Pulverized fuel ash flotation separation equipment with physical separation device

A separation equipment and physical separation technology, used in flotation, solid separation, etc., can solve the problems of difficult separation and low flotation efficiency of carbon particles, and achieve the effects of improving precision, improving flotation efficiency and reducing circulation volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

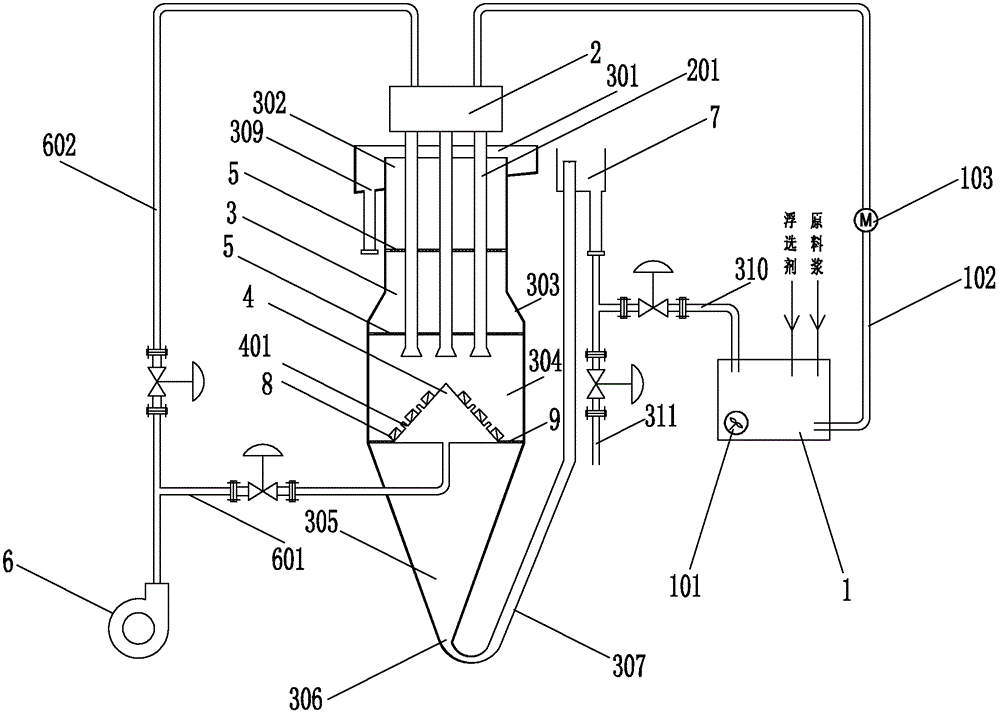

[0036] Such as figure 1 As shown, Embodiment 1 of the present invention includes: a material storage device 1, a distribution device 2, a vertical cylinder 3, a cone-shaped air diffuser 4, a multi-layer flotation plate 5, an air supply device 6, and a physical separation Devices such as ultrasonic separation device 8, tail ash box 7, filter plate 9, overflow collection section 301, tail ash collection section 305.

[0037] The cylinder body 3 arranged vertically can be divided into three parts, from top to bottom: the first flotation section 302 , the diffusion cone section 303 , and the second flotation section 304 . Wherein, the first flotation section 302 is relatively thin, and a layer of flotation plates 5 is arranged inside it. The second flotation section 304 is relatively thick, and a cone-shaped air diffuser 4 and a layer of flotation plates 5 are arranged in it. The diffusion cone section 303 is located between the first flotation section 302 and the second flotati...

