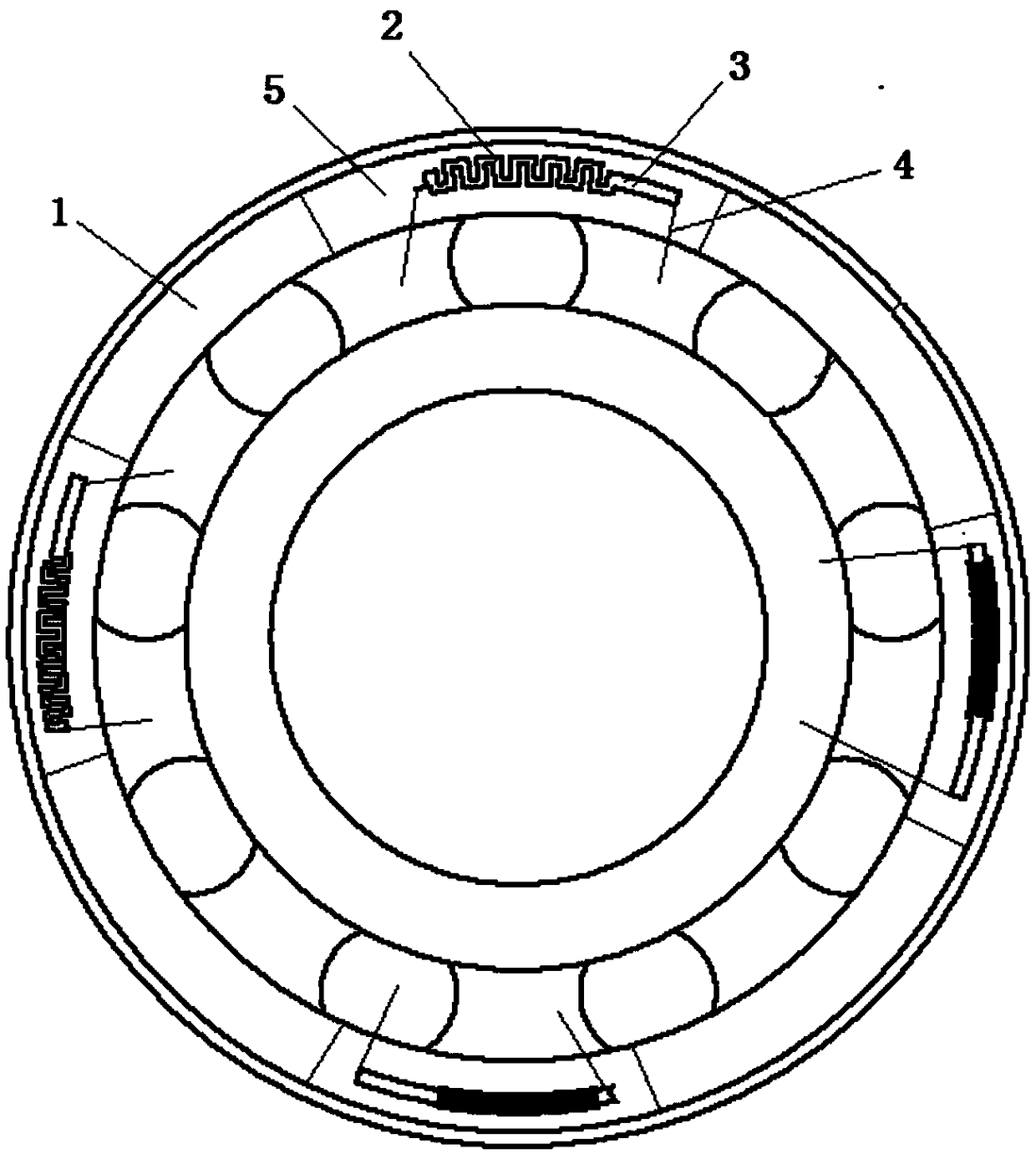

[0022] like figure 1 As shown, this embodiment takes a deep groove ball shaft for aviation as an example, and the steps of forming a temperature / strain signal monitoring sensor on the deep groove ball shaft using the technical solution of the present invention are as follows:

[0023] Step 1. Use the ion implantation method to inject aluminum elements on the end face 1 of the bearing outer ring made of M50, so that the end face 1 of the outer ring and the insulating layer 5 can make a smooth transition, and then use the reactive magnetron sputtering method to plate Al 2 o 3 / AlN multilayer insulating layer 5, the thickness of which is 10 μm, and the resistance value is greater than 1 MΩ;

[0024] Step 2: Plating a plurality of nickel-silicon strain-sensitive layers 2 on the surface of the insulating layer 5 along the circumference of the end face 1 of the outer ring, with a thickness of 150 nm, and then plating a corresponding number of nickel-chromium temperature-sensitive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com