Heat conduction graphite composite film and preparation method thereof

A heat-conducting graphite film and heat-conducting graphite technology are applied in the direction of adhesive types, adhesive additives, ester copolymer adhesives, etc., which can solve the problems of high cost, warping or burrs of the composite film, and complicated preparation process of the composite film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

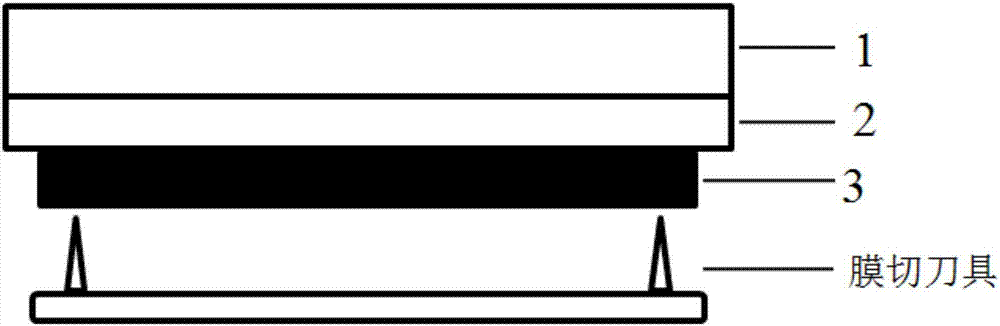

[0048] This embodiment provides a thermally conductive graphite composite film, such as figure 2 As shown, it includes a substrate 1 , a coating 2 and a thermally conductive graphite film 3 . Wherein, the coating 2 is arranged on one side surface of the base material 1, and its viscosity is less than that of the adhesive and its peeling force per unit area is greater than that of the release agent; the heat-conducting graphite film 3 is pressed onto the coating Layer 2 is on the surface of the side facing away from the substrate 1 .

[0049] The above-mentioned coating 2 is a film formed by a mixture of a release agent, an adhesive, and an auxiliary agent. The thickness of the film is optimally controlled at 3um, or 1um, 2um, 4um, 5um, 8um, 9um, 12um, 15um, It is best to control it within the range of 1um-15um. Of course, other sizes can be used according to the actual needs of customers, but it should not be too thick to prevent the coating 2 from being too sticky to the he...

Embodiment 2

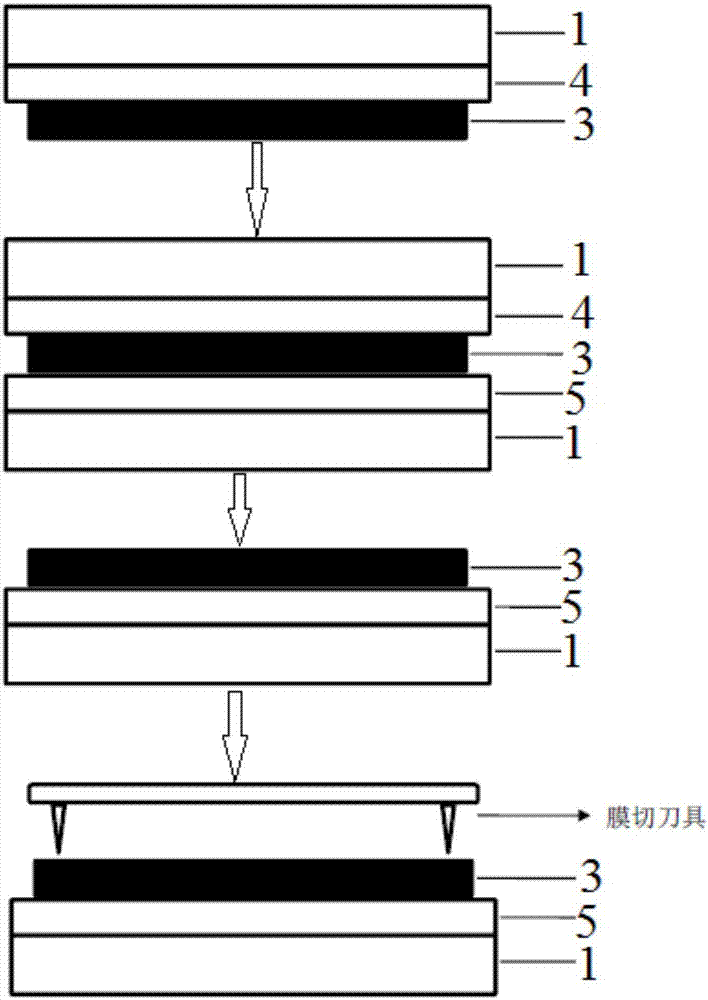

[0061] This embodiment provides a method for preparing the thermally conductive graphite composite film provided in Embodiment 1, comprising the following steps:

[0062] S2: Mix 40 parts of silicone oil, 30 parts of silica gel, and 5 parts of additives into the solvent to form a mixed solution; the additives are mainly defoamers and antistatic agents. The mass ratio is 6:1; use an inkjet printer to spray the mixed solution with a thickness of 3um on the top surface of the PET substrate 1, and form a base film with the PET substrate 1 after the mixed solution is cured;

[0063] S3: Using a double-roll calender, press the heat-conducting graphite film 3 onto the top surface of the coating layer 2 in the base film to form a composite film.

[0064] In the preparation method of the composite film in this embodiment, since the coating 2 has a certain viscosity and peeling force, it is only necessary to coat the coating 2 with the required thickness on the substrate 1, and then pre...

Embodiment 3

[0073] This embodiment provides a method for preparing a heat-conducting graphite composite film. Compared with the preparation method in Example 2, the only difference is that the coating 2 is formed in a different way, and the release agent and adhesive used are different. Agent, auxiliary agent and base material 1 are all the same as in Example 1, specifically, this preparation method comprises the steps:

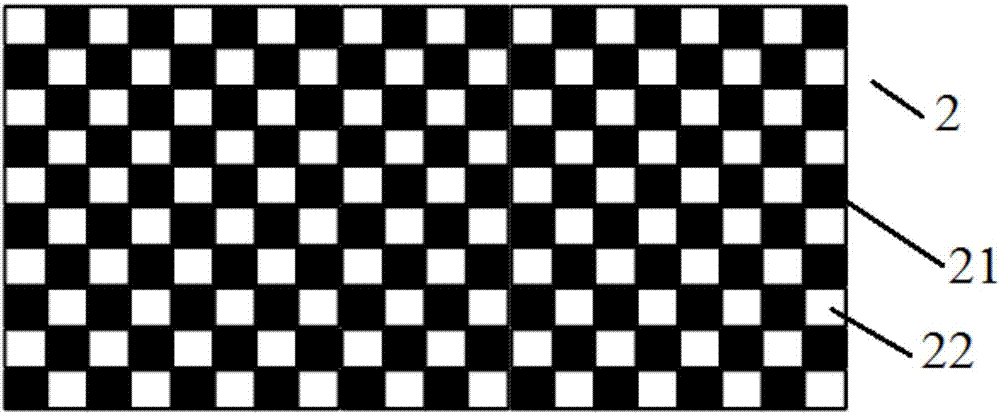

[0074] S1: According to the preset pattern, divide a plurality of first regions 21 and / or a plurality of second regions 22 of the desired pattern on the top surface of the substrate 1, such as image 3 As shown, the first area 21 is in the shape of a grid, and the second area 22 is also in the shape of a grid. The first area 21 and the second area 22 are arranged to cross each other, and the entire pattern is a black and white grid;

[0075] S2: add auxiliary agents to the release agent and the adhesive in advance, and use an inkjet printer to apply the release agent and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com