Embodiment 2

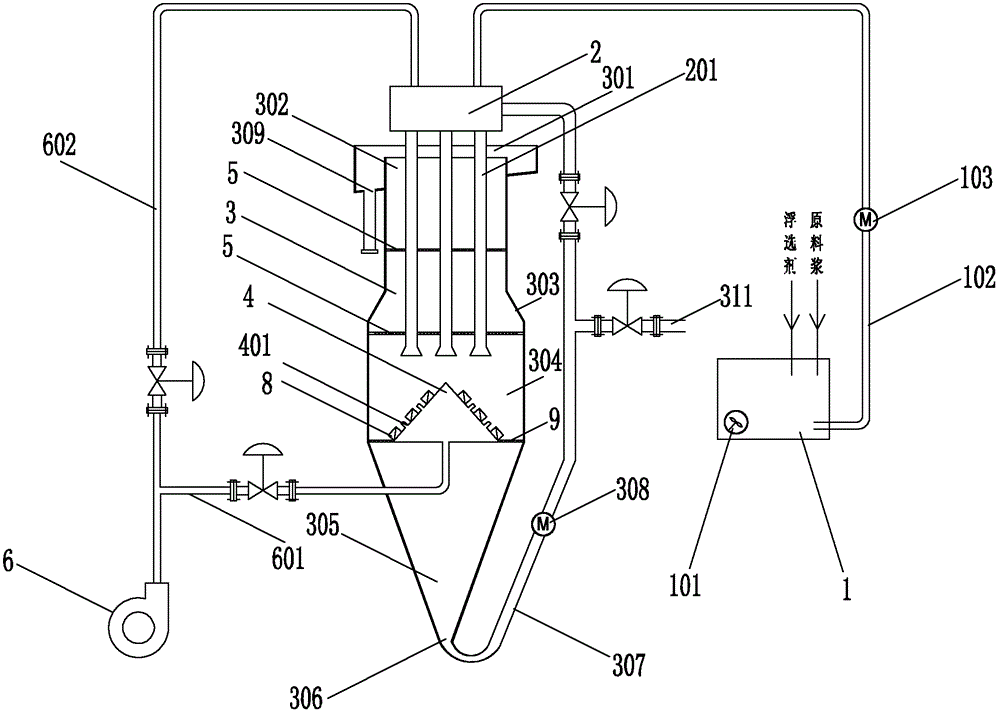

[0047] figure 2 Shown is embodiment 2 of the present invention, and its difference with embodiment 1 is: 1, the number of distributing pipeline 201 is 6; 3. The tail ash pipeline 307 is provided with a slurry pump 308; 4. The tail ash pipeline 307 is also provided with a branch pipeline as the ash discharge pipeline 311, the tail ash pipeline 307 and the discharge pipeline Ash pipes 311 are provided with valves. Similarly, according to the situation of the fly ash raw material and the specific process requirements, the tail ash can re-enter the flotation separation equipment through the tail ash pipeline 307 for flotation to recover the carbon particles therein; when the carbon content in the tail ash is too low , then discharged through the ash discharge pipe 311.

Embodiment 3

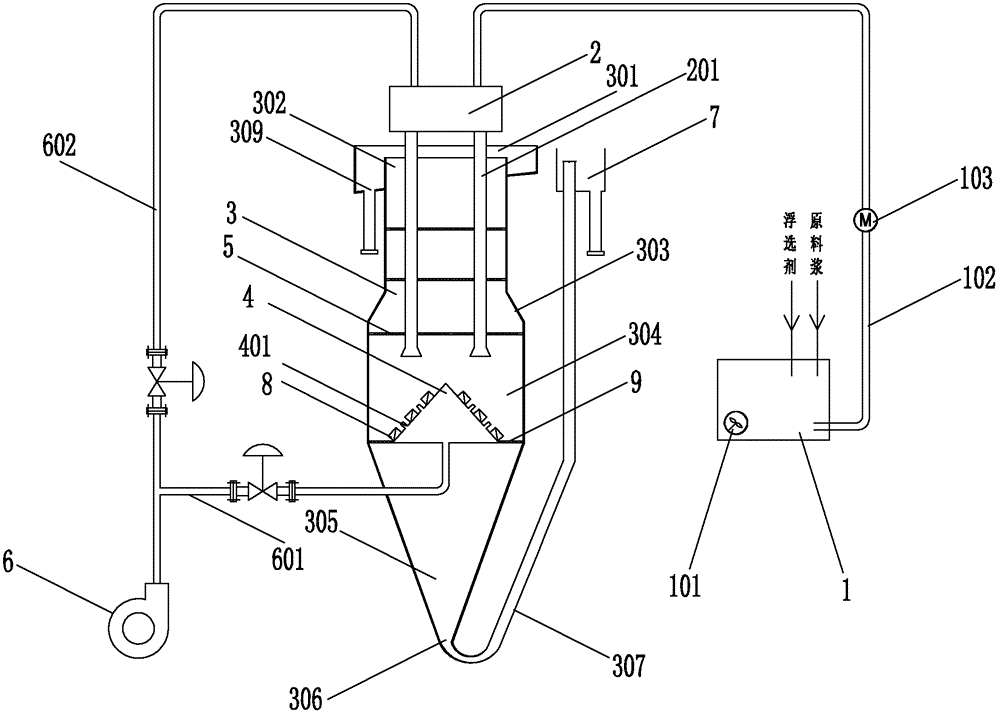

[0049] image 3 Shown is embodiment 3 of the present invention, and its difference with embodiment 1 is: 1, flotation plate is 3 layers; 2, the number of distribution pipeline 201 is 4; 3, tail ash box 7 is positioned at tail ash pipeline 307 and set outside the tail ash pipe 307, the height of the end of the tail ash pipe is above the top flotation plate, and the end of the tail ash pipe is provided with a liquid level regulating device for adjusting the height of the end of the tail ash pipe ; 4. There is no circulation pipeline 310 between the tail ash box 7 and the storage device 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com