Printed circuit board (PCB) manufacturing method

A technology of PCB board and manufacturing method, which is applied in the direction of improving the metal adhesion of insulating substrates, removing conductive materials by chemical/electrolytic methods, and manufacturing printed circuits. Fix problems such as poor bonding identification, achieve the effects of reducing burrs and side etching, good flatness, and improving etching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

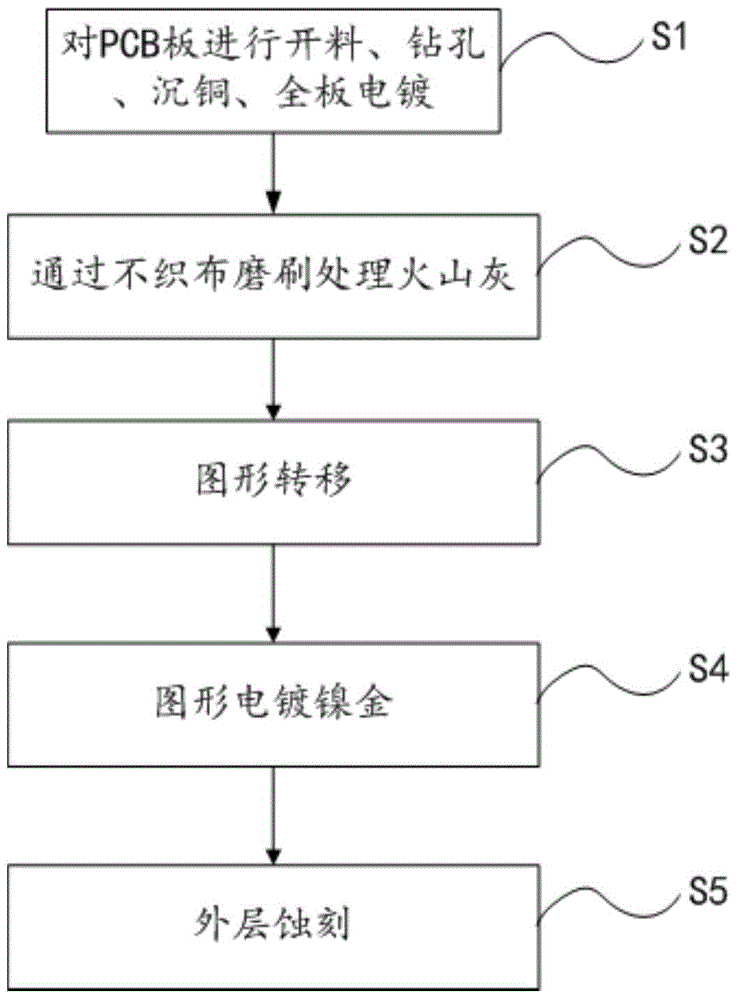

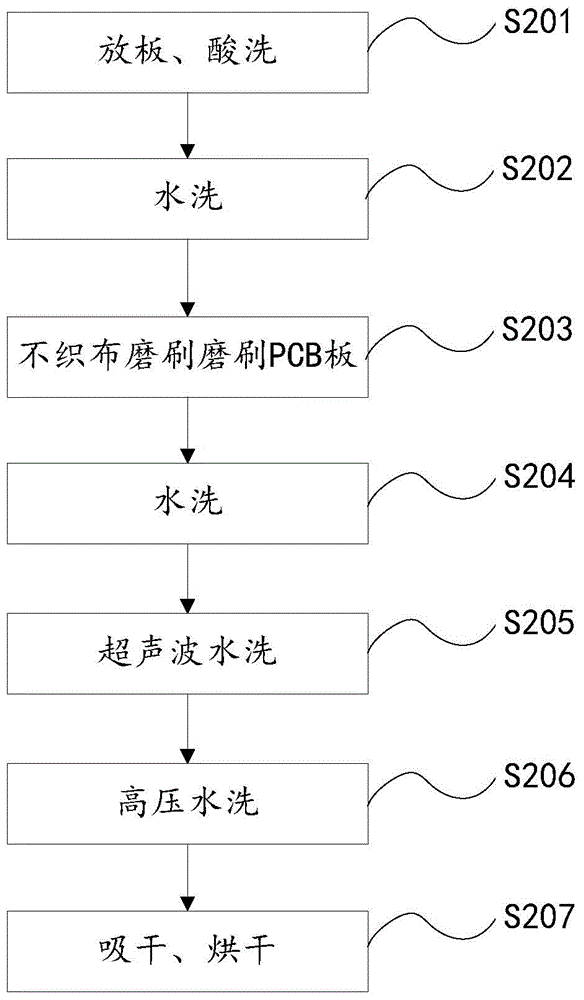

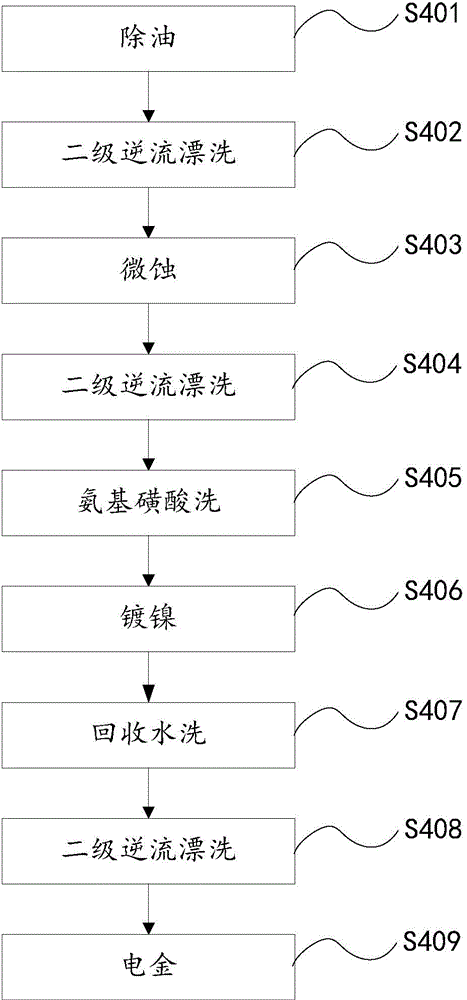

[0037] Such as figure 1 Shown, a kind of manufacturing method of PCB board comprises the following steps:

[0038] S1 performs material cutting, drilling, copper sinking, and full board electroplating on the PCB. The specific process is as follows:

[0039] S101 Cutting materials to form a jigsaw panel, which includes an inner layer substrate and an inner layer copper foil attached to the upper and lower surfaces of the inner layer substrate.

[0040] S102 Drilling, drilling the required holes on the PCB to form a conductive channel between the connecting lines.

[0041] S103 sinking copper, using the principle of chemical reaction to deposit a layer of 0.3um-0.5um copper on the hole wall, so that the originally insulated hole wall has conductivity, which facilitates the smooth progress of subsequent PCB surface plating and pattern plating, thus completing Electrical intercommunication between PCB board circuit networks.

[0042] S104 full board electroplating, protecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com