Automatic edge sealing machine provided with double saws

An edge banding machine and automatic technology, applied in the direction of circular saws, slotting machines, sawing equipment, etc., can solve the problems of increasing the user's installation site area, increasing user costs, and not having the function of double saws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

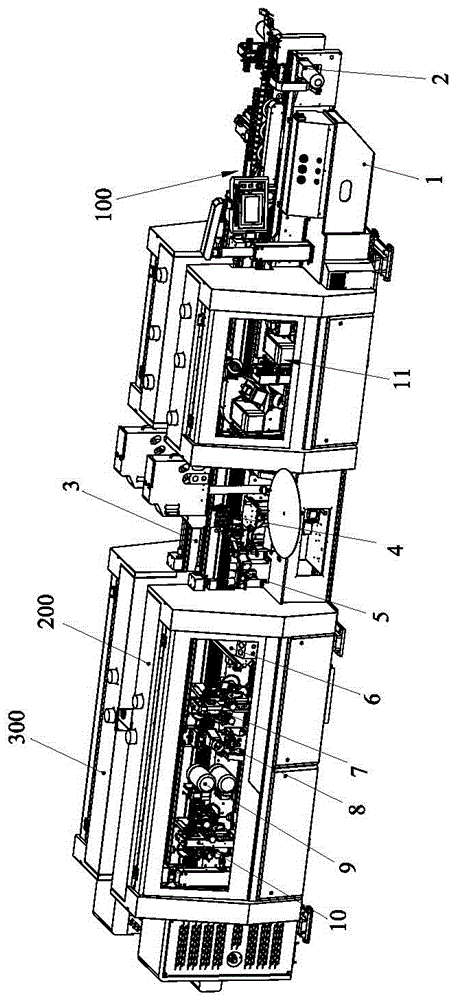

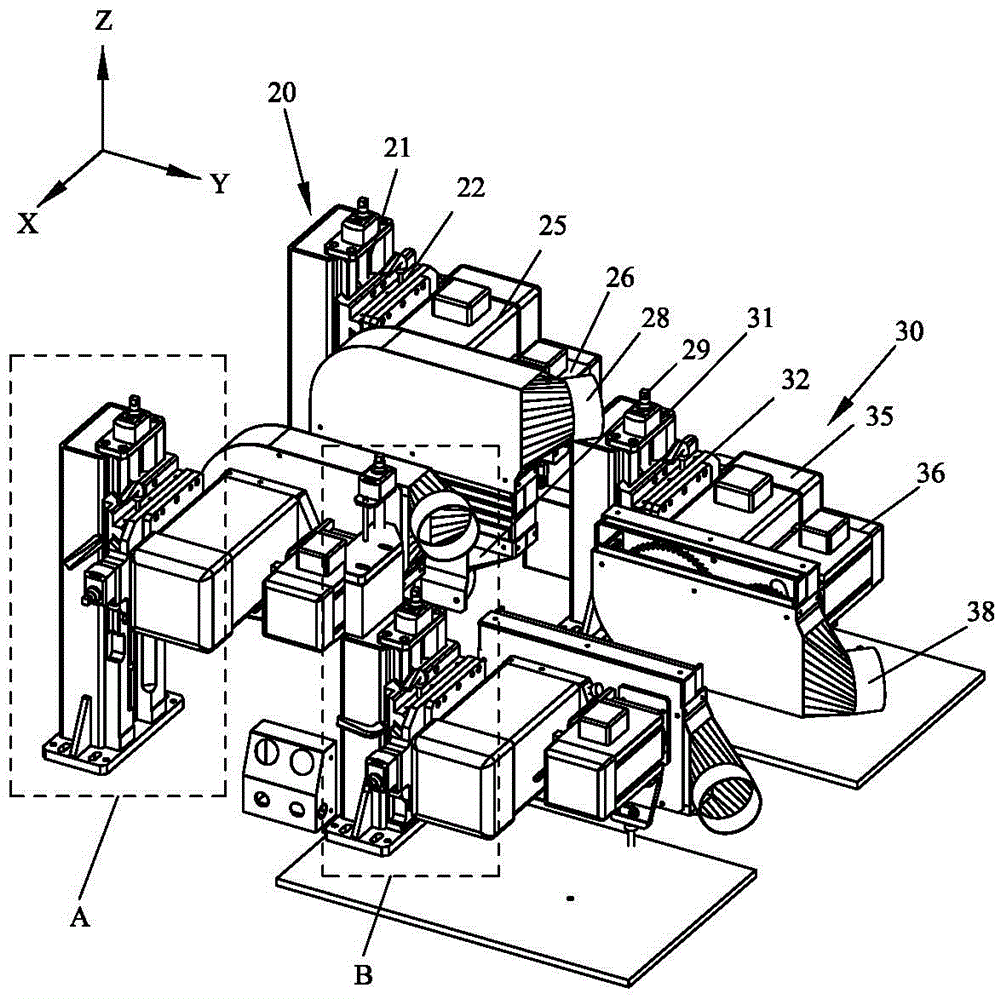

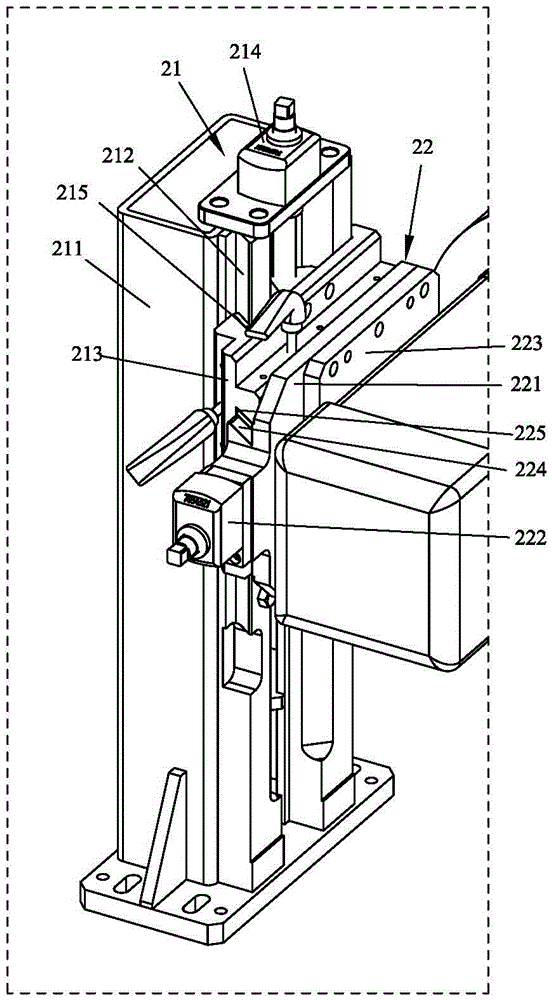

[0058] Please refer to figure 1 As shown, it shows the specific structure of a preferred embodiment of the present invention, which is an automatic edge banding machine with double saws, including an integrated base 100, a left machine 200 and a right machine 300 installed on the integrated base 100, The left machine 200 and the right machine 300 respectively include a machine tool main body 1, a conveying device 2 installed on the machine tool main body 1, a pressing device 3 arranged in sequence from the upstream to the downstream of the machine tool main body 1, an upper gluing device 4, a belt feeding cutter Belt pressure roller device 5, head and tail strip cutting device 6, finishing device 7, edge scraping device 8, polishing device 9, ink coating device 10. The focus is also that a double sawing device 11 is installed upstream of the upper gluing device 4, and the double sawing device 11 is for performing horizontal double-end alignment and slotting for medium and high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com