Leather scrap modified foamed shoe insole and preparation method thereof

A leather and modification technology, applied in the field of foam materials, can solve the problems of low utilization rate of leather waste, and achieve the effects of high-value utilization, improved compatibility and resource recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

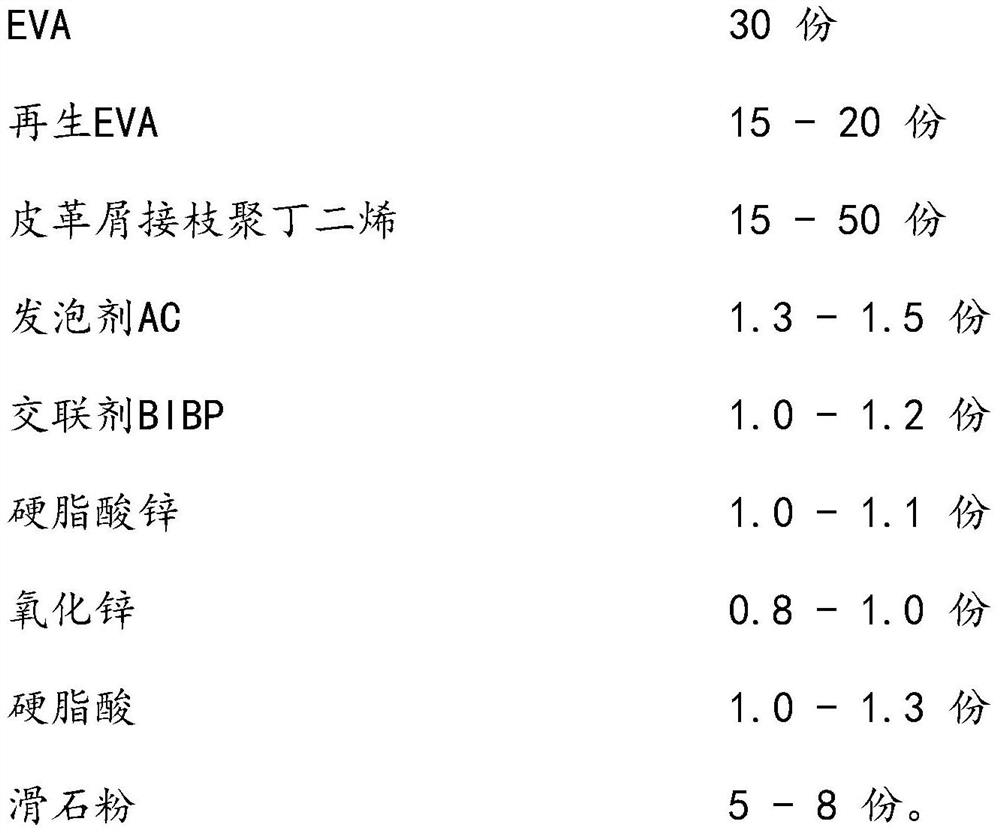

Embodiment 1

[0038] The preparation method of the midsole of foamed shoes modified by leather shavings comprises the following steps:

[0039] 1) Preparation of leather shavings grafted polybutadiene:

[0040] a) Put the tanned leather scraps and recycled waste leather products into a vacuum drying oven, and dry them in a vacuum at a drying temperature not higher than 90°C to obtain dried leather waste;

[0041] b) Crushing and grinding the leather waste to obtain 50-600 mesh leather scraps;

[0042] c) 400g maleic anhydride grafted polybutadiene (grafting rate 17% (mass fraction)) is put into the torque rheometer, after it is melted, add leather shavings 500g, melt and graft 2 hours, obtain leather Crumb grafted polybutadiene.

[0043] 2) Preparation of regenerated EVA:

[0044] Put the scraps, defective products, waste products, leftovers, and waste photovoltaic cell packaging EVA film produced in the process of producing EVA soles into a crusher to crush them, and then prepare them t...

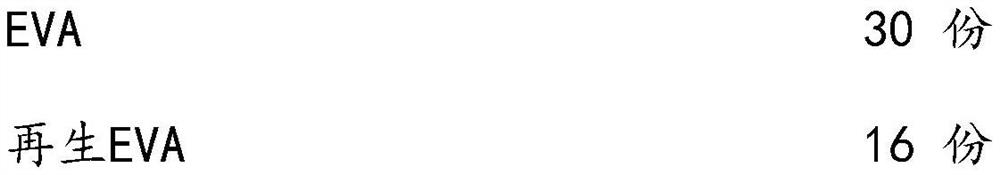

Embodiment 2

[0054] The preparation method of the midsole of foamed shoes modified by leather shavings comprises the following steps:

[0055] 1) Preparation of leather shavings grafted polybutadiene:

[0056] a) Put the tanned leather scraps and recycled waste leather products into a vacuum drying oven and dry them in a vacuum at a drying temperature not higher than 90°C to obtain dried leather waste;

[0057] b) Crushing and grinding the leather waste to obtain 50-600 mesh leather scraps;

[0058] c) 400g maleic anhydride grafted polybutadiene (grafting rate 17% (mass fraction)) is put into the torque rheometer, after it is melted, add leather shavings 500g, melt and graft 2 hours, obtain leather Crumb grafted polybutadiene;

[0059] 2) Preparation of regenerated EVA:

[0060] Put the scraps, defective products, waste products, leftovers, and waste photovoltaic cell packaging EVA film produced in the process of producing EVA soles into a crusher to crush them, and then prepare them th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com